Electric actuator current control responsive to temperature

一种执行器、电流限制的技术,应用在电气控制、发动机控制、燃料喷射控制等方向,能够解决升压控制退化、马达温度准确性降低、升压降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

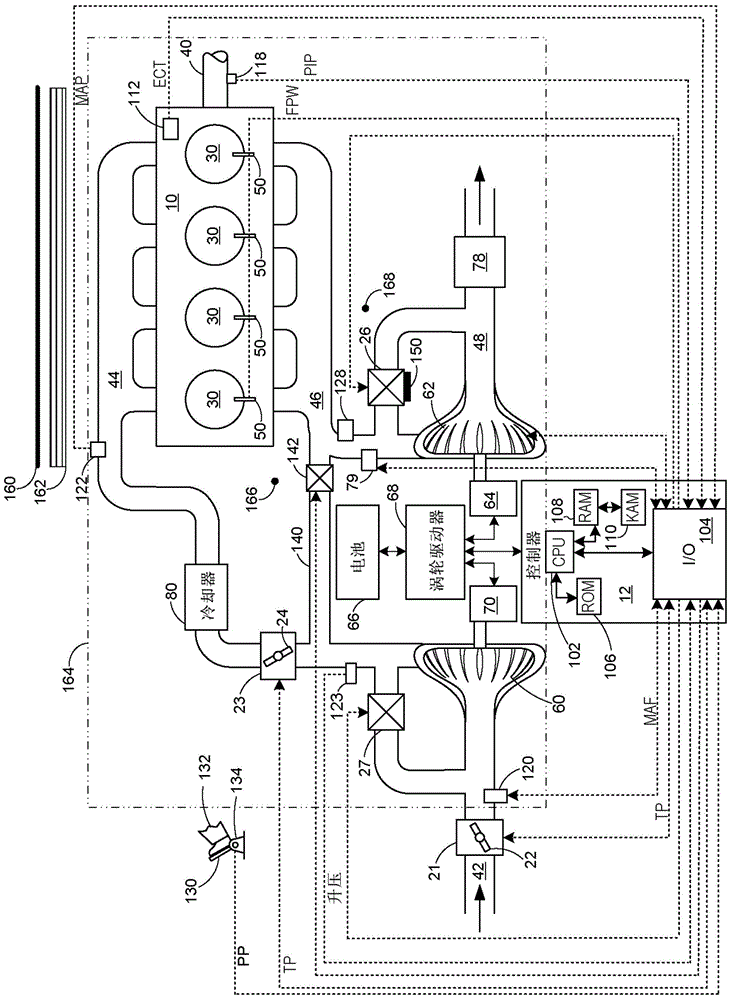

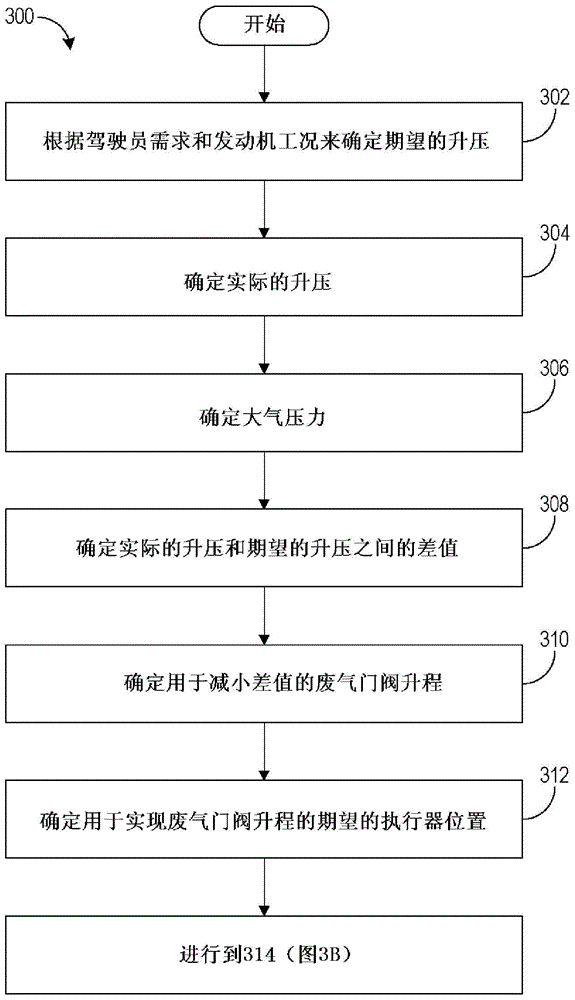

[0019] As mentioned above, some internal combustion engines may use compression devices such as turbochargers to increase airflow into the engine, and thus increase torque / power output. The pressure delivered to the intake manifold (hereinafter "boost" or "boost pressure") may be controlled by adjusting the amount of gas to the turbine of the turbocharger, eg, via a wastegate. An actuator such as an electric actuator (eg, an electric motor) may be operably coupled to the valve of the wastegate and actuated to position the wastegate at any position between a fully open position and a fully closed position based on operating conditions, to achieve the desired boost.

[0020] Under certain conditions, such as during conditions when maximum boost is continuously requested and the wastegate valve is maintained in a position with high holding force, the electric actuator may experience high temperatures due to high adjacent exhaust gas temperatures and continuous application of curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com