Coal seam air injection expansion secondary permeability improvement method adopted after liquid CO2 blasting and used for promoting gas extraction

A gas drainage, liquid technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of reduced coal seam permeability, affecting coal seam and coalbed methane mining efficiency and safe production, and narrowing of fracture channels, etc. , to increase the probability and danger, eliminate the possibility of gas explosion, and lower the gas injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The liquid CO that promotes gas extraction in this embodiment 2 The secondary permeability enhancement method of coal seam gas injection expansion after blasting is carried out according to the following steps:

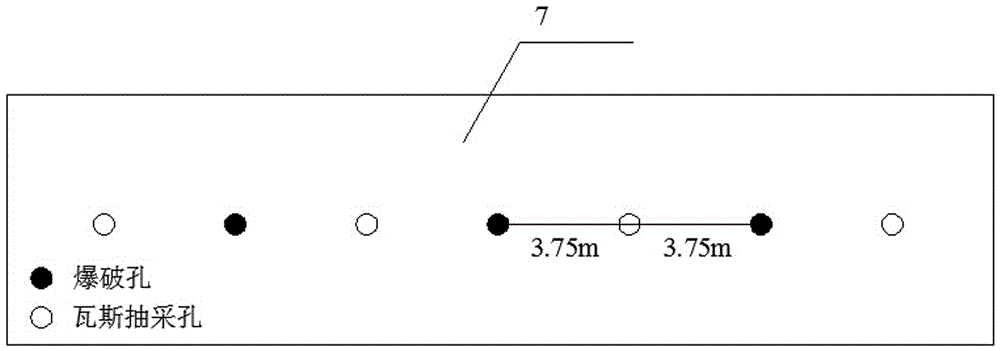

[0032] (1) Blasting holes and gas drainage holes are constructed on the working face 7, with a diameter of 100mm. The blasting holes and gas drainage holes are arranged at equal intervals, and the interval between adjacent blasting holes is 7.5m. figure 2 shown;

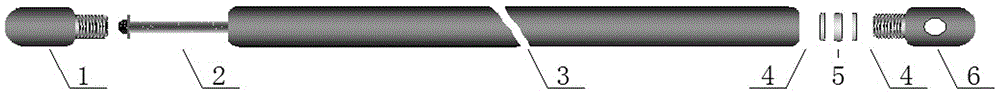

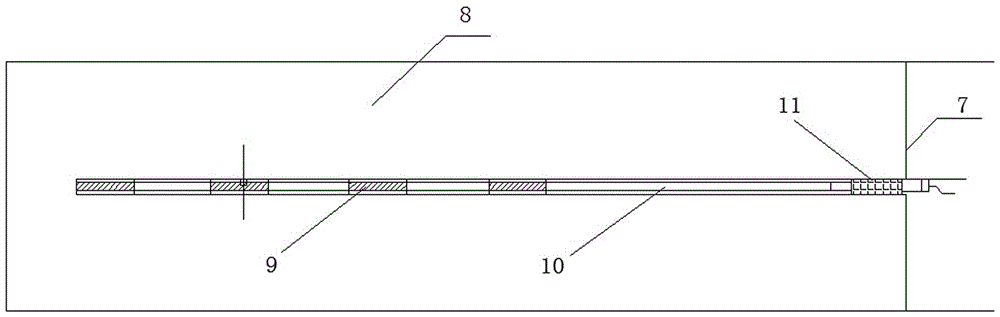

[0033] (2) Fill the blaster with liquid CO 2 , liquid CO 2 The filling pressure is 8~10MPa, and liquid CO is installed in the blast hole 2 Blaster 9, such as image 3 As shown, the blaster is inserted into the blast hole, and reaches the working surface 7 through the connecting pipe 10, and the hole is sealed with a hole sealer 11, and the blaster is started, and the liquid CO in the main tube 3 of the blaster 2 It quickly gasifies into high-pressure gas within 40ms. When the ultimate pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com