Nylon heat-resistant anti-yellowing agent not capable of adsorbing no formaldehyde and preparation method thereof

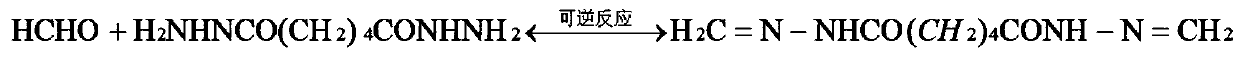

An anti-yellowing agent and a technology for adsorbing formaldehyde, which can be used in dyeing methods, organic chemistry, fiber types, etc., can solve the problems of high cost and poor water solubility, and achieve the effects of low cost, excellent water solubility, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

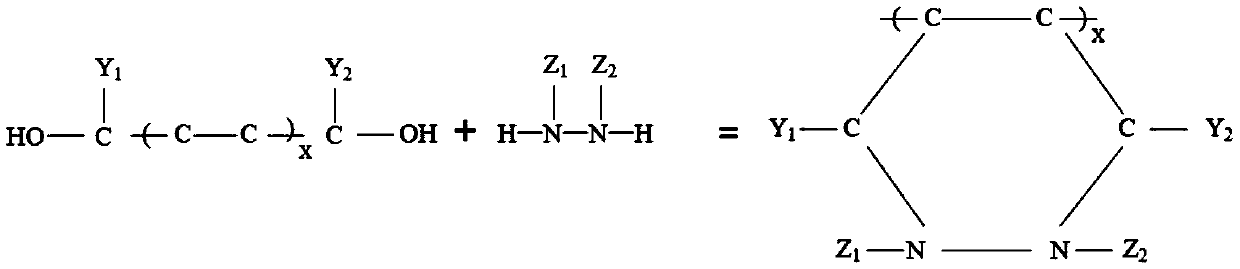

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A kind of polyamide fiber anti-yellowing agent that does not absorb formaldehyde, by mass percentage, is made up of following components: the antioxidant (containing solvent) 50% of nitrogen-containing heterocyclic structure; Deionized water 47%; Hydrogen Sodium oxide NaOH 3%.

[0022] The preparation method of the polyamide fiber anti-yellowing agent that does not absorb formaldehyde, comprises the following steps:

[0023] (1) Synthesis of antioxidants with a nitrogen-containing heterocyclic structure: use a 500ml four-necked flask, first add 40% solvent ethanol to the flask by mass ratio, start stirring, and then mix 23.5% The hydrazine hydrate was added, and the temperature was raised to 80°C after the dropwise addition, and then 36.0% glutaric acid was added in 5 times. After the addition, 0.5% potassium bisulfate was added, and the temperature of the material was controlled at 90°C and kept under pressure and stirred for 3 hours, and then cooled to ...

Embodiment 2

[0025] Embodiment 2: A kind of polyamide fiber anti-yellowing agent that does not absorb formaldehyde, by mass percentage, is made up of following components: the antioxidant (containing solvent) 60% of nitrogen-containing heterocyclic structure; Deionized water 37%; Hydrogen Sodium oxide NaOH 3%.

[0026] The preparation method of the polyamide fiber anti-yellowing agent that does not absorb formaldehyde, comprises the following steps:

[0027] (1) Synthesis of antioxidants with nitrogen-containing heterocyclic structure: use a 500ml four-necked flask, first add 30% solvent ethanol to the flask according to the mass ratio, start stirring, and then mix 25.2% hydrazine hydrate was added, and the temperature was raised to 80°C after the dropwise addition, and then 44.2% succinic acid was added in 5 times. hours, and then cooled to room temperature to obtain an antioxidant with a nitrogen-containing heterocyclic structure soluble in ethanol.

[0028] (2) Composite: use the four...

Embodiment 3

[0029] Embodiment 3: A kind of polyamide fiber anti-yellowing agent that does not absorb formaldehyde, by mass percentage, is made up of following components: the antioxidant (containing solvent) 25% of nitrogen-containing heterocyclic structure; Deionized water 70%; Hydrogen Sodium oxide NaOH 5%.

[0030] The preparation method of the polyamide fiber anti-yellowing agent that does not absorb formaldehyde, comprises the following steps:

[0031] (1) Synthesis of antioxidants with nitrogen-containing heterocyclic structure: use a 500ml four-necked flask, first add 50% solvent-ethanol into the flask according to the mass ratio, start stirring, and then 15.2 % of unsymmetrical dimethylhydrazine was added, and the temperature was raised to 80°C after the dropwise addition, and then 33.6% of adipic acid was added in 5 times, and after the addition, 1.2% of potassium bisulfate was added, and the temperature of the material was kept at 100°C under pressure and stirred for 4 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com