Environmentally-friendly superfine fiber non-woven facial mask cloth and making method thereof

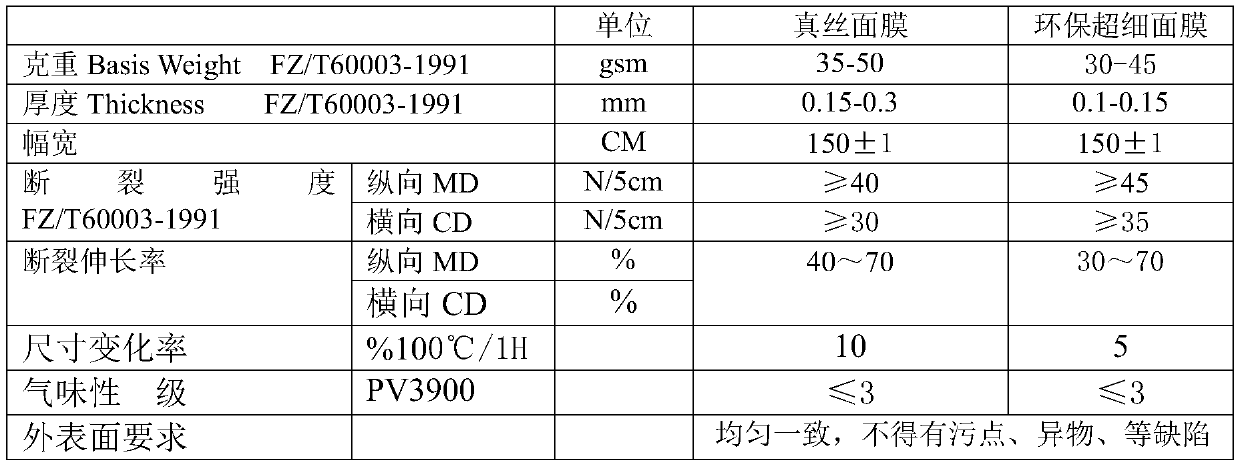

A technology of ultra-fine fiber and manufacturing method, applied in the field of non-woven fabrics, can solve the problems of unstable raw materials, poor skin-friendly effect, expensive price, etc. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

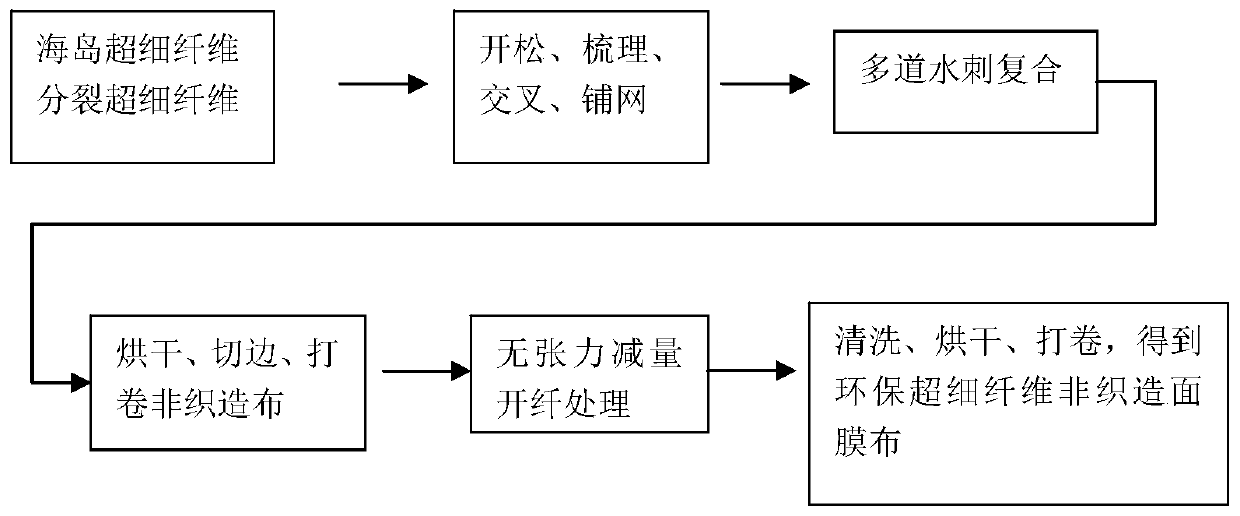

Method used

Image

Examples

Embodiment 1

[0045] A kind of environment-friendly microfiber non-woven facial mask base cloth is manufactured by the following method:

[0046] (1) The raw materials are mixed according to the following ratio:

[0047] A, brocade / polyester 70 / 30 island-in-the-sea superfine short fibers (nylon / polyester 70 / 30 represent nylon content 70%, polyester content 30%, the following representations are the same), 3D*51mm, weight ratio 10%;

[0048] B. Nylon / polyester 20 / 80 split ultrafine short fibers, 2D*51mm, 90% by weight;

[0049] (2) After opening, carding, web laying, spunlace process, drying, and winding, a spunlace composite nonwoven fabric with a gram weight of 60 g / m2 is obtained. The spunlace process uses full cross spunlace, The width of the door is 160cm, and the spunlace pressure of the spunlace unit is 40, 60, 90, 100, 120, 120 kg in sequence;

