Non-yellowing key and manufacturing method thereof

A technology of piano keys and content, applied in the field of piano keys, can solve the problems of unsightly appearance, yellowing and discoloration of the surface of keys, etc., and achieve the effect of improving yellowing resistance, highlighting impact resistance, and good yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

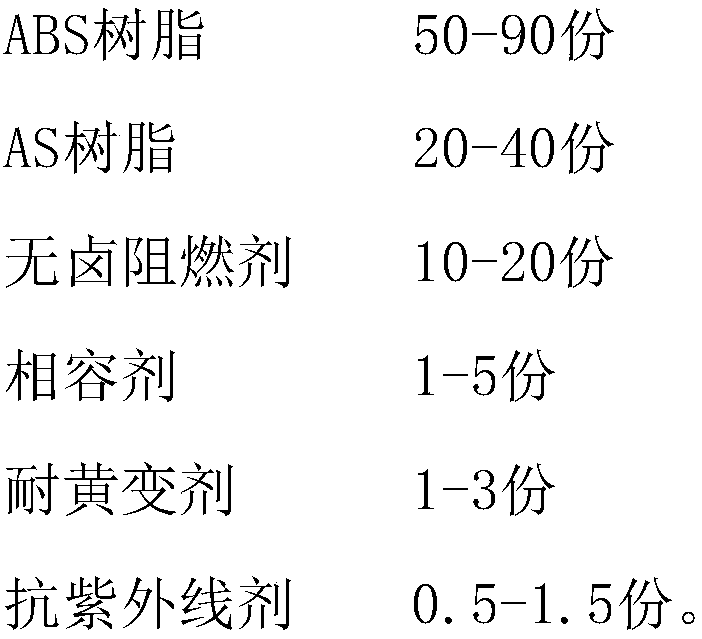

[0029] A non-yellowing piano key, the non-yellowing piano key includes the following raw materials in parts by weight:

[0030]

[0031] The ABS resin is an acrylonitrile-butadiene-styrene copolymer with an acrylonitrile unit content of 15%, a butadiene unit content of 25%, and a styrene unit content of 60%.

[0032] The AS resin is an acrylonitrile-styrene copolymer with an acrylonitrile unit weight content of 60%.

[0033] The flame retardant is a mixture composed of polycyanamide cyanurate, triphenyl phosphate, magnesium hydroxide and montmorillonite in a weight ratio of 1:0.8:1:0.4.

[0034] The compatibilizer is a four-element random copolymer formed by copolymerizing methyl styrene, methacrylonitrile, methacrylic acid and methyl methacrylate at a weight ratio of 2:2:0.8:0.5.

[0035] The anti-yellowing agent is composed of 2-(2'-hydroxyl-3',5'-dipentylphenyl)-benzotriazole, dibutyl hydroxytoluene and 2-hydroxyl-4-n-octyloxy A mixture of benzophenones in a weight rat...

