Accelerated storage test method for electronic equipment

A technology for accelerated storage test and complete machine, applied in the field of accelerated storage test, can solve the problem of lack of accelerated storage test method for complete machine products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

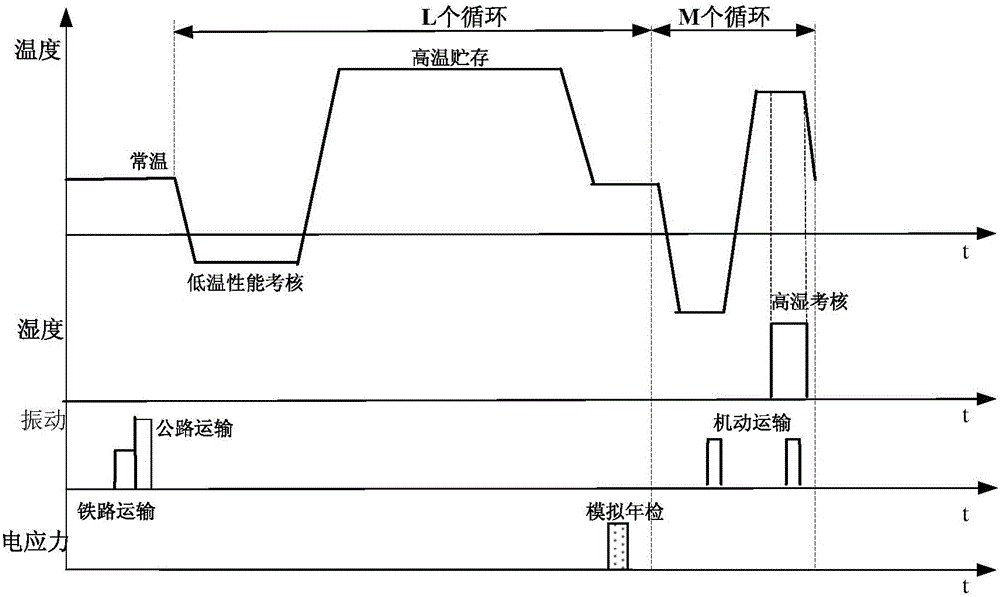

[0050] This embodiment provides an accelerated storage test method for electronic complete machines. In this method, the storage life cycle of electronic products is considered to include four processes including pick-up and transportation, warehouse storage, field work, and annual testing. The storage stresses considered are temperature, humidity , Transportation vibration stress and electrical stress. This method comprises the steps in turn:

[0051] Step 1. Pick-up and transportation stage

[0052] The pick-up and transportation stage of electronic products includes railway transportation and road transportation. In the test, an electromagnetic vibrating table is used to provide vibration stress for electronic products to accelerate the simulation of the actual situation of railway transportation and road transportation. Place the product to be tested in the packing box, and then fix the packing box on the electromagnetic vibration table,

[0053] Step 1.1 Railway transpo...

Embodiment 2

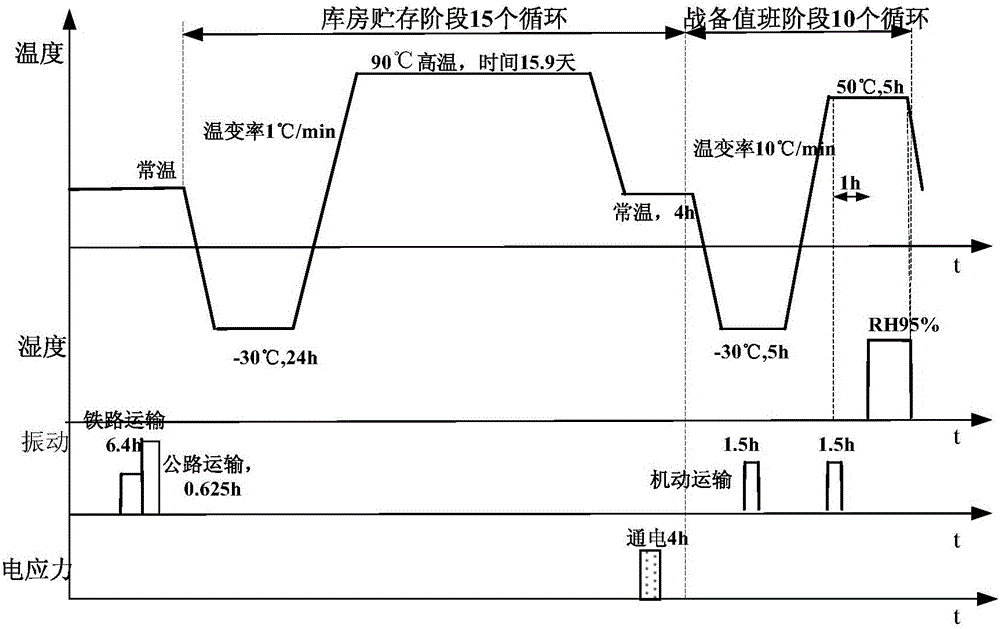

[0094] Below in conjunction with Embodiment 1, the receiver product on a certain vehicle is taken as the product to be tested, which belongs to the intelligent instrument product in the control system, and the present invention will be further described in detail.

[0095] Step 1. Determine the test conditions and time of the pick-up and transportation stage

[0096] The pick-up and transportation stage of this product includes railway transportation and road transportation. The cumulative transportation distance of one railway transportation is 8000km, so according to the formula (1), the test time is 6.4h, the temperature environment is normal temperature environment, the product is placed in the packing box, and the packing box fixed on a vibrating table. The test conditions are shown in the table below:

[0097] Table 3. Vibration stress conditions of a receiver railway transportation

[0098]

[0099] The accumulative transportation distance of one road transportatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com