Robot signal cable

A signal cable and robot technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of inapplicability, super softness, high strength, etc., and achieve increased bending resistance, strong wear resistance, and improved breaking force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

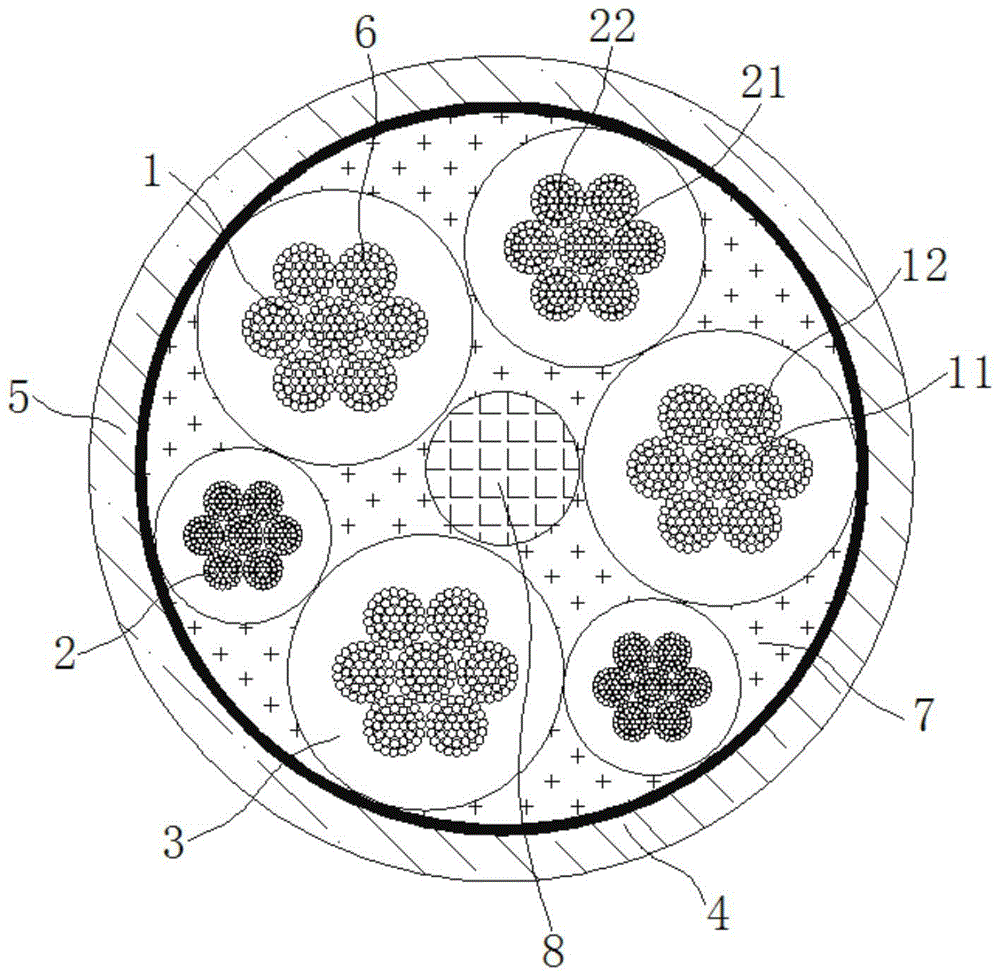

[0039] Embodiments 1 to 4: A signal cable for a robot, including a cable core formed by twisting three first composite stranded conductors 1 and three second composite stranded conductors 2, the diameter of the first composite stranded conductor 1 being larger than that of the second composite stranded conductor Stranded conductor 2 and the first composite stranded conductor 1 and the second composite stranded conductor 2 are alternately arranged at intervals, and the outer surfaces of the first composite stranded conductor 1 and the second composite stranded conductor 2 are covered with an ETFE insulating layer 3;

[0040] A wrapping tape 4 is wrapped around the outer surfaces of three first composite stranded conductors 1 and three second composite stranded conductors 2, an outer sheath layer 5 is wrapped on the outer surface of the wrapping tape 4, and the first composite stranded conductors 1 It includes a small-diameter central copper wire 11 located in the center and 6 sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com