Storage battery serial bus apparatus and charge and discharge control method

A bus device and storage battery technology, which is applied in the direction of secondary battery charging/discharging, battery circuit devices, circuit devices, etc., can solve the problems of increased vulcanization of battery plates, poor charging recovery ability, and reduced battery capacity, so as to prevent over-discharge phenomenon , Put an end to the problem of overcharging and avoid the effect of charging dissatisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

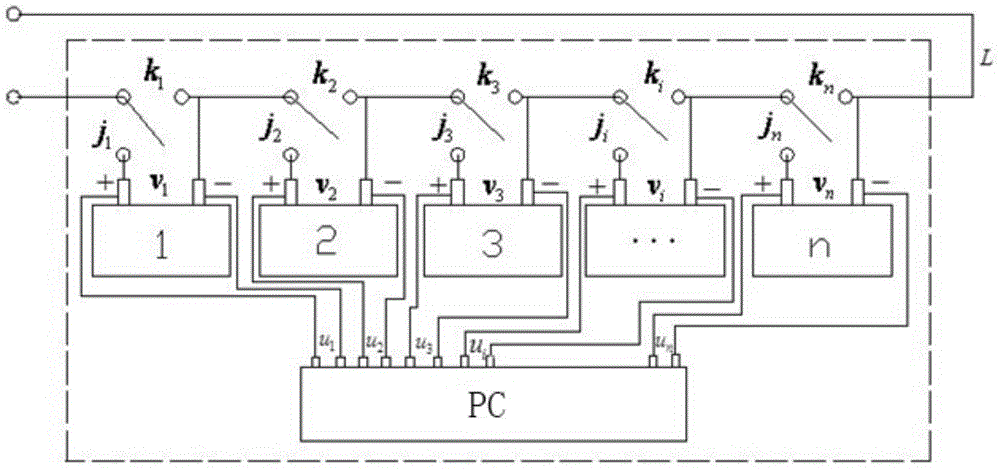

[0015] Such as figure 1 Shown: the present invention includes serial bus L, battery cell 1, 2,,,, n, battery cell cut-off switch knk 1 、k 2 ,,,, k n , single battery input switch j 1 , j 2 ,,,,j n , monomer voltage detection point u 1 , u 2 ,,,, u n And computer PC, battery cell n, battery cell cutoff switch k n , single battery input switch j n , monomer voltage detection point u n Both are multiple, multiple battery cut-off switches k n They are all connected in series on the series bus L, and the two ends of each single battery n correspond to each single battery cut-off switch k n Connected in parallel, each single battery input switch j n Correspondingly connected in series between the positive pole of the battery cell and the series bus, each cell voltage detection point u n Both are connected between the two ends of the single storage battery and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com