Patents

Literature

33results about How to "Enough heat exchange area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel hydrogenation reactor for synthesis gas-to-ethylene glycol process

InactiveCN104841339AImprove conversion rateReduce the temperatureOrganic compound preparationHydroxy compound preparationNuclear engineeringHydrogenation reaction

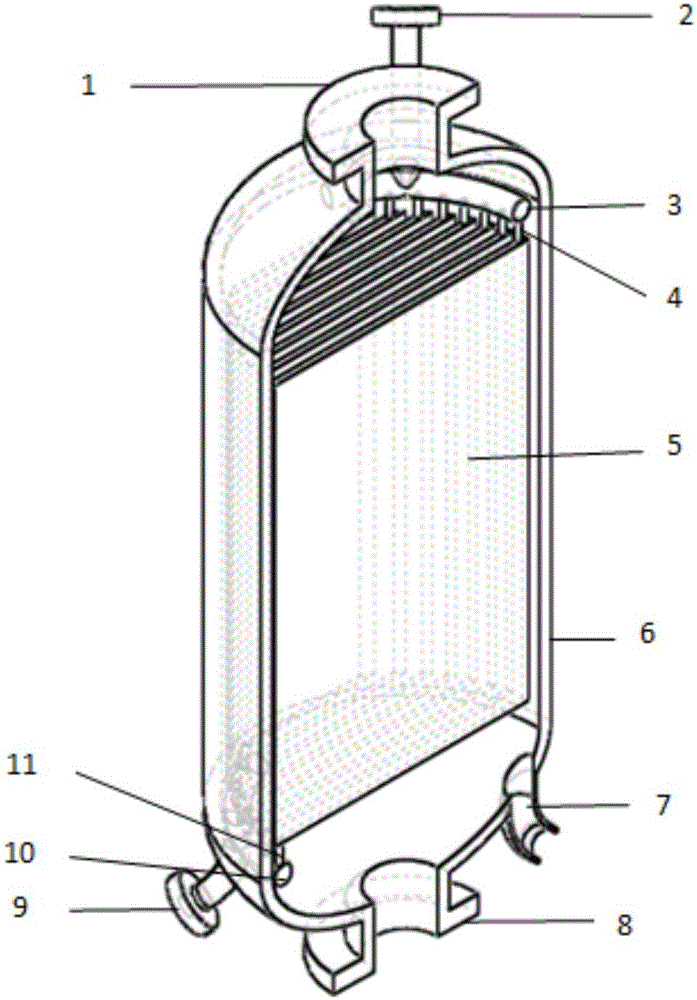

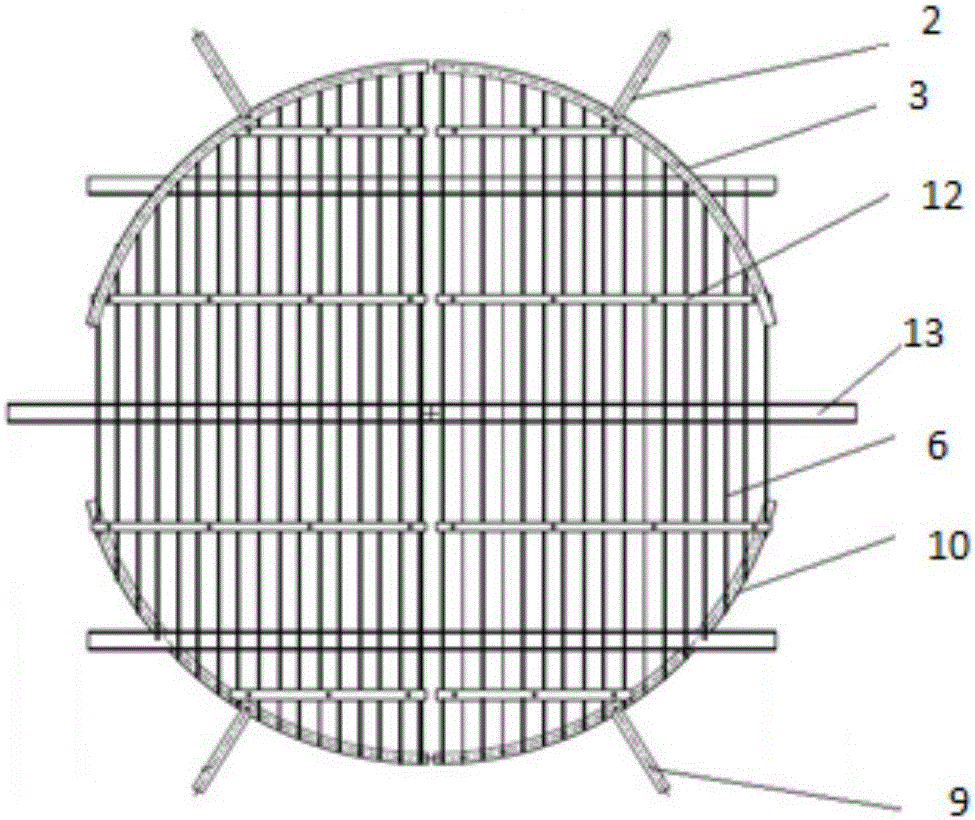

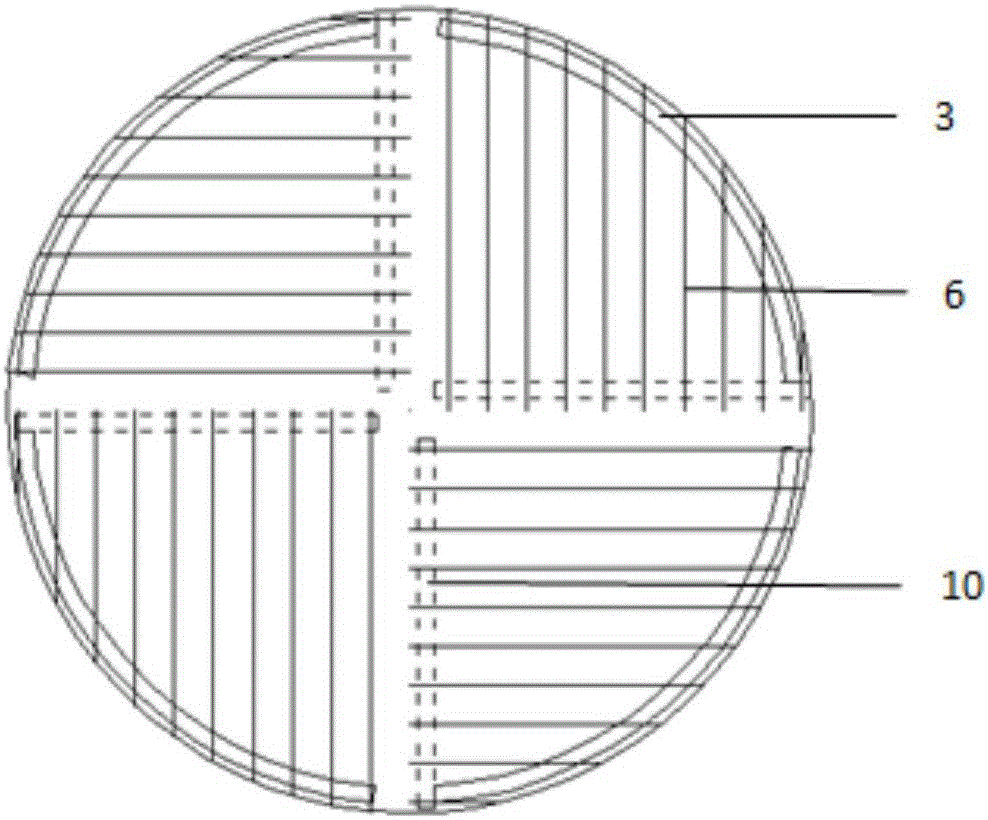

The present invention relates to a novel hydrogenation reactor for a synthesis gas-to-ethylene glycol process. The reactor comprises a reactor housing, a heat exchange plate pair beam, a cooling medium distribution total pipe, a cooling medium distribution branch pipe, a cooling medium collection total pipe, and a cooling medium collection branch pipe, wherein the bottom portion of the reactor housing is provided with a cooling medium inlet, the top portion is provided with a cooling medium outlet, one end of the heat exchange plate pair beam is connected with the cooling medium inlet of the reactor housing through the cooling medium distribution total pipe and the cooling medium distribution branch pipe, the other end is connected with the cooling medium outlet of the reactor housing through the cooling medium collection total pipe and the cooling medium collection branch pipe, the heat exchange plate pair beam comprises a plurality of heat exchange plate pairs, the plate space exists in the heat exchange plate, a catalyst is filled between the adjacent heat exchange plate pairs, the housing space exists between the adjacent heat exchange plate pairs, raw material gas comprising dimethyl oxalate and hydrogen enters the reactor, then passes through the housing space, and reacts through the catalyst catalysis to produce ethylene glycol, the