Welded plate conveying line system apparatus

A conveying line system and conveying system technology, which is applied to conveyor objects, transportation and packaging, cleaning methods using tools, etc., can solve the problems of feeding roller damage, feeding roller shrinkage, wear, etc., and reduce high strength. work, improve work efficiency, clean up evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

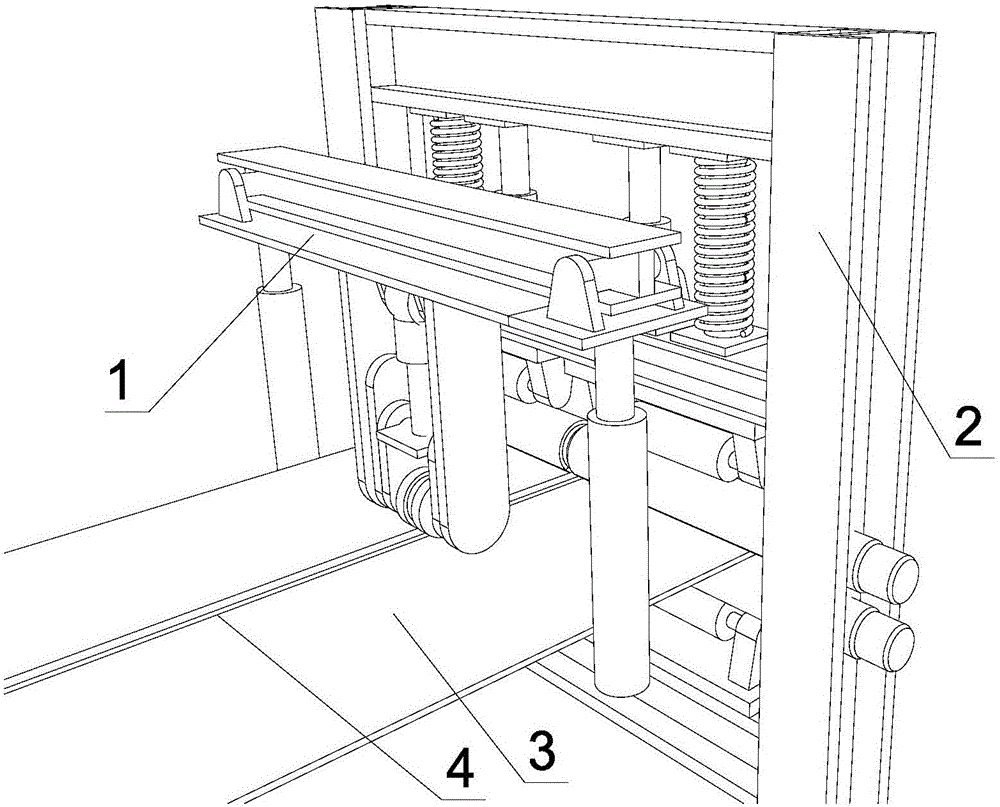

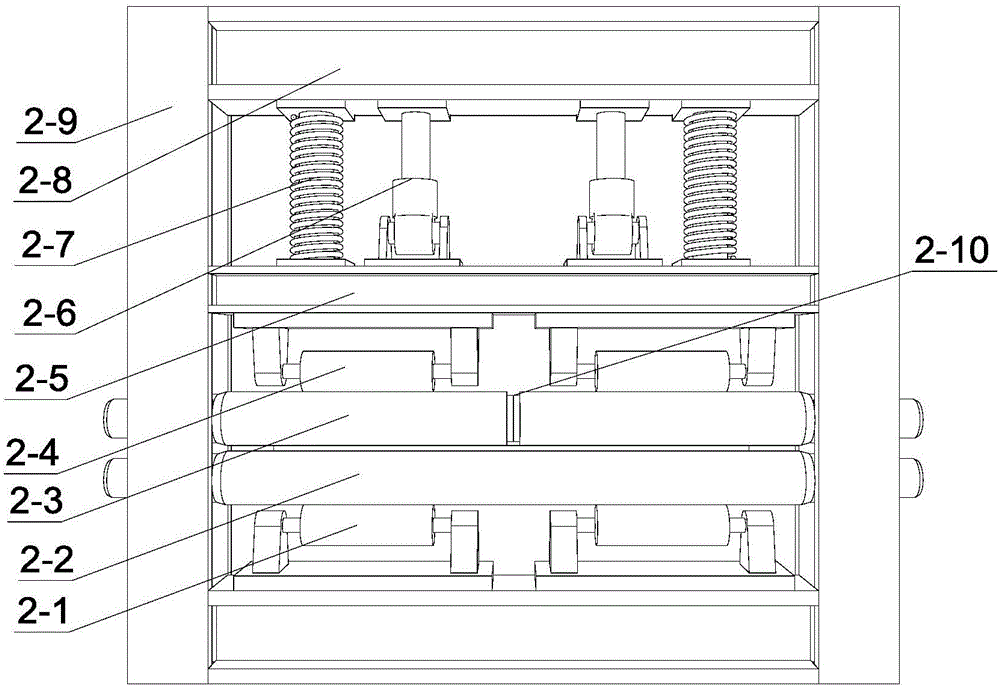

[0025] A welding plate conveying line system device, such as figure 1 As shown, it includes: transmission positioning system 1 and steel plate rolling conveying system 2;

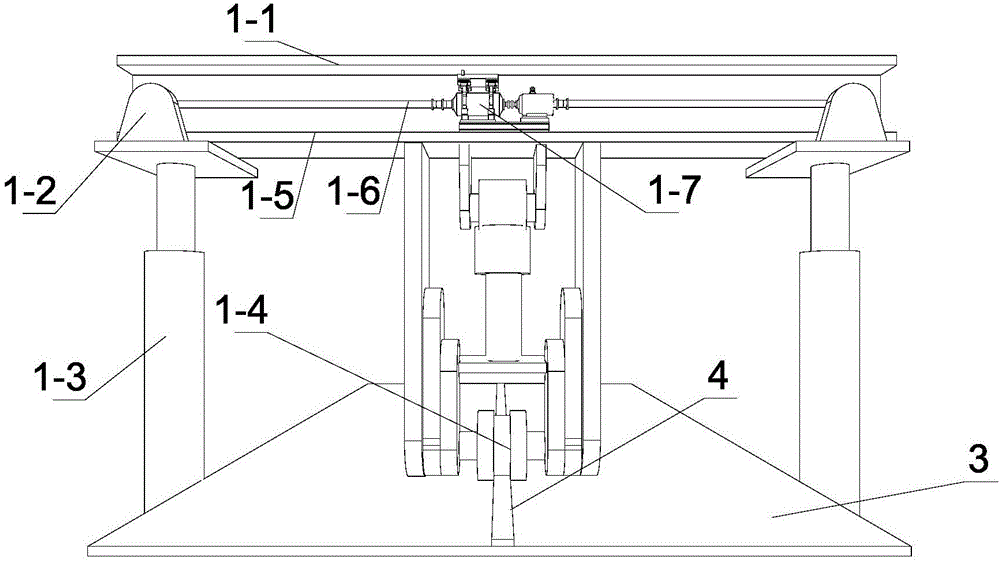

[0026] Such as figure 2 As shown, the transmission positioning system 1 includes: a welding seam positioning guide wheel 1-4, the welding seam positioning guide wheel 1-4 is fixedly connected to the beam 1-1 through a bracket, and the beam 1-1 is fixed to the frame 2-9 ; The beam 1-1 is provided with a slideway 1-5, and the slideway 1-5 is connected with two positioning vertical rollers 1-3 through the slideway roller 1-2; the beam 1-1 is provided with a motor 1- 7. The motor 1-7 is connected to the slideway roller 1-2 of the two positioning vertical rollers 1-3 through the transmission rod 1-6 and the transmission gear; Move the signal transmitter, the motor 1-7 is provided with a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com