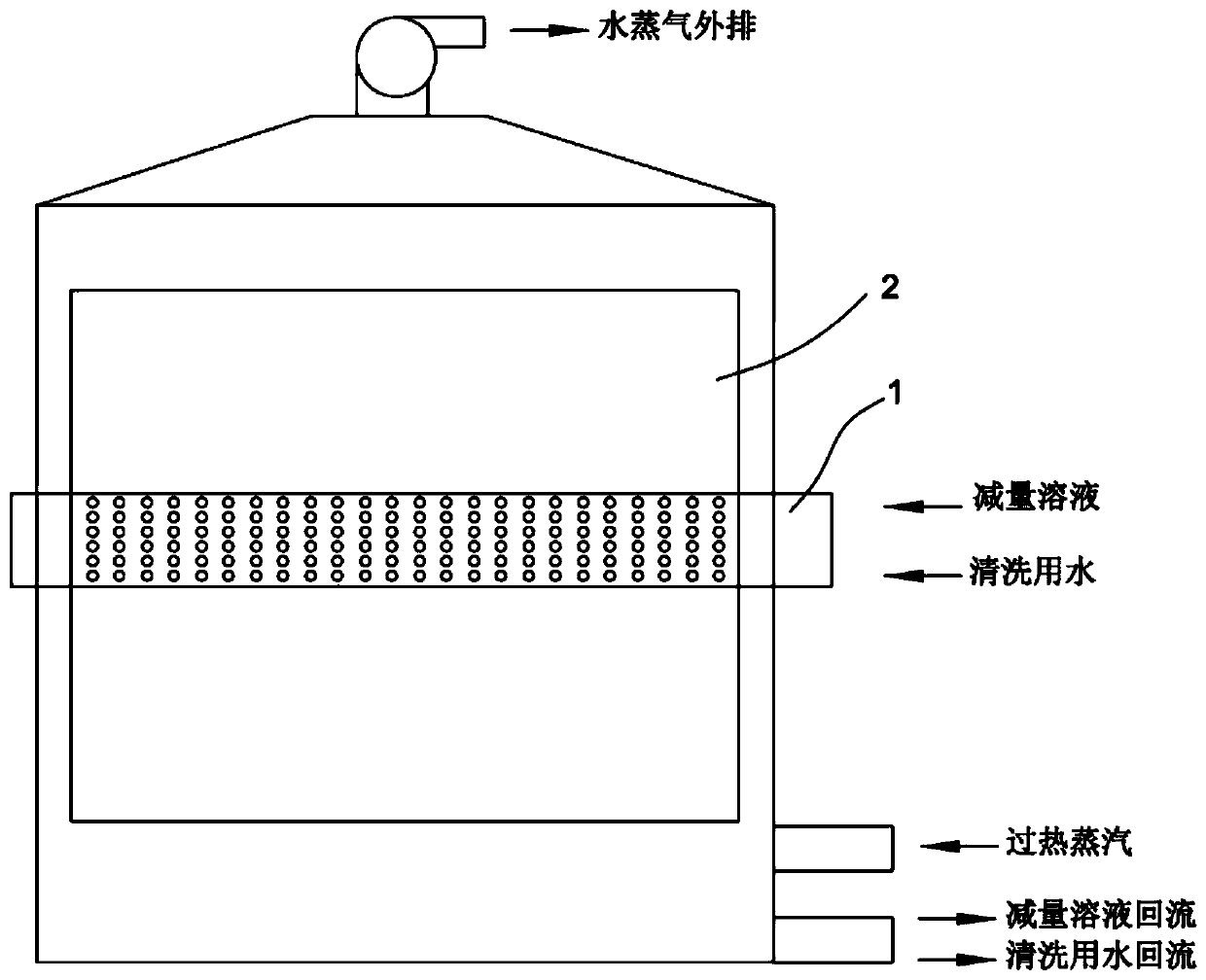

[0050] (3) Spunlace composite forming non-woven fabrics for weight reduction, process conditions: NaOH solution 40g / L, temperature 95°C, t...

Embodiment 2

[0054] A kind of environment-friendly microfiber non-woven facial mask base cloth is manufactured by the following method:

[0055] (1) The raw materials are mixed according to the following ratio:

[0056] A. Nylon / polyester 70 / 30 sea-island superfine short fiber, 3D*51mm, weight ratio 10%;

[0057] B. Nylon / polyester 30 / 70 split ultrafine short fiber, 2D*51mm, 90% by weight;

[0058] (2) After opening, carding, web laying, spunlace process, drying, and winding, a spunlace composite nonwoven fabric with a gram weight of 55 grams per square meter is obtained. In the spunlace process, full cross spunlace is used. The door width is 160cm, and the spunlace pressure of the spunlace unit is 40, 70, 90, 100, 110, and 130 kg in sequence;

[0059] (3) Spunlace composite forming non-woven fabrics for weight reduction, process conditions: NaOH solution 35g / L, temperature 95°C, time 50 minutes, weight reduction accelerator 3g / L,

[0060] (4) Combined use of pressure washing and ultras...

Embodiment 3

[0063] A kind of environment-friendly microfiber nonwoven fabric is manufactured by the following method:

[0064] (1) The raw materials are mixed according to the following ratio:

[0065] A. Nylon / polyester 70 / 30 sea-island superfine short fiber, 3D*51mm, weight ratio 50%;

[0066] B. Nylon / polyester 15 / 85 split ultrafine short fiber, 2D*51mm, weight ratio 50%;

[0067] (2) After opening, carding, web laying, spunlace process, drying, and winding, a spunlace composite nonwoven fabric with a gram weight of 60 g / m2 is obtained. The spunlace process uses full cross spunlace, The door width is 160cm, and the spunlace pressure of the spunlace unit is 40, 70, 90, 100, 110, and 130 kg in sequence;

[0068] (3) Spunlace composite forming non-woven fabrics for weight reduction, process conditions: NaOH solution 25g / L, temperature 95°C, time 45 minutes, weight reduction accelerator 2g / L;

[0069] (4) Pressure washing, after cleaning NaOH and decrementing accelerator, hot air penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com