Angle head cutter breaking detection device

A detection device and angle head technology, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of affecting machining accuracy, cumbersome trouble, broken tools, etc., and achieve the convenience of workpiece punching processing, Ensure stability and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

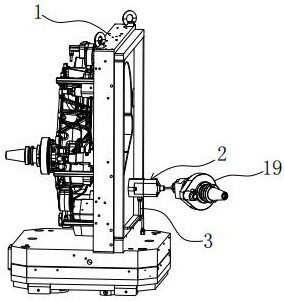

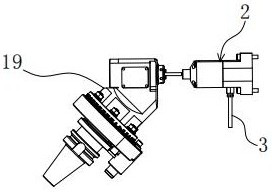

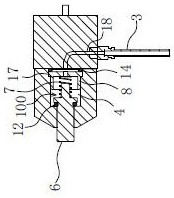

[0025] Such as Figure 1-Figure 7 As shown, the angle head broken knife detection device includes: a fixture table 1 and a detection body 2, an air pipe 3 is arranged on the fixture table 1, the detection body 2 is installed on the fixture table 1, and an inner cavity 4 is opened inside the detection body 2, The trachea 3 is arranged at the bottom end of the detection body 2 and communicates with the inner cavity 4. The front end of the detection body 2 is provided with a pin hole 5 communicating with the inner cavity 4, and the inner cavity 4 is provided with a guide assembly 100 movable against it, guiding The assembly 100 has a positioning pin, and the positioning pin 6 is in clearance fit with the pin hole 5 .

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com