Patents

Literature

47results about How to "Easy for stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

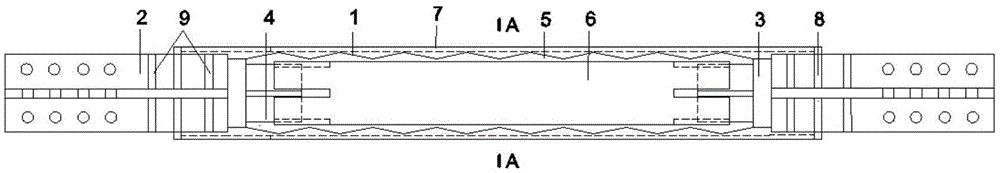

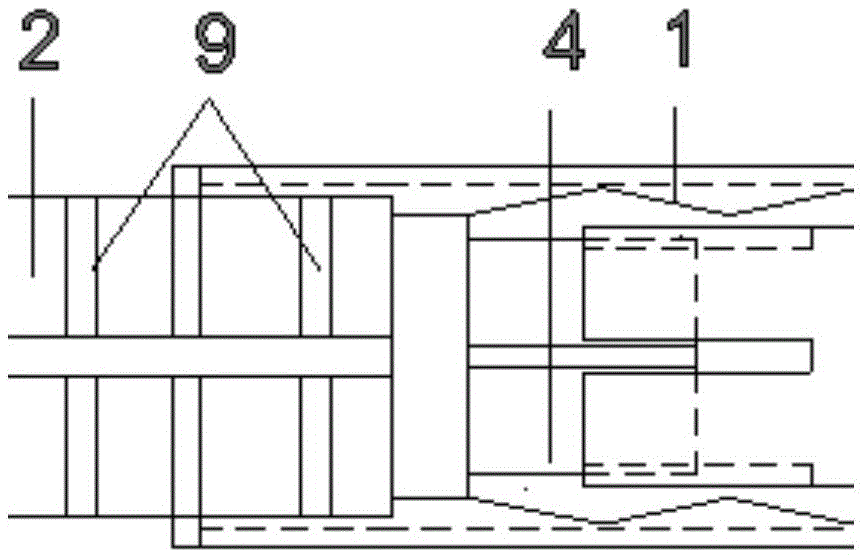

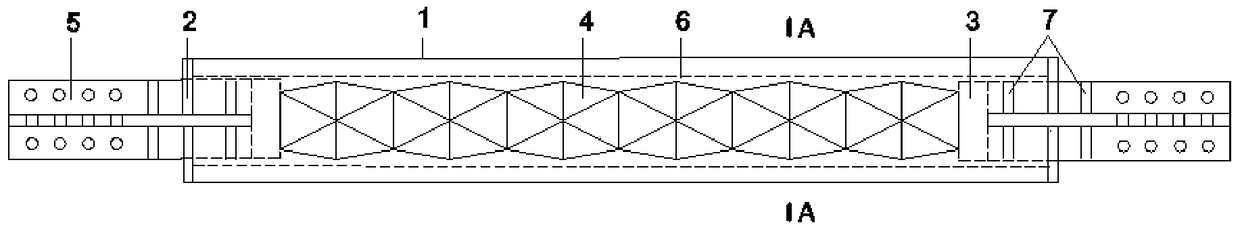

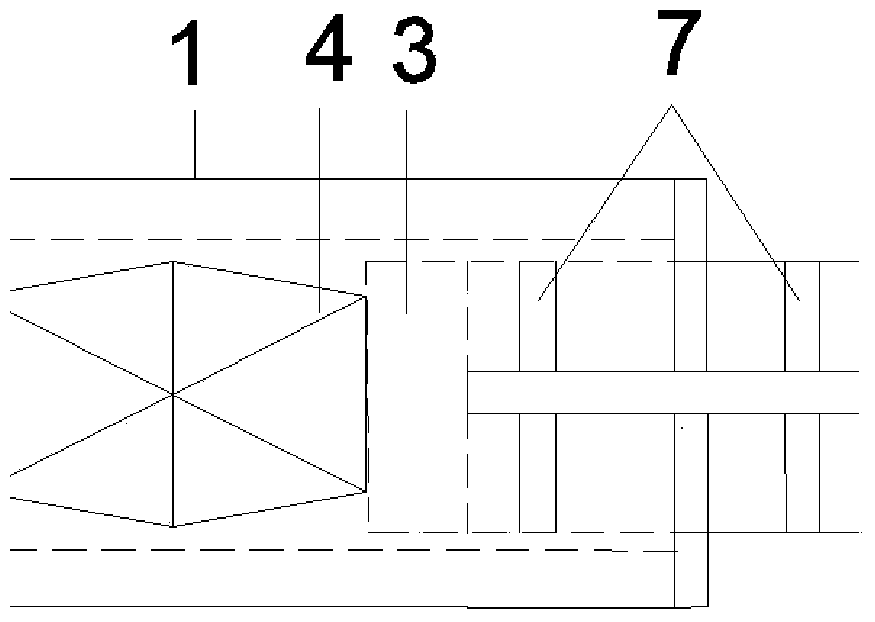

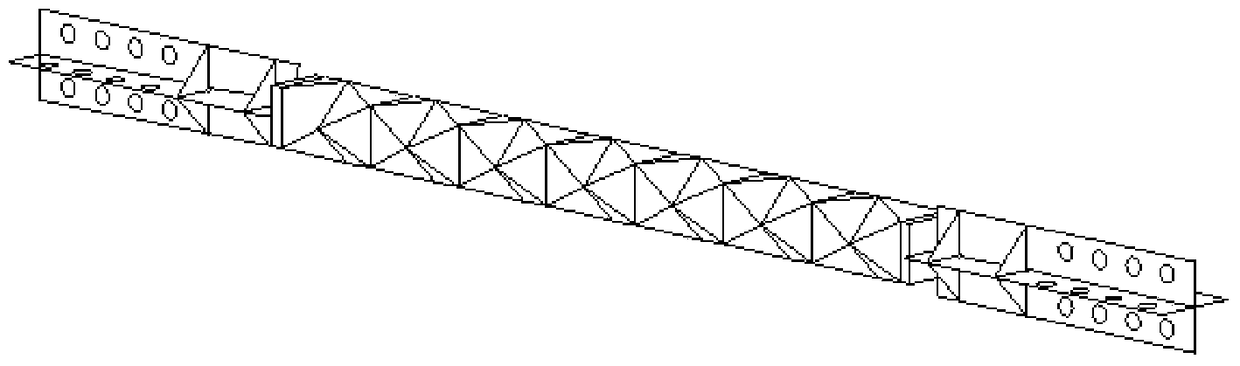

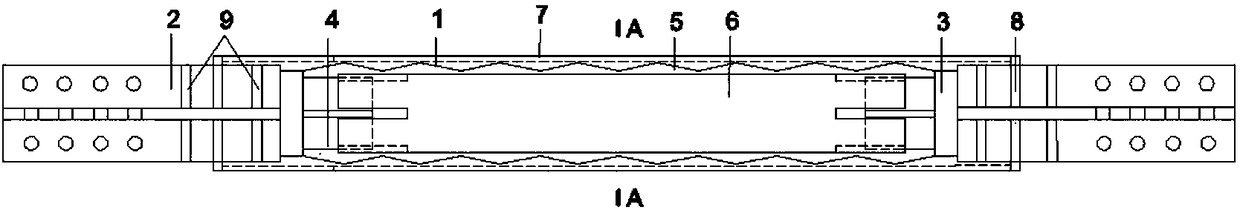

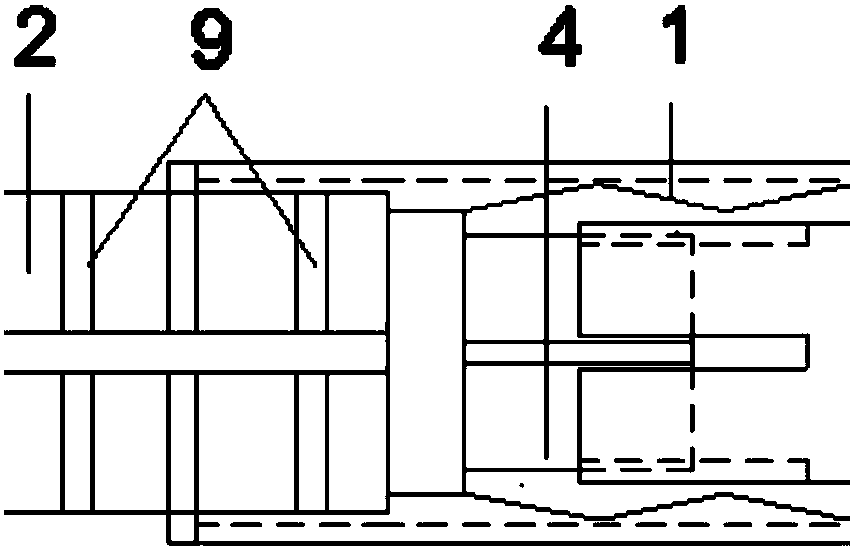

Internal and external double-sleeve restraining folded steel plate energy-consuming support

Owner:SOUTHEAST UNIV

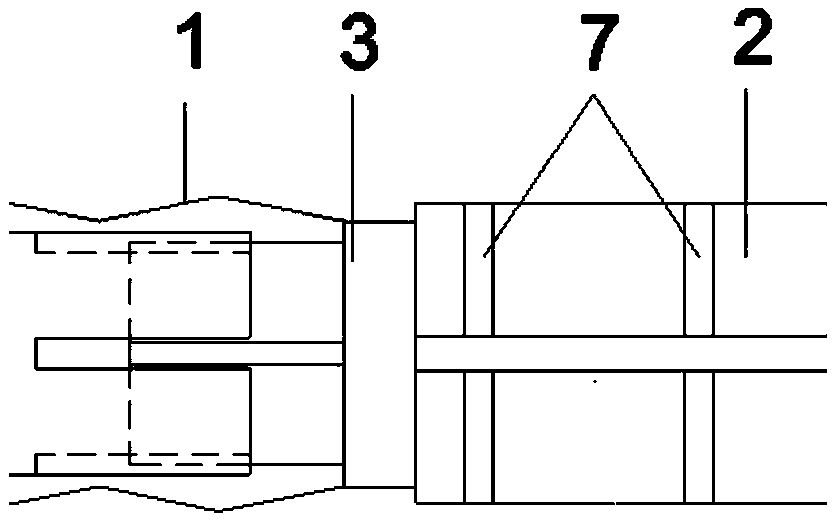

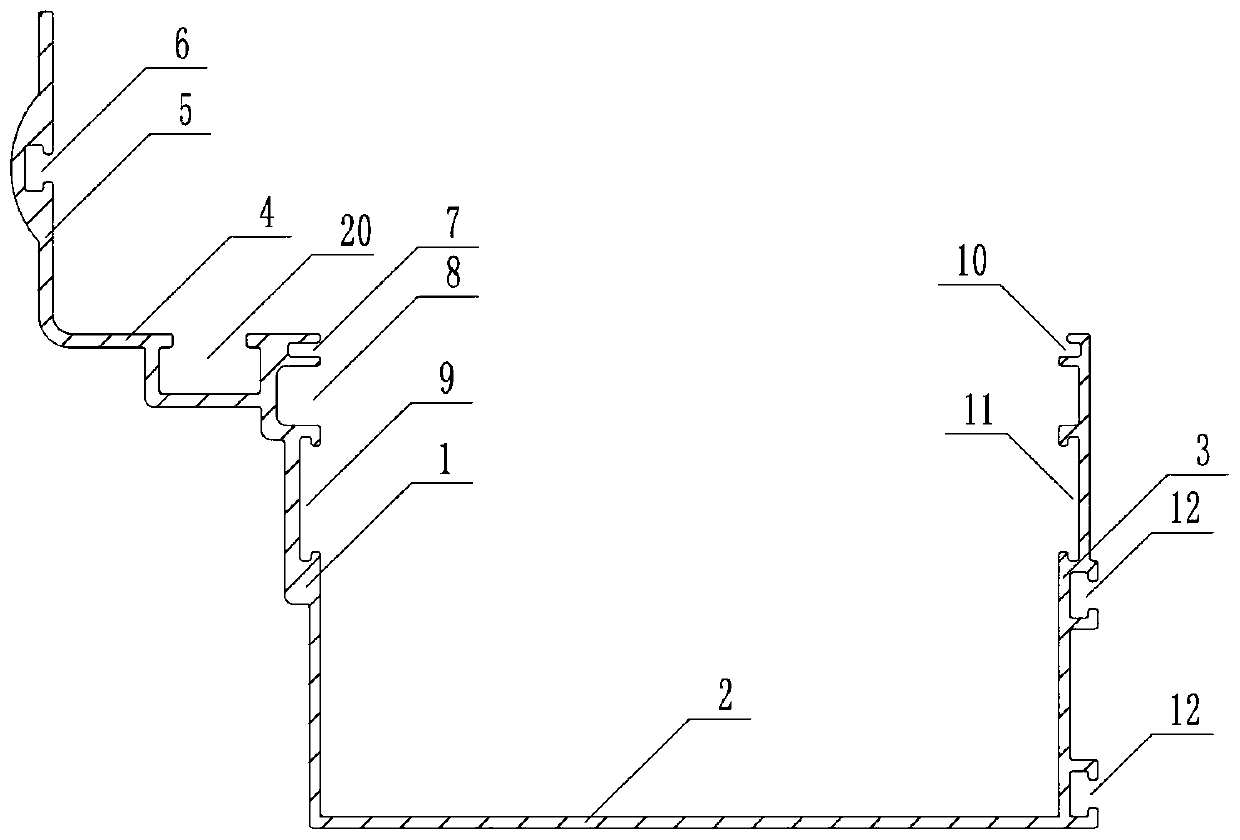

Outer casing pipe constraint folding steel plate energy consumption support

ActiveCN105507445AIncrease stiffnessIncrease ultimate bearing capacityShock proofingOuter CannulaEarthquake disaster

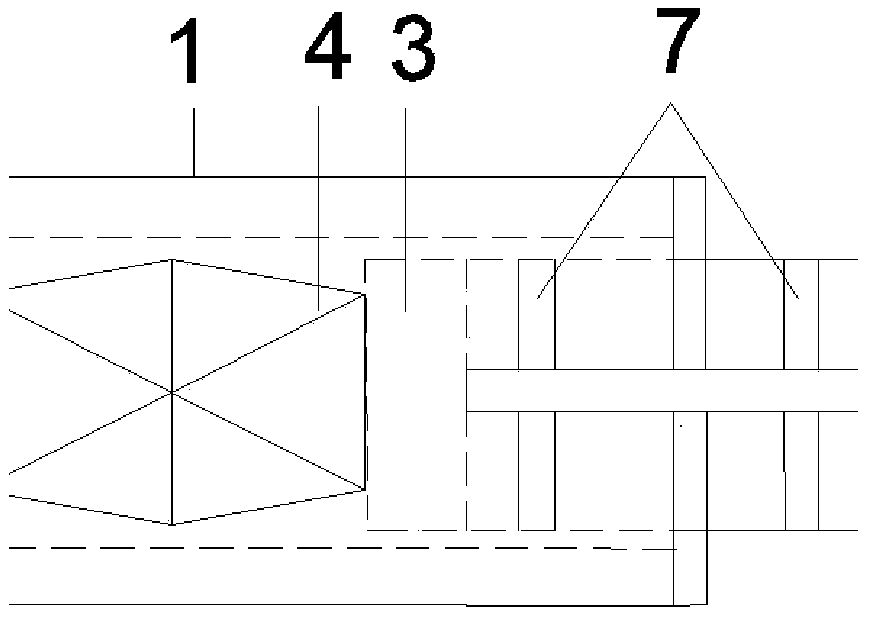

The invention discloses an outer casing pipe constraint folding steel plate energy consumption support. The support comprises an outer casing pipe, a core barrel arranged in the outer casing pipe, end bearing plates arranged at barrel openings of the two sides of the core barrel and outer casing pipe seal plates arranged at the ends of the two side of the outer casing pipe; the end bearing plates are connected with cross-shaped node plates penetrating through the outer casing pipe seal plates, and the core barrel is formed by sequentially connecting multiple energy consumption units. The support reduces earthquake responses of buildings through the good post-yielding energy consumption capacity, is easy to manufacture and convenient to install and can be applied to structural earthquake resisting and effectively reduce earthquake disasters.

Owner:SOUTHEAST UNIV

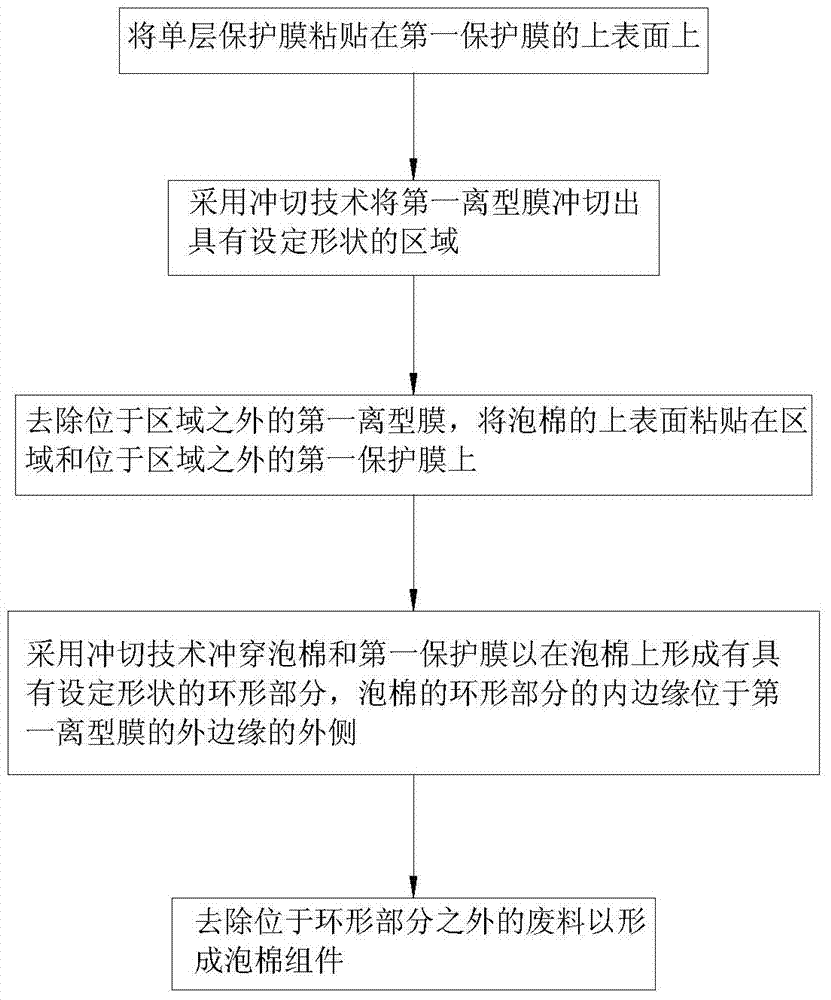

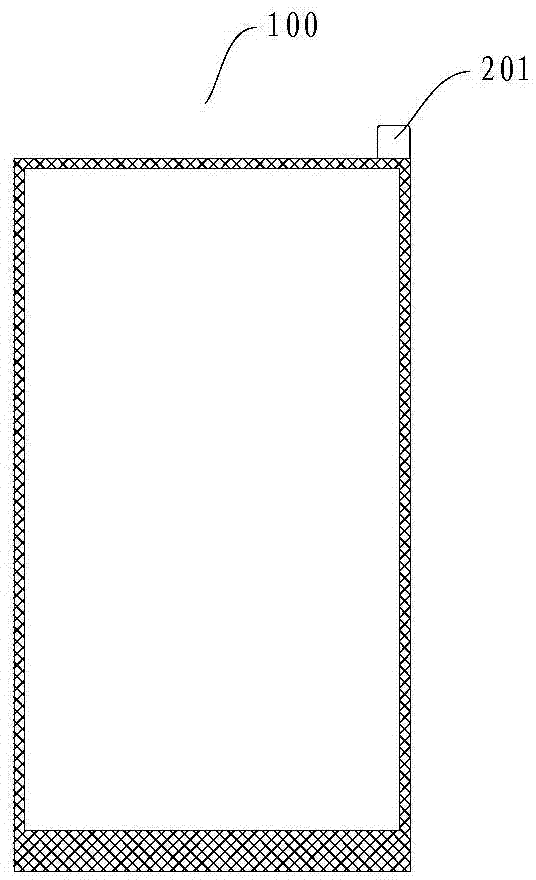

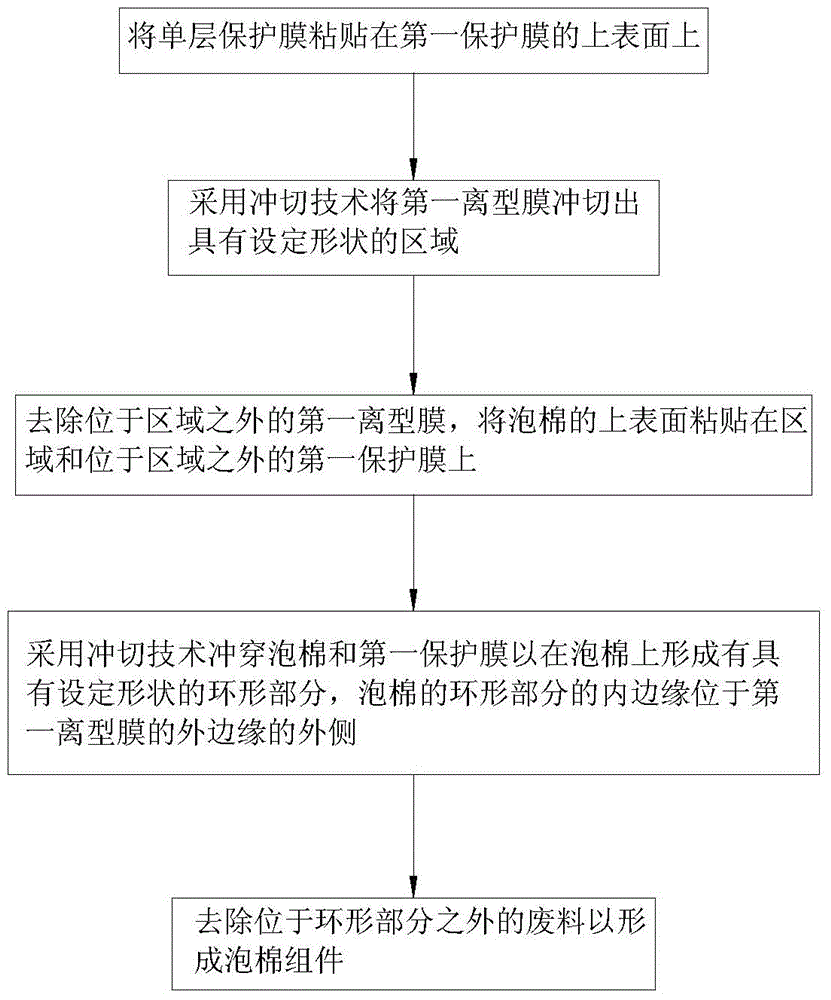

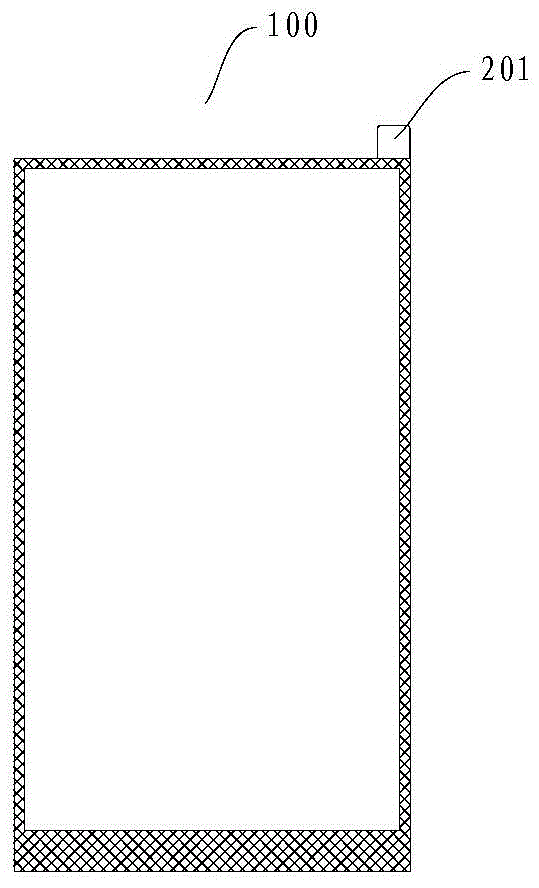

Foam component and processing method thereof

ActiveCN104710945AEasy for stampingReduce the risk of displacement deformationFilm/foil adhesivesMetal working apparatusTectorial membranePunching

The invention discloses a foam component and a processing method thereof. The processing method includes the steps of: S1: sticking a monolayer protective film to the upper surface of a first protective film; S2: punching an area with a set shape on a release film by a punching technology; S3: removing a first release film located outside the area, and sticking the upper surface of the foam on the first protective film in the area and beyond the area; S4: punching the foam and the first protective film through by a punching technology to form an annular part on the foam, with the inner edge of the foam's annular part located outside the outer edge of the first release film; and S5: removing the water material outside the annular part. The processing method for the foam component provided by the invention facilitates the punching processing of foam and reduces the shift deformation risk of the foam frame.

