Application of ultraviolet absorbent in finishing of textile

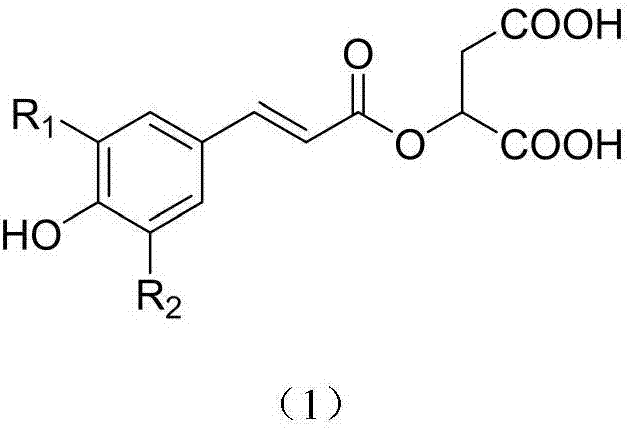

A UV absorber and fabric finishing technology, which is applied in fiber treatment, plant fiber, textiles and paper making, can solve the problems of yellowing and low washing fastness, and achieve good anti-yellowing, good washing fastness, Good anti-ultraviolet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

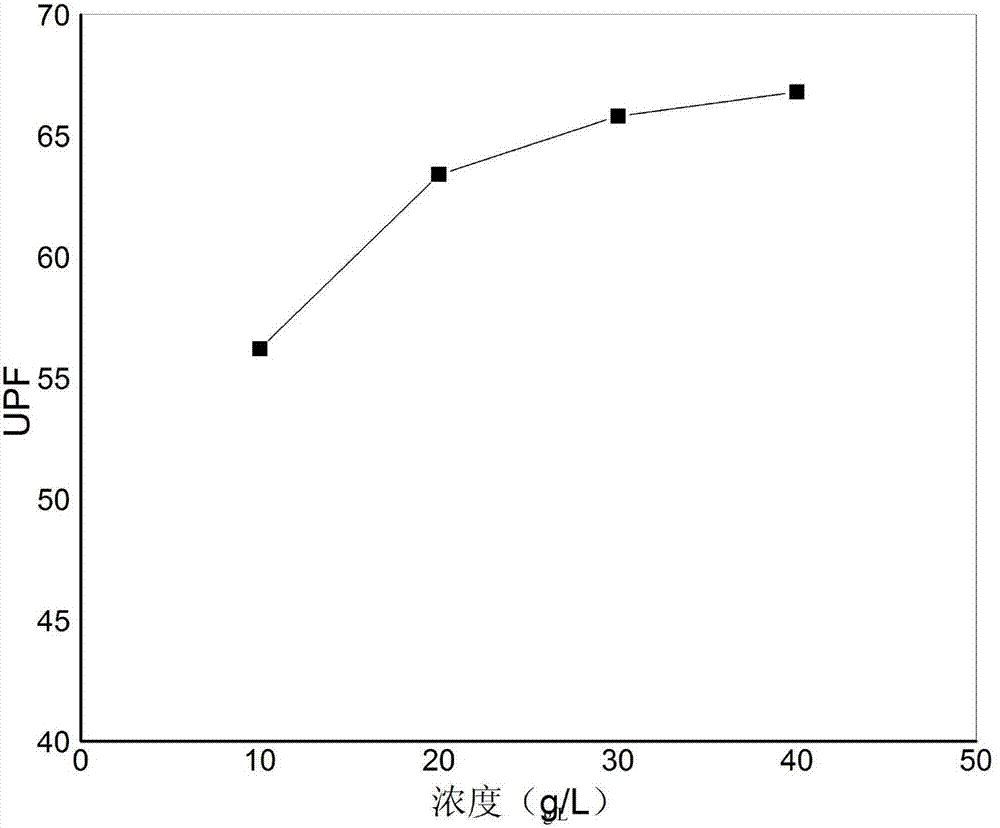

[0029] Embodiment 1: the anti-ultraviolet finishing of cotton fabric by independent ultraviolet absorber

[0030] Dissolve 30g / L of the UV absorber of chemical formula (I) in the finishing solution and heat to 40°C, put the pre-moistened cotton fabric into the solution, the bath ratio is 1:20, and add 3g / L of salt at the same time , reacted for 30 minutes, then raised the temperature to 90°C, kept it warm for 60 minutes, took out the fabric, washed it with water, and dried it at 60°C for 2 hours to obtain the finished fabric, and measured its UV absorption effect (UPF value 65.8±5) and other properties (see table 2).

