Energy-dissipating support of folded steel plates constrained by inner and outer double casings

An energy-dissipating support and double-sleeve technology, which is applied to building components, earthquake resistance, etc., can solve the problems of less plastic hinges, the uncontrollable number of plastic hinges, and the inability to achieve precise control of energy dissipation performance of supports, etc., to achieve simple structure, increase Stiffness, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

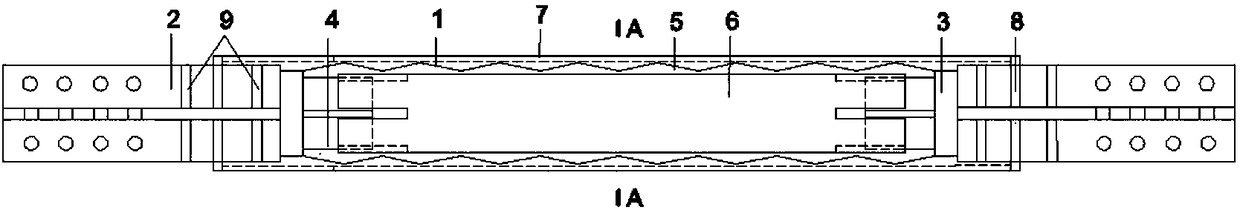

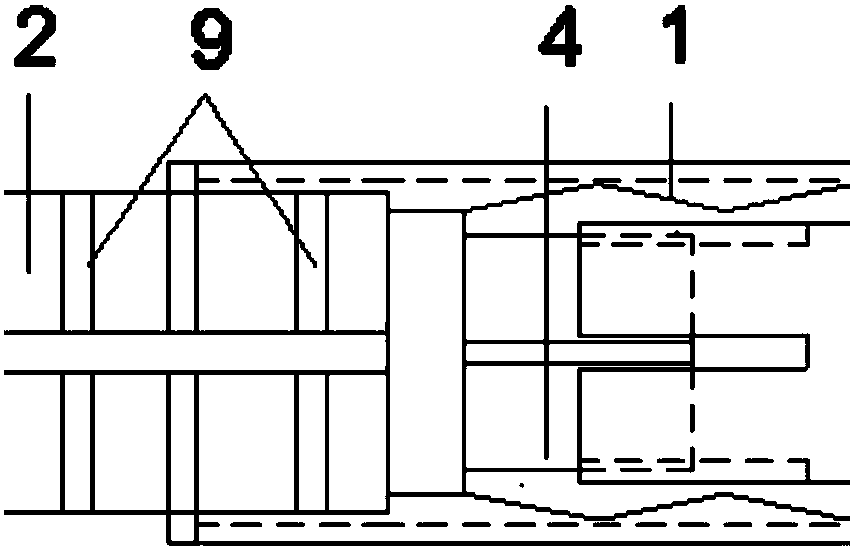

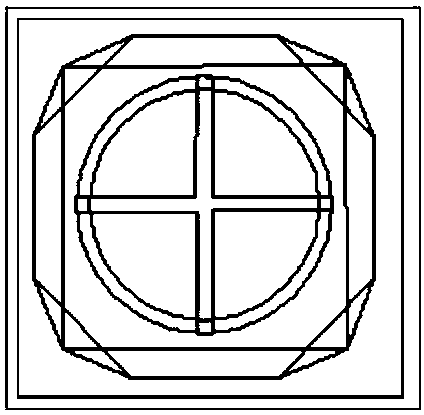

[0037] as follows Figure 1 to Figure 5 As shown, the present invention is composed of a core barrel 1, a cross gusset plate 2, an end bearing plate 3, a cross fixing plate 4, an inner casing 5, an unbonded material 6, an outer casing 7, an outer casing sealing plate 8, a stiffening The ribs are composed of nine parts. The core barrel 1 is formed by punching steel plates into different simple geometric figures, and then welded to form a cylindrical shape. As shown in FIG. 4 , in this embodiment, the geometric figure on the core barrel 1 is a combination of isosceles triangles. Figure 5 is the crease pattern in this example. like figure 2 As shown, the end pressure plate 3 is connected to the core barrel 1, and the end pressure plate 3 is welded to the four sides of the mouth of the core barrel 1, and the size of the end pressure plate 3 is the same as that of the mouth of the core barrel 1. At the same time, the cross fixing plate 4 is welded on the inner side of the end...

Embodiment 2

[0039]This embodiment is the same as the rest of Embodiment 1, except that the inner and outer double casings are replaced with tubes of other shapes to provide constraints.

[0040] In order to express the spatial structure of the sub-unit more clearly, a space rectangular coordinate system is established to describe the coordinates of each node. The coordinate origin O is the center of the sub-unit, and the straight line where the diagonal line FH of the quadrilateral EFGH is located is taken as the X-axis, pointing from F to H. In the positive direction, take the straight line where the other diagonal line EG of the quadrilateral is located as the Z axis, pointing from E to G as the positive direction, and take the straight line passing through the point O and perpendicular to the X axis and Z axis as the Y axis, and the positive direction is the slave surface ABCD Pointing to face IJKL.

[0041] The size of the energy dissipation unit should meet the following conditions (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com