Weather-resistant halogen-free and flame retardant reinforced nylon material and preparation method

A nylon and weather-resistant technology, applied in the field of flame-retardant polymer materials, can solve the problems of easy surface precipitation and degradation, easy aging and discoloration of products, poor thermal stability, etc., and achieves good thermal stability and anti-yellowing aging effect. , the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

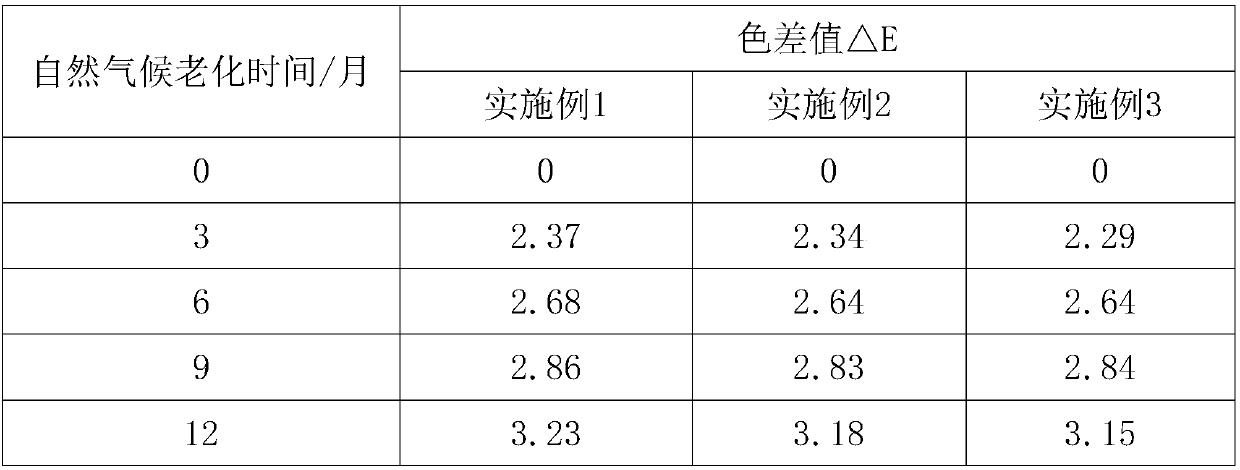

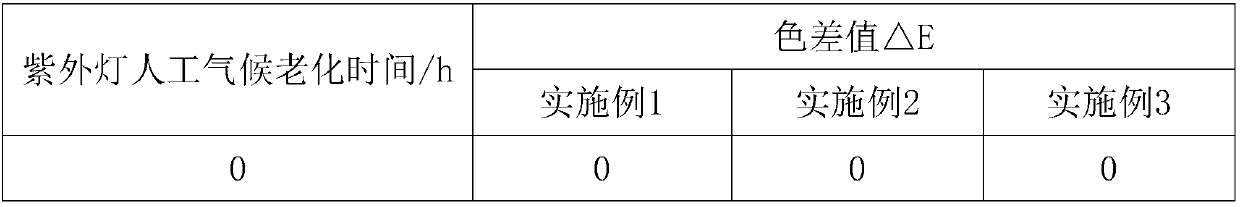

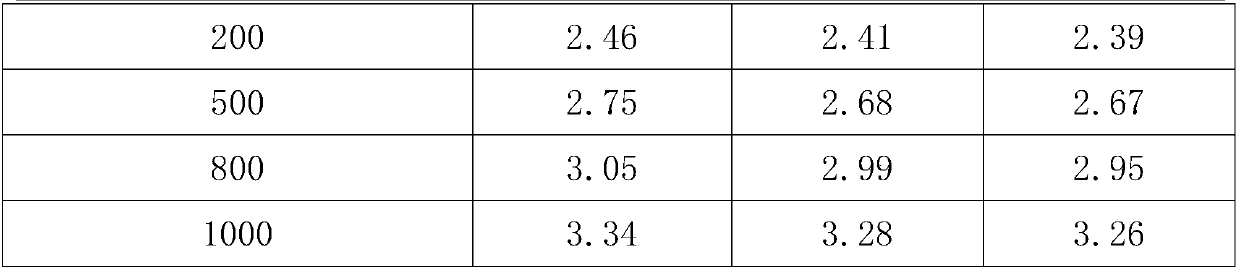

Examples

Embodiment 1

[0025] The invention discloses a weather-resistant halogen-free flame-retardant reinforced nylon material, which comprises the following components by weight percentage:

[0026] PA66 20-30%, PA6 10-25%, A-type halogen-free flame retardant 5-10%, B-type halogen-free flame retardant 3-8%, compatibilizer 3-10%, glass fiber 20-30% , lubricant 0.5-1.5%, composite antioxidant 0.3-1.0%, light stabilizer 0.3-1.0%, ultraviolet absorber 0.4-1.2%.

[0027] Among them, the relative viscosity of PA66 and PA6 is 2.0-2.6.

[0028] Among them, the A-type halogen-free flame retardant is an organic hypophosphite flame retardant, and the B-type halogen-free flame retardant is guanidine sulfamate.

[0029] Wherein, the compatibilizer is one of polyolefin elastomer grafted maleic anhydride (POE-g-MAH) or ethylene-propylene-diene rubber grafted maleic anhydride (EPDM-g-MAH) copolymer or a mixture thereof.

[0030] Wherein, the glass fiber is chopped glass fiber, and the lubricant stearamide lubr...

Embodiment 2

[0039] The present embodiment is based on embodiment 1, carries out experimental comparison explanation for the formula disclosed in embodiment 1, has set up some experimental groups, specifically as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com