cooling fluid passes through the plate space, and the heat released by the reaction is taken away. Compared with the reactor in the prior art, the reactor of the present invention has advantages of flexible structure adjustment, high heat exchange efficiency, good reaction selectivity, on site assembly, and the like.

Owner:WUHUAN ENG +2

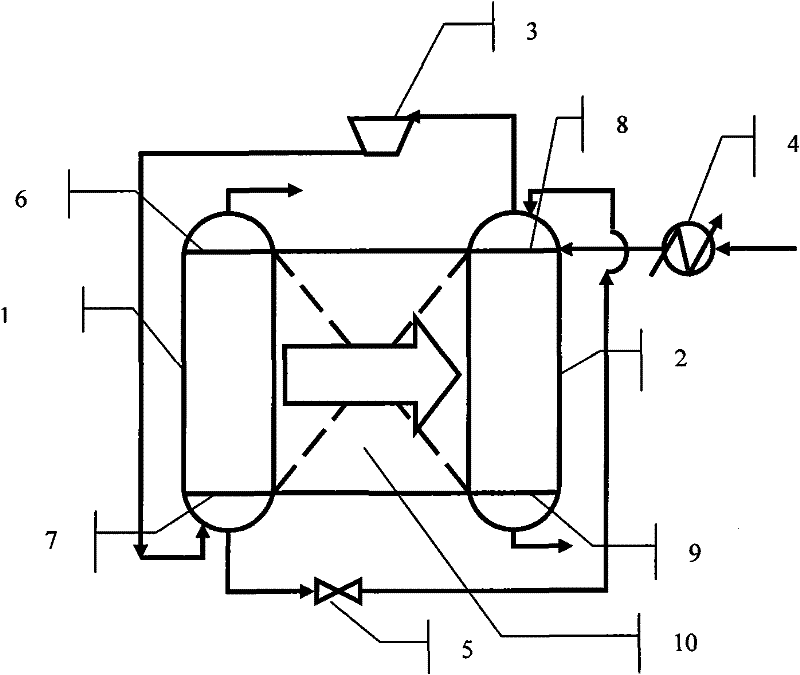

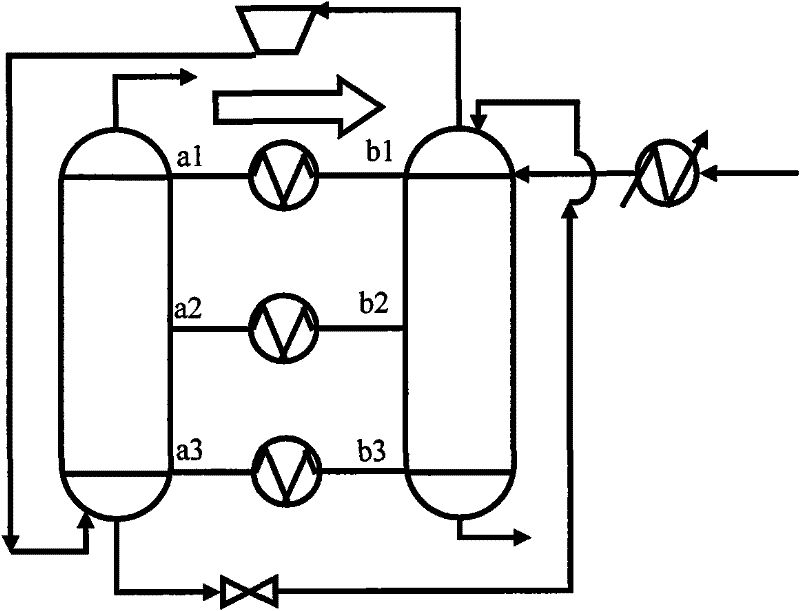

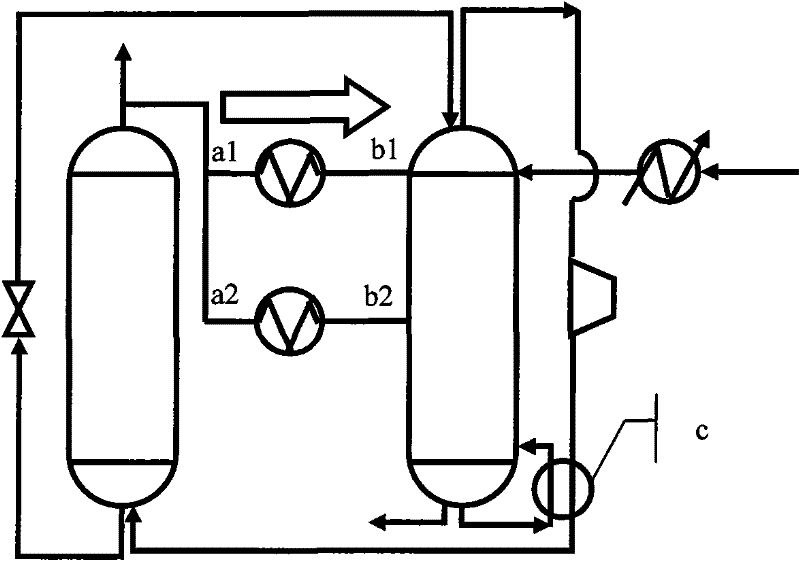

High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method

ActiveCN105036168AReduce the temperatureEfficient use ofAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesFlue gasProcess engineering

The invention relates to the technical field of non-metal novel materials and particularly provides a high-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and a novel method. In the invention, a cyclone preheater group (may comprises two stages, three stages and four stages), and a cooling apparatus are added at the tail of a hollow long kiln to cooling high-temperature-calcined materials. The cyclone preheater group is fully utilized to reduce the temperature of high-temperature flue gas at about 400 DEG C at the tail of a hollow rotary long kiln to 160-220 DEG C. Meanwhile, by means of the unique cooling apparatus, more than 60% of heat energy can be recycled. The apparatus can save fuel by more than 30% when compared with an apparatus in the prior art. The apparatus and the method fully utilize the heat energy in the tail gas of the rotary kiln, can effectively recycle the heat energy in the calcined materials, can greatly reduce the temperature of tail gas and recycle the heat energy when the product is cooled as more as possible, thereby achieving energy saving and emission reduction and laying the foundation of non-metal new material industry.

