hermetic compressor

A closed compressor and compression mechanism technology, which is applied to liquid variable volume machinery, mechanical equipment, variable volume pump components, etc., can solve the problems of high cost, high application cost, complex process, etc., and reduce the cost of metal processing. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

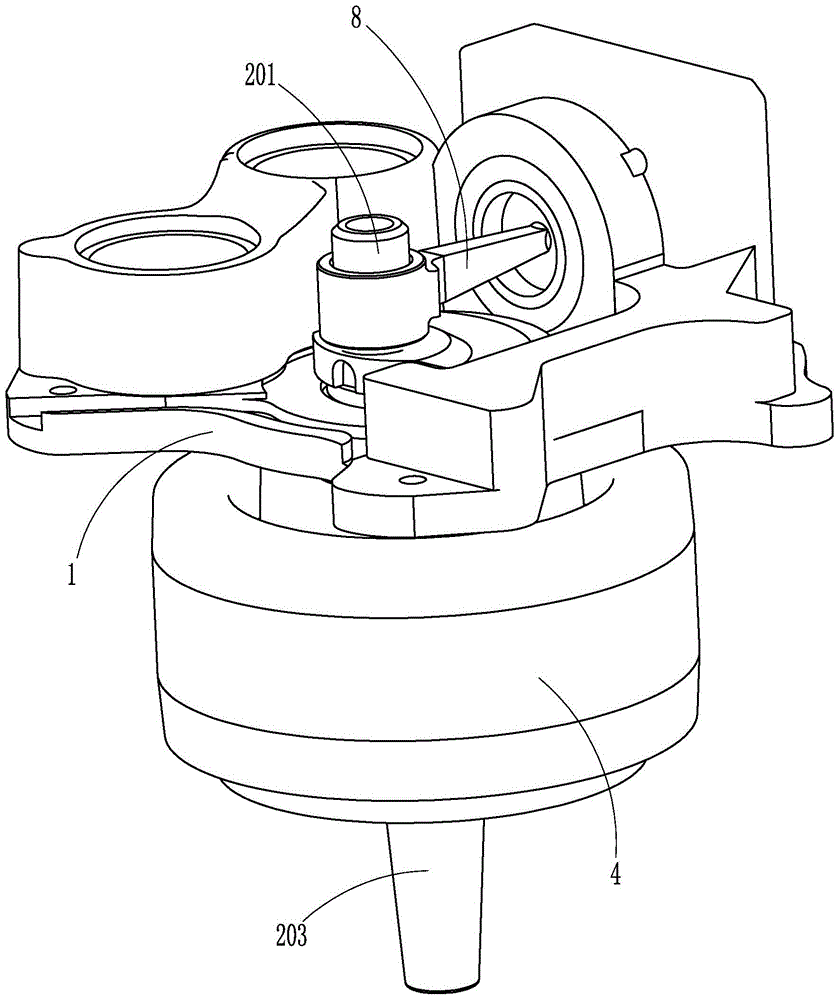

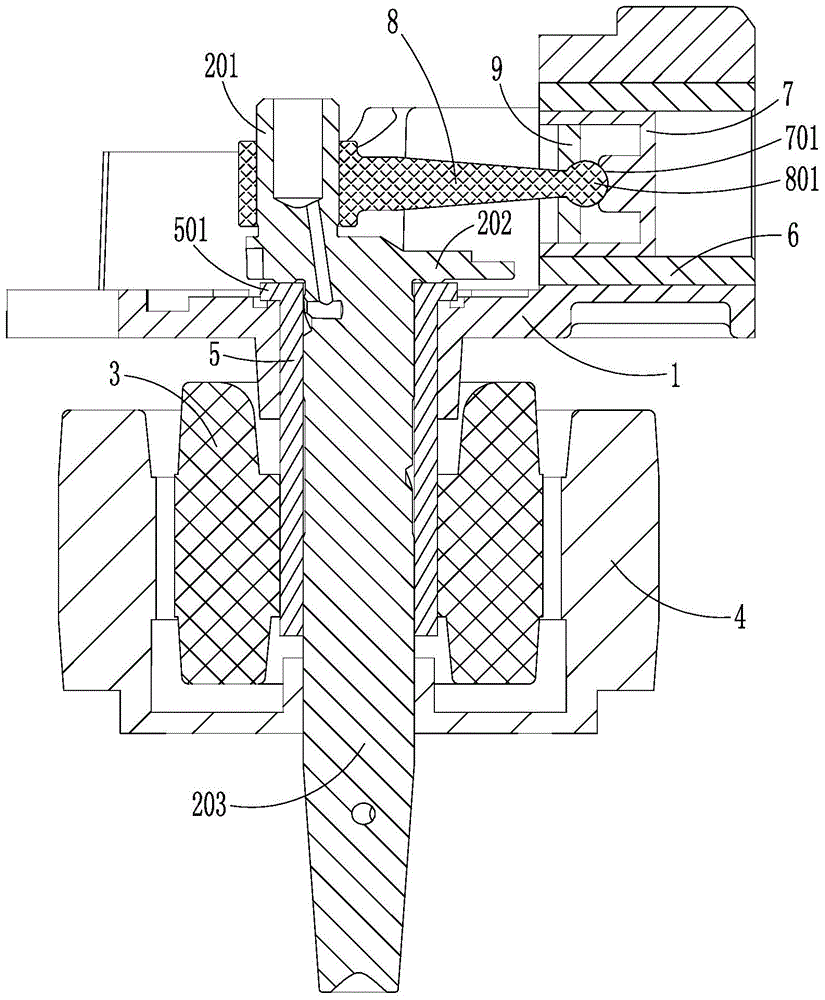

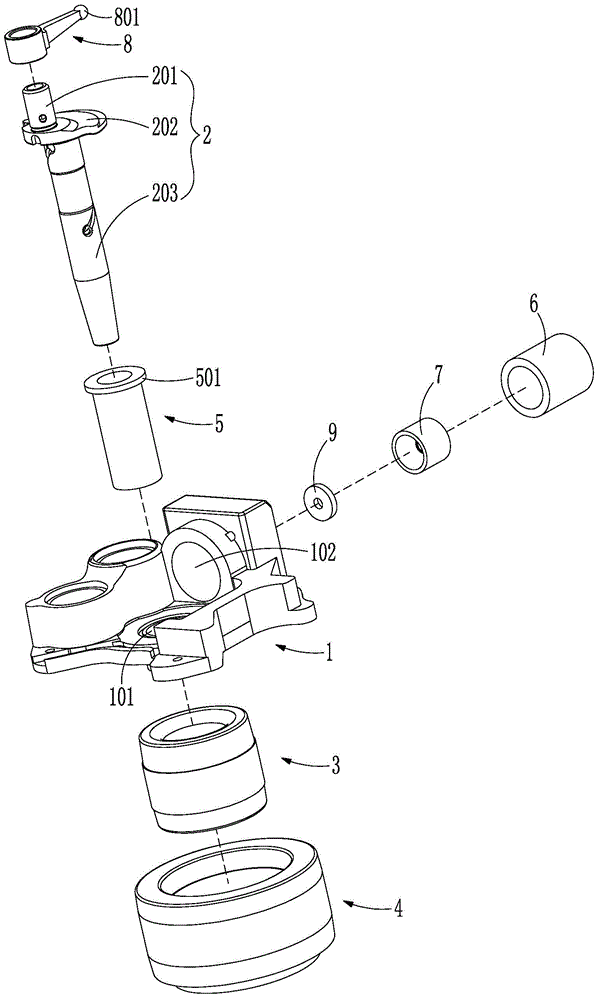

[0021] as attached figure 1 to attach image 3 As shown, the hermetic compressor of this embodiment includes a frame 1, a crankshaft 2, a piston 7 compression mechanism, a stator 3 and a rotor 4, the crankshaft 2 has an eccentric part 201, a balance part 202 and a straight shaft part 203, and the frame 1 There are a first installation position 101 and a second installation position 102 on the top, a hollow support sleeve 5 can be detachably installed in the first installation position 101, and one end of the support sleeve 5 has a flange 501 that expands circumferentially. 501 is pressed against the frame 1, the straight shaft part 203 is located in the support sleeve 5 and partially protrudes outside the support sleeve 5, part of the support sleeve 5 protrudes outside the frame 1 and the stator 3 is fixedly installed on this part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com