Owner:BYD CO LTD

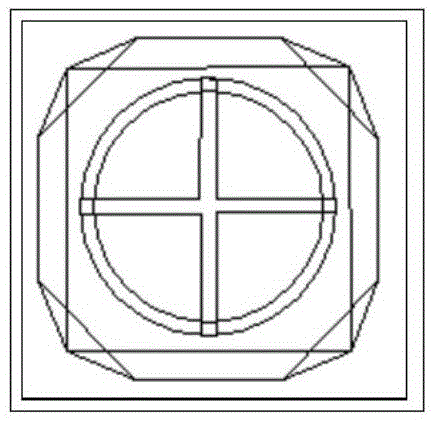

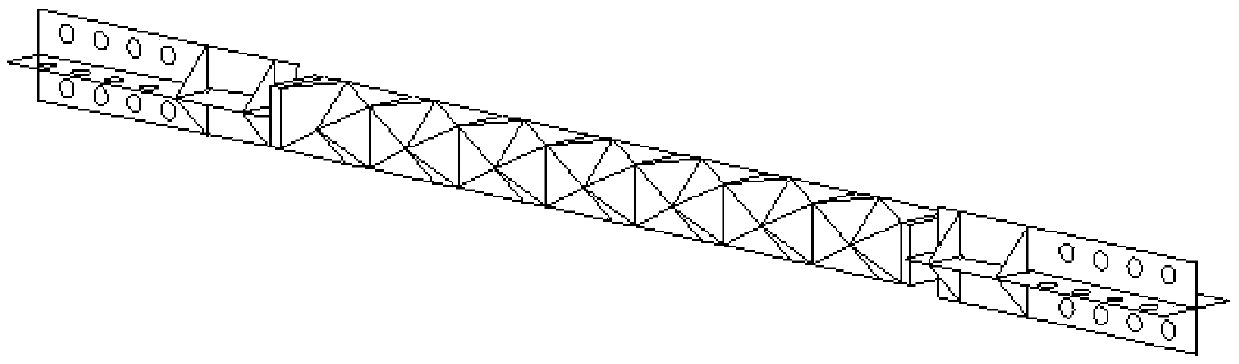

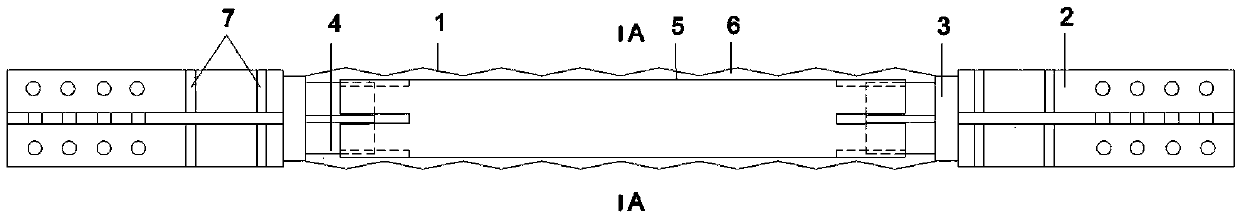

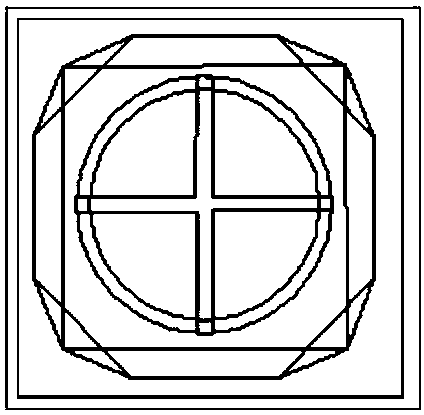

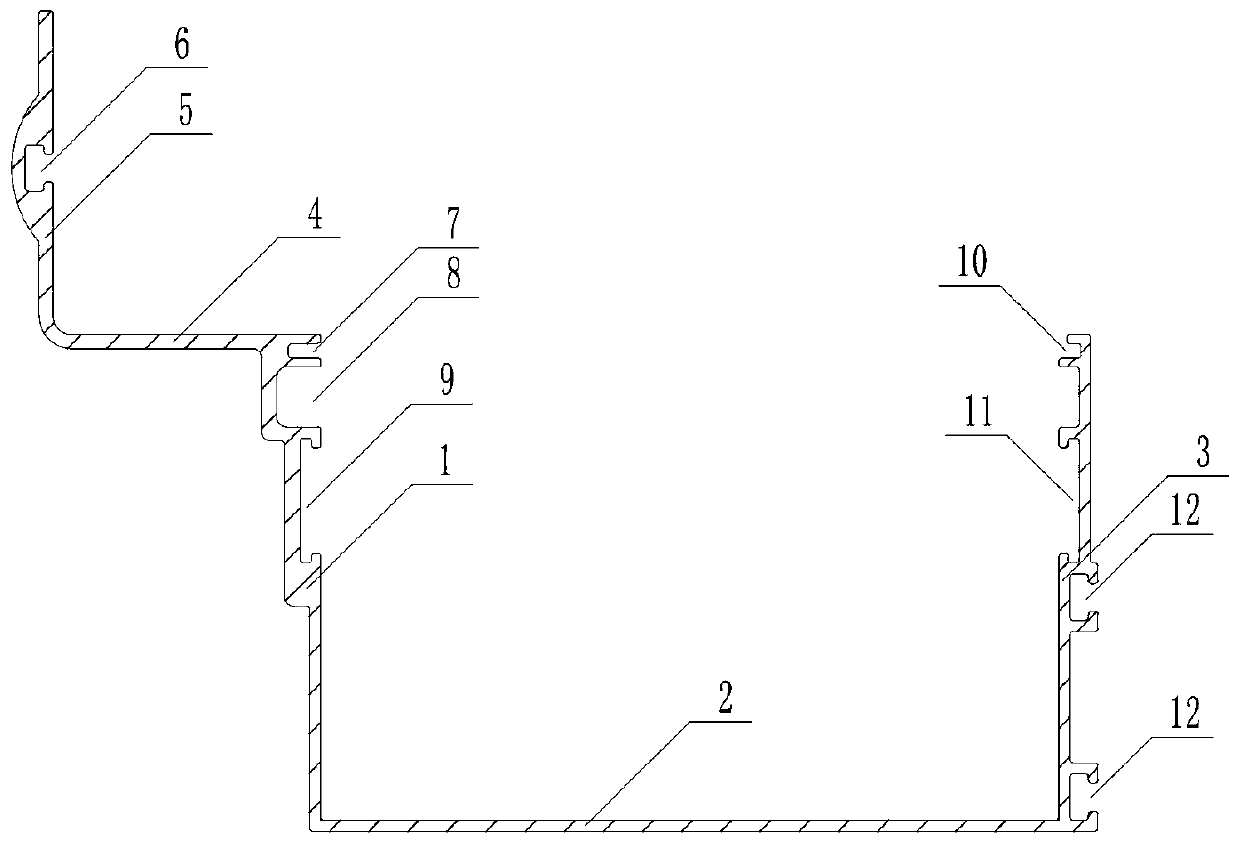

Inner sleeve constraint folding steel plate energy dissipation support

ActiveCN105507444AImprove stabilityLess prone to out-of-plane bucklingShock proofingGusset plateEngineering

The invention discloses an inner sleeve constraint folding steel plate energy dissipation support. The energy dissipation support comprises a core cylinder, an inner sleeve arranged in the core cylinder, end load bearing plates arranged at cylinder openings in the two sides of the core cylinder, a crossed fixed plate arranged in the inner sleeve and connected with the inner sides of the end load bearing plates and a crossed gusset plate connected to the outer sides of the end load bearing plates. The core cylinder is formed by sequentially connecting multiple energy consumption units. Each energy consumption unit consists of 4n triangles with different surfaces. The energy dissipation support produces pre-folding traces through folding steel plates and can produce plastic hinge lines at the folding traces when bearing a load, and the energy consumption capacity of the support is enhanced through the plastic hinge lines; meanwhile, the sleeve is arranged in the core cylinder to improve annular constraint to the core cylinder, and therefore the rigidity and ultimate bearing capacity of the support can be improved conveniently.

Owner:SOUTHEAST UNIV

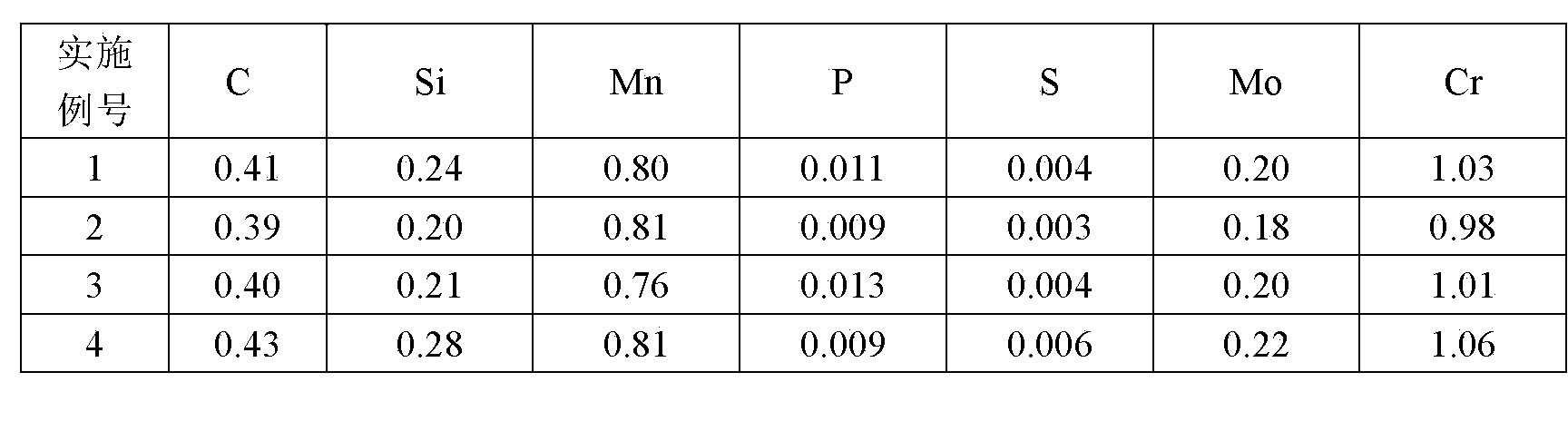

42 CrMo steel cold-rolled sheet and its production method

The invention discloses a 42CrMo steel cold-rolled plate and its production method, and the 42CrMo steel cold-rolled plate comprises the following chemical components by mass: 0.38-0.45% of C, 0.17-0.37% of Si, 0.50-0.90% of Mn, less than 0.035% of P, less than 0.035% of S, 1.02-1.14% of Cr, 0.15-0.25% of Mo, and balance of Fe. The production method comprises molten steel smelting, continuous casting, hot rolling, cold rolling, bell-type furnace annealing, finishing and other processes, and is characterized in that, the hot rolled steel billet heating temperature is 1170-1270 DEG C, the finish rolling temperature is 850-950 DEG C, the coiling temperature is 700-750 DEG C, the cold rolling ratio down press rate is 25%-55%, the annealing temperature is Ac1-(10-30) DEG C, the heat insulation time is 8-14h, air cooling is performed when the billet is heat insulated to 400 DEG with a bell, and the flat elongation is 0.5%-1.2%. The 42CrMo steel cold-rolled plate is good in plasticity, toughness and cutting performances, and helps a user to perform cutting, stamping process and subsequent heat treatment.

