A differential speed method driven by multiple motors

A multi-motor drive and differential speed technology, which is applied in electric vehicles, control drives, power management, etc., to reduce the difficulty of design, manufacture and selection, and improve long-term reliability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

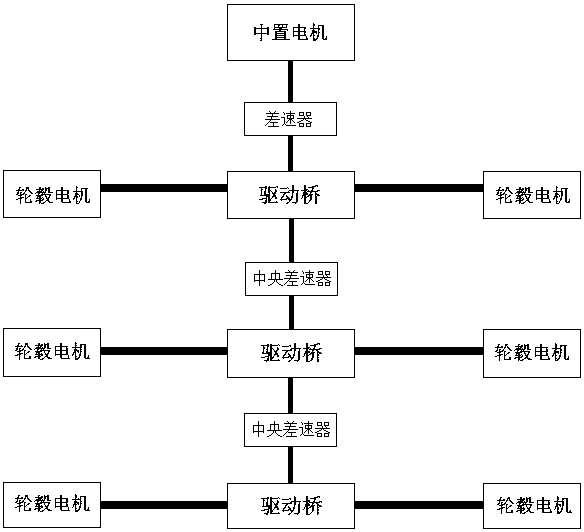

[0016] like figure 1 As shown, the present invention discloses a multi-motor driven differential method. The motor vehicle installs three pairs of left and right symmetrical driving motors on the driving wheels, each pair of driving wheels is respectively connected to the same drive axle, and a middle motor passes through The electronic differential is connected to one drive axle, and if there are more than one pair of drive wheels, the drive axles are connected in turn through the center differential. The driving motor is a hub motor or a wheel motor. The transmission form between the wheel motor and the drive wheel is belt drive, chain drive or planetary gear drive, and the output shaft of the wheel motor is parallel to the drive wheel shaft.

[0017] The power of the central motor is 1 to 3 times of the maximum torque difference Nd between the left and right sides of the electronic differential. The function of the combination of the central motor, the differential gear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com