Special steel coil transport bracket capable of being used in ISO container

A container and bracket technology, applied in the field of steel coil brackets, can solve the problems of not being able to transport other types of goods and rising transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further illustrate the features and advantages of this patent, a further description will be made below in conjunction with the accompanying drawings.

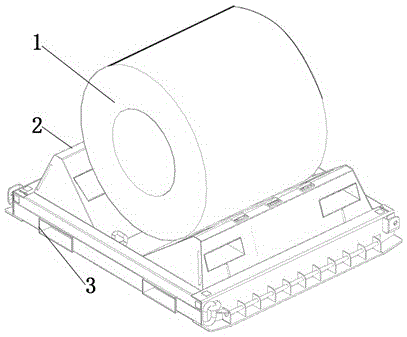

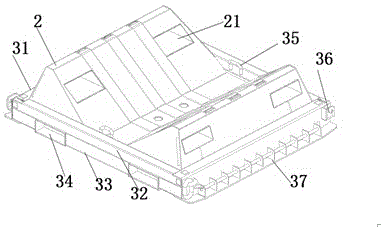

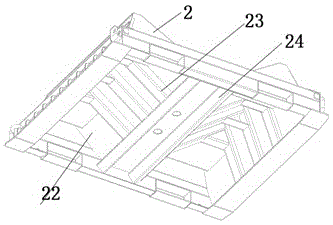

[0016] As shown in the figure, a special bracket 2 for steel coil transportation that can be used in an ISO container is composed of a bottom frame 3 and a bracket 2. The bottom frame 3 is square and made of steel profiles. The bottom The longitudinal length of the frame 3 is greater than the length of the steel coil 1; the bottom of the bottom frame 3 is longitudinally provided with a lower forklift groove 34; the bottom frame 3 is composed of two trapezoidal support seats; the two trapezoidal support seats are embedded On the bracket 2, it is horizontally fixed on both sides of the bracket 2 to form a V-shaped bracket 2, and the distance between the trapezoidal support seats is adapted to the width of the steel coil; the support seats are hollow The support seat, the bottom hollow position of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com