System and method for energy cascade utilization of small steam turbines in thermal power plants

A technology for small steam turbines and thermal power plants, applied in steam engine installations, mechanical equipment, machines/engines, etc., can solve the problems of difficulty in fully utilizing steam energy, high requirements for the design and manufacture of supporting main steam turbines and safe operation, and is easy to popularize and apply. , Reduce the requirements for design and manufacture and safe operation, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

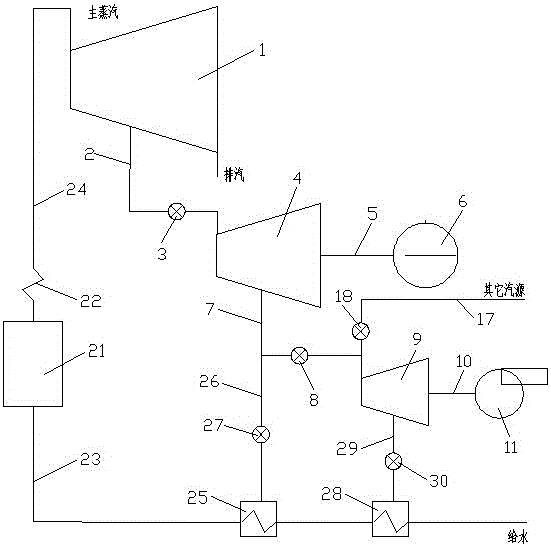

[0017] see figure 1 , the thermal power plant small steam turbine energy cascade utilization system in the present embodiment consists of a main steam turbine 1, a main steam inlet pipe 2, a main steam inlet regulating valve 3, a small steam turbine for driving a feedwater pump 4, a feedwater pump connecting shaft 5, a feedwater pump 6, a No. 1 steam inlet pipe 7, No. 1 regulating valve 8, No. 1 driving induced draft fan small steam turbine 9, No. 1 induced draft fan connecting shaft 10, No. 1 induced draft fan 11, No. 1 other air source steam inlet pipe 17, No. 1 other air source Steam inlet pipe regulating valve 18, boiler 21, evaporator 22, water supply pipe 23, main steam pipe 24, high pressure heater 25, high pressure heating pipe 26, No. 3 regulating valve 27, low pressure heater 28, No. 1 low pressure heating pipe 29 And No. 4 regulating valve 30 forms.

[0018] In this embodiment, one end of the main steam pipe 24 is connected to the evaporator 22, the other end of th...

Embodiment 2

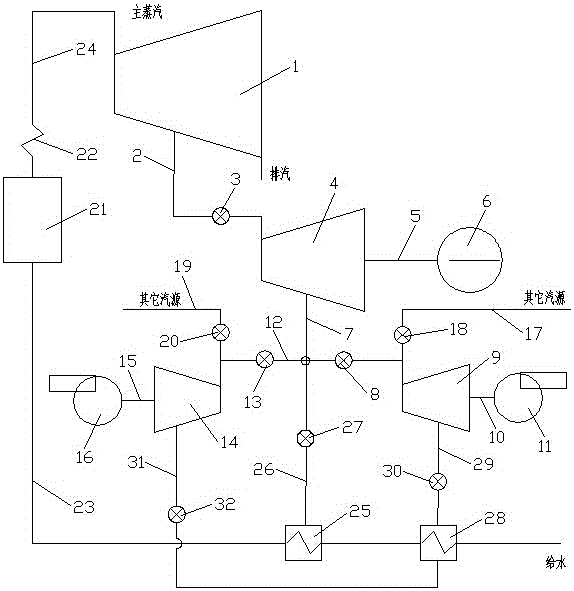

[0025] see figure 2 , the thermal power plant small steam turbine energy cascade utilization system in the present embodiment consists of a main steam turbine 1, a main steam inlet pipe 2, a main steam inlet regulating valve 3, a small steam turbine for driving a feedwater pump 4, a feedwater pump connecting shaft 5, a feedwater pump 6, a No. 1 steam inlet pipe 7, No. 1 regulating valve 8, No. 1 driving induced draft fan small steam turbine 9, No. 1 induced draft fan connecting shaft 10, No. 1 induced draft fan 11, No. 2 steam inlet pipe 12, No. 2 regulating valve 13, No. 2 Drive induced draft fan small steam turbine 14, No. 2 induced draft fan connecting shaft 15, No. 2 induced draft fan 16, No. 1 other air source inlet pipe 17, No. 1 other air source inlet pipe regulating valve 18, No. 2 other air source inlet steam Pipe 19, No. 2 other gas source inlet pipe regulating valve 20, boiler 21, evaporator 22, water supply pipe 23, main steam pipe 24, high-pressure heater 25, hig...

Embodiment 3

[0036] see figure 1 and figure 2 , the steps of the energy cascade utilization method of the small steam turbine in the thermal power plant in the present embodiment are: the main steam generated in the evaporator 22 enters the main steam turbine 1 along the main steam pipe 24, and the main steam turbine 1 only directly provides steam to the small steam turbine 4 for driving the feed pump, After the pressure and temperature parameters of the small steam turbine 4 driving the feed pump have been worked, part of the steam is directly pumped to the small steam turbine of the induced draft fan to drive the small steam turbine of the induced fan to do work, and the steam that has done the work of the small steam turbine of the induced fan is then drawn to the low-pressure heater 28 to heat the feed water in the water supply pipe 23, and another part of the steam is pumped to the high-pressure heater 25 to heat the feed water in the water supply pipe 23, so that the heat of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com