Owner:SHANDONG LUBEI ENTERPRISE GROUP +1

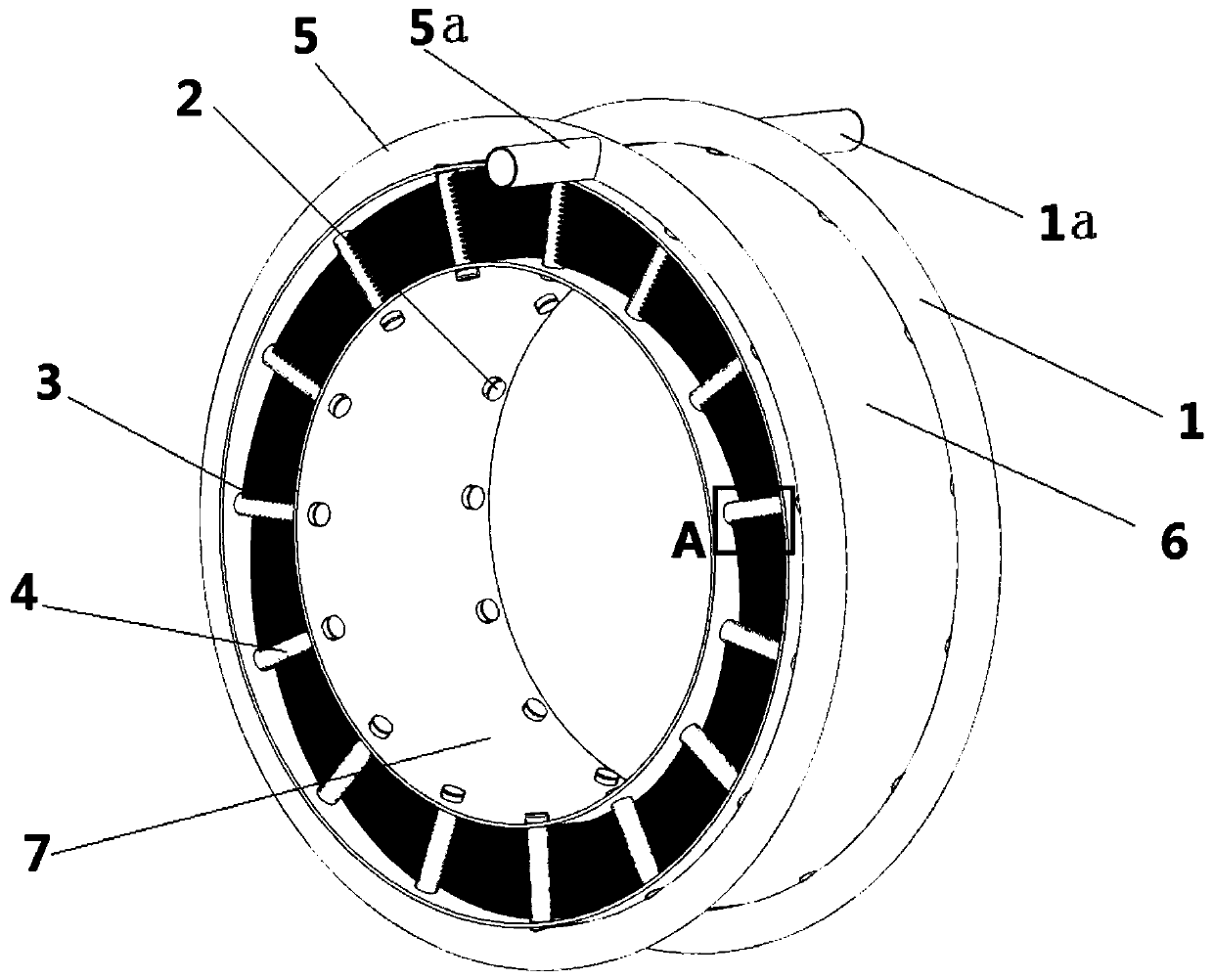

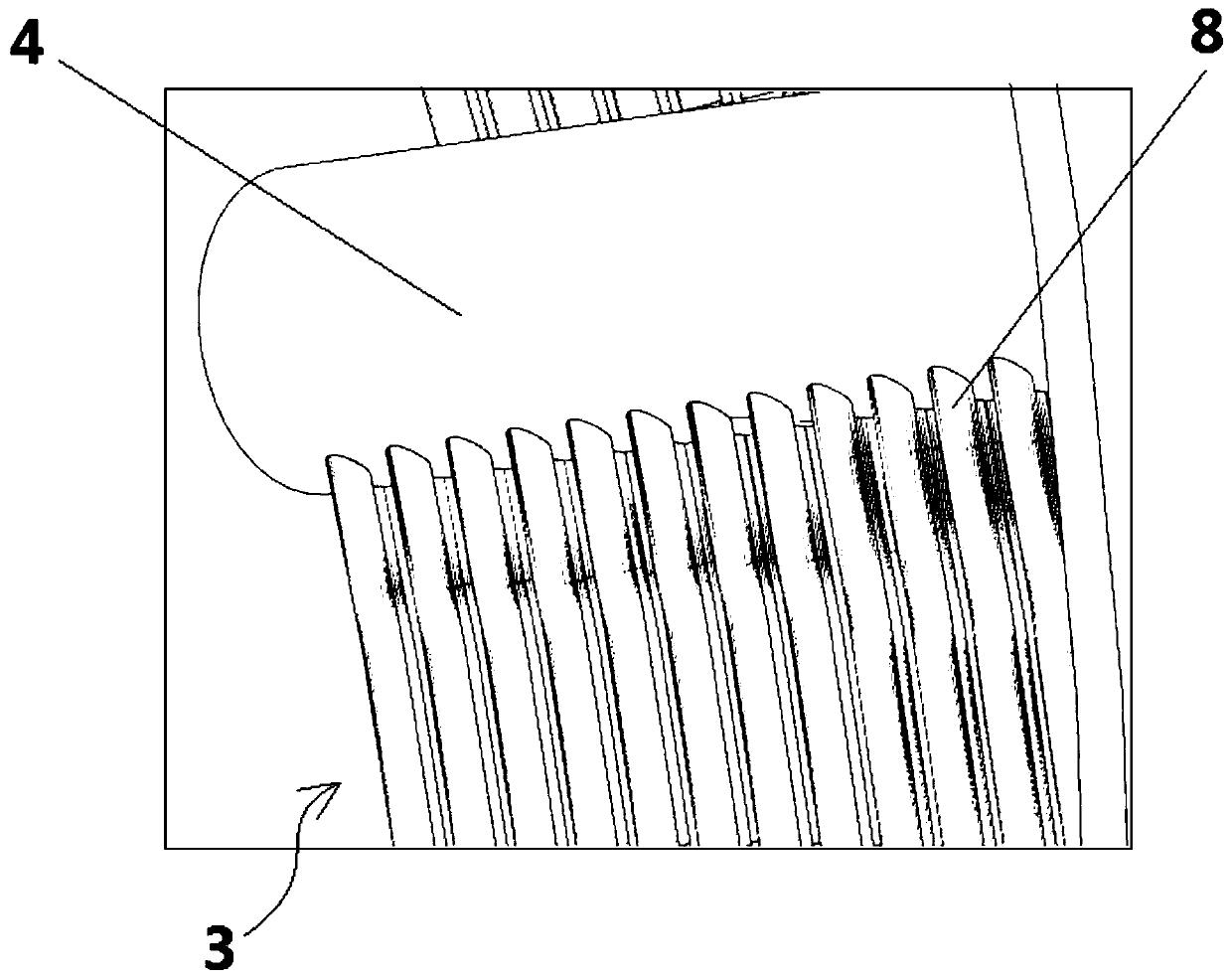

