Repair method for burnt-red and air-leakage part of pipeline

A pipe and wind running technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of high cost, prone to burning red and running wind on the pipe wall, and long time on the pipe wall, so as to achieve reliable The effect of patching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0019] The method of repairing the place where the pipe burns red and runs out of wind, the repairing steps are as follows:

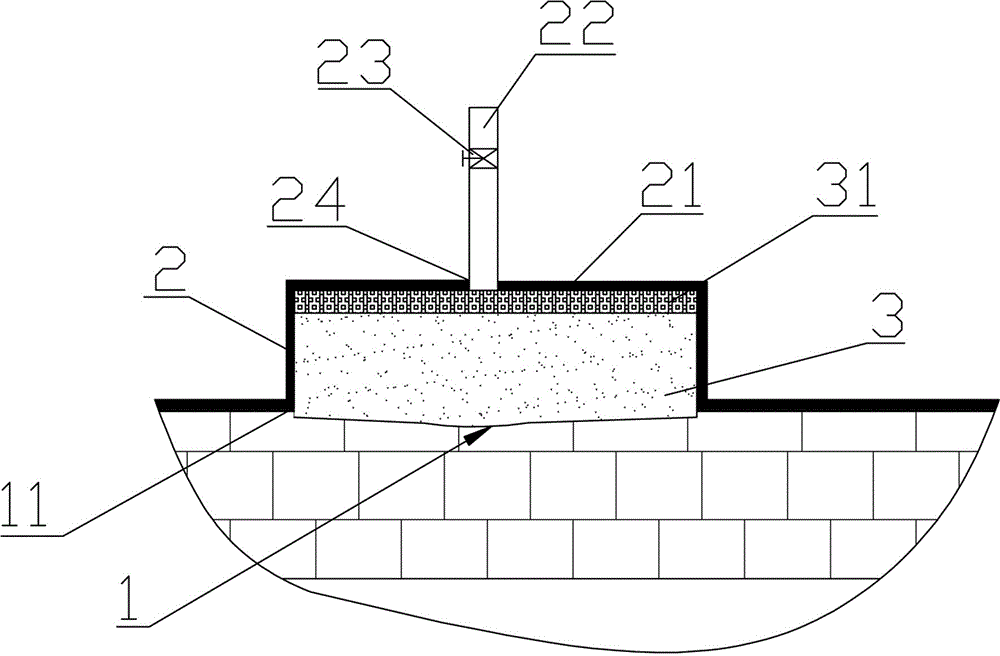

[0020] (1) if figure 1 As shown, first confirm how big the cut hole 11 will be produced after the cutter cuts off the damaged pipe wall around the hot red and windy part 1 of the pipe, and then determine the size of the metal frame 2 and the metal cover plate 21 according to the size of the cut hole 11, The metal frame 2 needs to be able to surround the cut hole 11, and the metal cover plate 21 needs to be able to close the opening of the metal frame 2. The metal cover plate 21 is also provided with an exhaust hole 24, and the exhaust hole 24 is provided with an exhaust pipe 22. A valve 23 is arranged on the exhaust pipe 22;

[0021] (2) Make the metal frame 2 and the metal cover plate 21, and then prepare the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com