Device and method for rapid dust reduction during tunnel blasting

A technology of dust suppression and tunneling, which is applied in safety devices, dust prevention, earth square drilling and mining, etc. It can solve problems such as long dust suppression time, incomplete dust suppression, and affecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

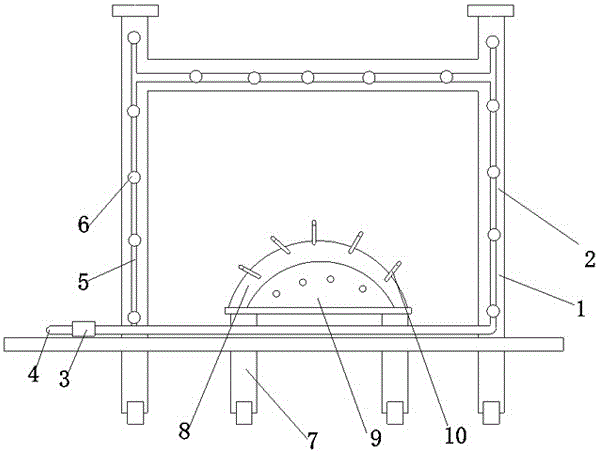

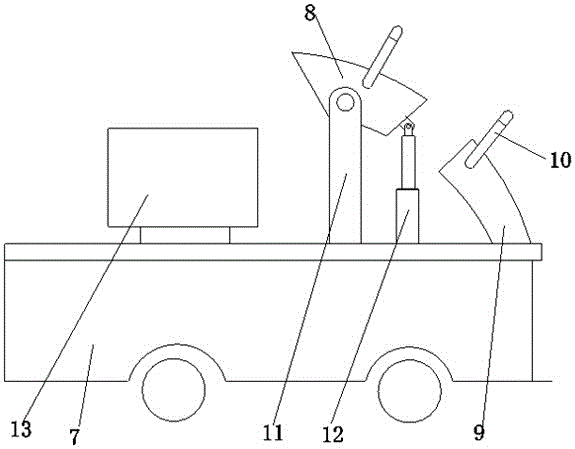

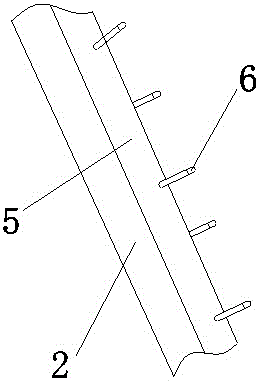

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] Such as figure 1 Described is the structural representation of the device for fast dust reduction when the present invention is used for tunnel blasting; image 3 The above is a side view of the face of the tunnel blasting device of the present invention for rapid dust reduction. The present invention is a device for rapid dust reduction of tunnel blasting, including a tunnel excavation trolley 1 and a mobile trolley 7. A water pipe 5 is provided on the face 2 of the tunnel excavation trolley 1, and a nozzle I6 is arranged on the water pipe 5. The nozzle I6 is arranged along an H shape on the water pipe 5, and one end of the water pipe 5 is close to the water inlet pipe. A booster pump 3 is provided at the joint 4, and a mobile water spray device is provided on the mobile trolley 7.

[0024] In this embodiment, the booster pump 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com