radial multistage turbine engine

A turbine engine and turbine technology, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of difficult manufacturing, poor low-speed performance, and slender structure, and achieve good high-low speed performance, large jet torque, and reduced pressure. The effect of small manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

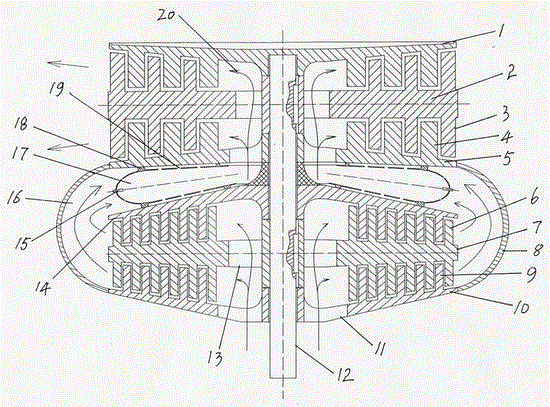

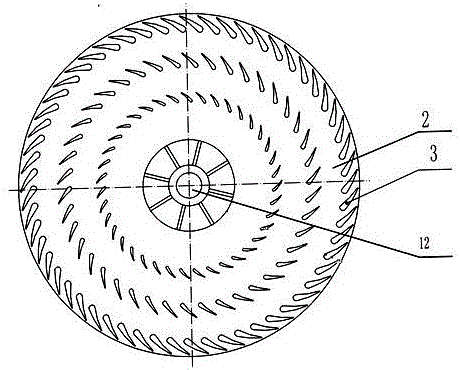

[0012] Describe embodiment in detail in conjunction with accompanying drawing, the present invention is on a main shaft 12 near the output end and is fixed with a compressor motor disk 7 with key, is provided with air intake passage 13 around main shaft on this disk, on the two disk surfaces of this disk Along the radial direction from inside to outside, there are multi-stage moving blades 6 installed step by step. On the main shaft, an outer static disk 10 of the compressor is installed in cooperation with the output end of the moving disk, and on the other side of the compressor moving disk. A compressor inner static disk 14, on the two compressor static disks are respectively provided with compressor static vanes 9 which are matched with the gaps between the compressor motor blades, and on the compressor outer static disk at the output end of the main shaft is provided with a ring diameter larger than the intake passage The air inlet 11 of the air inlet 11 is installed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com