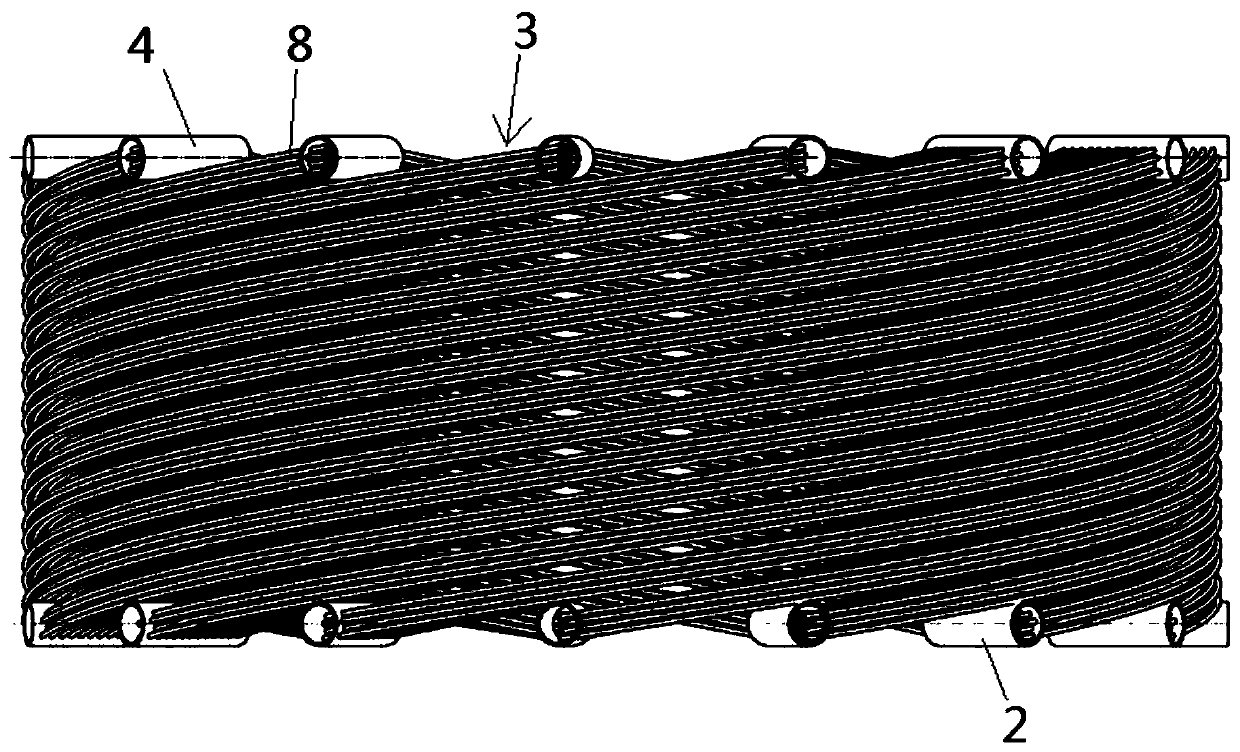

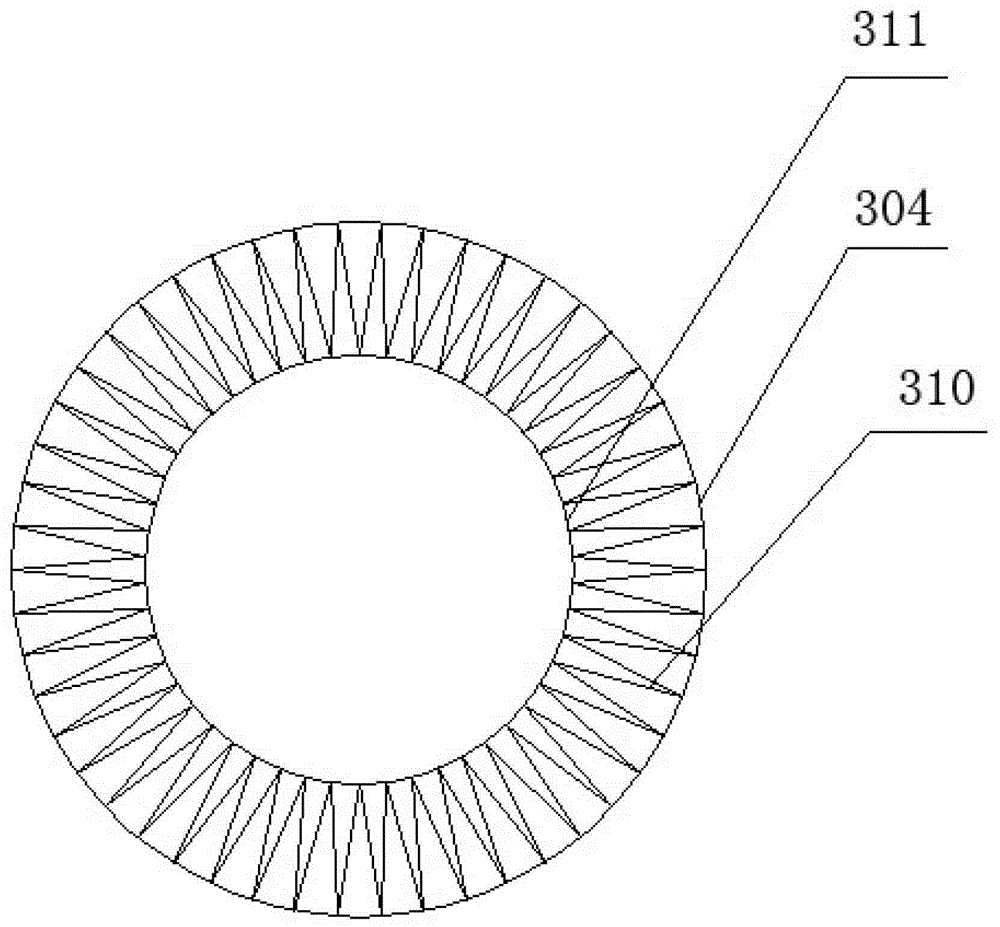

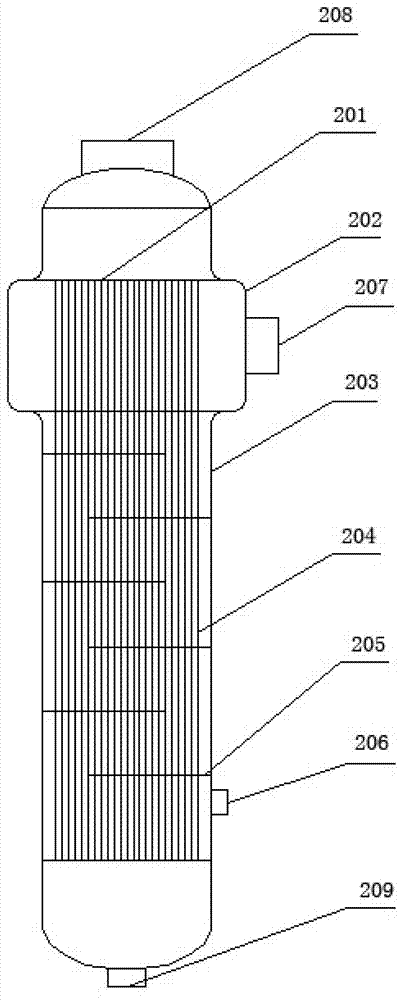

