Preparation method of medical bubble cap two-way stretching nylon film

A biaxially stretched nylon and film technology, applied in applications, household appliances, flat products, etc., can solve the problems of low heat shrinkage, achieve low heat shrinkage, small difference in heat shrinkage, and good mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

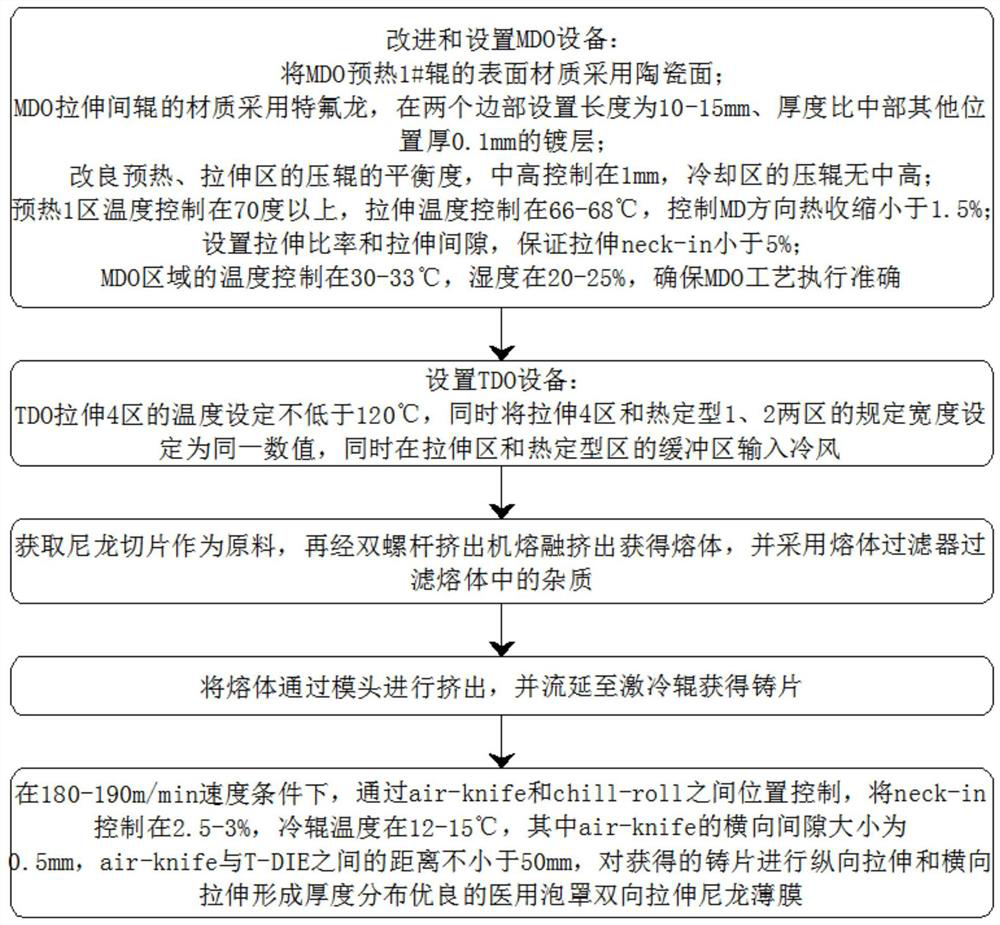

[0032] A preparation method of a medical blister biaxially stretched nylon film, comprising the steps of:

[0033] S1. Improve and set MDO device:

[0034] The surface material of the MDO preheating 1# roller is made of ceramic surface;

[0035] The material of the MDO stretching roller is Teflon, and a coating with a length of 10mm and a thickness of 0.1mm thicker than other positions in the middle is provided on the two sides;

[0036] Improve the balance of the pressure rollers in the preheating and stretching areas, the middle height is controlled at 1mm, and the pressure rollers in the cooling area have no middle height;

[0037] The temperature in the preheating zone 1 is controlled above 70 degrees, the stretching temperature is controlled at 66 degrees C, and the heat shrinkage in the MD direction is controlled to be less than 1.5%;

[0038] Set the stretch ratio and stretch gap to ensure that the stretch neck-in is less than 5%;

[0039] The temperature in the MDO ...

Embodiment 2

[0054] A preparation method of a medical blister biaxially stretched nylon film, comprising the steps of:

[0055] S1. Improve and set MDO device:

[0056] The surface material of the MDO preheating 1# roller is made of ceramic surface;

[0057] The material of the MDO stretching roller is Teflon, and a coating with a length of 12mm and a thickness of 0.1mm thicker than other positions in the middle is provided on the two sides;

[0058] Improve the balance of the pressure rollers in the preheating and stretching areas, the middle height is controlled at 1mm, and the pressure rollers in the cooling area have no middle height;

[0059] The temperature in the preheating zone 1 is controlled above 70 degrees, the stretching temperature is controlled at 67 degrees, and the heat shrinkage in the MD direction is controlled to be less than 1.5%;

[0060] Set the stretch ratio and stretch gap to ensure that the stretch neck-in is less than 5%;

[0061] The temperature in the MDO area...

Embodiment 3

[0076] A preparation method of a medical blister biaxially stretched nylon film, comprising the steps of:

[0077] S1. Improve and set MDO device:

[0078] The surface material of the MDO preheating 1# roller is made of ceramic surface;

[0079] The material of the MDO stretching roller is Teflon, and a coating with a length of 15mm and a thickness of 0.1mm thicker than other positions in the middle is provided on the two sides;

[0080] Improve the balance of the pressure rollers in the preheating and stretching areas, the middle height is controlled at 1mm, and the pressure rollers in the cooling area have no middle height;

[0081] The temperature in preheating zone 1 is controlled above 70°C, the stretching temperature is controlled at 68°C, and the heat shrinkage in the MD direction is controlled to be less than 1.5%;

[0082] Set the stretch ratio and stretch gap to ensure that the stretch neck-in is less than 5%;

[0083] The temperature in the MDO area is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com