Owner:ANGANG STEEL CO LTD

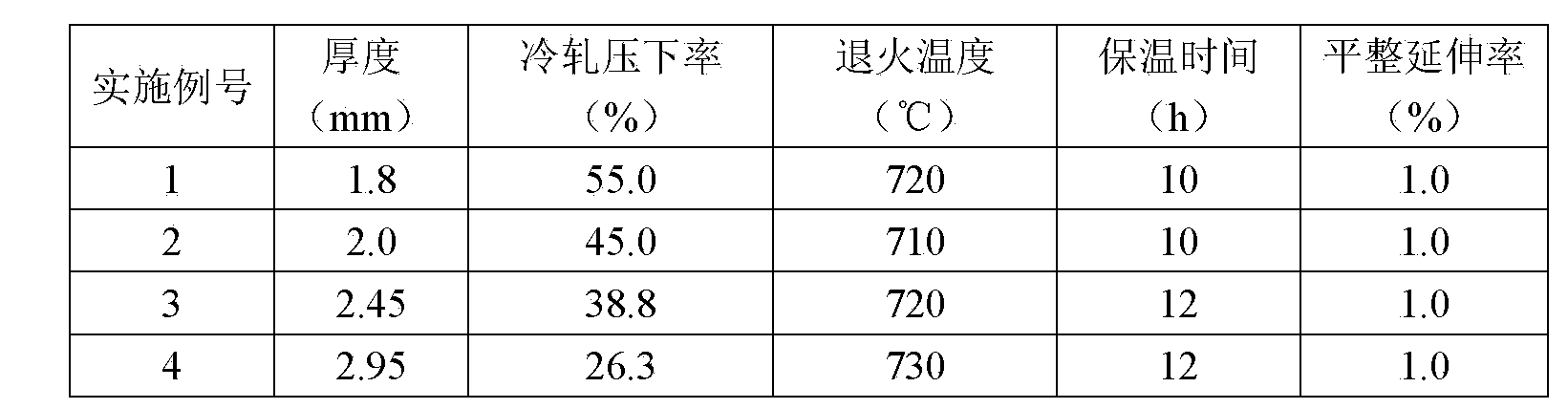

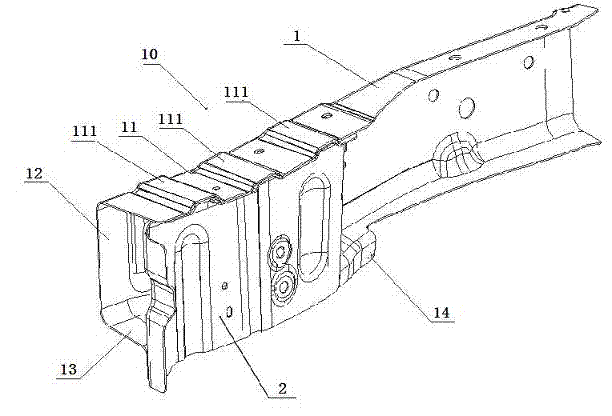

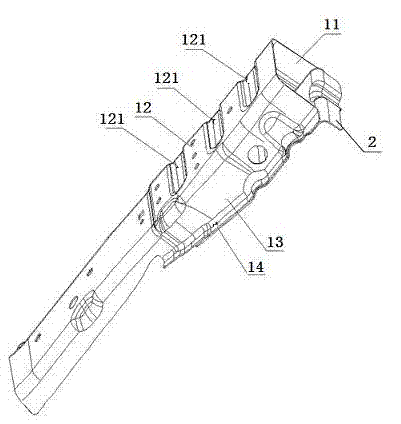

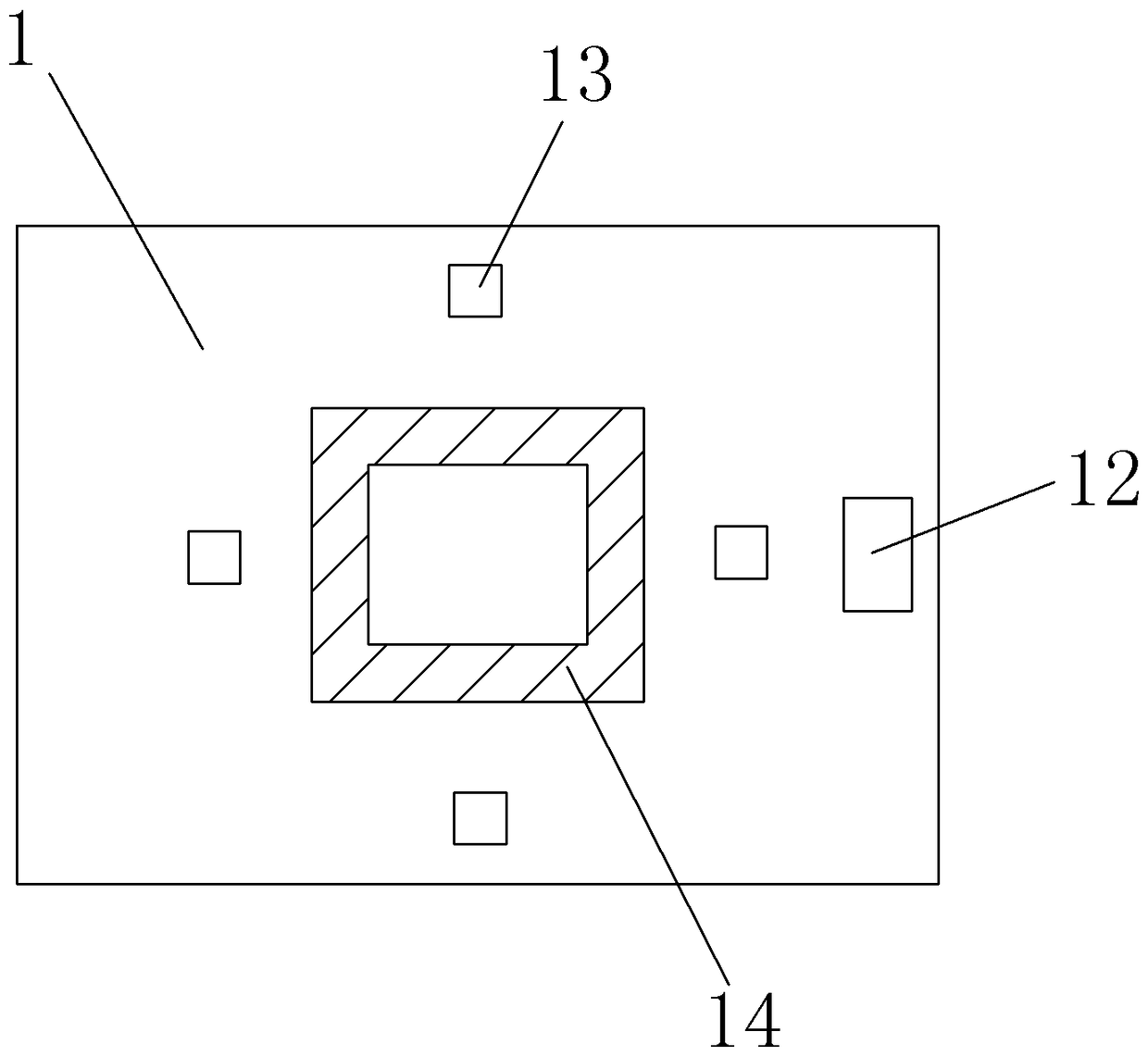

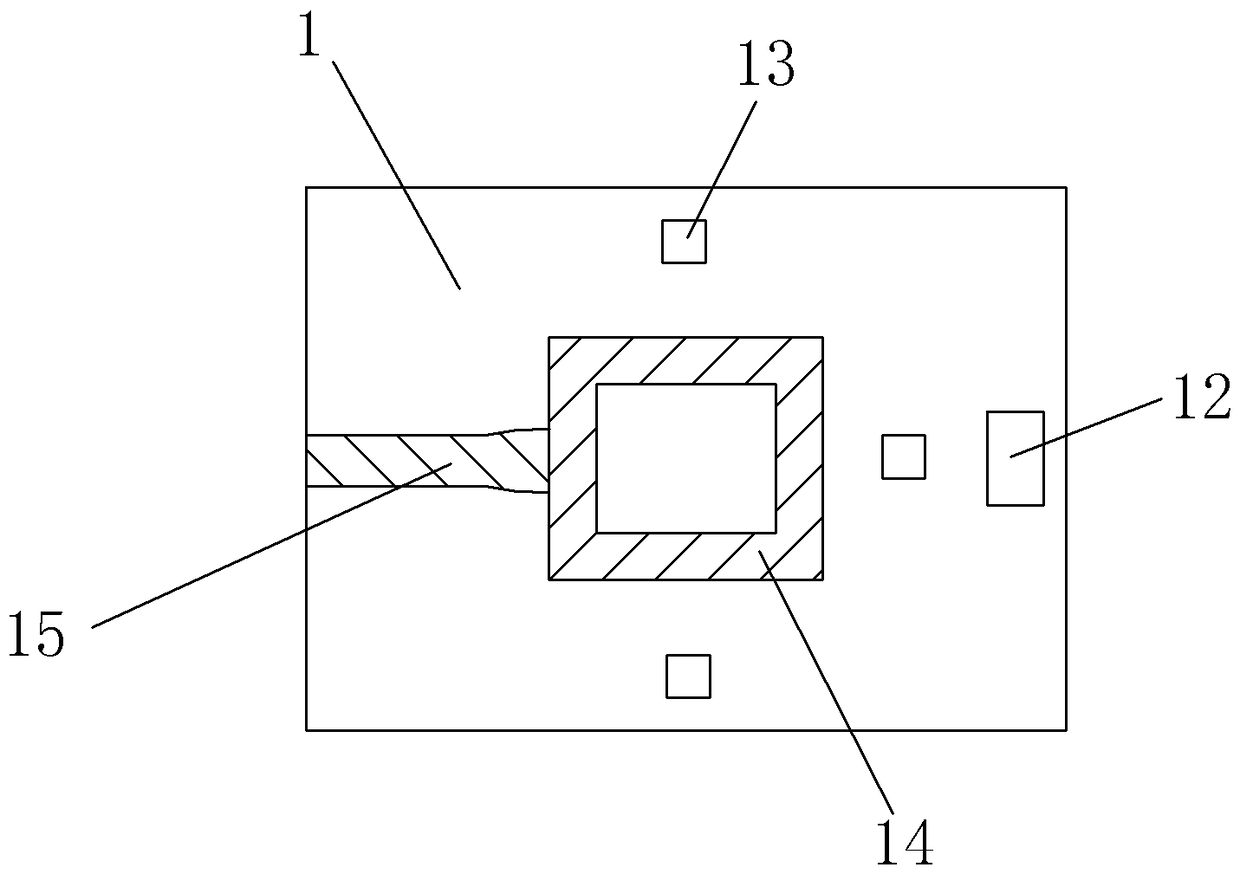

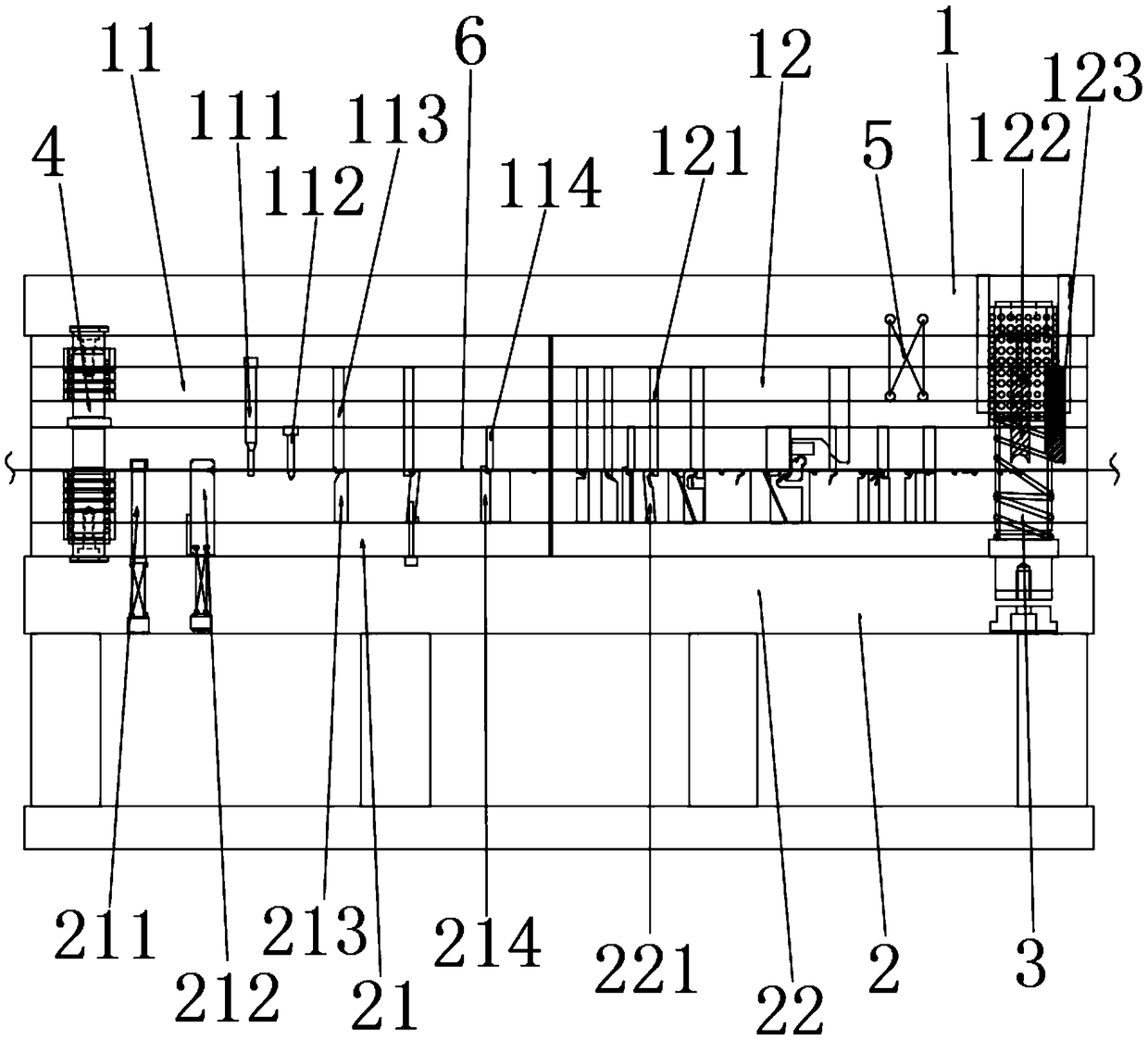

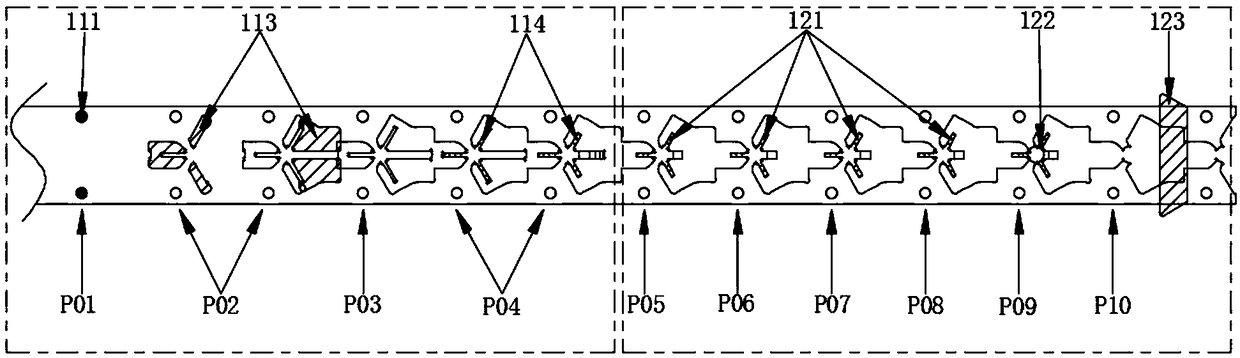

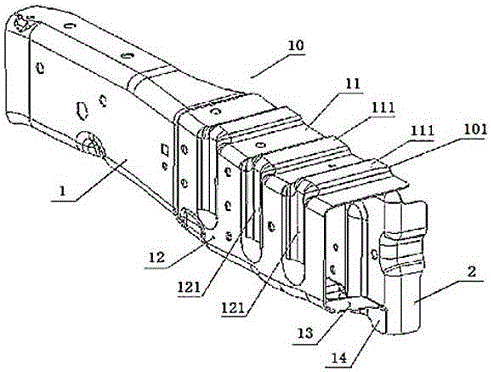

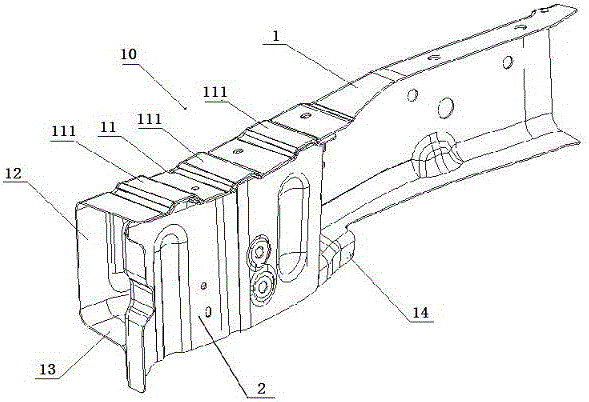

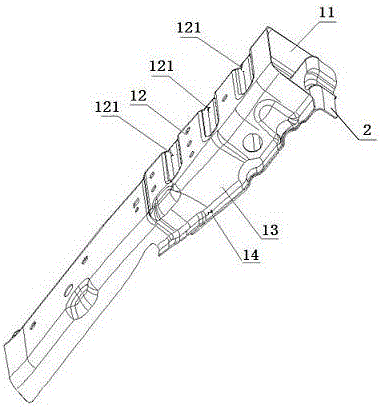

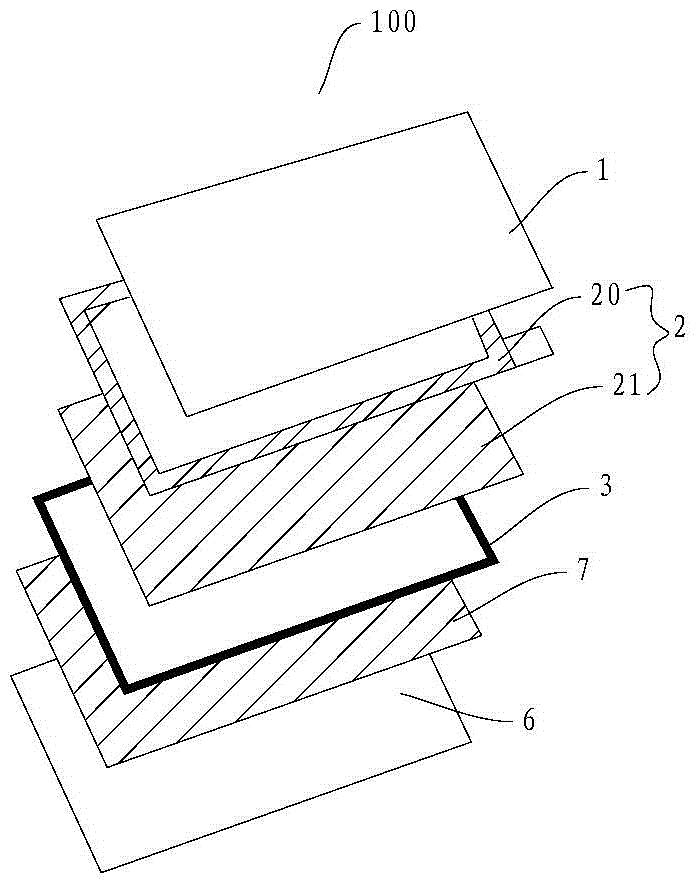

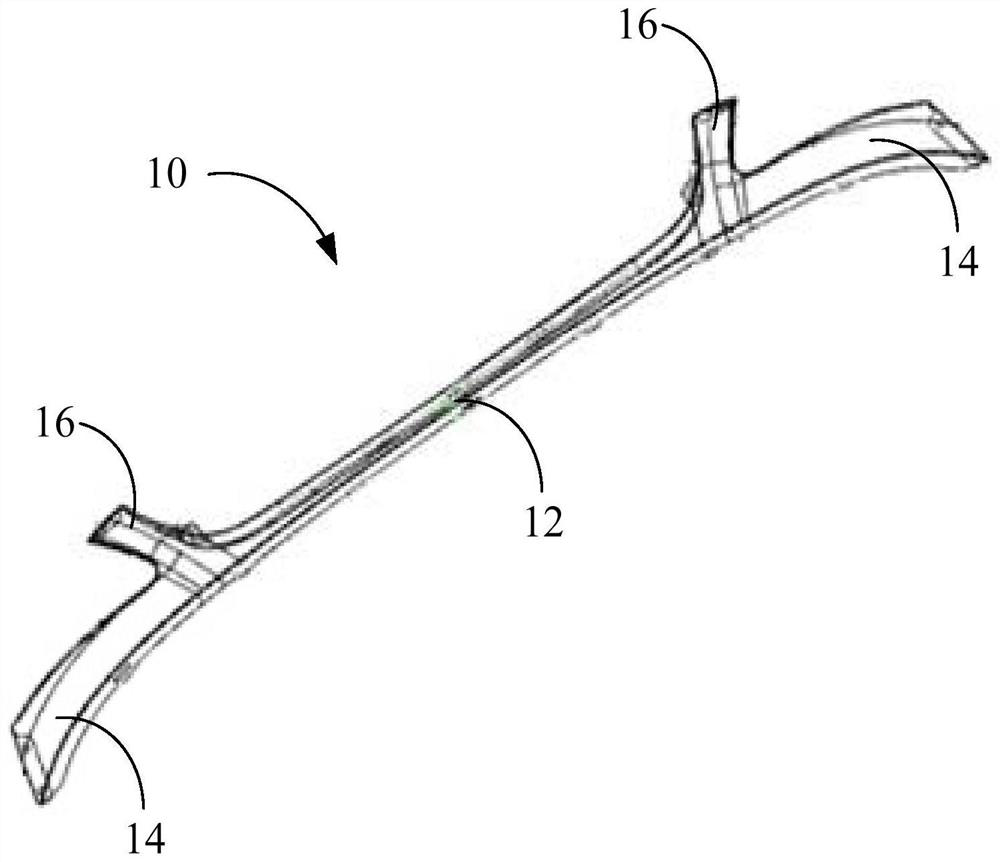

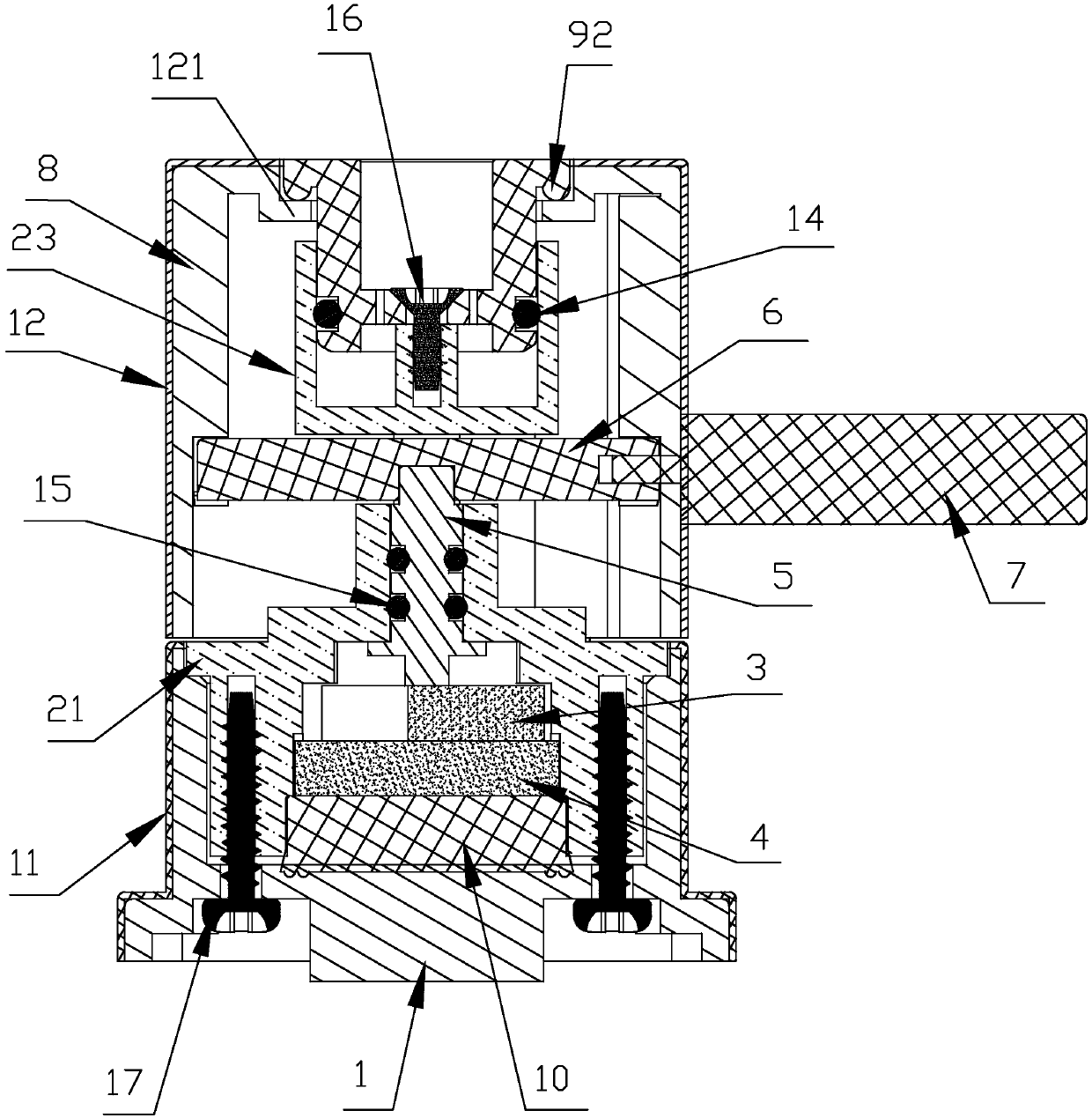

Front longitudinal beam energy-adsorption structure for vehicle

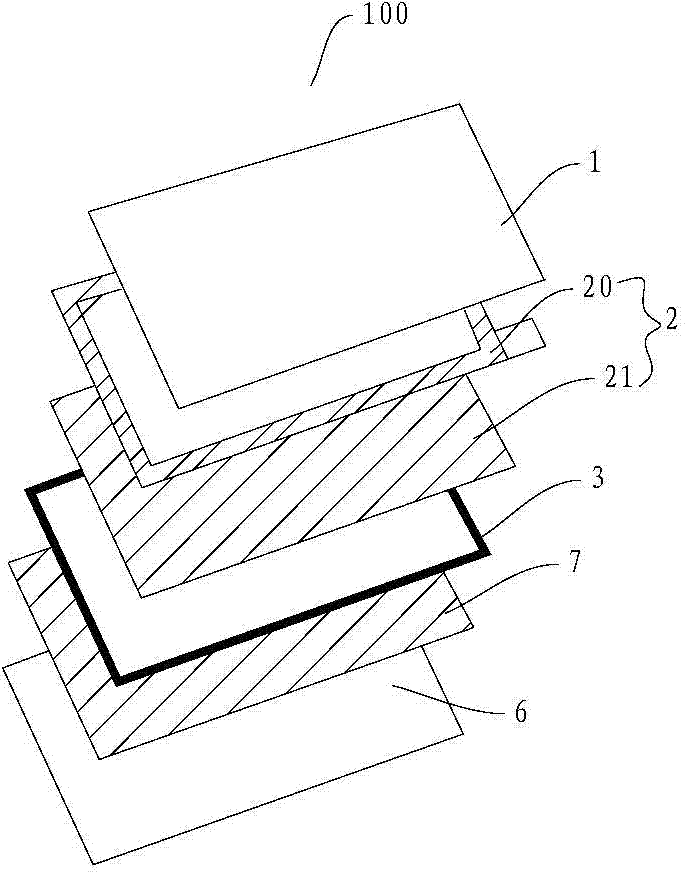

ActiveCN103085880AImprove mechanical propertiesDeformation stableUnderstructuresConvex structureBeam energy

The invention relates to a front longitudinal beam energy-adsorption structure for a vehicle. The front longitudinal beam energy-adsorption structure comprises a front longitudinal beam assembly (10), wherein the front longitudinal beam assembly (10) comprises a body (1) and a cover plate (2); the body (1) has a U-shaped structure and is provided with a body upper wing (11), a body inside wing (12), a body lower wing (13) and a body lower flange (14); the cover plate (2) is provided with a cover plate upper flange (21) and a cover plate outside wing (22); one or more first L-shaped conduction structure (101) is arranged on the body (1); one side of each first L-shaped conduction structure (101) consists of convex structures (111) on the body upper wing; the other side of each first L-shaped conduction structure (101) consists of concave structures (121) on the body inside wing; and in order to match the first L-shaped conduction structures on the body (1), second L-shaped conduction structures (102) also can be arranged at corresponding positions on the cover plate (2). The front longitudinal beam energy-adsorption structure for the vehicle has a good mechanical property, good modeled processability and good welded processability.

Owner:CHERY AUTOMOBILE CO LTD

Plate punching method

ActiveCN106694746AImprove securityAvoid personal injuryShaping safety devicesMechanical energy handlingPunchingPiston

The invention discloses a plate punching method. A punching device is adopted in the method; the punching device includes a base and a mounting base; a punching die is arranged in the mounting base; a bracket is arranged on one side of the base, and is connected with a mounting frame; a cylinder is arranged at the lower part of the mounting frame, and is connected with a punching head; an intake port of the cylinder is connected with an intake pipe; the intake pipe is slidingly connected with a valve element; a mounting hole is formed in the mounting frame; the valve element extends into the mounting hole; an electromagnet is arranged in the mounting hole, and is provided with a magnet exciting coil; multiple air collecting tanks are formed in the punching head; a piston is arranged in a piston cavity; the tail part of the piston extends out of the punching head, and is connected with a first rack; a rotating shaft is connected with a generator; photoelectric switches are arranged on the base; and the punching device further includes two accumulators and a light source. The plate punching method prevents potential safety hazards of workers caused by the cylinder driving the punching head to downwards move due to misoperation of the workers when hands of workers do not leave a punching area yet.