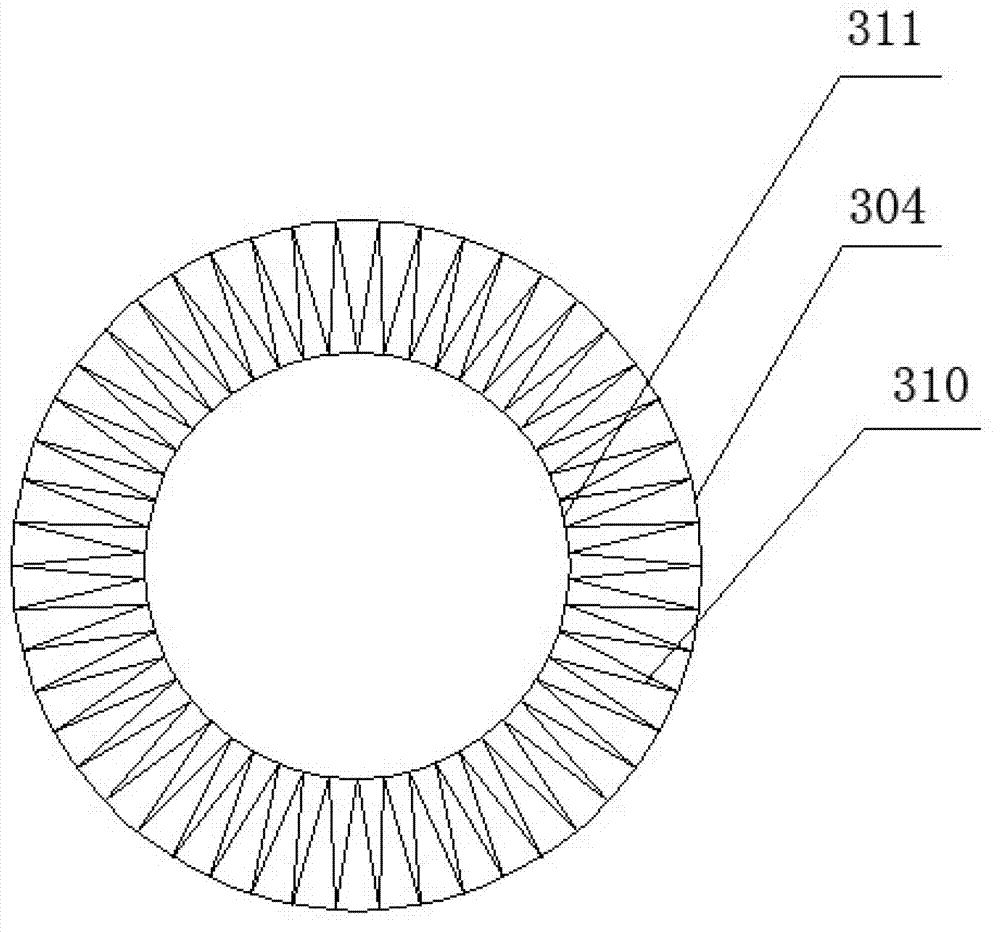

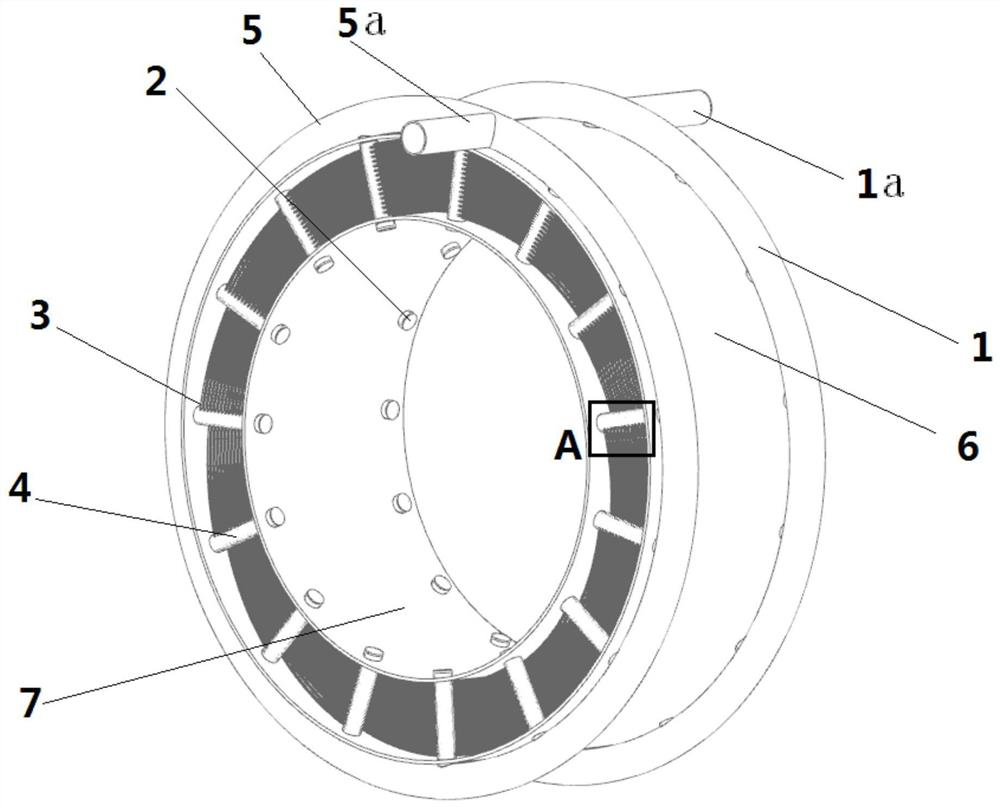

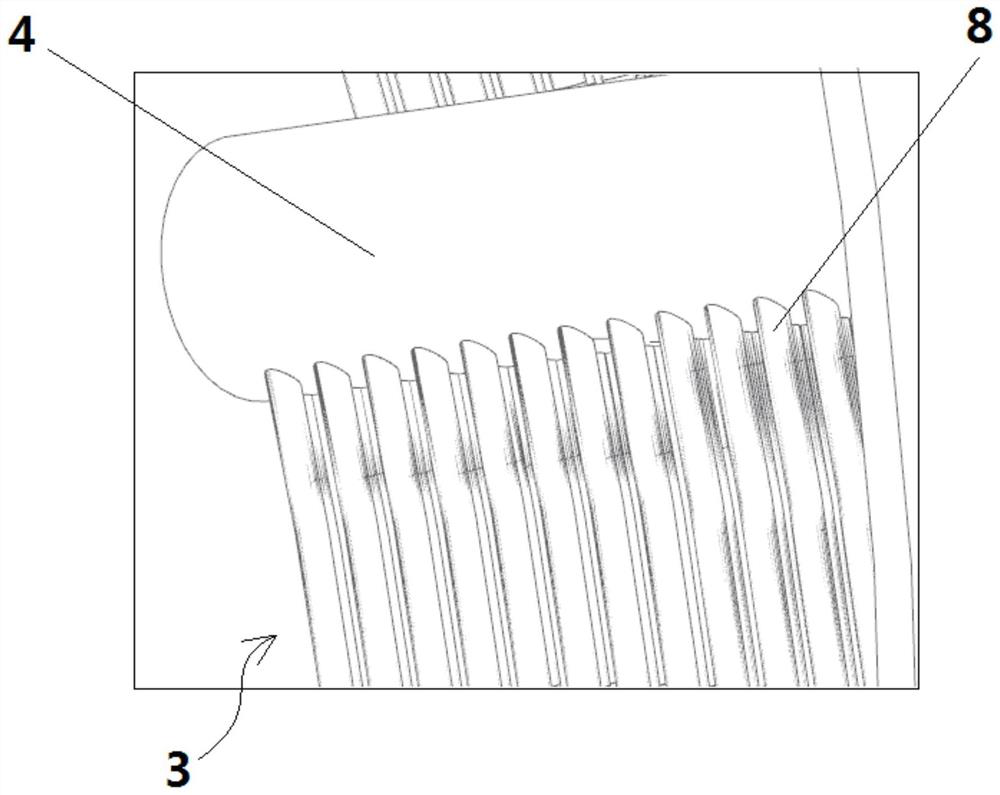

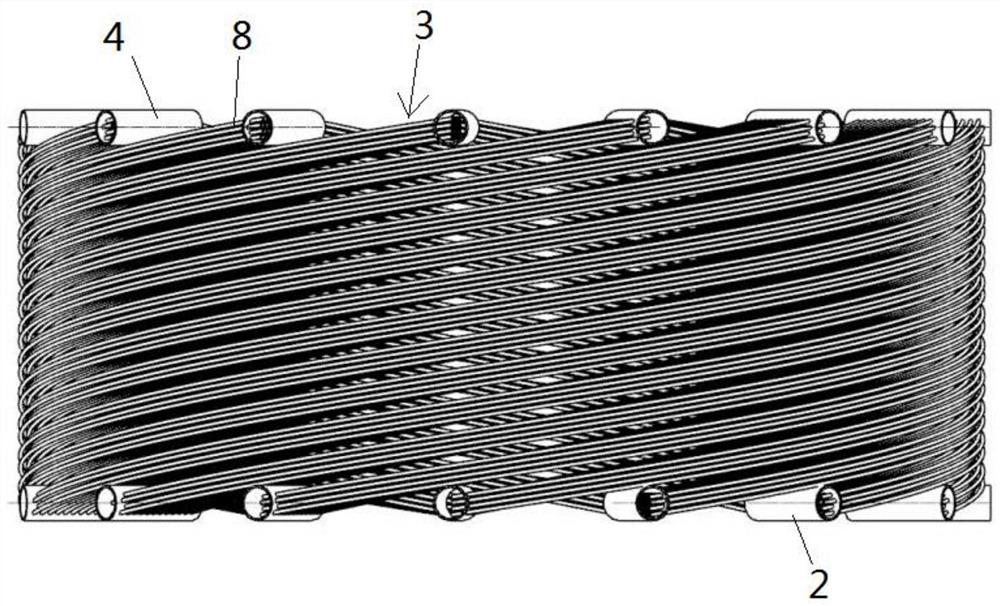