Embodiment 2

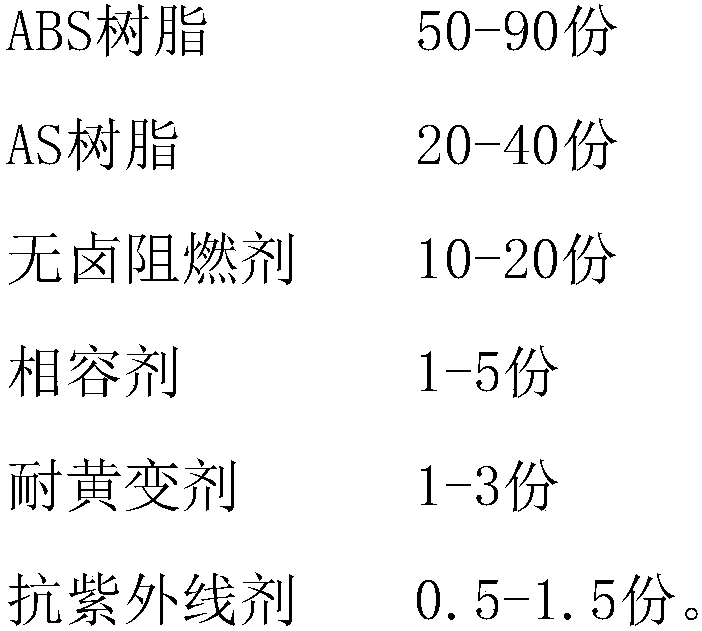

[0041] The difference between this embodiment and the above-mentioned embodiment 1 is that: the non-yellowing piano key includes the following raw materials in parts by weight:

[0042]

[0043] The ABS resin is an acrylonitrile-butadiene-styrene copolymer with an acrylonitrile unit content of 17.5%, a butadiene unit content of 27.5%, and a styrene unit content of 55%.

[0044] The AS resin is an acrylonitrile-styrene copolymer with an acrylonitrile unit weight content of 65%.

[0045] The flame retardant is a mixture composed of polycyanamide cyanurate, triphenyl phosphate, magnesium hydroxide and montmorillonite in a weight ratio of 1.2:0.9:1:0.5.

[0046] The compatibilizer is a four-element random copolymer formed by copolymerizing methyl styrene, methacrylonitrile, methacrylic acid and methyl methacrylate at a weight ratio of 2.5:2.5:0.9:0.8.

[0047] The anti-yellowing agent is composed of 2-(2'-hydroxyl-3',5'-dipentylphenyl)-benzotriazole, dibutyl hydroxytoluene and...

Embodiment 3

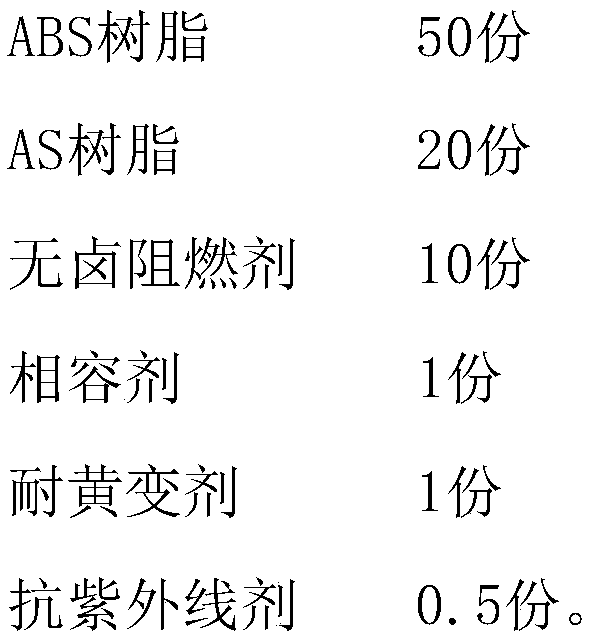

[0052] The difference between this embodiment and the above-mentioned embodiment 1 is that: the non-yellowing piano key includes the following raw materials in parts by weight:

[0053]

[0054] The ABS resin is an acrylonitrile-butadiene-styrene copolymer with an acrylonitrile unit content of 20%, a butadiene unit content of 30%, and a styrene unit content of 50%.

[0055] The AS resin is an acrylonitrile-styrene copolymer with an acrylonitrile unit weight content of 70%.

[0056] The flame retardant is a mixture composed of polycyanamide cyanurate, triphenyl phosphate, magnesium hydroxide and montmorillonite in a weight ratio of 1.5:1:1:0.6.

[0057] The compatibilizer is a four-element random copolymer formed by copolymerization of methyl styrene, methacrylonitrile, methacrylic acid and methyl methacrylate in a weight ratio of 3:3:1:1.

[0058] The anti-yellowing agent is composed of 2-(2'-hydroxyl-3',5'-dipentylphenyl)-benzotriazole, dibutyl hydroxytoluene and 2-hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com