Ultrathin luminous logo used for flat panel television and production method thereof

A flat-panel TV and a technology of a production method, which are applied to parts of color TVs, parts of TV systems, TVs, etc., can solve problems such as uneven lighting and thick luminous logos, achieve uniform lighting, omit assembly processes, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with the accompanying drawings.

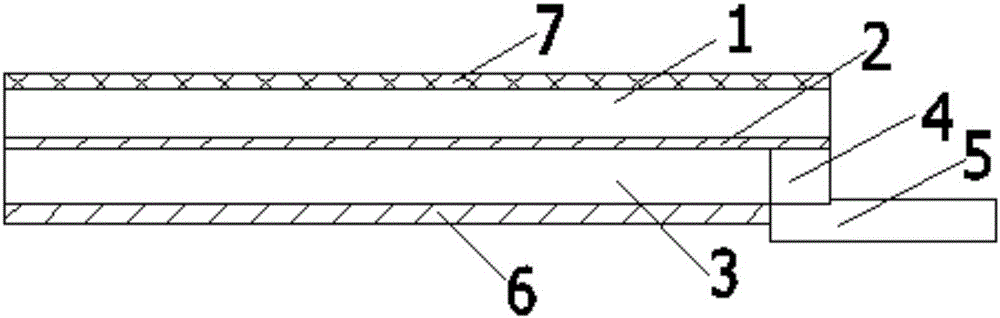

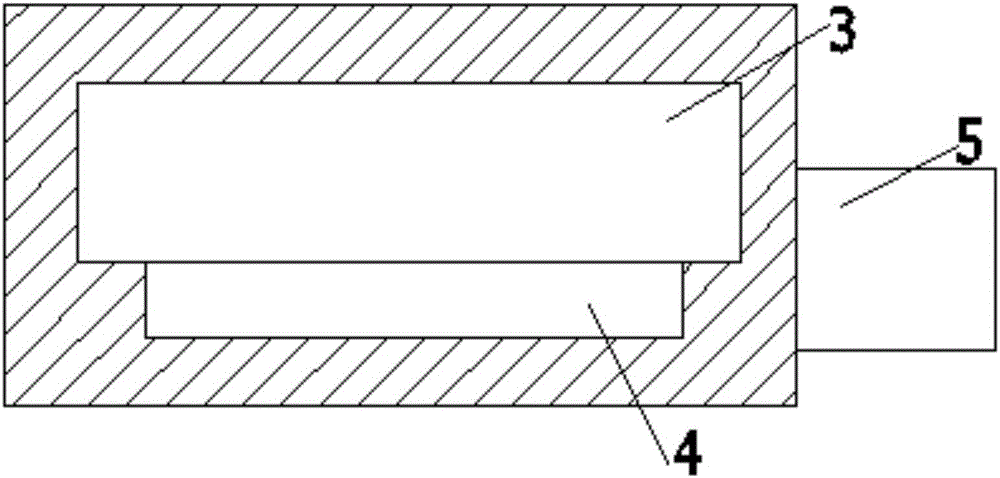

[0035] Such as figure 1 and figure 2 An ultra-thin luminescent logo used in a flat-panel TV is shown, which is mainly composed of a translucent or transparent logo layer 1, a transparent adhesive layer 2 and a backlight source, and the translucent or transparent logo layer 1 passes through the transparent adhesive layer 2 Fitted and installed on the surface of the backlight, the backlight includes a light guide plate 3, an LED lamp 4 and a PCB board 5, the LED lamp 4 is installed on the PCB board 5, and the LED lamp 4 is in contact with one end surface of the light guide plate 3 , and the end face is the light incident surface, the side of the light guide plate 3 close to the transparent adhesive layer 2 is a light guide surface, and the other side is a smooth surface, the light guide surface is perpendicular to the light incident surface, and on the There are seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com