Owner:DOOR IND CO LTD CHONGQING DTOMO

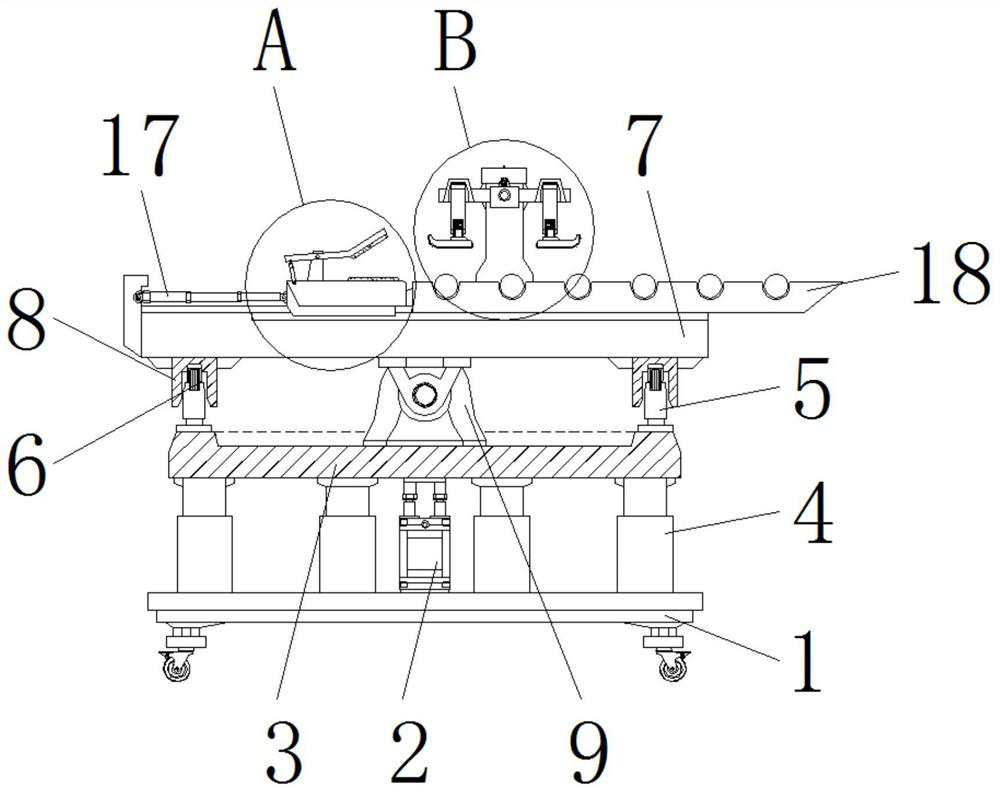

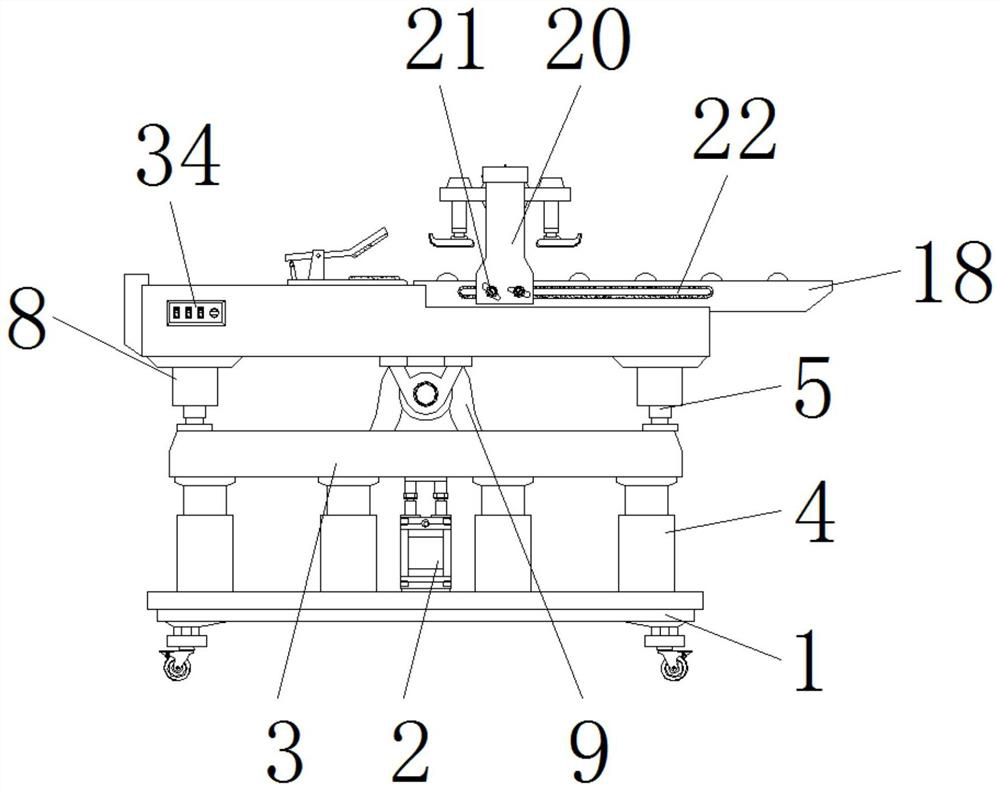

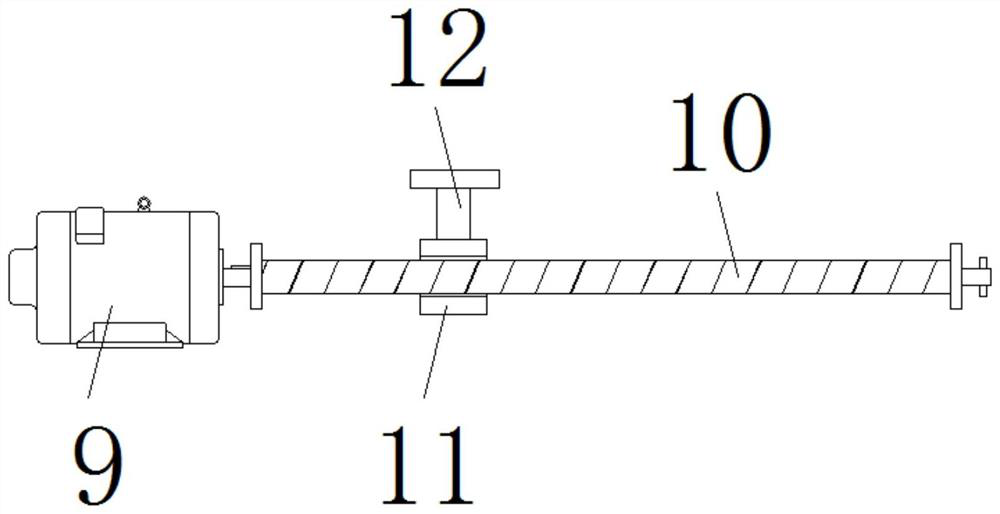

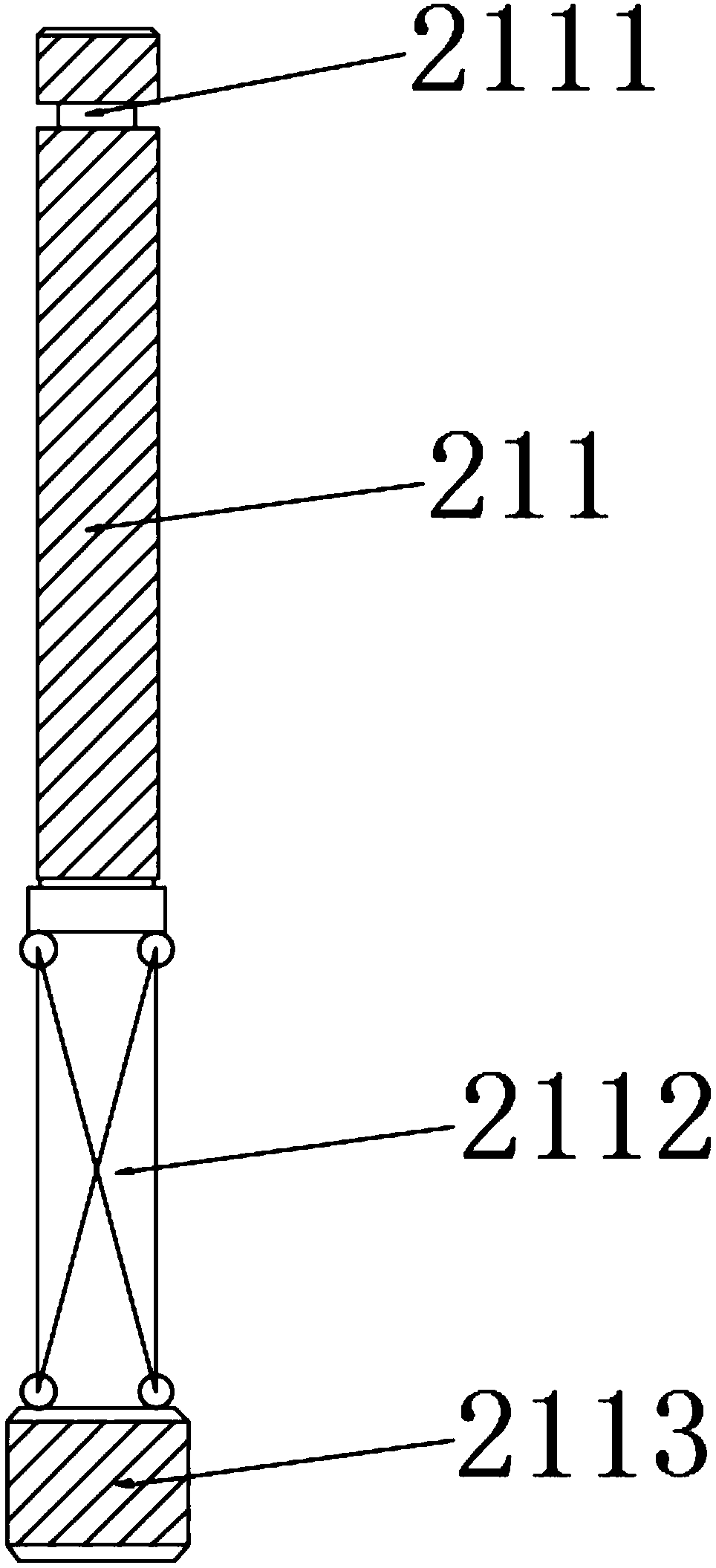

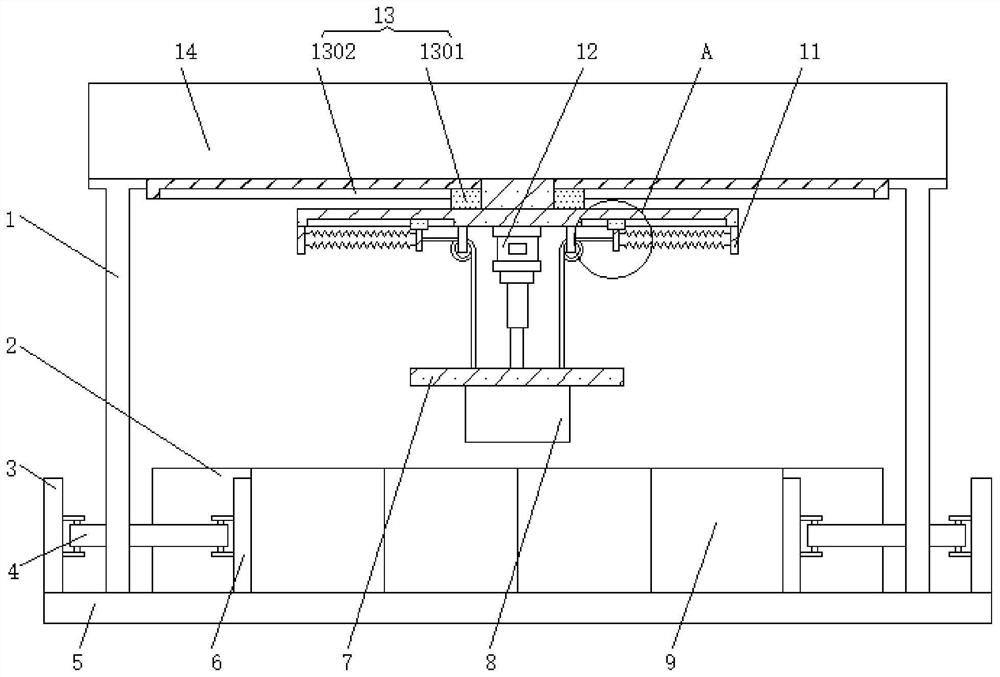

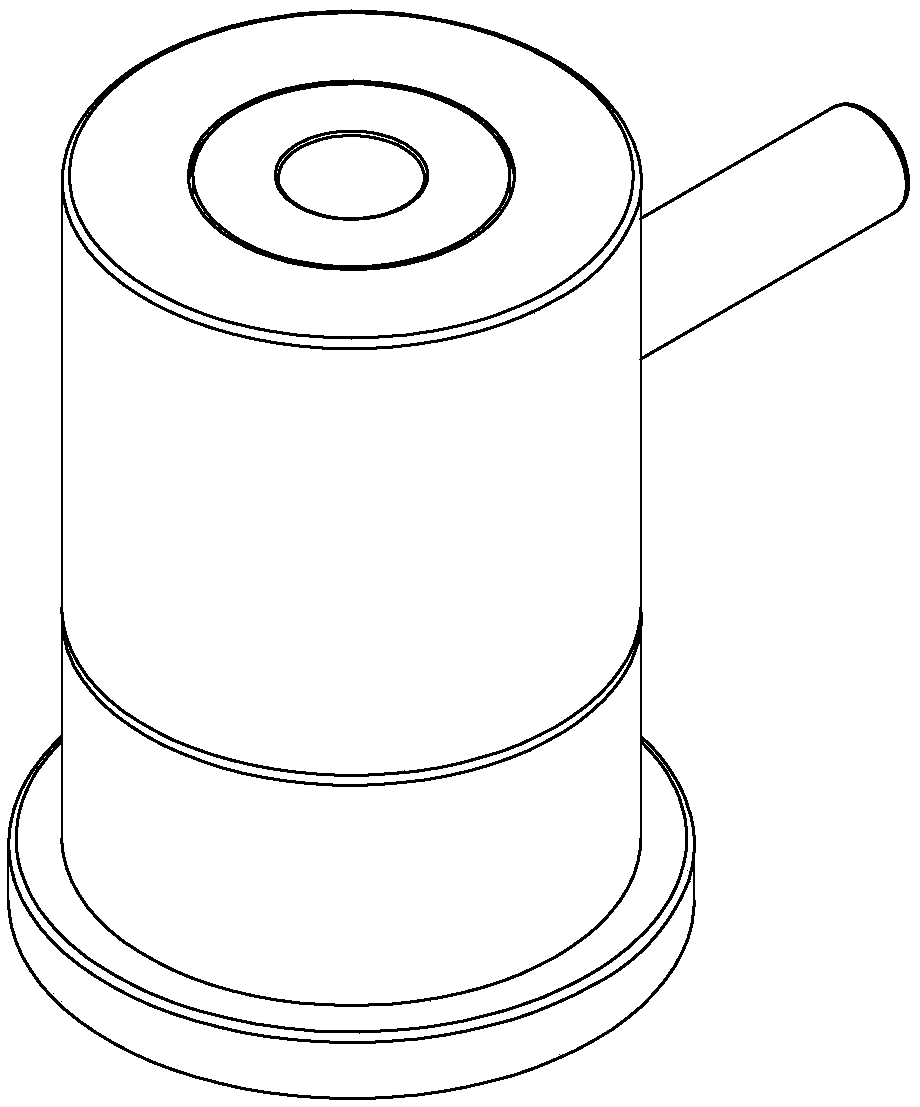

Metal part stamping auxiliary equipment for shock absorber accessory production

ActiveCN111872250AImprove stabilityAffect stabilityMetal-working feeding devicesOther workshop equipmentElectric machineryMachining

The invention discloses metal part stamping auxiliary equipment for shock absorber accessory production. The equipment comprises a base, a first pneumatic cylinder is installed in the middle of the top of the base, a lifting plate is installed at the top of the first pneumatic cylinder, and cylindrical inner and outer telescopic pipes are evenly installed at the edge of the bottom of the lifting plate; and the other ends of the cylindrical inner and outer telescopic pipes are fixed to the base, sliding assemblies are arranged on the two sides of the top of the lifting plate correspondingly, and a transverse moving plate is arranged over the lifting plate through the sliding assemblies. The equipment is provided with a connecting block, a rolling wheel, the transverse moving plate, a sliding rail, a first stepping motor, a first lead screw shaft, a first lead screw sleeve and a connecting piece, the first stepping motor drives the connecting piece to transversely move through the firstlead screw shaft and the first lead screw sleeve, the longitudinal position of a metal plate is automatically adjusted, and a connecting block slides on the inner side of the sliding rail through therolling wheel; and the stability of the transverse moving sliding process is improved, and the situation that inclination affects the stability and accuracy of stamping machining is avoided.

Owner:安徽春晟机械有限公司

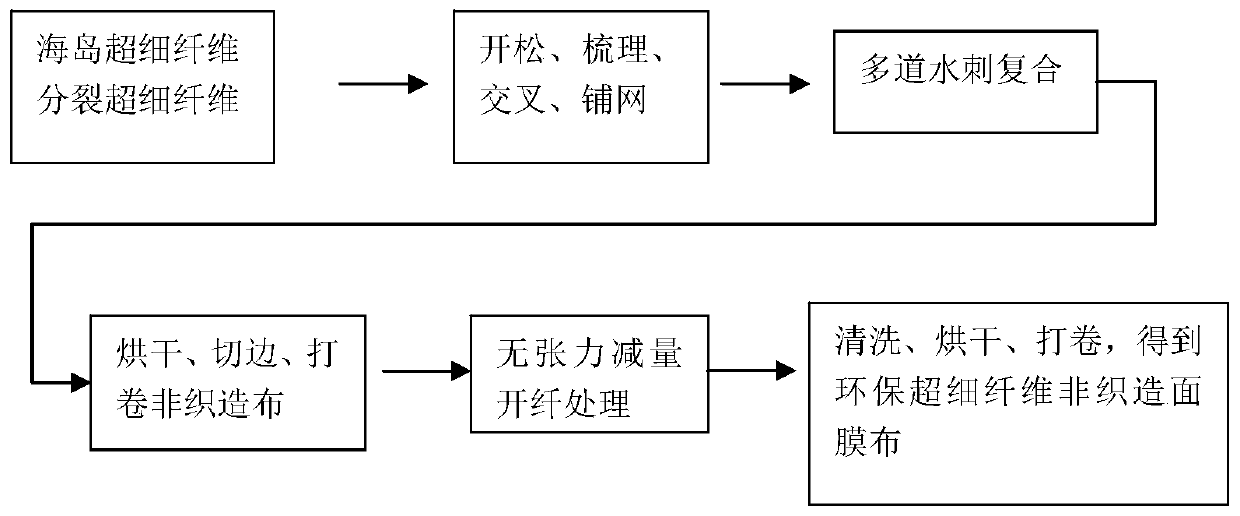

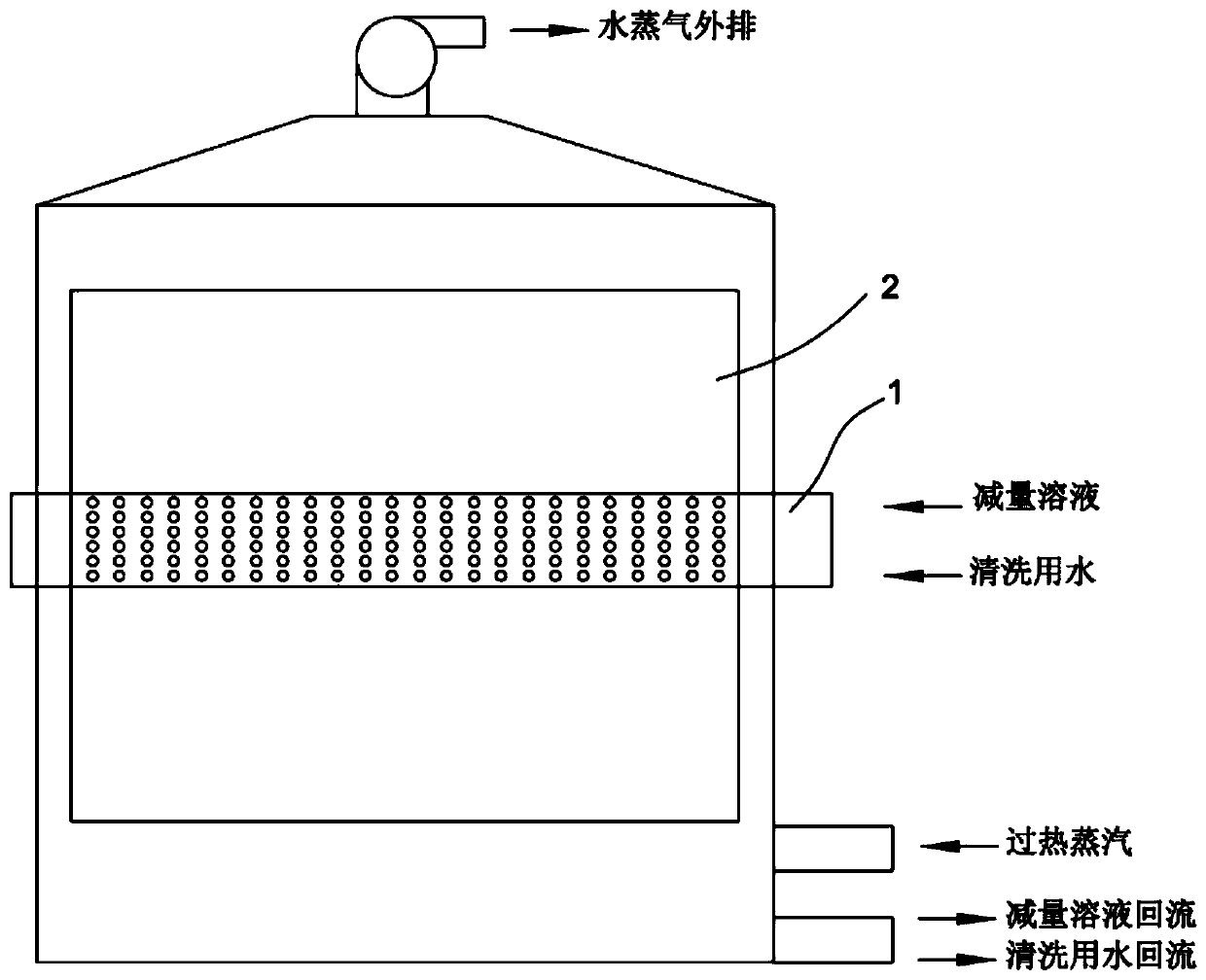

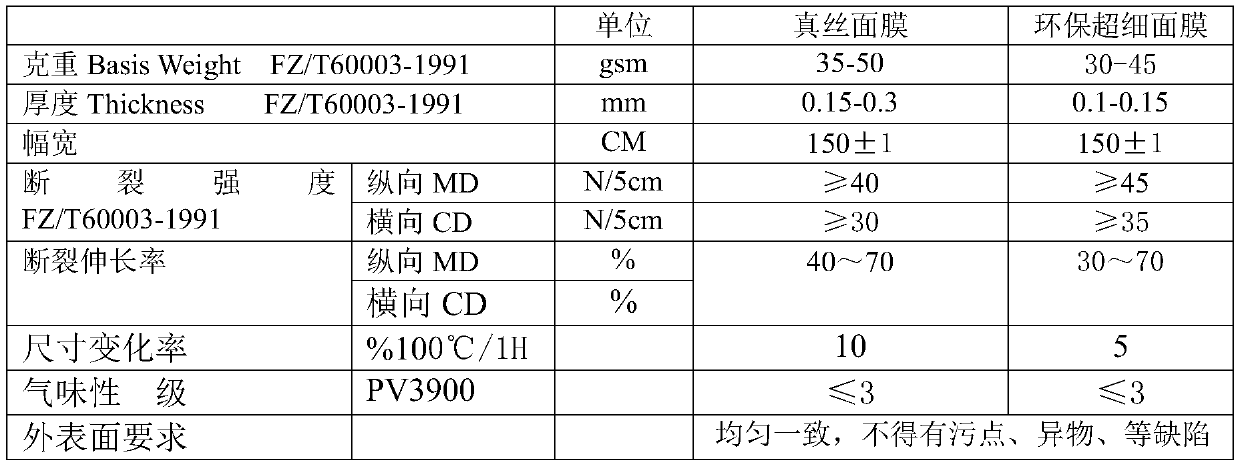

Environmentally-friendly superfine fiber non-woven facial mask cloth and making method thereof

InactiveCN109722791AGood mechanical and physical propertiesSkin-friendlyFibre treatmentNon-woven fabricsEnvironmentally friendlyTextile

The invention relates to the technical field of non-woven clothes, in particular to an environmentally-friendly superfine fiber non-woven facial mask cloth and a making method thereof. Sea-island typeand splitting type super-thin short fibers are mixed according to a proportion, carded and laid into a fiber net with a uniform gram weight, a matched non-woven spunlaced composite strengthening technology is used for forming a composite spunlaced non-woven cloth, and the non-woven cloth is used for making the environmentally-friendly superfine fiber non-woven facial mask cloth according to a tension-free fiber splitting technology. The environmentally-friendly superfine fiber non-woven facial mask cloth has the advantage of being well attached and being skin-friendly.

Owner:杭州海拓皮革有限公司

Sheet stamping method

ActiveCN106694746BImprove securityAvoid personal injuryShaping safety devicesMechanical energy handlingPunchingEngineering

Owner:DOOR IND CO LTD CHONGQING DTOMO

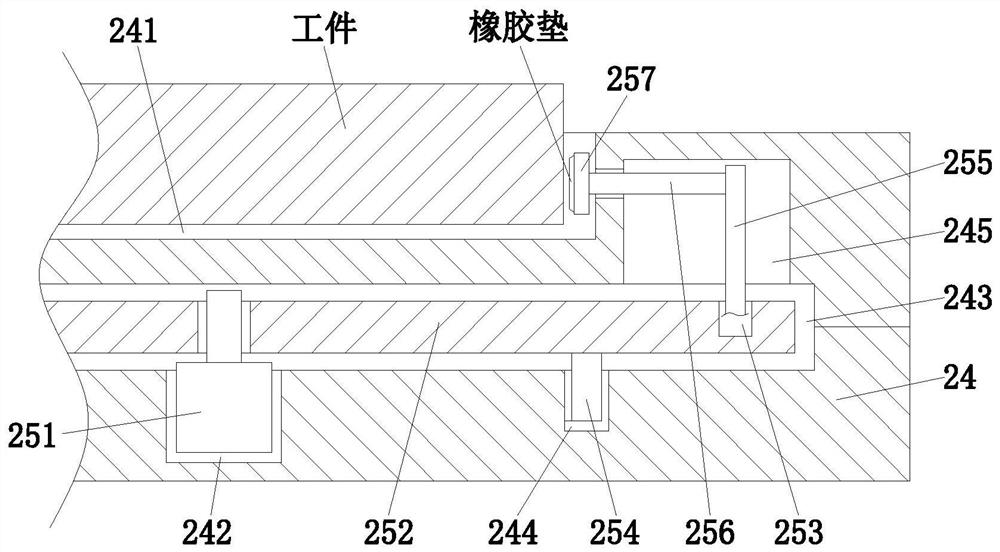

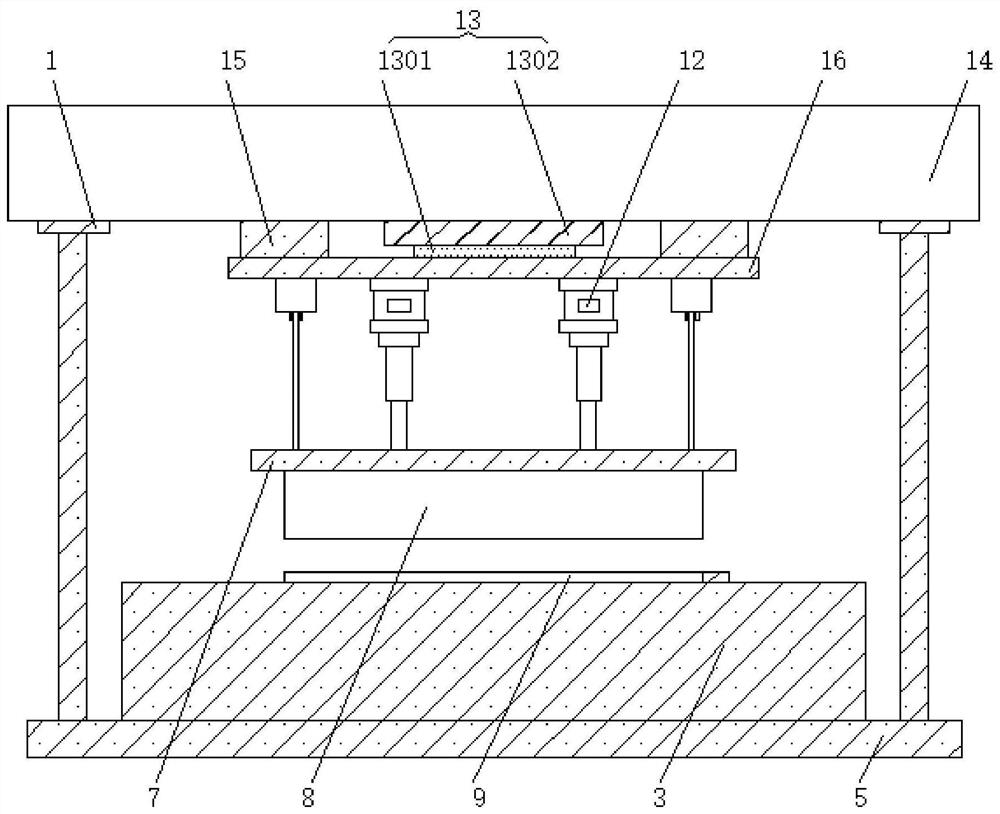

High-precision hydraulic numerical control punching machine

The invention provides a high-precision hydraulic numerical control punching machine, which comprises a workbench, a discharging unit and a blanking knife, wherein the discharging unit is mounted at the upper end of the workbench, and the blanking knife is arranged above the discharging unit. The invention can solve the following problems: firstly, when a workpiece is mounted and fixed by the existing numerical control punching machine, a support pin matched with a hole site on the workpiece is mostly arranged on a workbench, and the support pin is mostly directly inserted into the hole site of the workpiece during working, only plays a role in limiting the workpiece and cannot effectively fix the workpiece, so that the problem that the workpiece cannot be effectively fixed is solved, and therefore, the workpiece is lack of stability during processing; and secondly, when a workpiece is replaced by a general numerical control punching machine, the support pin cannot be adjusted according to the workpiece, so that the support pin matched with the workpiece needs to be replaced, and needs to be frequently disassembled and assembled, and thus, the workload is increased, the support pin is easy to deviate due to frequent disassembly and assembly, and the machining deviation of the workpiece is easy to cause.