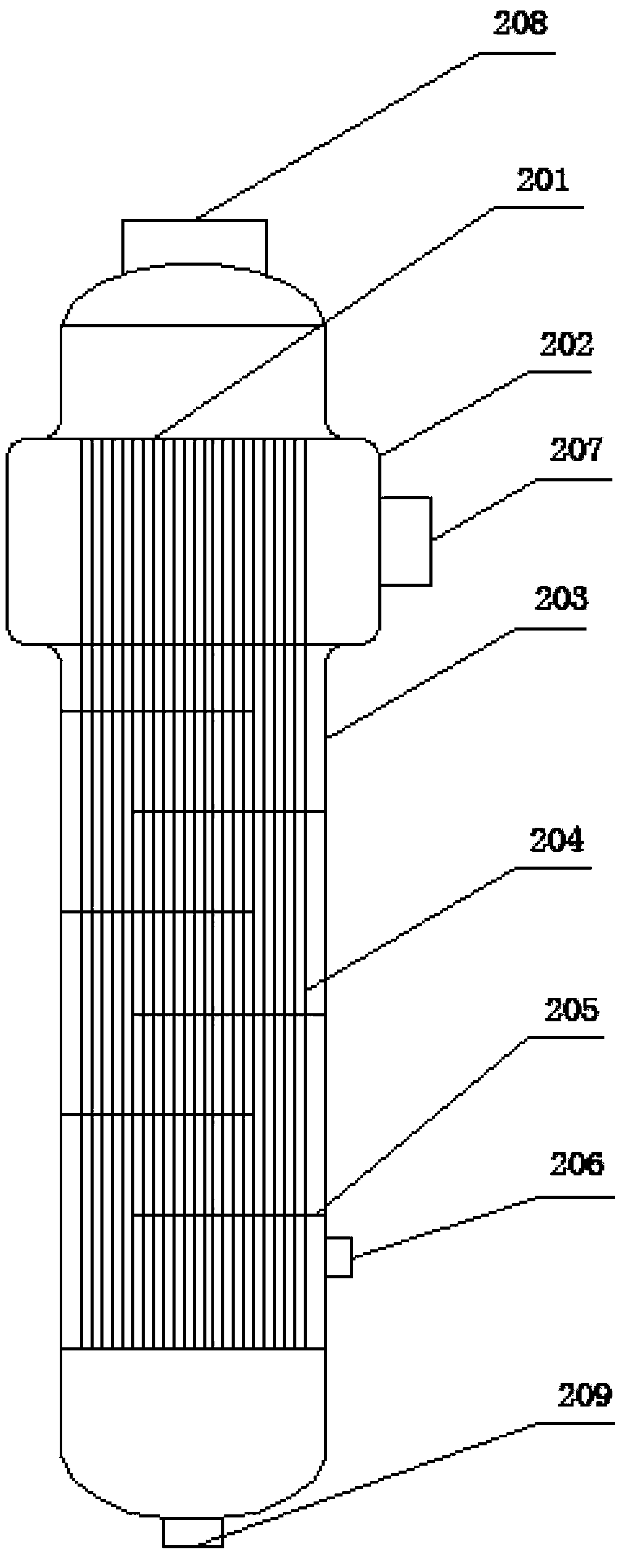

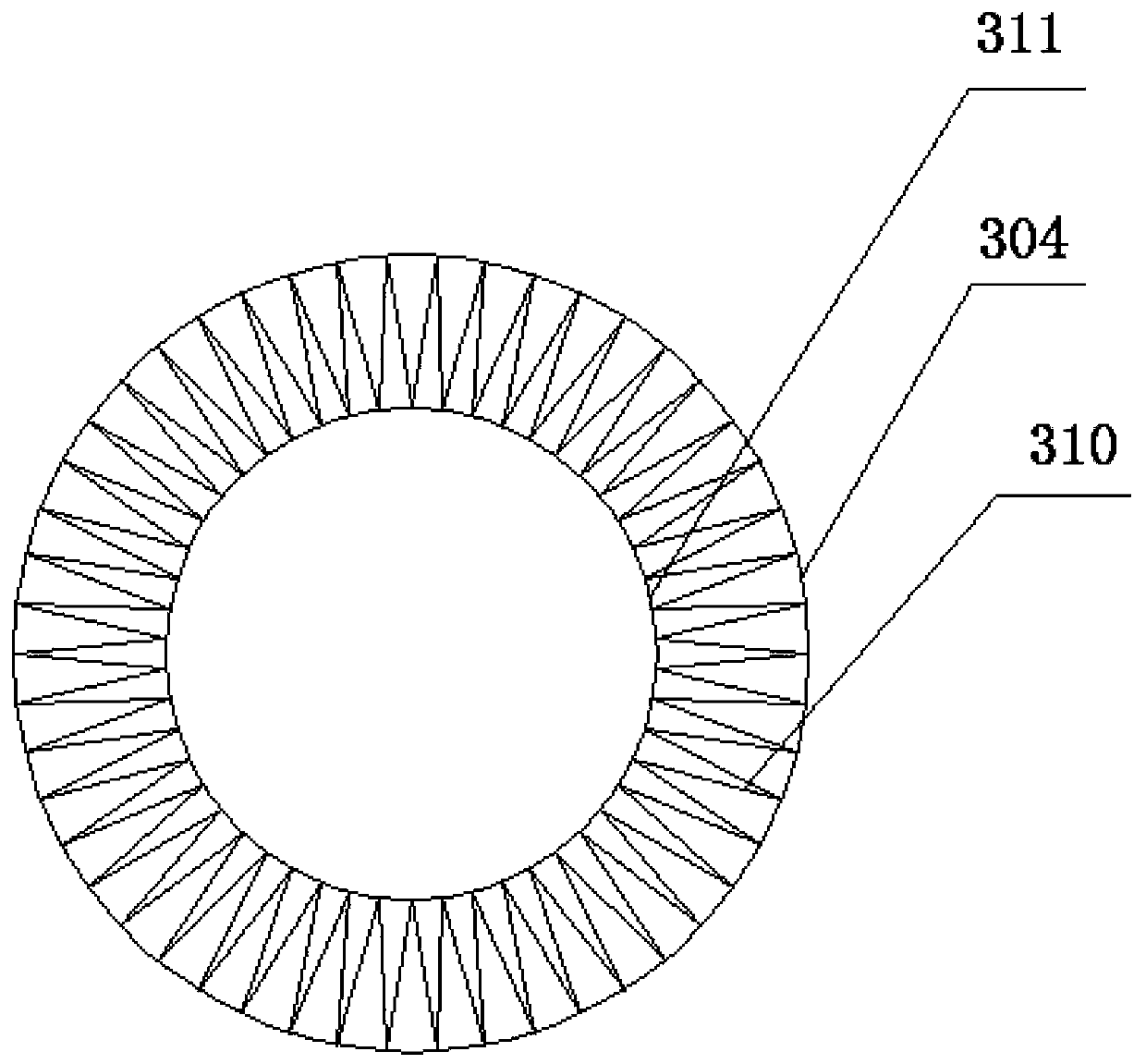

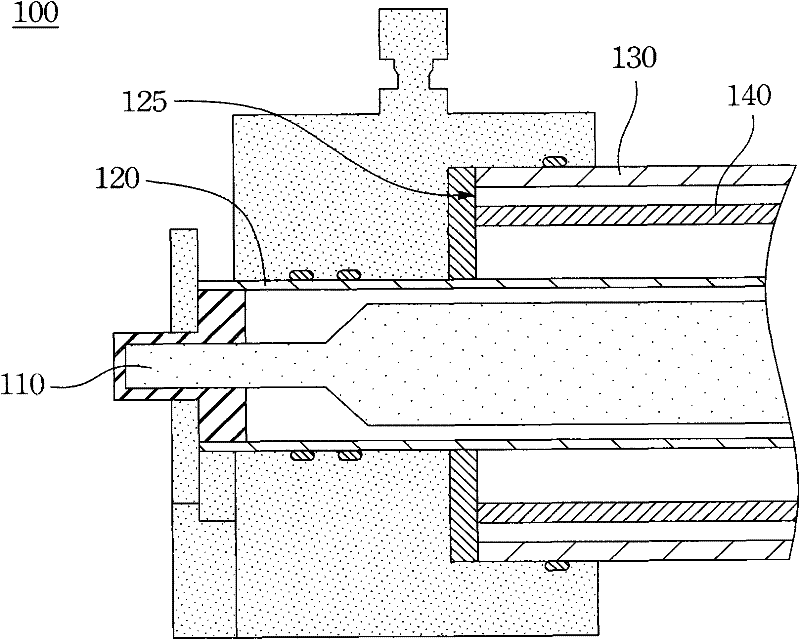