[0031] Table 1 Cotton fabric alone UV absorber finishing prescription

[0032]

[0033] Table 2 Comparison of properties of cotton fabrics before and after separate finishing

[0034]

Embodiment 2

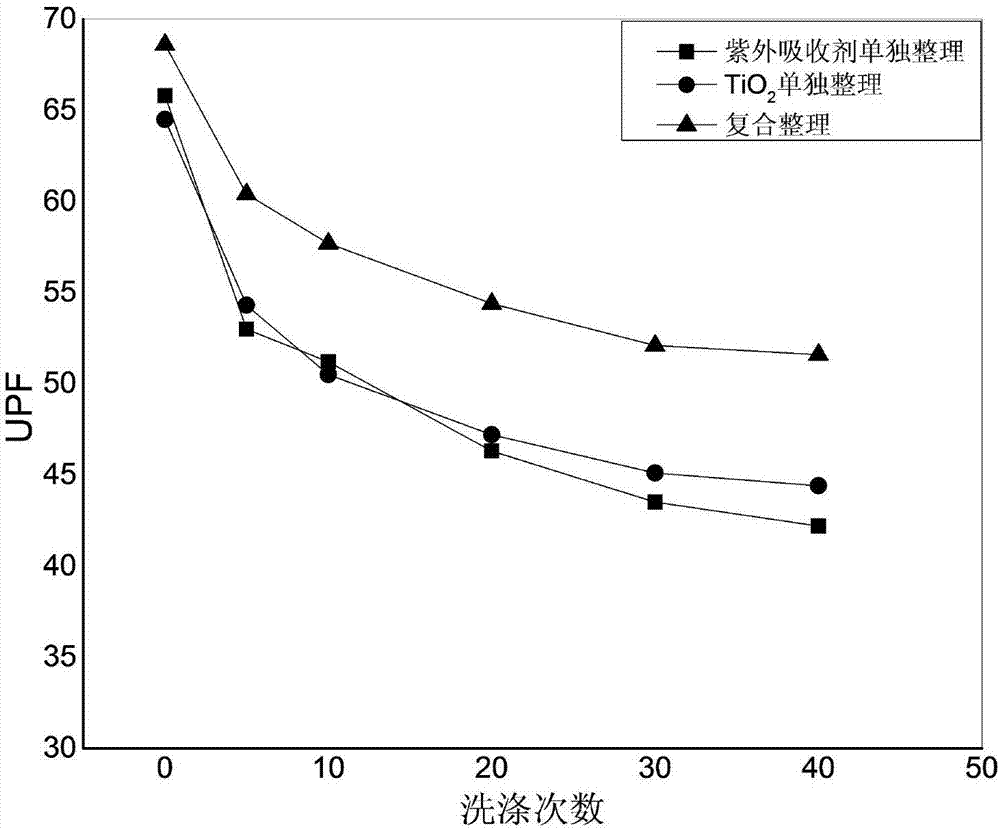

[0035] Embodiment 2: Cotton fabric washing resistance test of UV absorber finishing separately

[0036] The cotton fabric obtained in Example 1 after UV protection was subjected to washing durability test.

[0037] Specific experimental conditions: The bath ratio is 1:30, the concentration of the lotion is 1.1g / L, wash at 30°C for 10 minutes, dehydrate, then wash with water for 2 minutes, spin dry, wash with water for 2 minutes, and dry. Then the above operation was repeated 5 times on the fabric, and the UPF value of the fabric after 5 washings was tested by a textile ultraviolet protection factor tester (Cary50) was 53.0±4.

Embodiment 3

[0038] Embodiment 3: Cotton fabric washing resistance test of UV absorber alone finishing

[0039] The cotton fabric obtained in Example 1 after UV protection was subjected to washing durability test.

[0040] Specific experimental conditions: The bath ratio is 1:30, the concentration of the lotion is 1.1g / L, wash at 30°C for 10 minutes, dehydrate, then wash with water for 2 minutes, spin dry, wash with water for 2 minutes, and dry. Then the above operation was repeated 10 times on the fabric, and the UPF value of the fabric after 10 washings was tested by a textile ultraviolet protection factor meter (Cary50) was 51.2±5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com