Owner:武汉天客行知科技有限公司

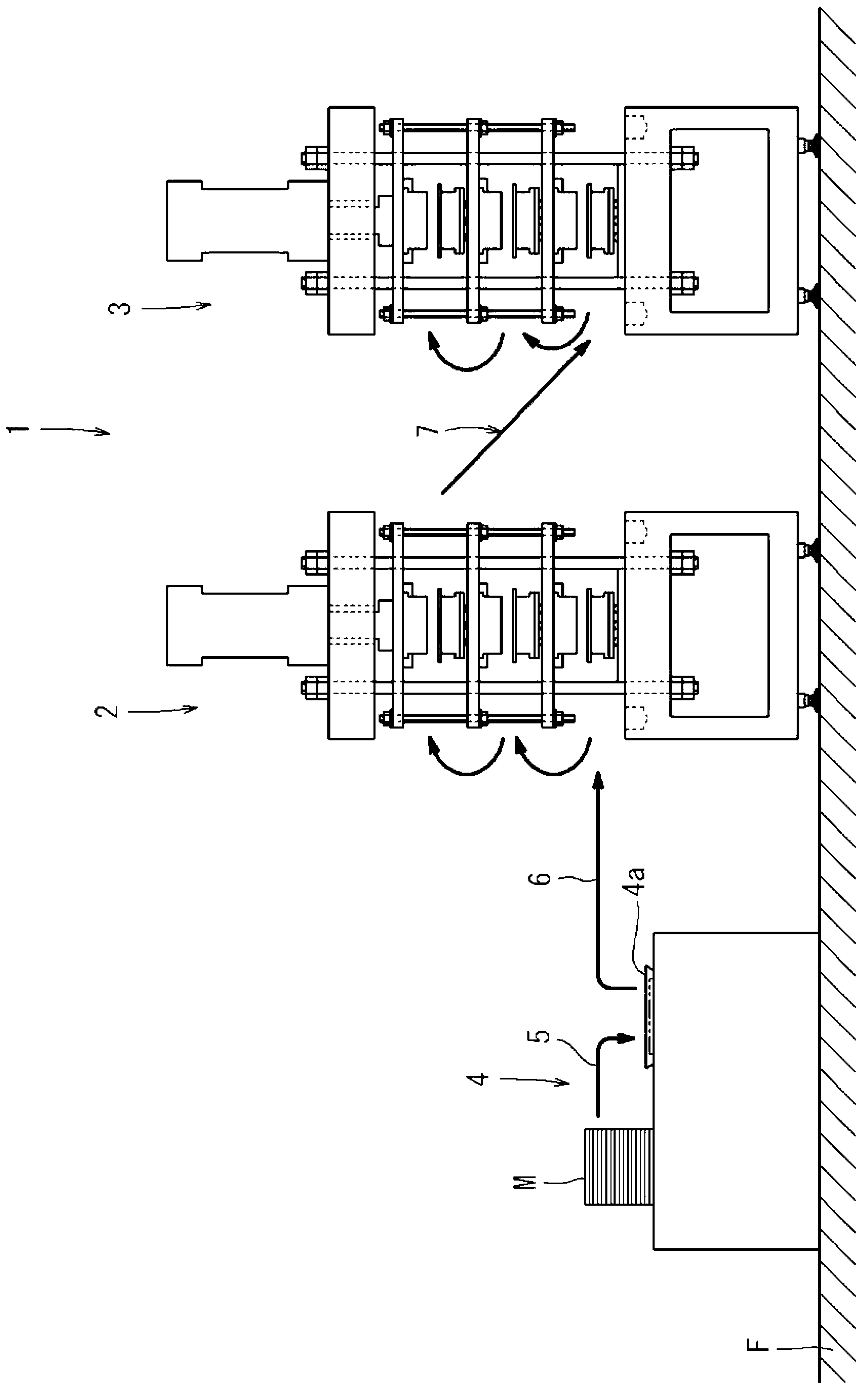

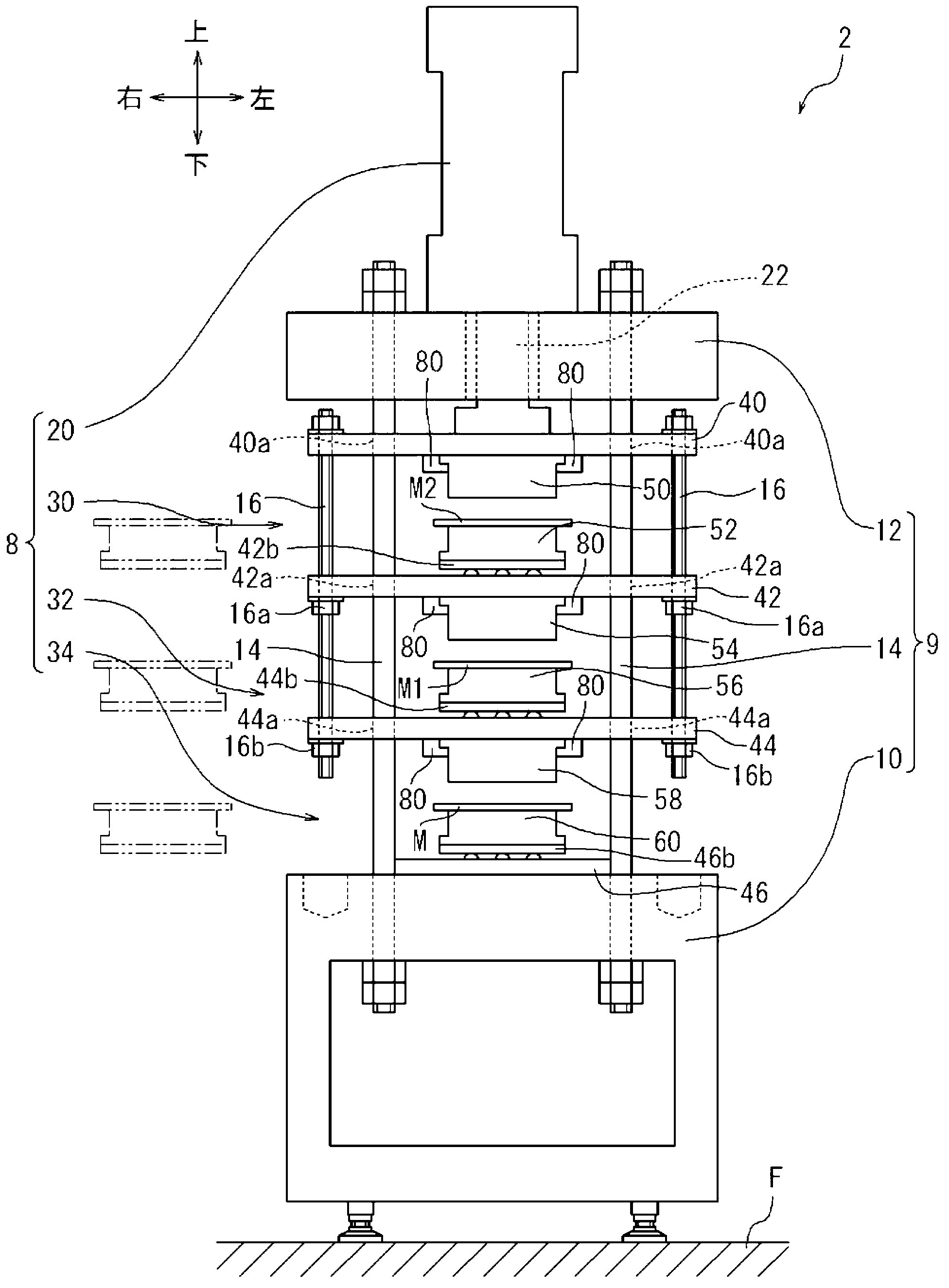

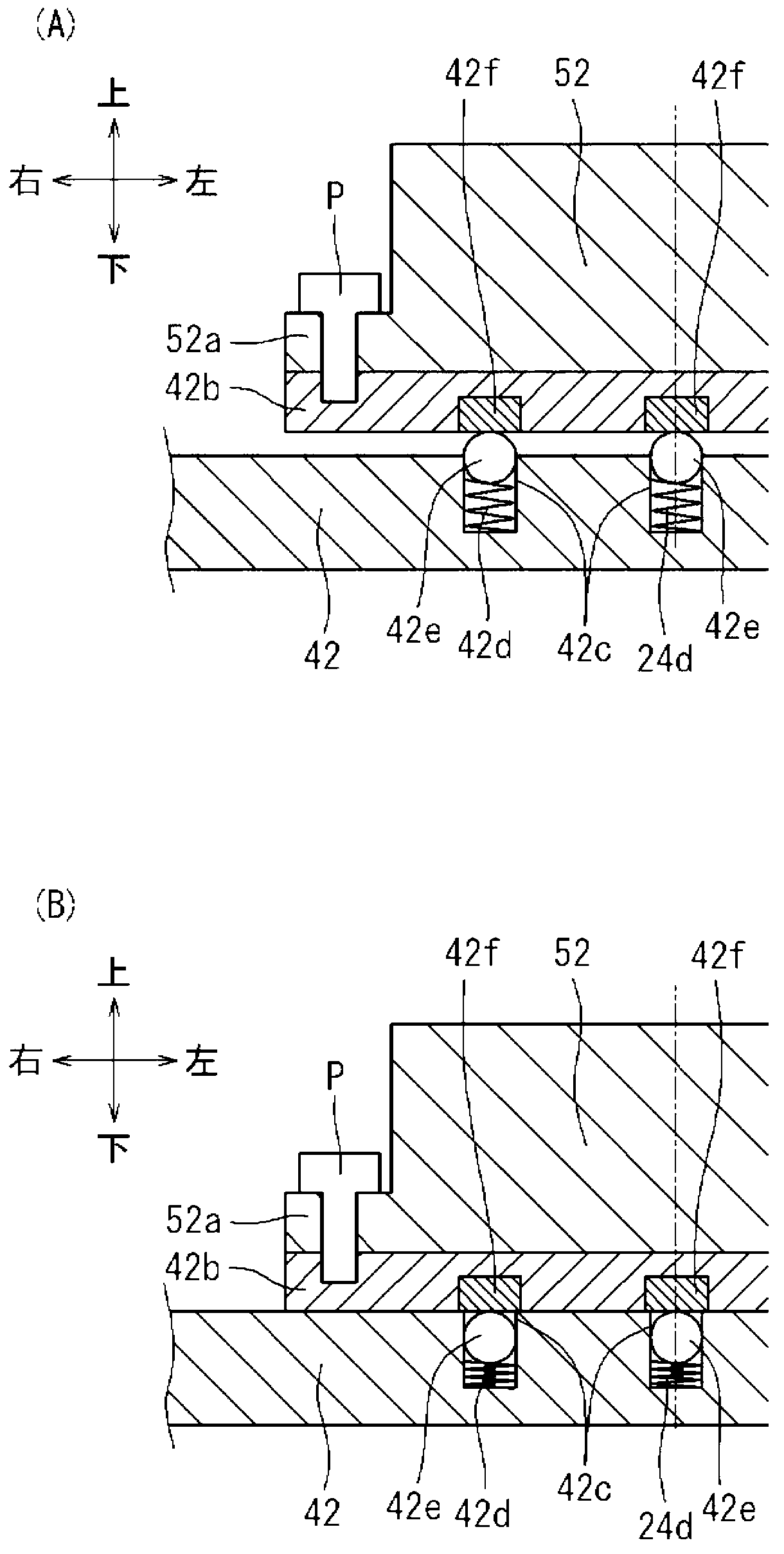

Press-molding system

InactiveCN103347624AEasy for stampingImprove energy efficiencyShaping toolsPressesEngineeringMechanical engineering

Owner:KOJIMA PRESS IND CO LTD

Sheet metal stamping device

ActiveCN106825309BImprove securityAvoid personal injuryShaping safety devicesMechanical energy handlingEngineeringElectric generator

Disclosed is a sheet stamping device. The sheet stamping device comprises a base and a mounting base. A stamping die is arranged in the mounting base. A support is arranged on one side of the base, and a mounting frame is connected to the support. An air cylinder is arranged at the bottom of the mounting frame, a stamping head is connected to the air cylinder, an air inlet pipe is connected to an air inlet of the air cylinder, and a valve element is connected to the air inlet pipe in a sliding mode. A mounting hole is formed in the mounting frame, and the valve element stretches into the mounting hole. An electromagnet is further arranged in the mounting hole, and an excitation coil is arranged on the electromagnet. A plurality of air collecting grooves are formed in the stamping head. A piston is arranged in a piston cavity, and a piston tail portion stretches out of the stamping head and is connected with a first rack. An electric generator is connected to a rotating shaft. Photoelectric switches are further arranged on the base. The sheet stamping device further comprises two storage batteries and a light source. By the adoption of the scheme, the hidden danger that before the hands of a worker leave from a stamping region, due to the misoperation, the air cylinder drives the stamping head to move downwards, and the safety is the worker is affected is avoided.

Owner:DOOR IND CO LTD CHONGQING DTOMO

Full-automatic cup-shaped mask machine

The invention discloses a full-automatic cup-shaped mask machine. The full-automatic cup-shaped mask machine comprises a frame, wherein a speed reducing motor is arranged at the bottom of the frame; an electric heater is arranged on the outer side of a baffle; an electric heating plate is arranged at the end part of the electric heater; a temperature sensor is arranged at the top of the electric heating plate and embedded in the baffle; a punching pressing die is fixedly arranged at the top end of the electric heating plate through a support frame; the top end of the punching pressing die is connected with a cylinder through a telescopic rod; and an ultraviolet sterilization lampshade is arranged on the outer side of the punching pressing die through the support frame. According to the full-automatic cup-shaped mask machine, a servo controller can fully automatically control the punching processing of cup-shaped masks, a sterilization effect can be achieved, and local preheating is performed at the punching position, so that the sterilization effect is enhanced. Meanwhile, a non-woven fabric can be punched more conveniently through a punching die, and forming of the cup-shaped masks is better facilitated. Meanwhile, thread residues are prevented from occurring in local punching in the process that the non-woven fabric is punched into a cup shape, and the quality of the whole non-woven fabric is not affected.

Owner:由力自动化科技(上海)有限公司

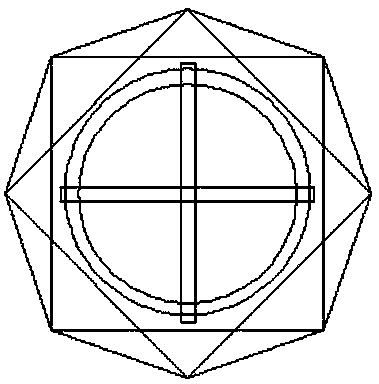

Die for three-jaw spring contact gaskets

The invention provides a die for three-jaw spring contact gaskets. The die comprises an upper base plate, a lower base plate and an outer guide column arranged between the upper base plate and the lower base plate. A rough trimming die and a blanking die are connected to the lower portion of the upper base plate. A bottom hole die matched with the rough trimming die and a collection die matched with the blanking die are connected to the upper portion of the lower base plate. Inner guide columns are arranged between the rough trimming die and the bottom hole die as well as between the blankingdie and the collection die. A pressing rod, a guide pin, a punching block and a bending block are connected to the rough trimming mold. A shaping block, a stripping knife and a cutting knife are connected to the blanking die. A dual-use pin, a guide block, a hole abutting block and a connecting bent block are connected to the bottom hole die. A bottom block and a cutting-off groove are connected to the collection die. According to the die for the three-jaw spring contact gaskets, the three-jaw spring contact gaskets can be sequentially punched to be formed through a belt, and a separated design mode of a conventional die for spring contact gaskets is changed, so that the uniformity and accuracy of products are effectively improved, and the production quality of the products is ensured.

Owner:浙江天越汽车制动系统有限公司

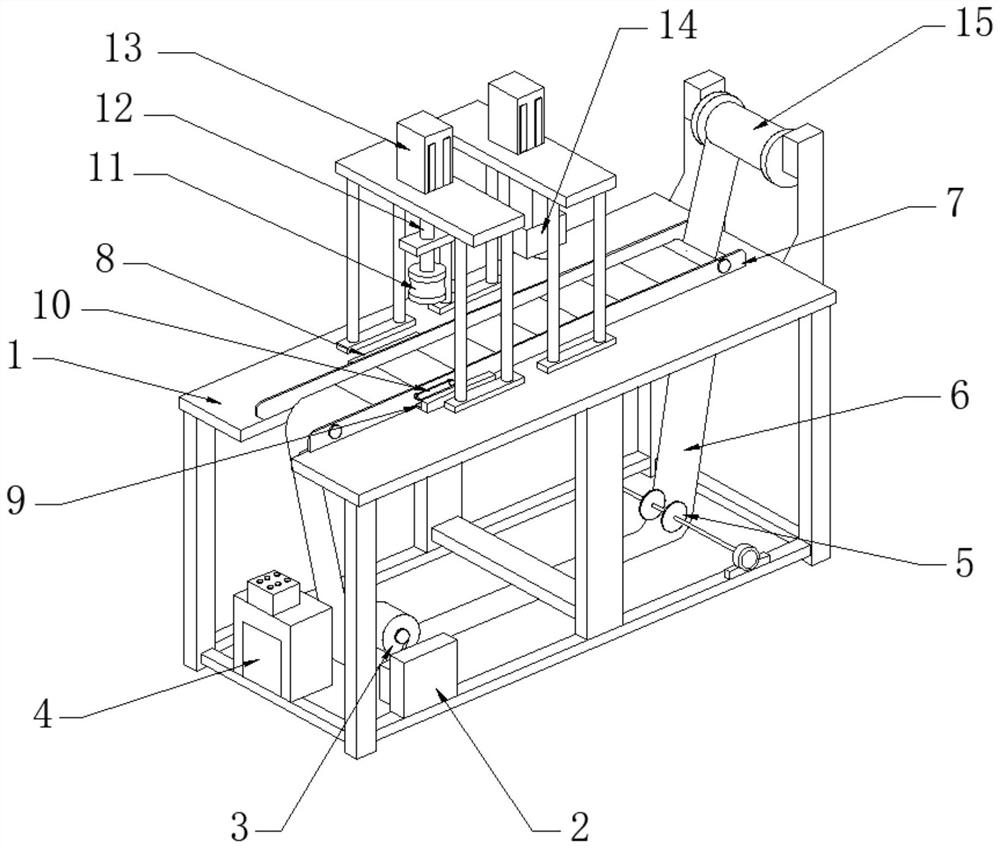

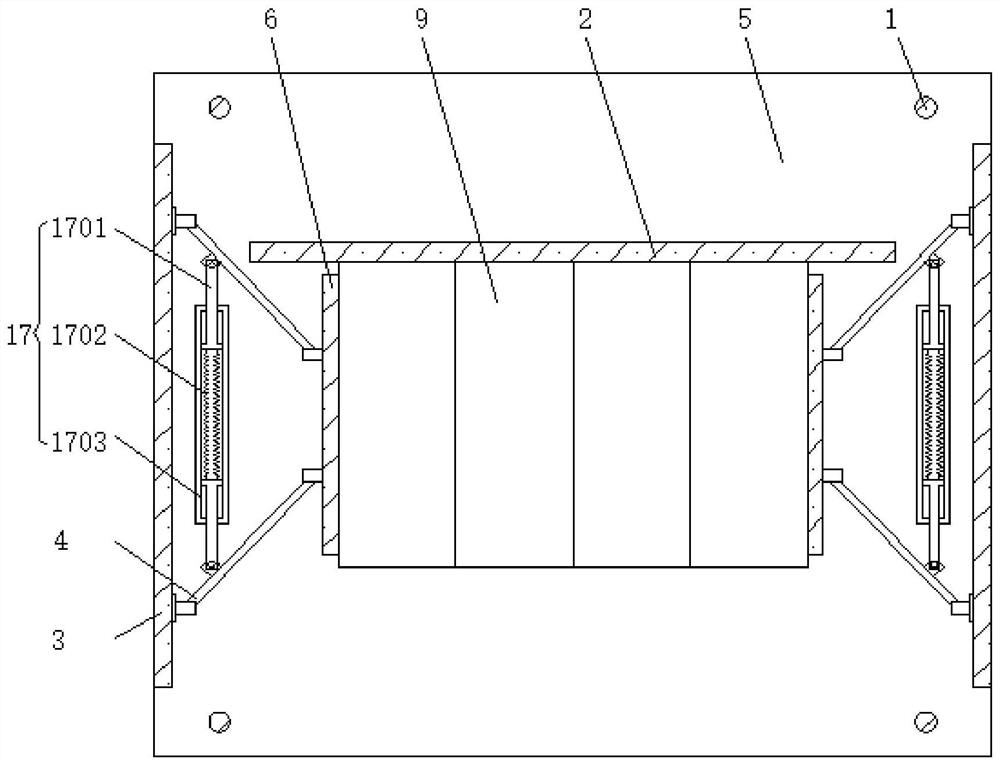

Plate punching machine feeder and feeding method thereof

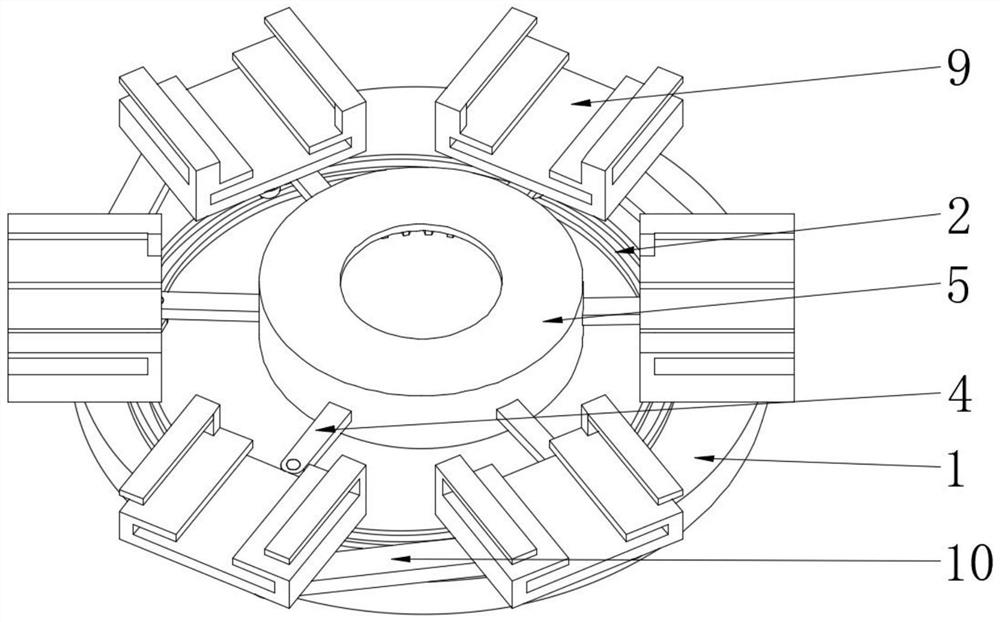

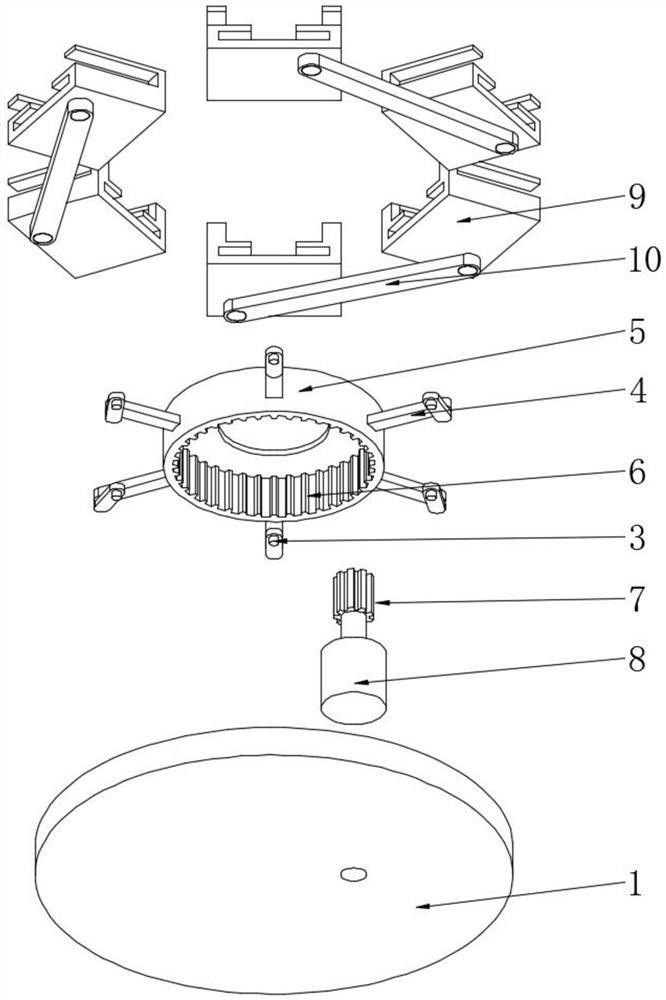

PendingCN113634675AEasy for stampingEasy loading and unloadingMetal-working feeding devicesPositioning devicesGear wheelMachine

The invention relates to the technical field of plate machining, and discloses a plate punching machine feeder. The feeder comprises a supporting plate, a rotating rail is fixedly installed on the upper portion of the supporting plate, a rotating block is movably installed in the rotating rail, and the upper end of the rotating block is fixedly installed at the bottom of one end of a swing rod. The other end of the swing rod is fixedly connected to a rotating table, the bottom of the rotating table is movably installed in the middle of the upper portion of the supporting plate, and a gear groove is formed in the rotating table. According to the plate punching machine feeder and the feeding method thereof, the supporting plate is arranged as a circular tray, circular feeding and discharging of the device are facilitated through the circular tray; and because the feeding plate is movably installed on the upper portion of the supporting plate through the rotating rail, the rotating block, the swing rod and the rotating table, the direction of the feeding plate on the upper portion of the supporting plate can be conveniently and regularly adjusted when the device rotates, and a plate on the upper portion of the feeding plate can be conveniently punched.

Owner:邓彩霞

Sheet stamping device

ActiveCN106825309AImprove securityAvoid personal injuryShaping safety devicesMechanical energy handlingElectricityEngineering

Disclosed is a sheet stamping device. The sheet stamping device comprises a base and a mounting base. A stamping die is arranged in the mounting base. A support is arranged on one side of the base, and a mounting frame is connected to the support. An air cylinder is arranged at the bottom of the mounting frame, a stamping head is connected to the air cylinder, an air inlet pipe is connected to an air inlet of the air cylinder, and a valve element is connected to the air inlet pipe in a sliding mode. A mounting hole is formed in the mounting frame, and the valve element stretches into the mounting hole. An electromagnet is further arranged in the mounting hole, and an excitation coil is arranged on the electromagnet. A plurality of air collecting grooves are formed in the stamping head. A piston is arranged in a piston cavity, and a piston tail portion stretches out of the stamping head and is connected with a first rack. An electric generator is connected to a rotating shaft. Photoelectric switches are further arranged on the base. The sheet stamping device further comprises two storage batteries and a light source. By the adoption of the scheme, the hidden danger that before the hands of a worker leave from a stamping region, due to the misoperation, the air cylinder drives the stamping head to move downwards, and the safety is the worker is affected is avoided.

Owner:DOOR IND CO LTD CHONGQING DTOMO

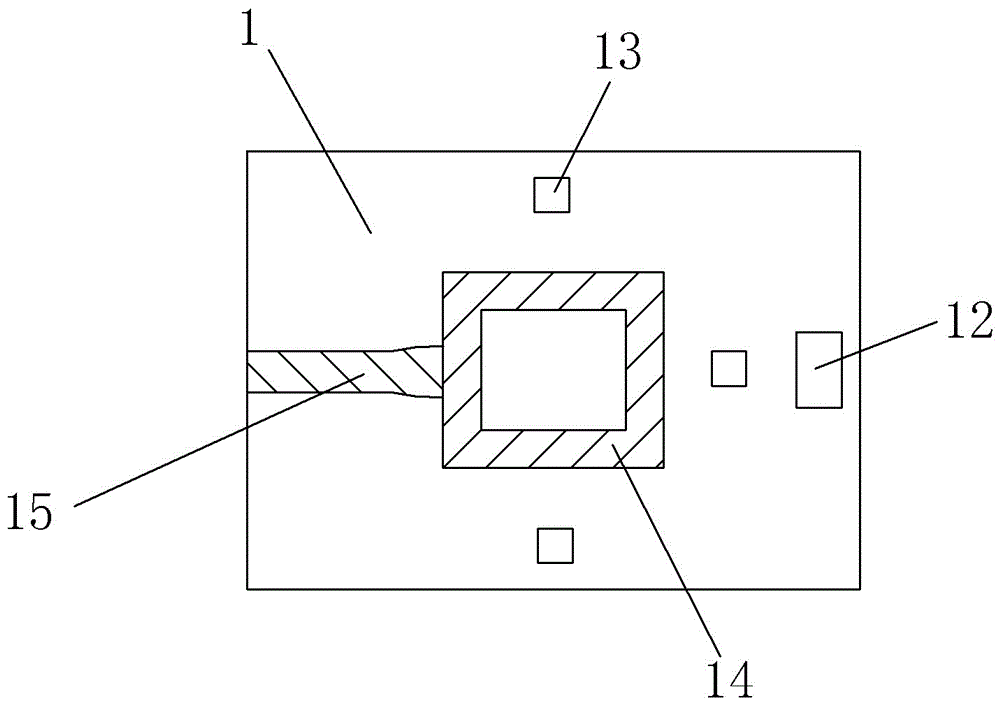

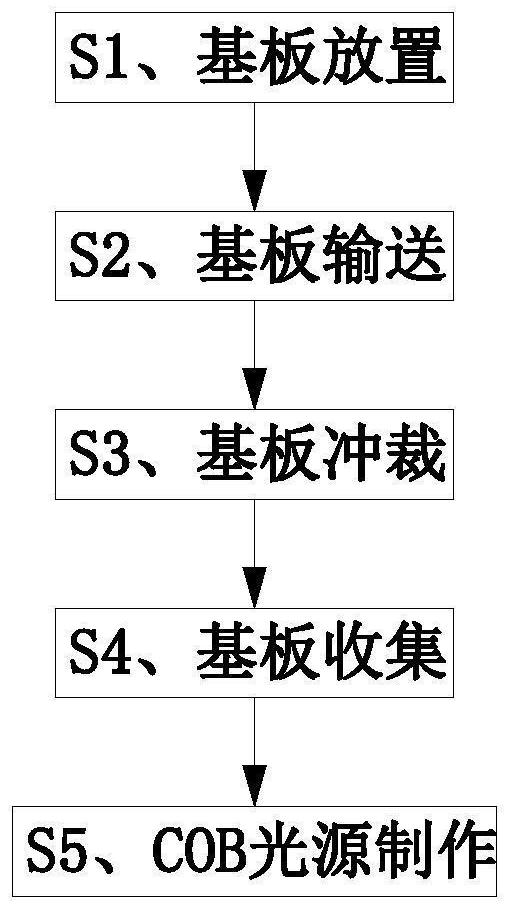

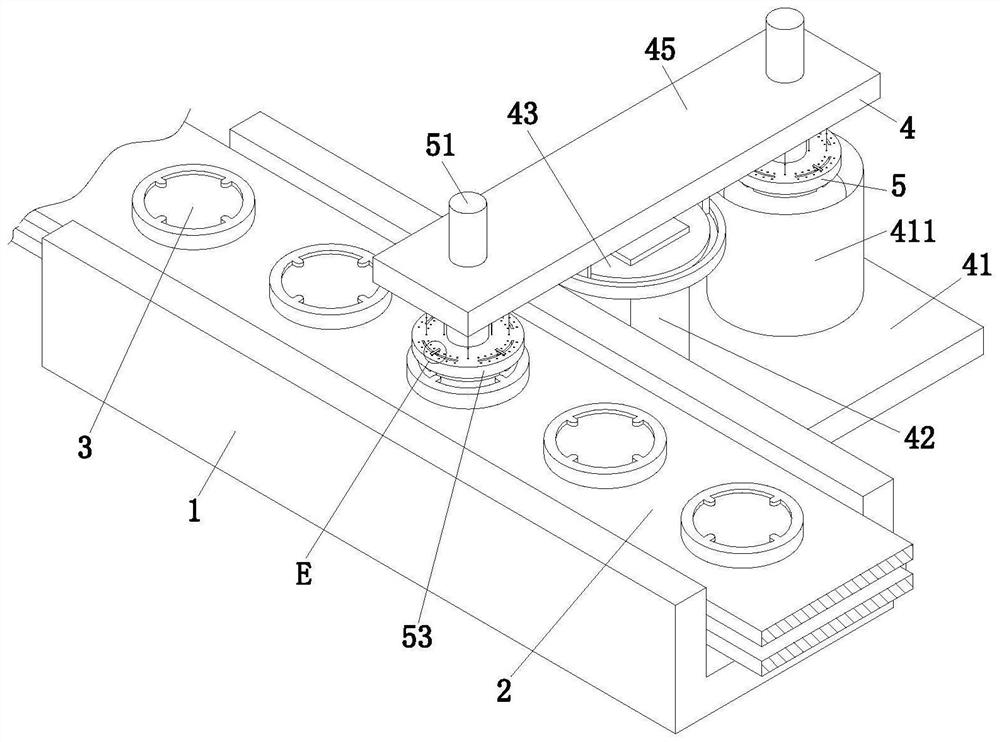

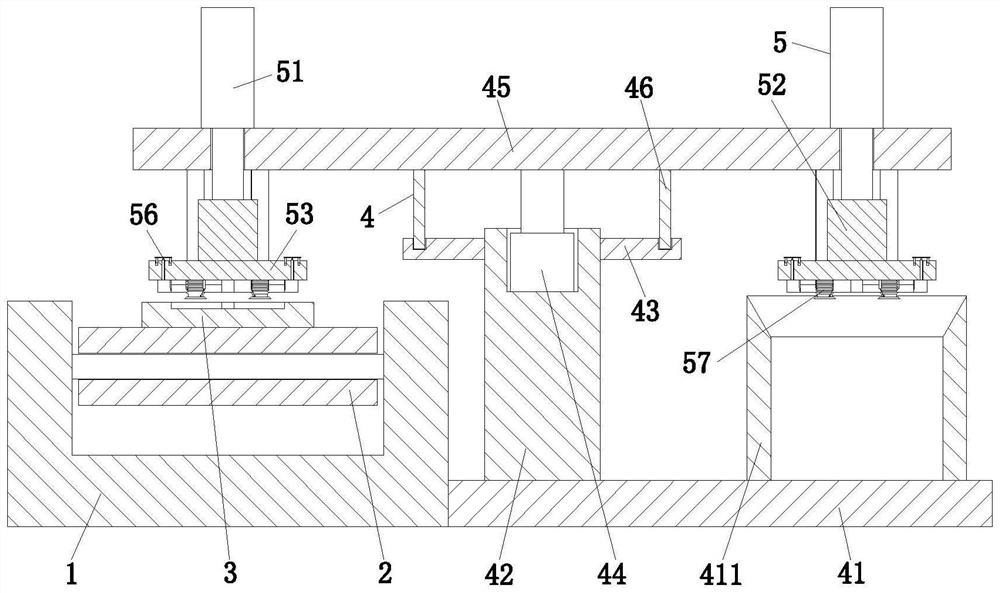

Manufacturing method of double-color COB light source

InactiveCN114700411AEasy for stampingImprove punching efficiencyShaping toolsSemiconductor devicesPunchingEngineering