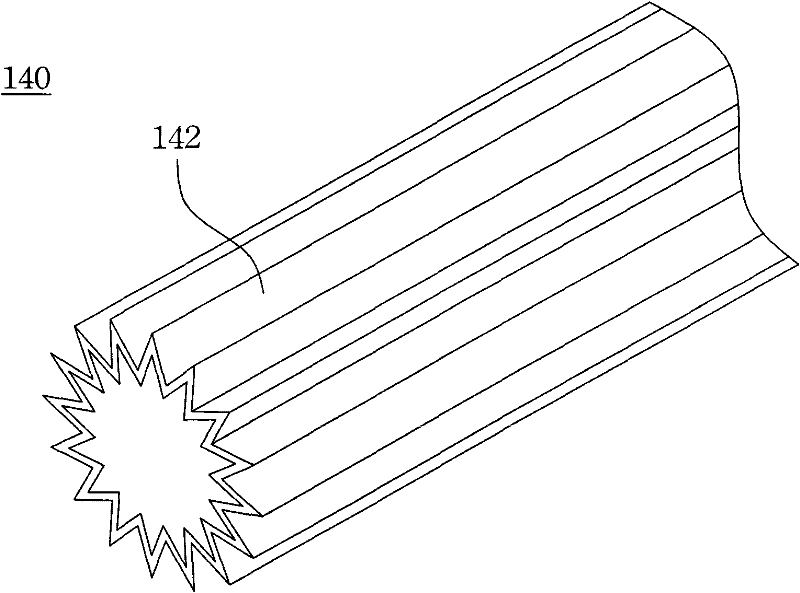

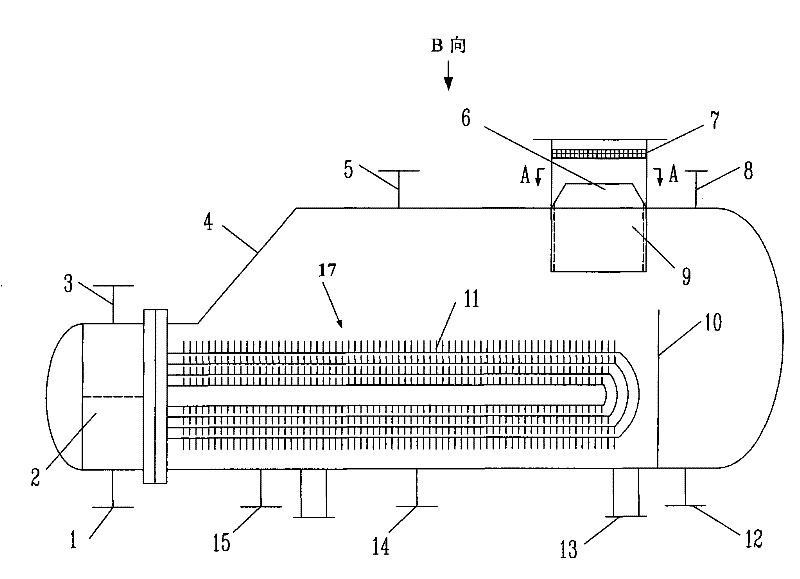

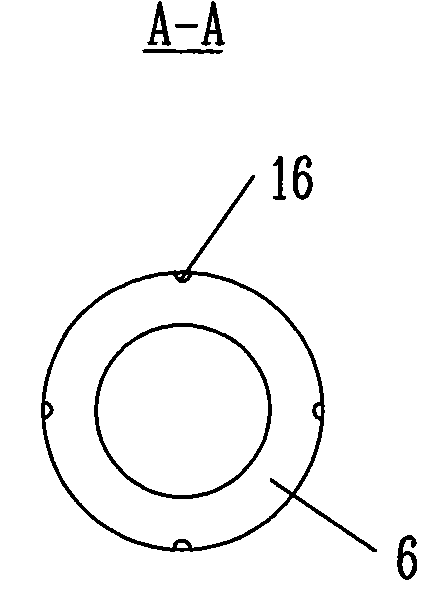

