Roller for transporting hollow filaments, manufacturing method for hollow filaments, and manufacturing method and manufacturing device for hollow filament membrane sheets

A manufacturing device and technology for thread-like objects, which are applied in the field of manufacturing hollow thread-like objects, and can solve problems such as difficulty in setting an elastic adjustment roller and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0384] Hereinafter, although an Example demonstrates concretely, this invention is not limited to this.

[0385] [Example]

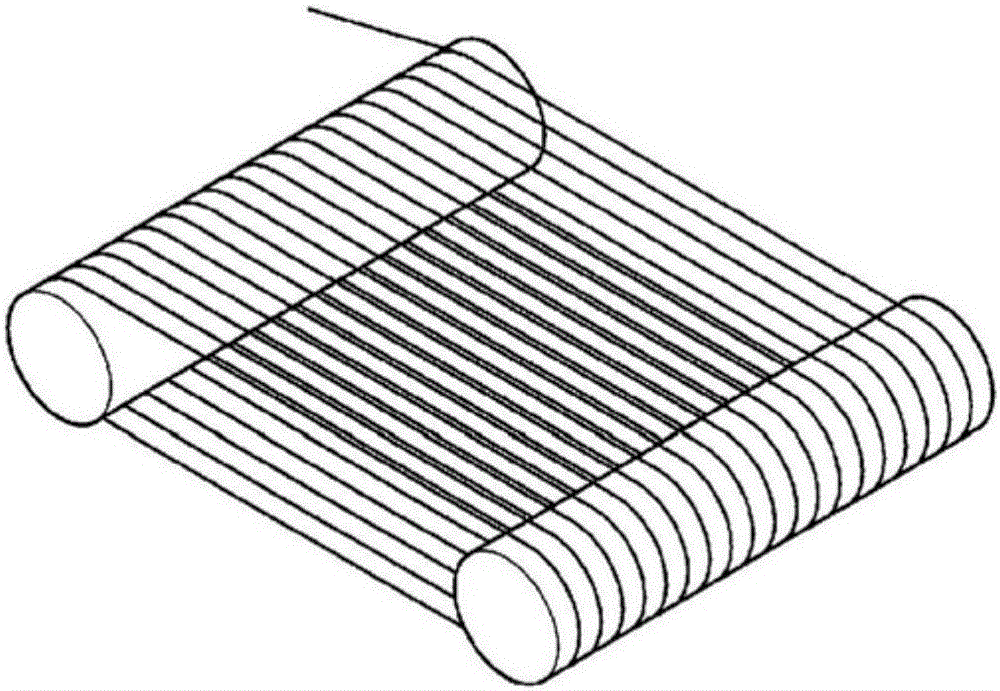

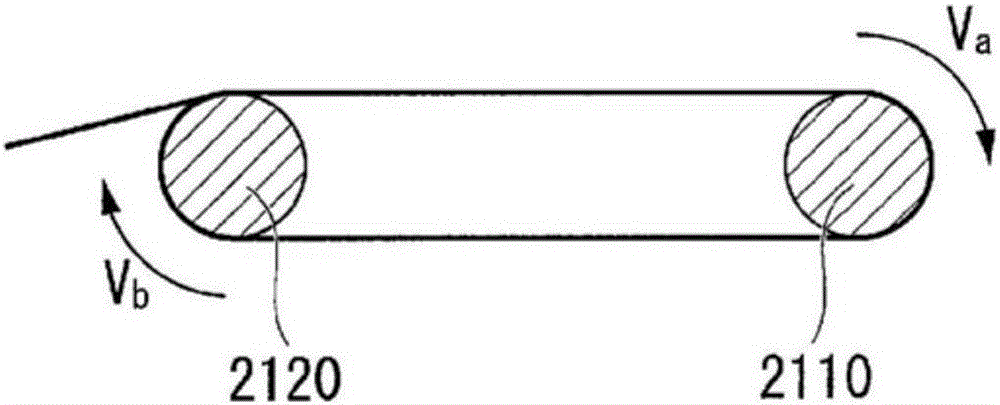

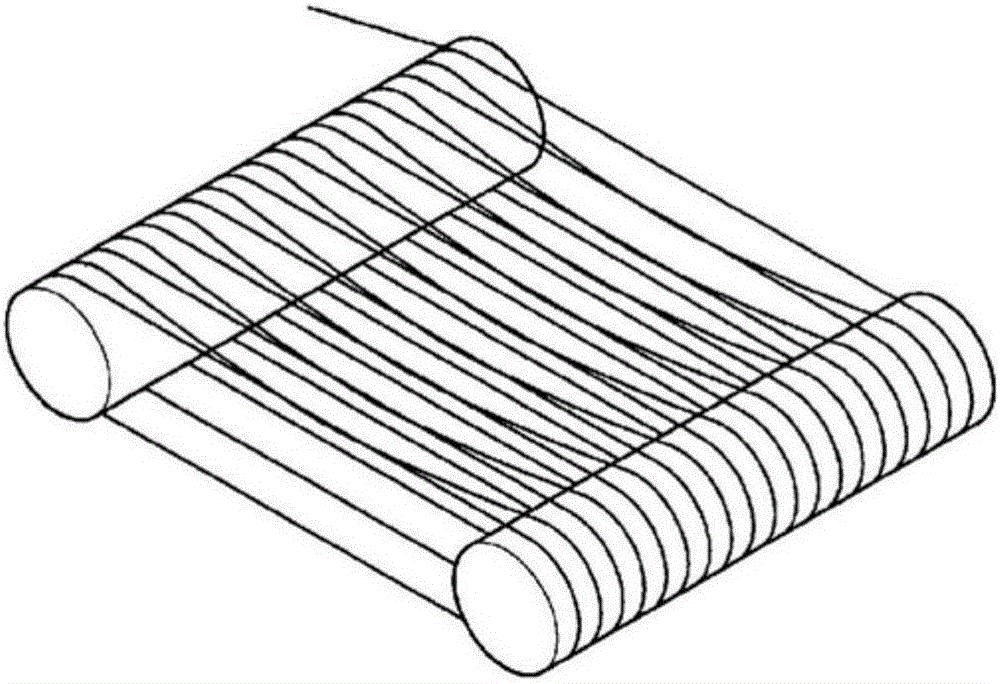

[0386] In roll (diameter 160×effective width 640mm, material: PVC) After forming 200 parallel grooves with a groove pitch of 3.2mm, a groove height of 1.3mm, and groove R1.5 on the surface, set eight positions at equal intervals in the circumferential direction from the top of the groove 3mm deep depression (width 10mm), fit a flexible part (INOAC EPDM series rubber sponge E-4188, width: 10mm x height: 5mm x length: 600mm) into the depression and fix it with double-sided tape, ready Such two sets of rolls are used as the first roll and the second roll.

[0387] A bobbin wound with a hollow fiber membrane with an outer diameter of 2.8mm (type: ADF2800CA-1 (material: PVDF), manufactured by Mitsubishi Rayon Corporation) was set on the bobbin unwinding device, and the bobbin was wound around the first roller and In the state where the top end of the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com