A passive cooling device and system for a floating spent fuel pool in a nuclear power plant

A spent fuel pool and passive cooling technology, applied in the field of nuclear power, can solve the problems of only 72 hours of effective time, limited, individual dose increase, etc., to improve heat removal capacity, reduce radiation dose, and infinitely long time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

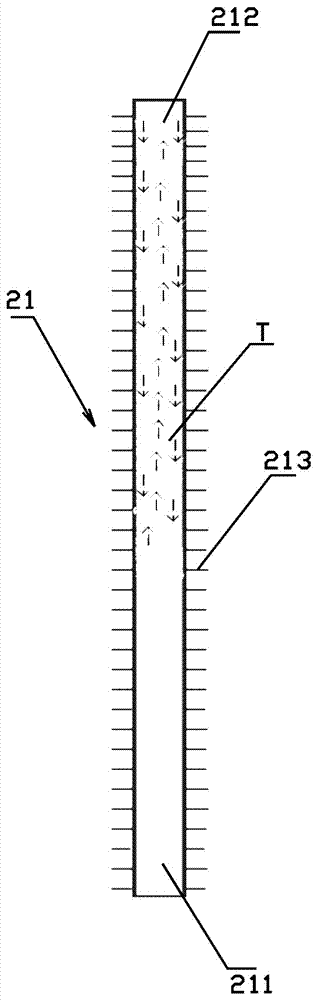

[0043] In other embodiments, the heat exchange tube assembly 2 can be stacked and assembled, that is, a large component is formed by assembling multiple groups. For example, four or eight heat exchange tube assemblies 2 can be assembled and fixed together. Such setting can further enhance the stability of the passive cooling device of the floating spent fuel pool of the nuclear power plant standing vertically on the water surface, and can also enhance its heat dissipation performance.

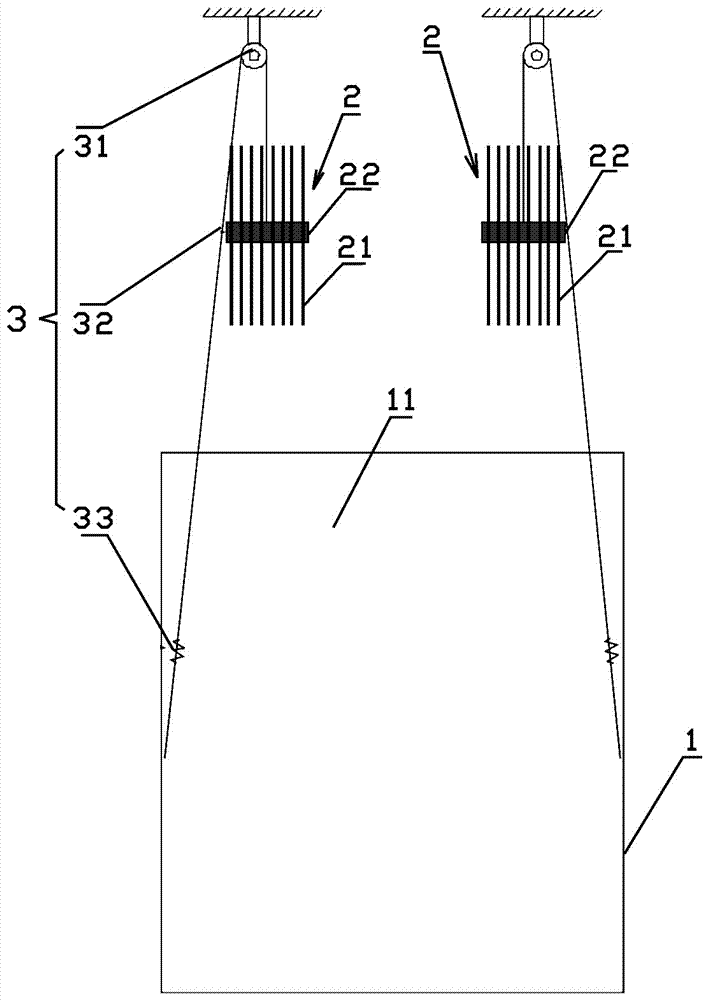

[0044] Preferably, multiple sets of heat exchange tube assemblies 2 can stand vertically on the liquid surface 11 of the spent fuel pool 1 .

[0045] It should be noted that the hollow cylindrical sealed barrel of the grid 22 can also play the following functions. When multiple sets of heat exchange tube assemblies are assembled, the cylindrical grid 22 can reduce heat exchange with adjacent heat transfer tubes. Tangent lines or points of contact between tube assemblies, thereby reducing the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com