The invention relates to the technical field of COB light sources, in particular to a manufacturing method of a double-color COB light source, a manufacturing device of the double-color COB light source is used, and the manufacturing device of the double-color COB light source comprises a U-shaped frame, a conveying belt, a fixing base, a supporting unit and a blanking unit. An existing stamping device has the following problems that according to the stamping device, aluminum substrates need to be frequently installed, the aluminum substrates cannot be continuously stamped, and the stamping efficiency of the aluminum substrates is prone to being reduced; according to the punching device, a punch needs to be replaced frequently, the situation that the punch is not installed in place possibly can be caused, and therefore the punching precision of an aluminum substrate is easily affected; intermittent and continuous blanking processing can be carried out on the substrate through the supporting unit and the blanking unit, and the blanking efficiency of the substrate can be improved; blanking machining can be conveniently conducted on substrates of different models through the U-shaped cutter, and the U-shaped cutter can be limited and fixed, so that the situation that the blanking precision of the substrates is affected due to shaking of the U-shaped cutter is avoided.

Owner:孟勇勇

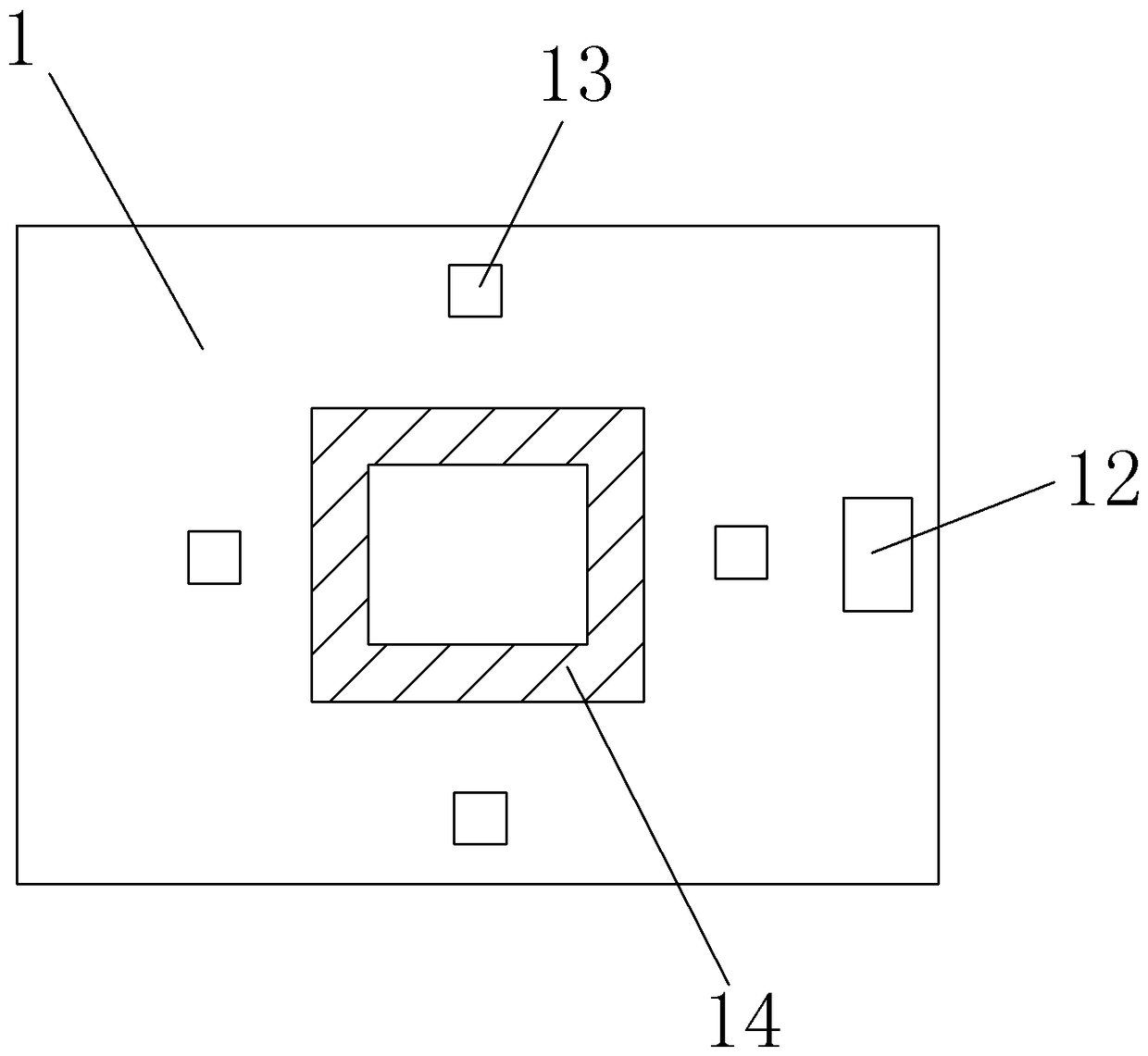

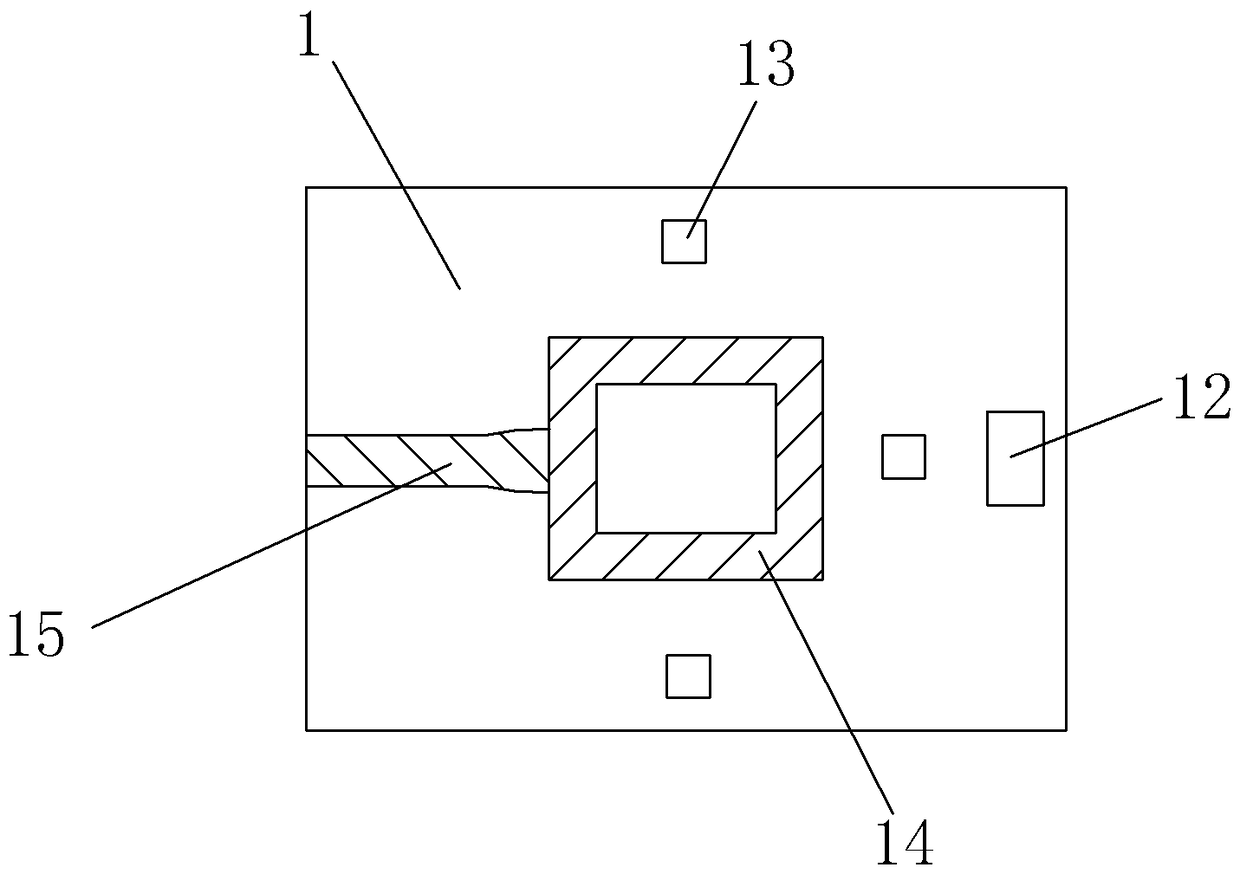

Energy-absorbing structure of front longitudinal beam of automobile

ActiveCN103085880BImprove mechanical propertiesDeformation stableUnderstructuresConvex structureBeam energy

A front longitudinal beam energy-adsorption structure for a vehicle comprises a front longitudinal beam assembly (10), the front longitudinal beam assembly (10) comprising a body (1) and a cover plate (2). The body (1) has a U-shaped structure and is provided with a body upper wing (11), a body inner side wing (12), a body lower wing (13), and a body lower flange (14). The cover plate (2) is provided with a cover plate upper flange (21) and a cover plate outer side wing (22). One or more first L-shaped conduction structures (101) are arranged on the body (1). One side of each first L-shaped conduction structure (101) consists of convex structures (111) on the body upper wing, and the other side of each first L-shaped conduction structure (101) consists of concave structures (121) on the body inner side wing. In order to match the first L-shaped conduction structures on the body (1), second L-shaped conduction structures (102) also can be arranged at corresponding positions on the cover plate (2). The front longitudinal beam energy-adsorption structure for a vehicle has a good mechanical property, good molding processability, and good welding processability.

Owner:CHERY AUTOMOBILE CO LTD

Production process for connecting copper sheet of automobile battery

InactiveCN105390662AHigh hardnessEasy for stampingElectrode thermal treatmentAutomotive batteryHardness

The invention discloses a production process for a connecting copper sheet of an automobile battery. The production process comprises the following steps of pretreatment, drying treatment, punch forming, surface treatment, heat treatment, cooling, checking, and packaging. According to the production process, the copper sheet is soaked by utilizing lime water and a methanol solution containing 30% of ethyl ether before being punched, so that the treatment effect is good, the hardness of the copper sheet is enhanced, and the copper sheet is easy to punch and machine; and the copper sheet is quenched before being punched, so that the machinability of the copper sheet can be further improved.

Owner:ANHUI HENGLI ELECTROMECHANICAL TECH CO LTD

Foam component and its processing method

ActiveCN104710945BEasy for stampingReduce the risk of displacement deformationFilm/foil adhesivesMetal working apparatusTectorial membranePunching

The invention discloses a foam component and a processing method thereof. The processing method includes the steps of: S1: sticking a monolayer protective film to the upper surface of a first protective film; S2: punching an area with a set shape on a release film by a punching technology; S3: removing a first release film located outside the area, and sticking the upper surface of the foam on the first protective film in the area and beyond the area; S4: punching the foam and the first protective film through by a punching technology to form an annular part on the foam, with the inner edge of the foam's annular part located outside the outer edge of the first release film; and S5: removing the water material outside the annular part. The processing method for the foam component provided by the invention facilitates the punching processing of foam and reduces the shift deformation risk of the foam frame.

Owner:BYD CO LTD

Outer sleeve constrained folded steel plate energy dissipation support

ActiveCN105507445BIncrease stiffnessIncrease ultimate bearing capacityShock proofingEngineeringEarthquake disaster

The invention discloses an outer casing pipe constraint folding steel plate energy consumption support. The support comprises an outer casing pipe, a core barrel arranged in the outer casing pipe, end bearing plates arranged at barrel openings of the two sides of the core barrel and outer casing pipe seal plates arranged at the ends of the two side of the outer casing pipe; the end bearing plates are connected with cross-shaped node plates penetrating through the outer casing pipe seal plates, and the core barrel is formed by sequentially connecting multiple energy consumption units. The support reduces earthquake responses of buildings through the good post-yielding energy consumption capacity, is easy to manufacture and convenient to install and can be applied to structural earthquake resisting and effectively reduce earthquake disasters.

Owner:SOUTHEAST UNIV

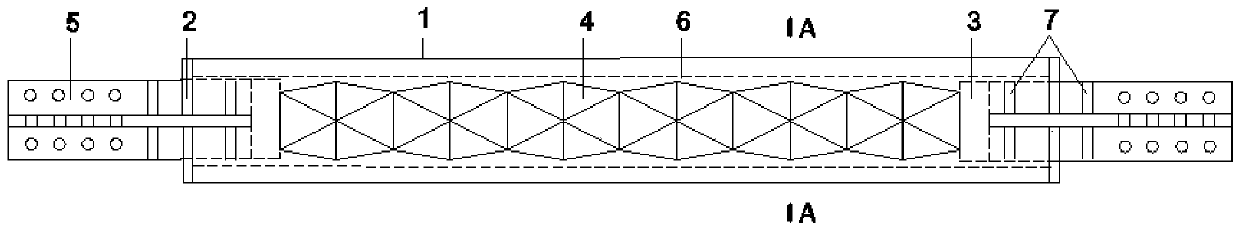

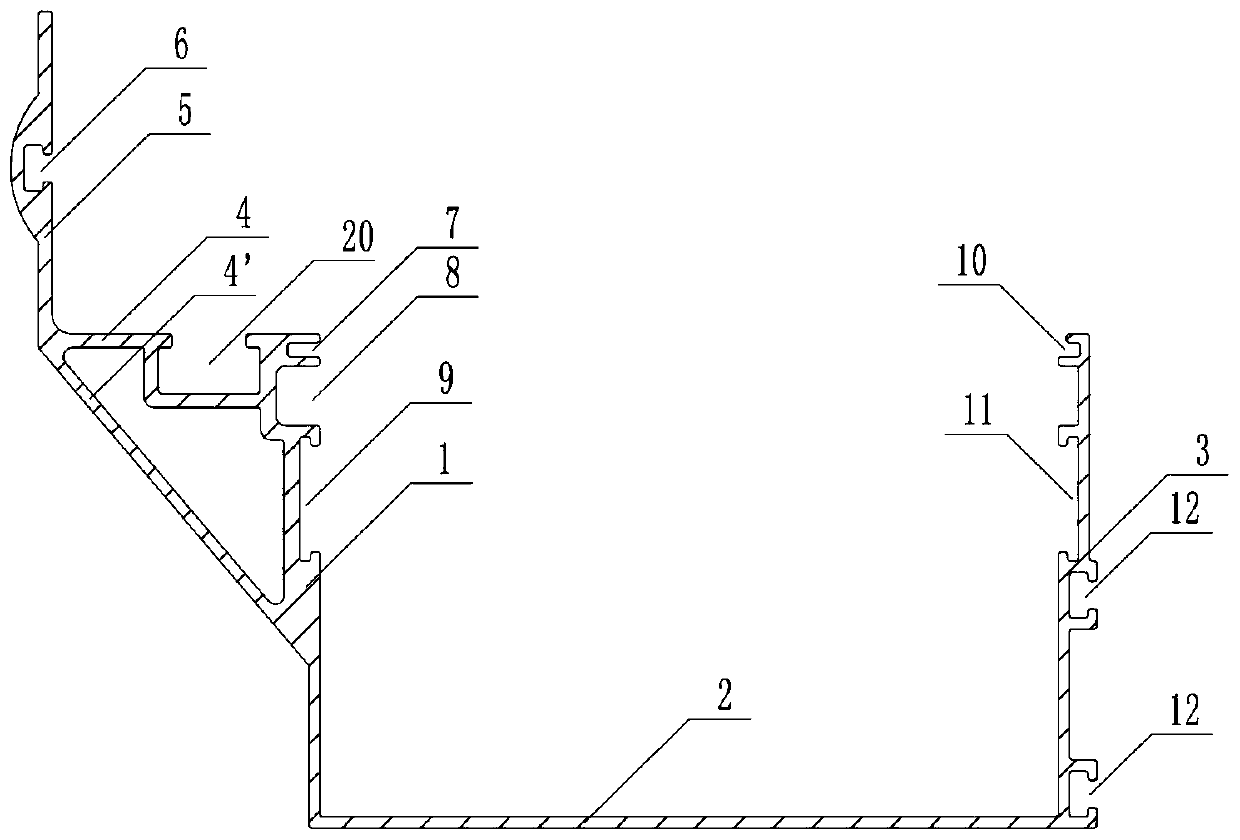

Energy-dissipating support of folded steel plates constrained by inner and outer double casings

ActiveCN105544763BIncrease stiffnessIncrease ultimate bearing capacityShock proofingOuter CannulaEngineering

Owner:SOUTHEAST UNIV

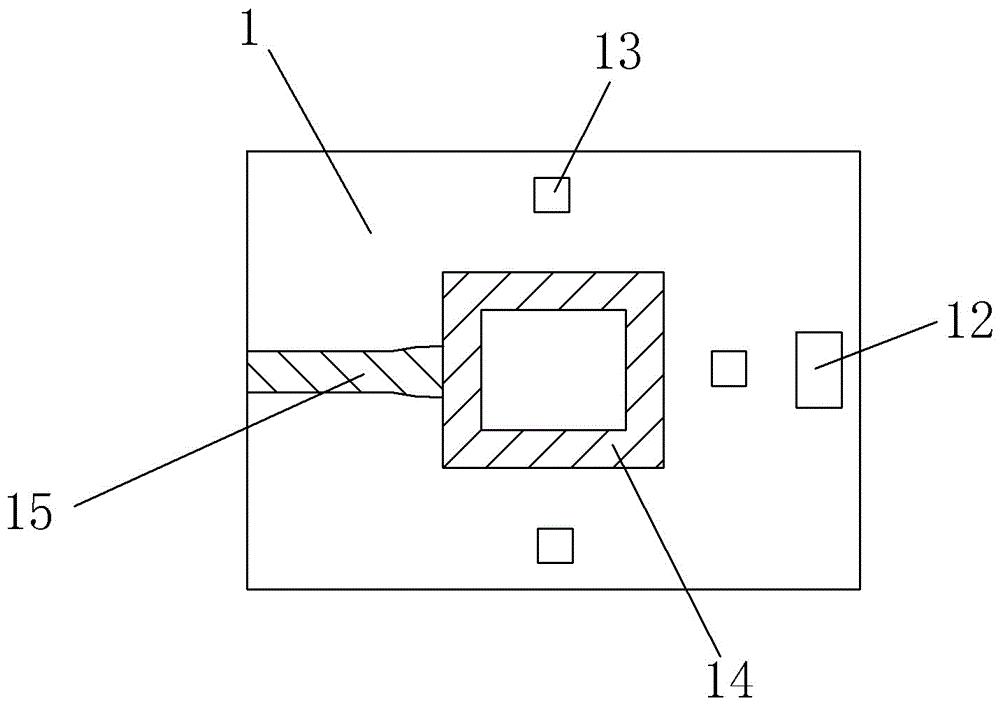

Aluminum profile window frame for filter window

The invention discloses an aluminium profile window frame for a filter window. The aluminium profile window frame for the filter window comprises a U groove-shaped window frame main body of the filter window which consists of a front side plate, an outer side plate and a rear side plate and is used for arranging various types of equipment internally, a web plate which is arranged on the U groove-shaped window frame main body, a flange plate and a reserved sealing strip groove which are arranged on the outer edge of the web plate, a reserved inner side front fixing groove which is formed in the inner side of a notch of the front side plate of the U groove-shaped window frame main body, a reserved electric wire groove which is formed in the inner side of the front side plate of the U groove-shaped window frame main body, a reserved upper corner assembling piece groove which is formed in the inner side of the front side plate of the U groove-shaped window frame main body, a reserved lower corner assembling piece groove which is formed in the inner side of the rear side plate of the U groove-shaped window frame main body, a reversed inner side rear fixing groove which is formed in the inner side of the notch of the rear side plate of the U groove-shaped window frame main body, and a rear side plate sealing strip mounting groove which is formed in the outer side of the rear side plate. The aluminium profile window frame for the filter window has the advantages that the weight is light, the appearance is attractive, and the filter window frames in various sizes are conveniently connected and machined by using corner assembling pieces and corner connectors by adopting an aluminium profile window frame material; the shape of the U groove-shaped window frame main body facilitates the punching machining of a waterproof air inlet hole in the filter window frame and the mounting of various components of the filter window frame.

Owner:吉林省世能科技有限公司

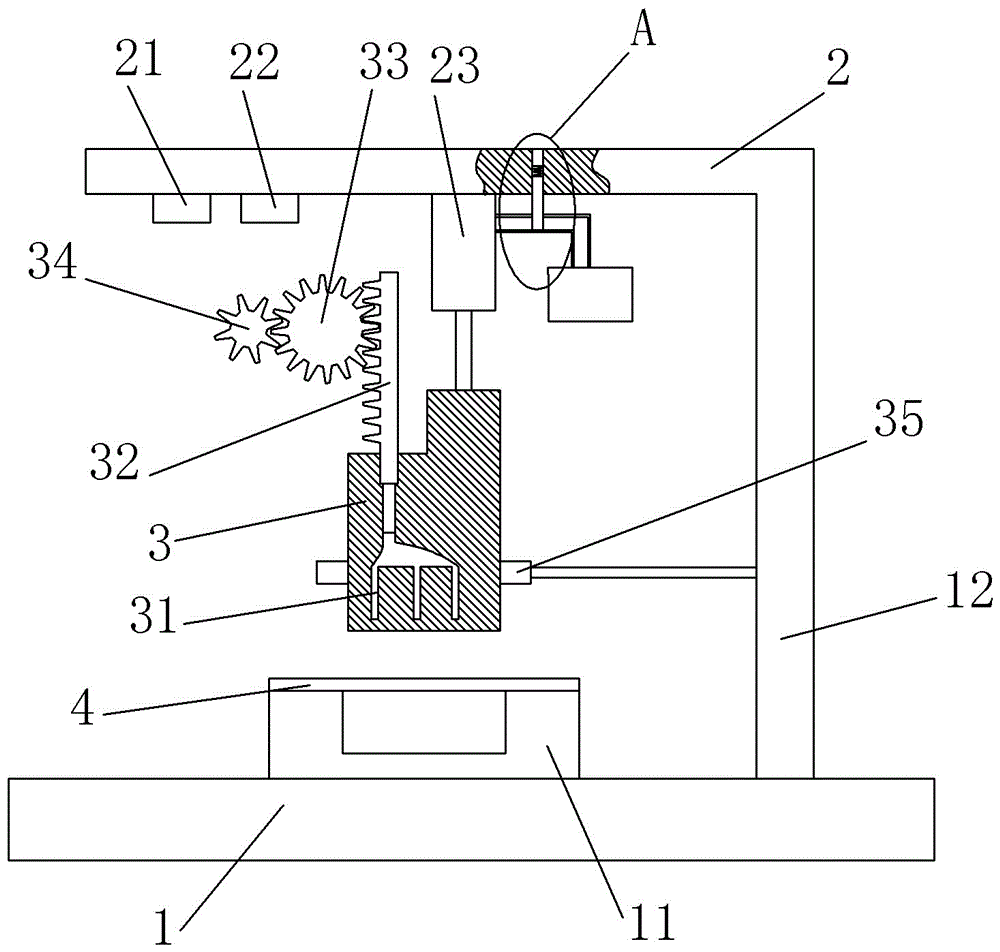

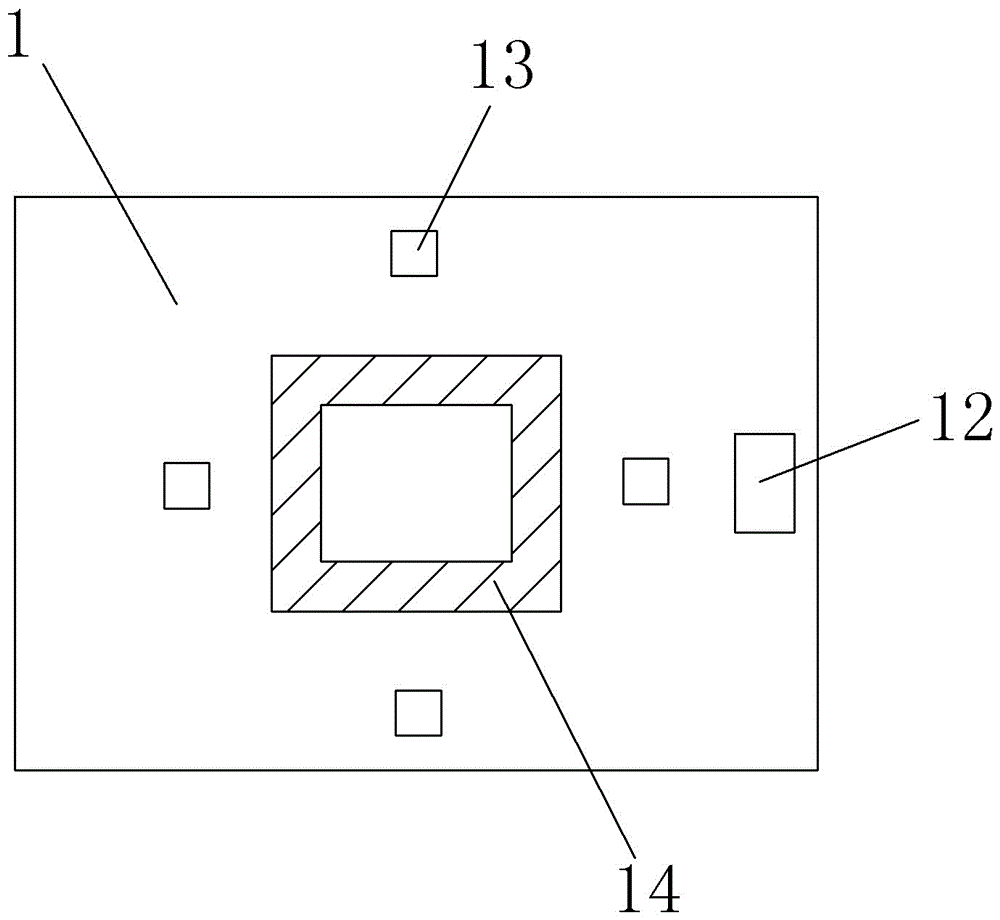

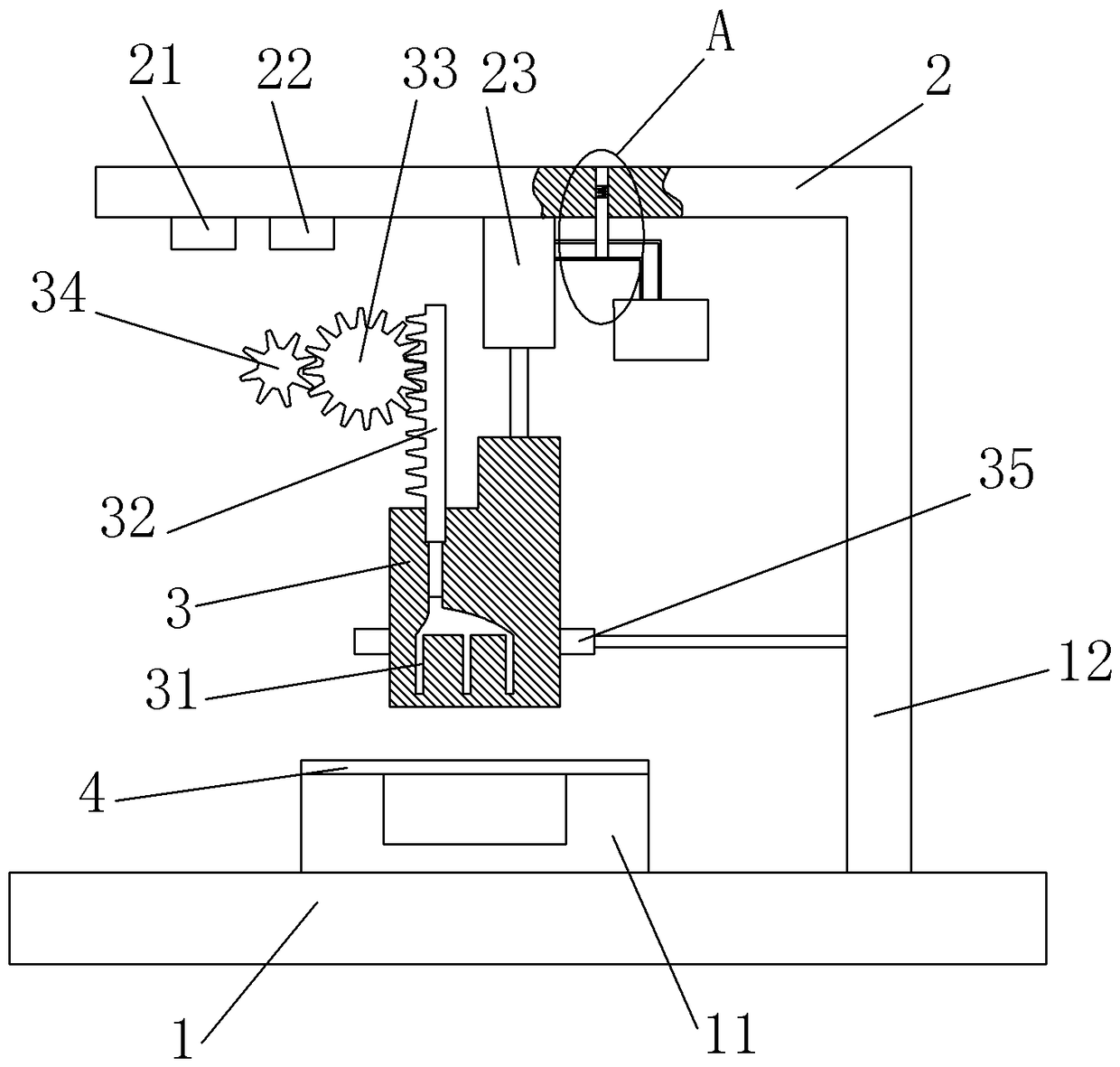

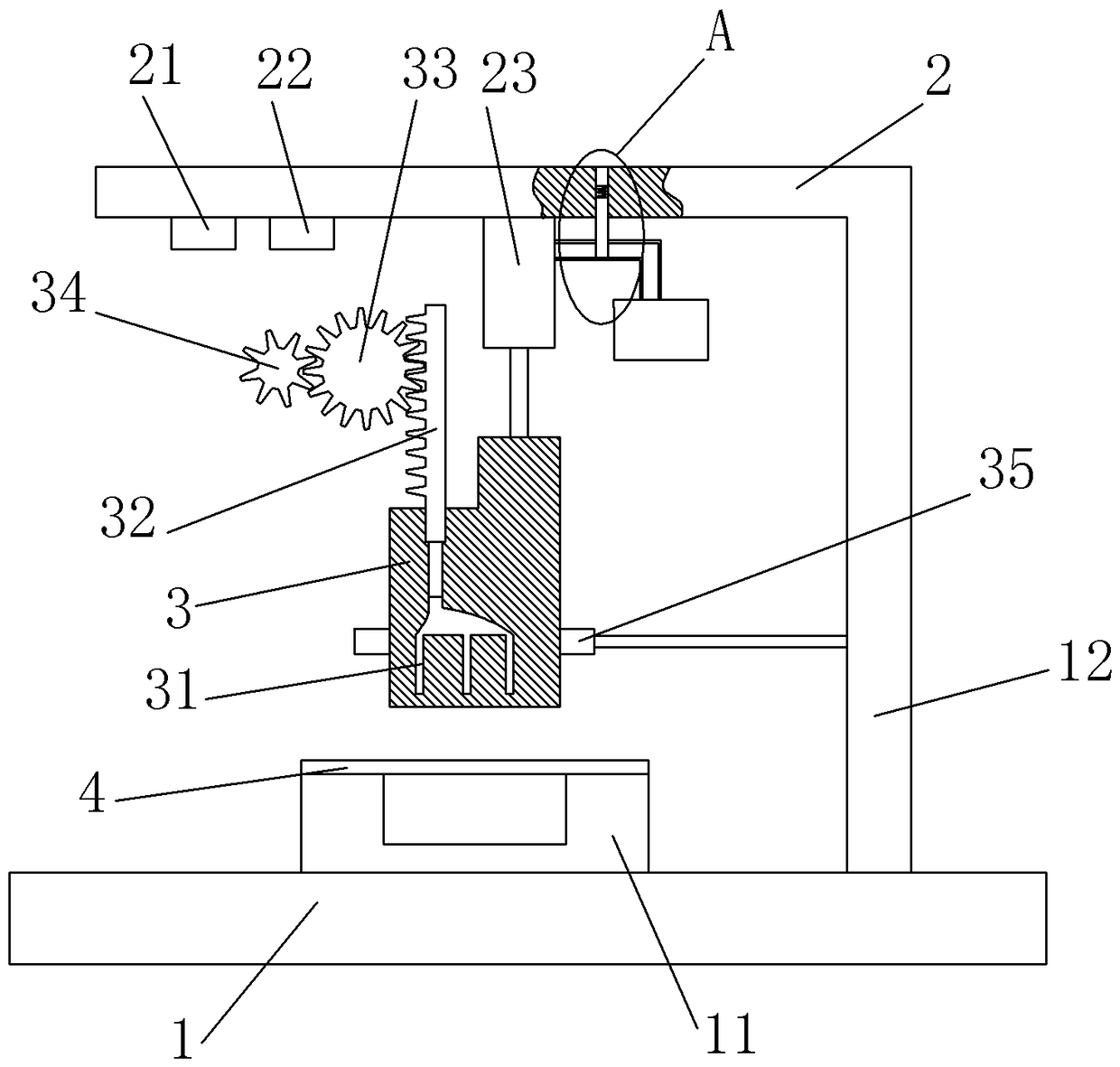

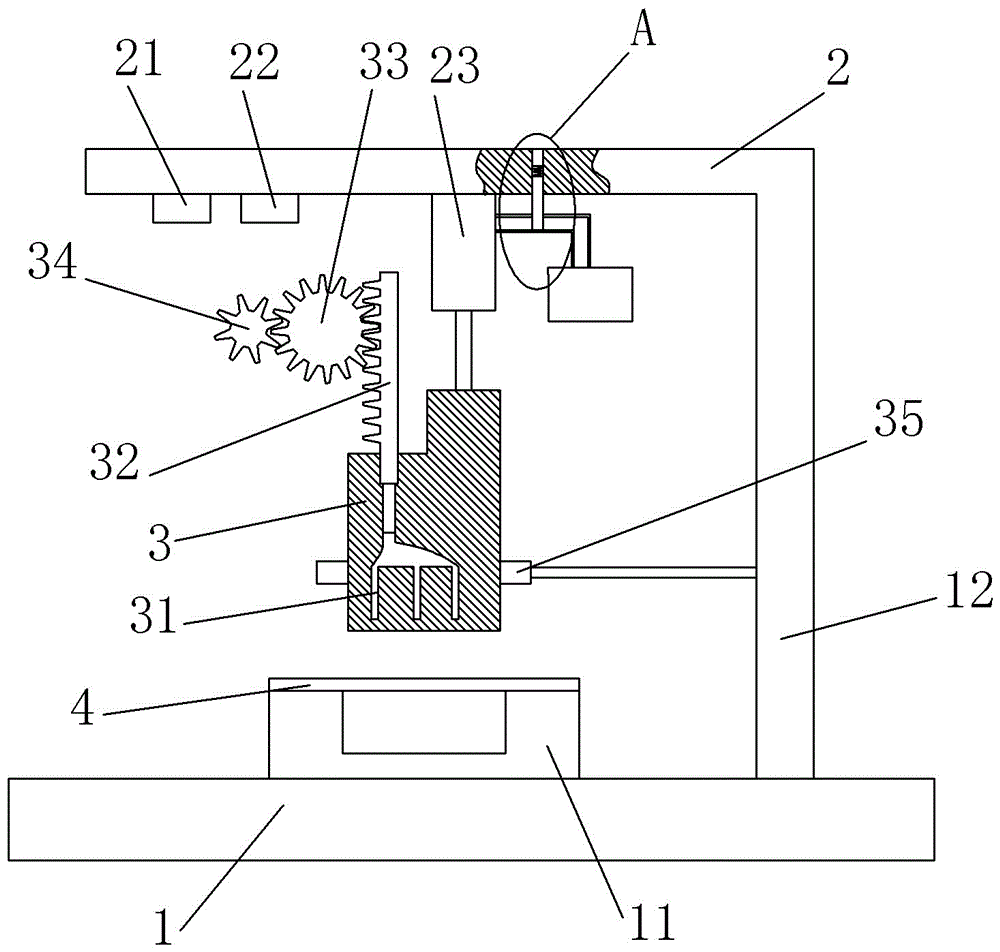

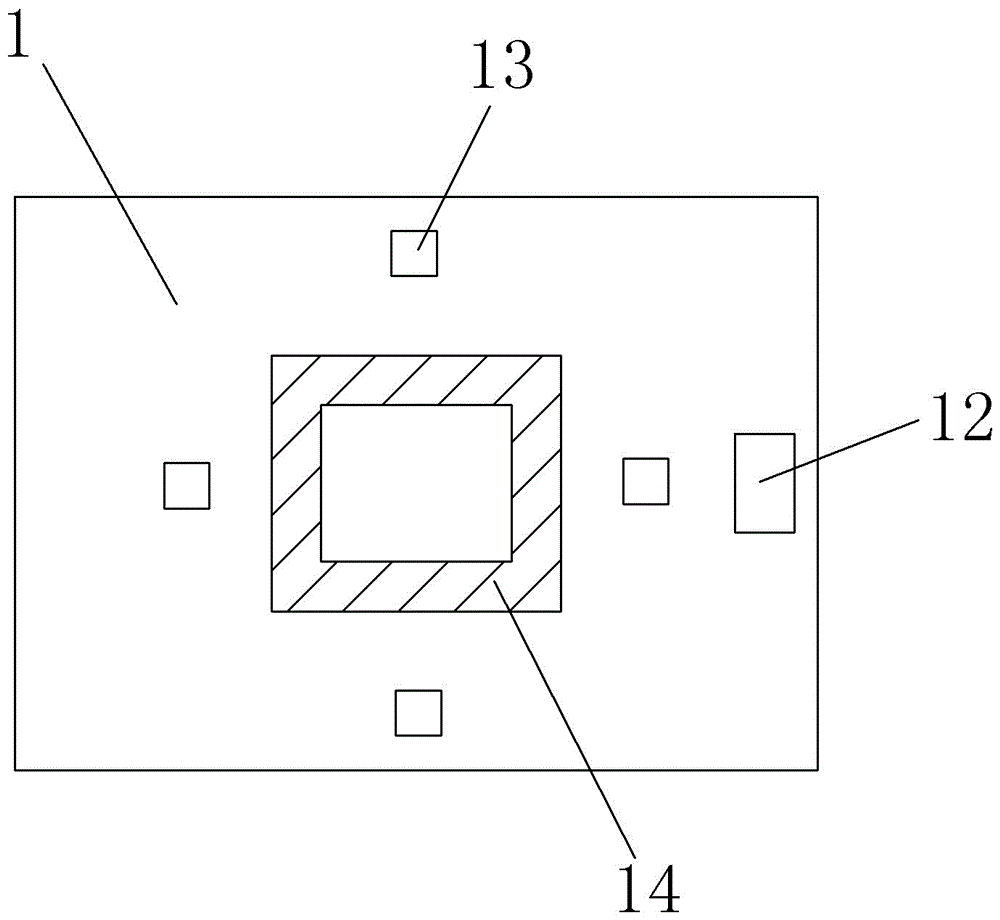

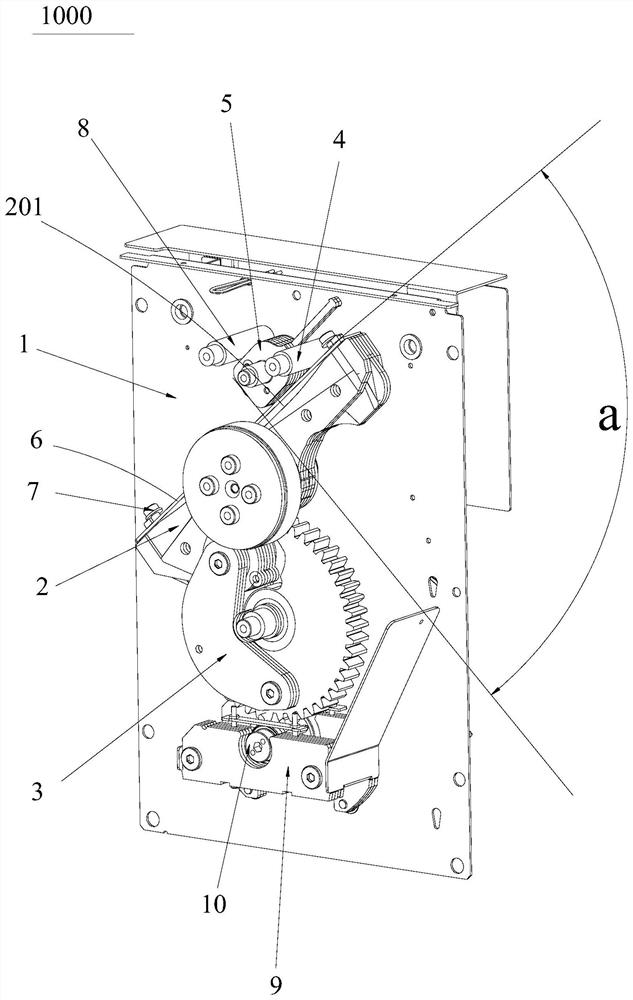

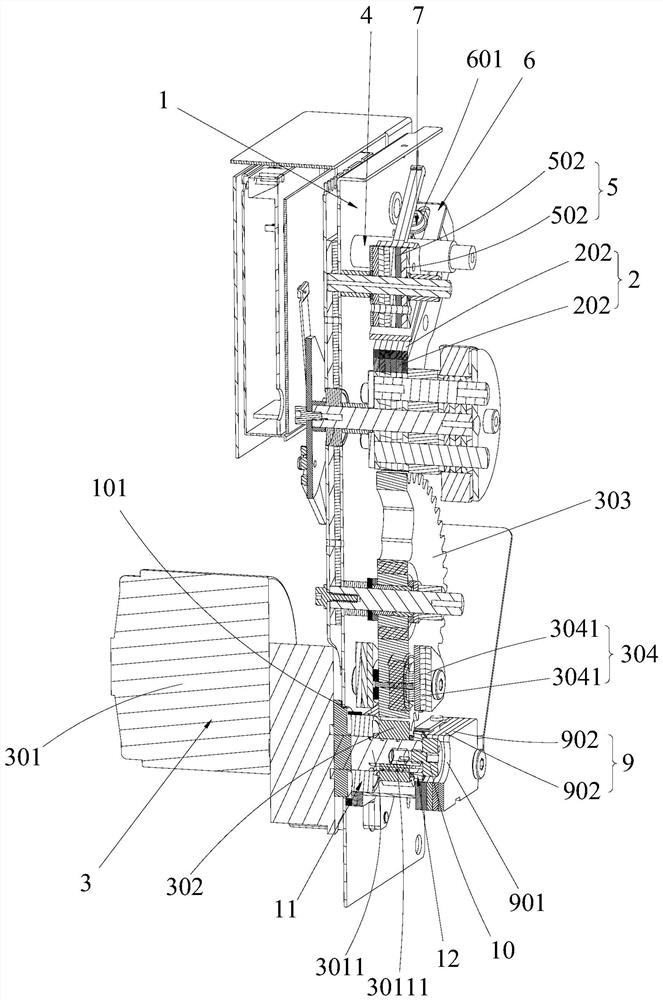

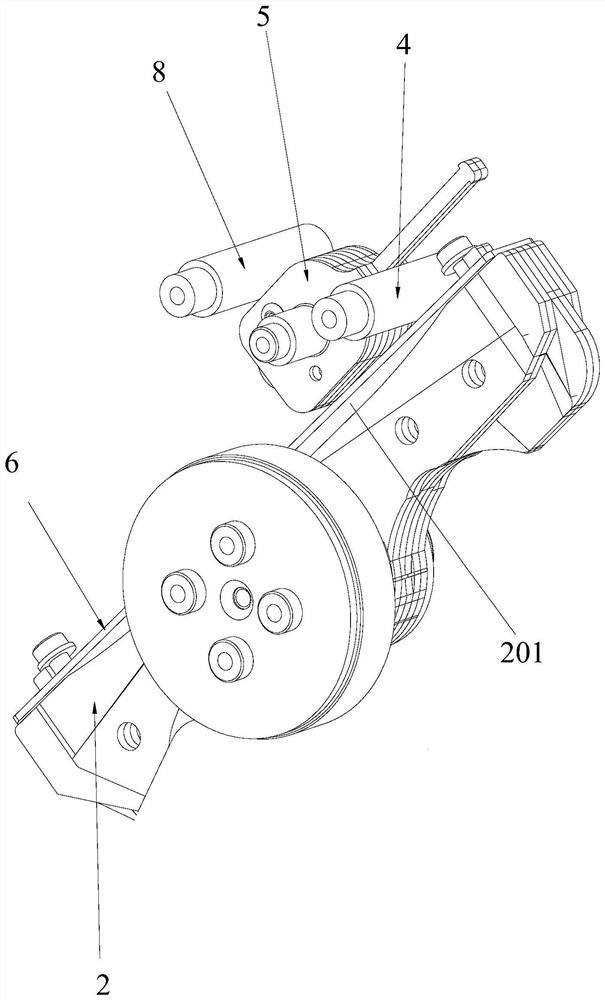

Machine core and barrier gate

PendingCN114592455AAchieve ups and downsEasy for stampingTraffic restrictionsGear wheelElectric machinery

The invention discloses a machine core and a barrier gate. The machine core comprises a mounting plate, a swing part rotationally mounted on the mounting plate and used for being connected with the brake bar, and a lifting driving mechanism used for driving the swing part to rotate. The lifting driving mechanism comprises a driving motor, a driving gear mounted on an output shaft of the driving motor, a driven gear rotationally mounted on the mounting plate and meshed with the driving gear, and a connecting rod piece connected between the driven gear and the swinging piece; the connecting rod piece is rotationally connected with the driven gear and the swinging piece; the connecting rod piece comprises a plurality of first laminated plates, and the plurality of first laminated plates are stamped to form the connecting rod piece. The driving motor drives the driving gear to rotate so as to drive the driven gear to rotate, the driven gear applies force to the connecting rod piece, and the connecting rod piece applies force to the swing piece to drive the swing piece to rotate so as to drive the brake bar to rise and fall. The connecting rod piece comprises the multiple first laminated plates, the multiple first laminated plates are stamped to form the connecting rod piece, stamping machining is convenient, and the machining technology is simple.

Owner:DONGGUAN ZKTECO ELECTRONICS TECH

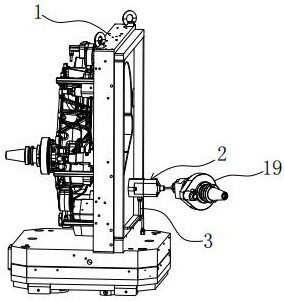

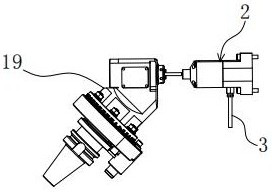

Angle head cutter breaking detection device

ActiveCN114012508AGuaranteed stabilityImprove work efficiencyMeasurement/indication equipmentsEngineeringMachining

The invention belongs to the field of machining equipment, and provides an angle head cutter breaking detection device. The device comprises a clamp table and a detection body, an air tube is arranged on the clamp table, the detection body is installed on the clamp table, an inner cavity is formed in the detection body, the air tube is arranged at the bottom end of the detection body and communicated with the inner cavity, the front end of the detection body is provided with a pin hole communicated with the inner cavity, a guide assembly movably abutting against the inner cavity is arranged in the inner cavity, the guide assembly is provided with a positioning pin, and the positioning pin is in clearance fit with the pin hole. Compared with the prior art, the device has the advantages that after machining is completed, the tool touches the detection body, the positioning pin shaft on the detection body is pushed into the containing cavity, a first sealing ring on an annular part is separated from the inner cavity, and gas runs out of the gap between the positioning pin and the pin hole, so whether the tool is in a normal value or not and is broken or not is detected.

Owner:NINGBO XUSHENG AUTO TECH CO LTD

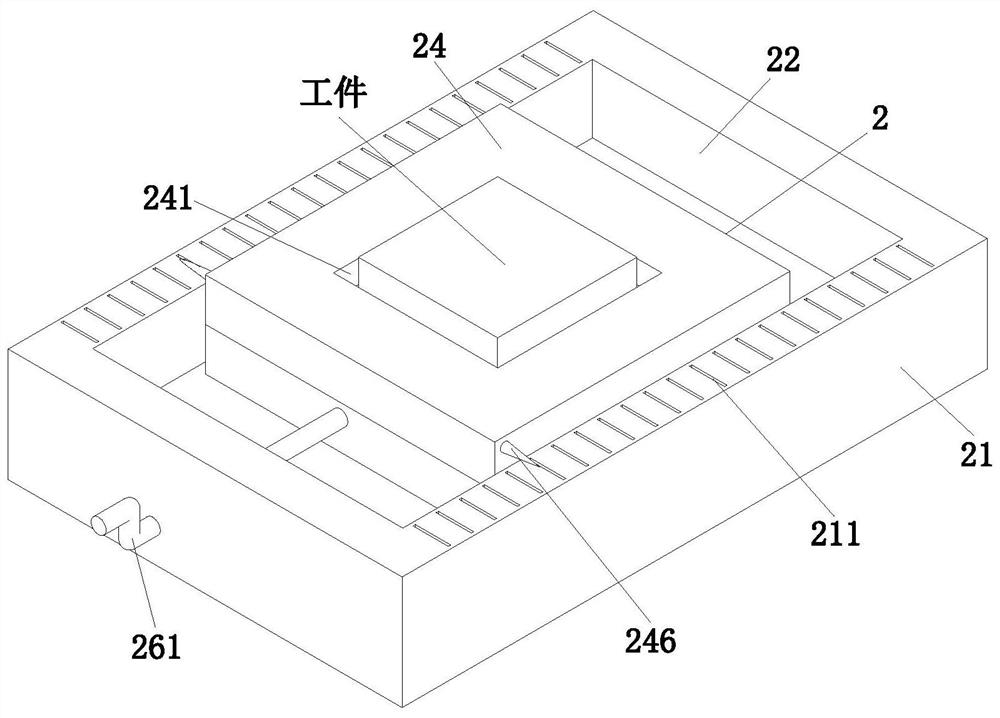

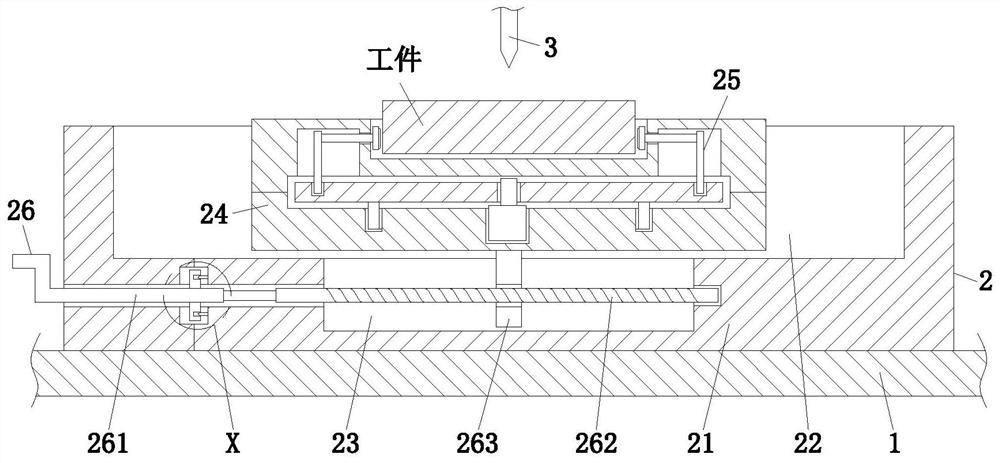

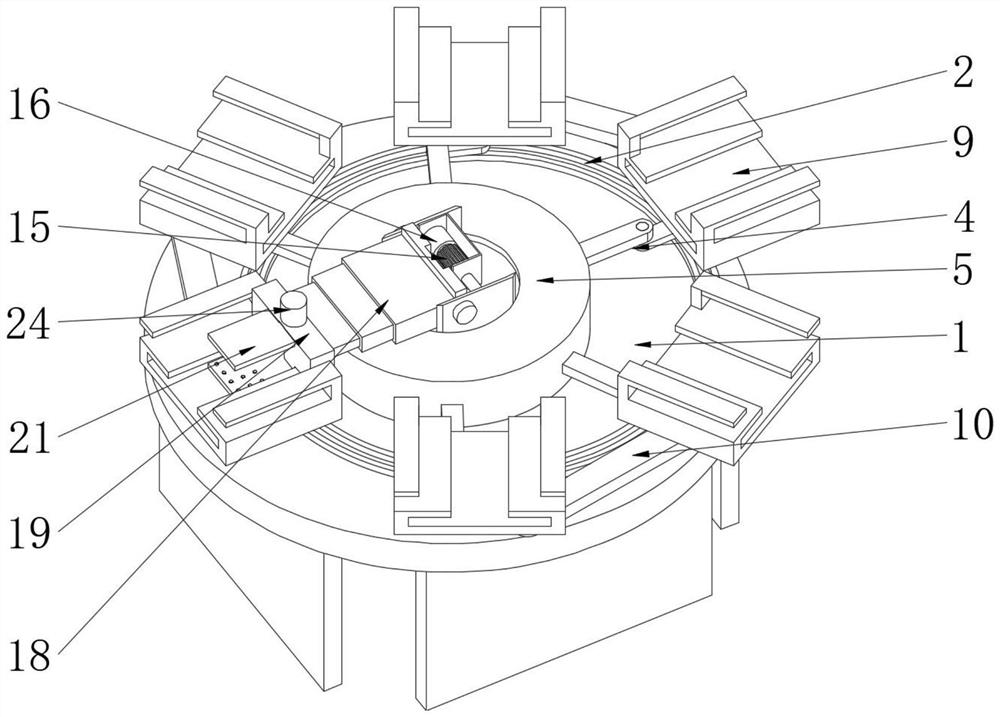

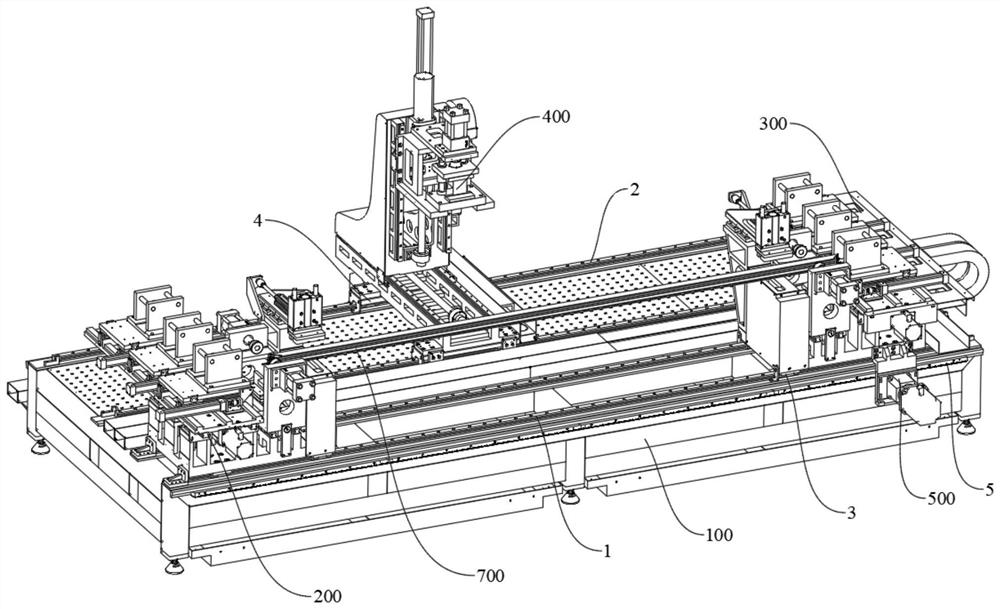

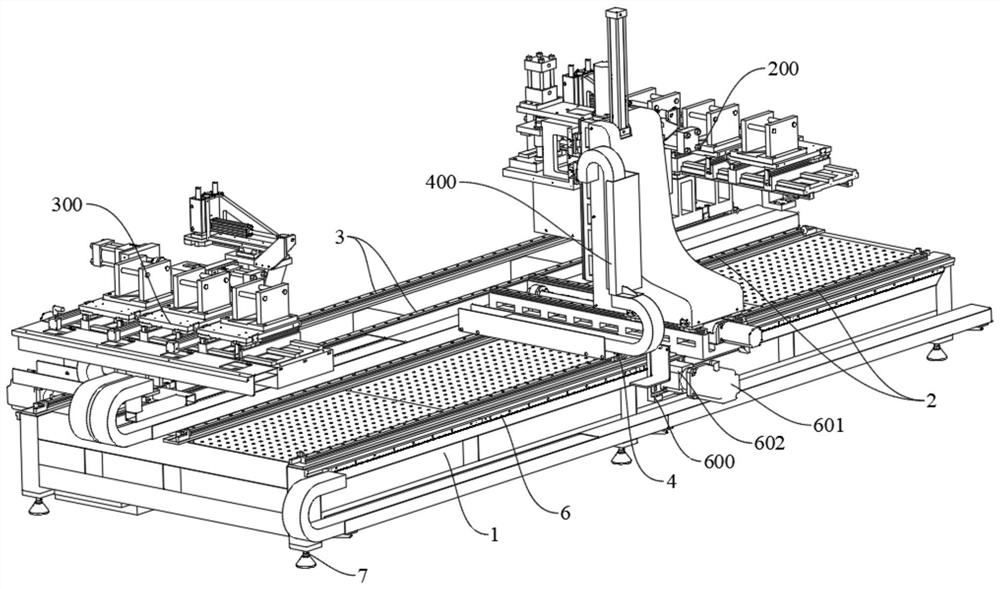

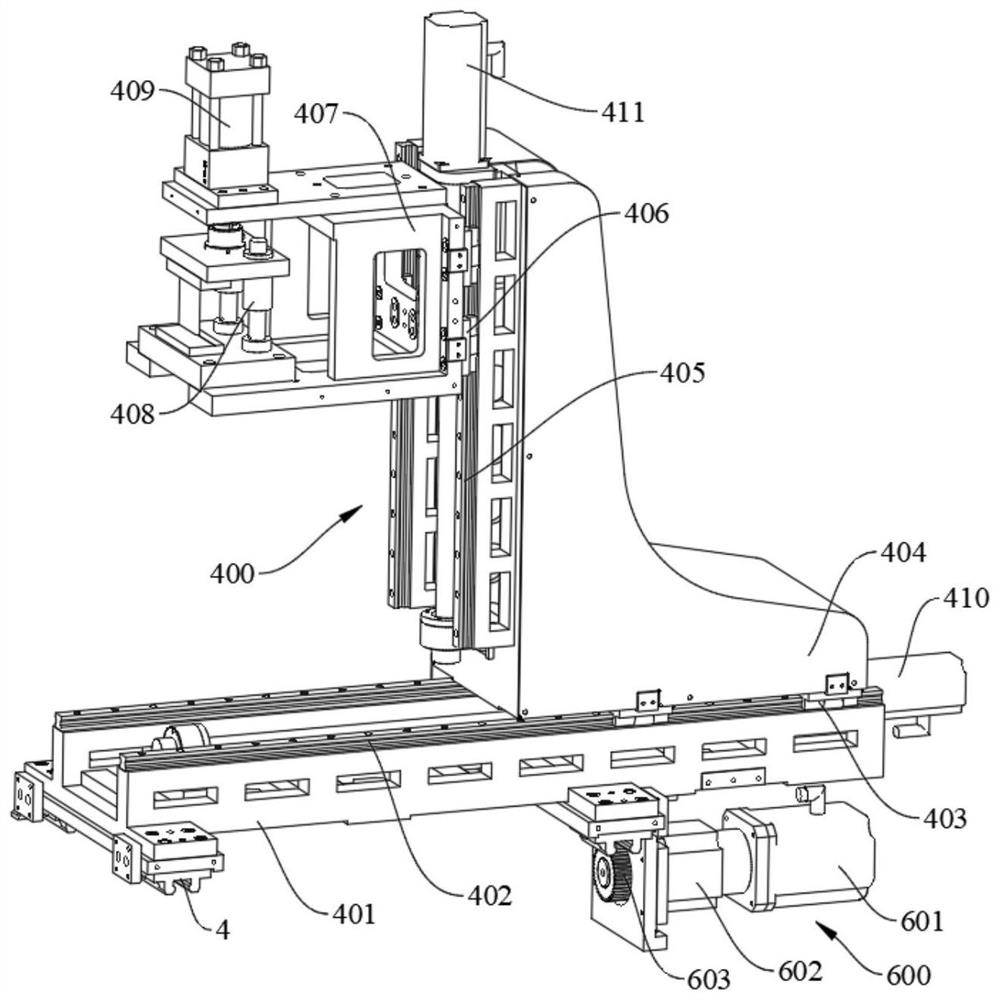

Multi-station punching machine for aluminum alloy doors and windows

The invention discloses a multi-station punching machine for aluminum alloy doors and windows, and belongs to the technical field of aluminum alloy door and window processing. The multi-station punching machine comprises a machine body, a driving mechanism, two end machine heads and a middle machine head, wherein a plurality of molds, a workbench, an upper pressing mechanism, a horizontal pressing mechanism, a front stamping oil cylinder and a rear stamping oil cylinder are arranged on the end machine head, and the middle machine head is provided with a vertical middle machine head stamping oil cylinder and a middle machine head stamping mold installed at the lower end of the middle machine head stamping oil cylinder. According to the invention, a workpiece is supported through a workbench, and is positioned through a horizontal pressing mechanism and an upper pressing mechanism; a mold is pressed through a front punching oil cylinder and a rear punching oil cylinder, so that machining of different process holes in the two ends of the workpiece is achieved; a middle machine head stamping oil cylinder stretches out to drive a middle machine head stamping mold to conduct stamping operation on a workpiece, so that convenient stamping machining of the handle hole and the drainage hole of the workpiece is achieved, the operation efficiency is greatly improved, and the production cost is reduced; and through one-time clamping, the high machining precision can be guaranteed, and the product quality is guaranteed.

Owner:济南天辰智能装备股份有限公司

Stamping machine

The invention discloses a stamping machine. The stamping machine comprises a stamping bottom plate, stand columns are fixedly welded to the periphery of the top of the stamping bottom plate, a stamping top frame is fixedly welded to the tops of the four stand columns, a first sliding mechanism is fixedly welded to the middle of the bottom of the stamping top frame, a second mounting top plate is fixedly mounted in the middle of the bottom of the first sliding mechanism, air cylinders are fixedly mounted on the front side and the rear side of the middle of the bottom of the second mounting topplate correspondingly, a first mounting top plate is fixedly welded to the bottom output ends of the two air cylinders, a stamping head is fixedly welded to the middle of the bottom of the first mounting top plate, and the positions, located at the bottom of the second mounting top plate, of the left sides and the right sides of the air cylinders are provided with second sliding mechanisms. According to the stamping machine, a forward-reverse motor drives a rotating shaft to rotate to drive a belt pulley to rotate, and the belt pulley drives a connecting belt to rotate to drive a fixing blockto move left and right so as to drive the second mounting top plate to move left and right, and therefore, multiple stamping parts can be conveniently stamped and machined.

Owner:大冶市祺顺科技有限公司

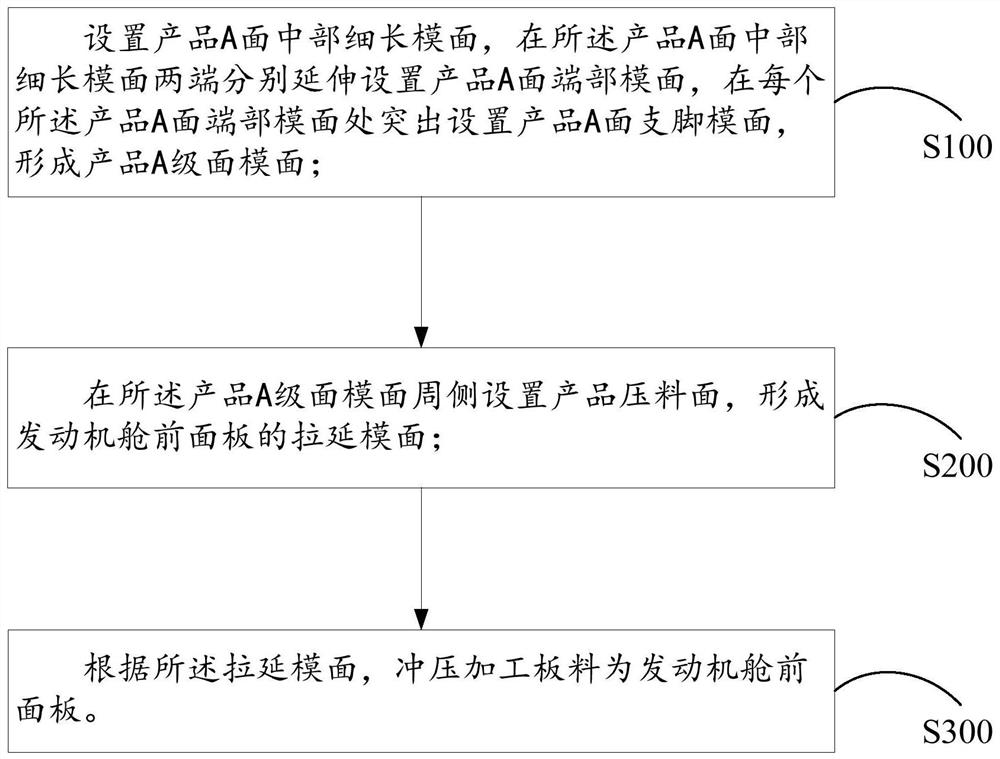

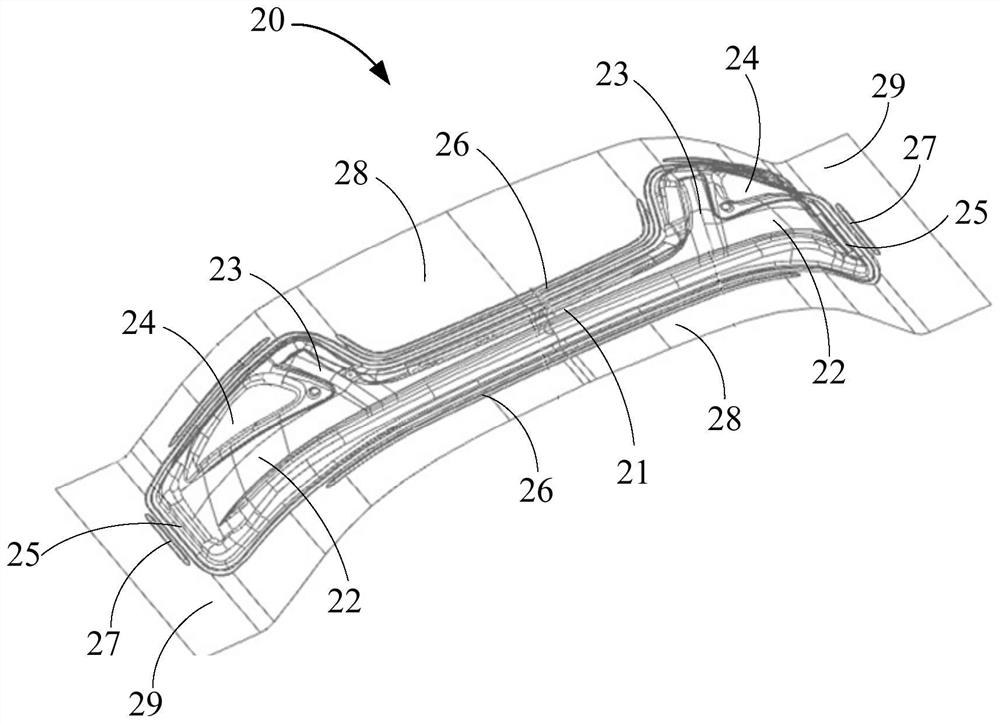

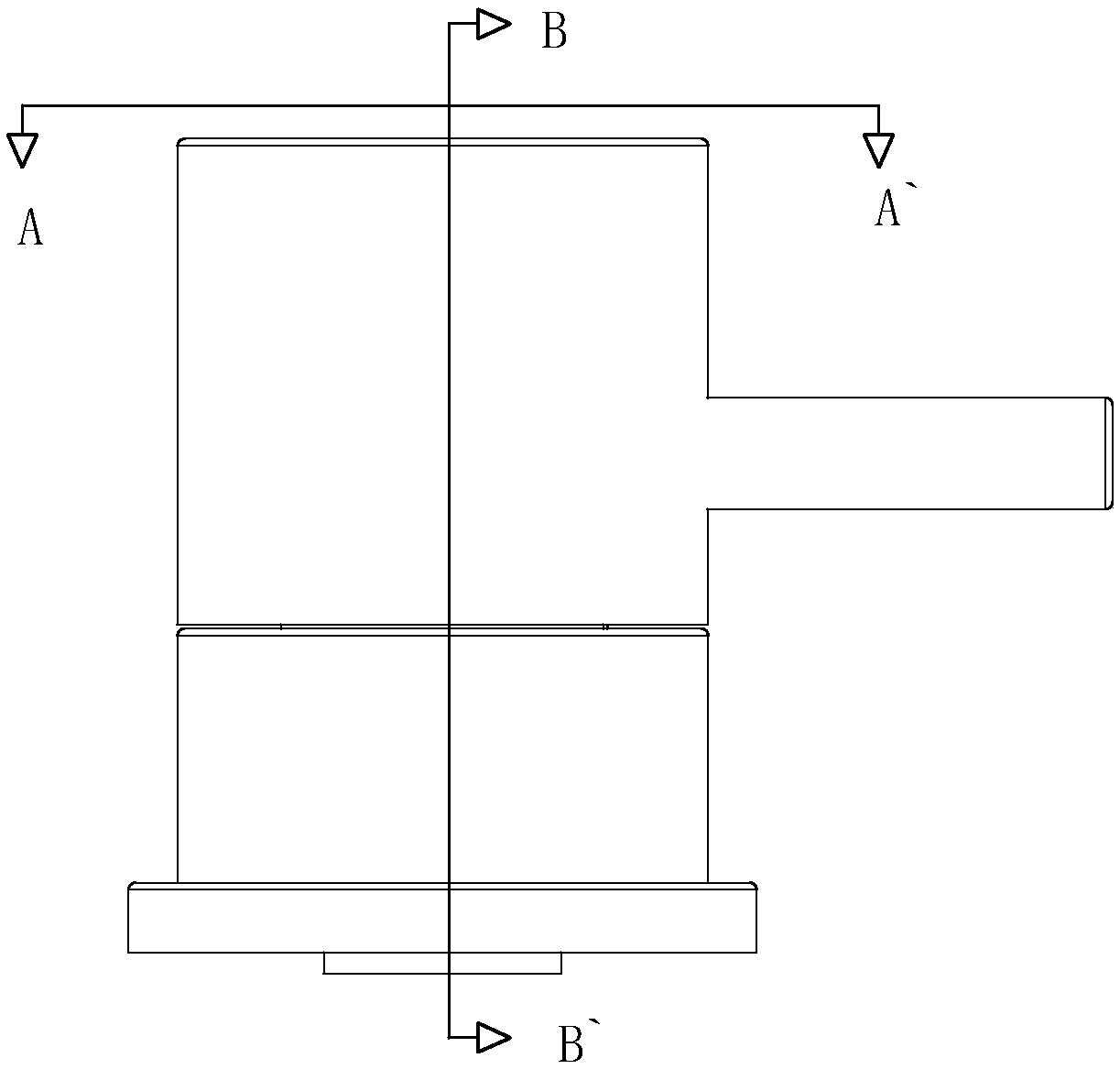

Stamping method of engine compartment front panel and engine compartment front panel

ActiveCN111687271AEasy for stampingMeet quality requirementsSuperstructure subunitsStructural engineeringMachining process

The invention relates to a stamping method of an engine compartment front panel and the engine compartment front panel. The stamping method of the engine compartment front panel comprises the following steps: 1, a product surface-A middle elongated die surface is arranged, the two ends of the elongated die surface are provided with product surface-A end die surfaces in an extending mode, a productsurface-A supporting foot die surface is arranged at each of the product surface-A end die surface to form a product A-level surface die surface; 2, product binder surfaces are arranged on the peripheral side of the product A-level surface A die surfaces to form a drawing die surface of the engine compartment front panel; and 3, according to the drawing die surface, a stamping processing plate material is used as the engine compartment front panel. The invention aims to solve the problems that because the die surfaces and the machining process for stamping and machining fine, narrow, long, multiple-foot and large-drop appearance type stamping parts are lack in the prior art, products meeting the requirement cannot be machined is solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Simple faucet

PendingCN109630709ACompact structureReduce volumeOperating means/releasing devices for valvesSlide valveClamp connectionEngineering

The invention provides a simple faucet. The simple faucet comprises a bottom shell, a waterway control base, a rotating shaft, a rotating rod, an upper shell and a gland with a sinking groove which shear a vertical axial line. The waterway control base is arranged in a cavity defined by the bottom shell and the upper shell and comprises a lower end cavity body, a middle end portion and an upper end cavity body which are integrally formed, the annular bottom face of the lower end cavity body is in threaded connection with the bottom shell, the rotating rod transversely penetrates through the middle end portion, the two ends of the rotating rod are in clamped connection with the inner wall of the upper shell, a transverse handle is connected to the side wall of the upper shell, a lower ceramic valve block is clamped in the lower end cavity body, an upper ceramic valve block is arranged on the top face of the lower ceramic valve block, the bottom end of the rotating shaft is connected with the top face of the upper ceramic valve block, and the top end of the rotating shaft is connected with the bottom face of the rotating rod. According to the simple faucet, the structure of the wholefaucet is compact, and it is ensured that the size of the faucet can be further reduced.

Owner:ZHONGSHAN LEMON ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com