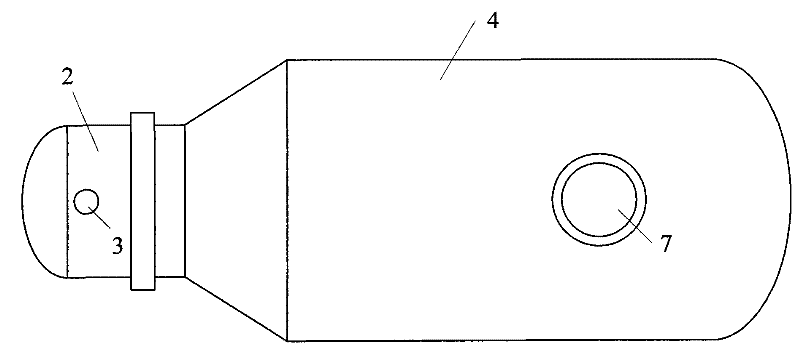

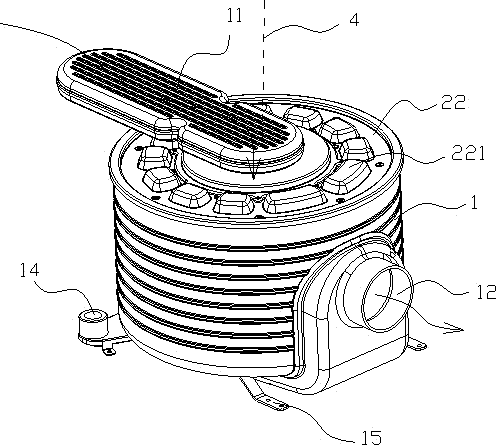

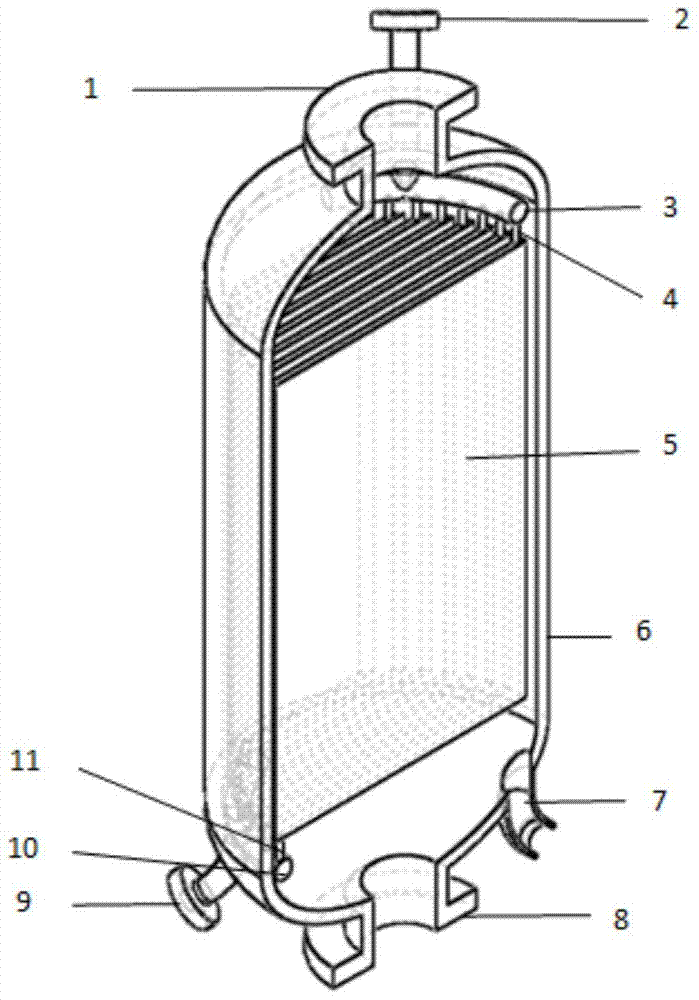

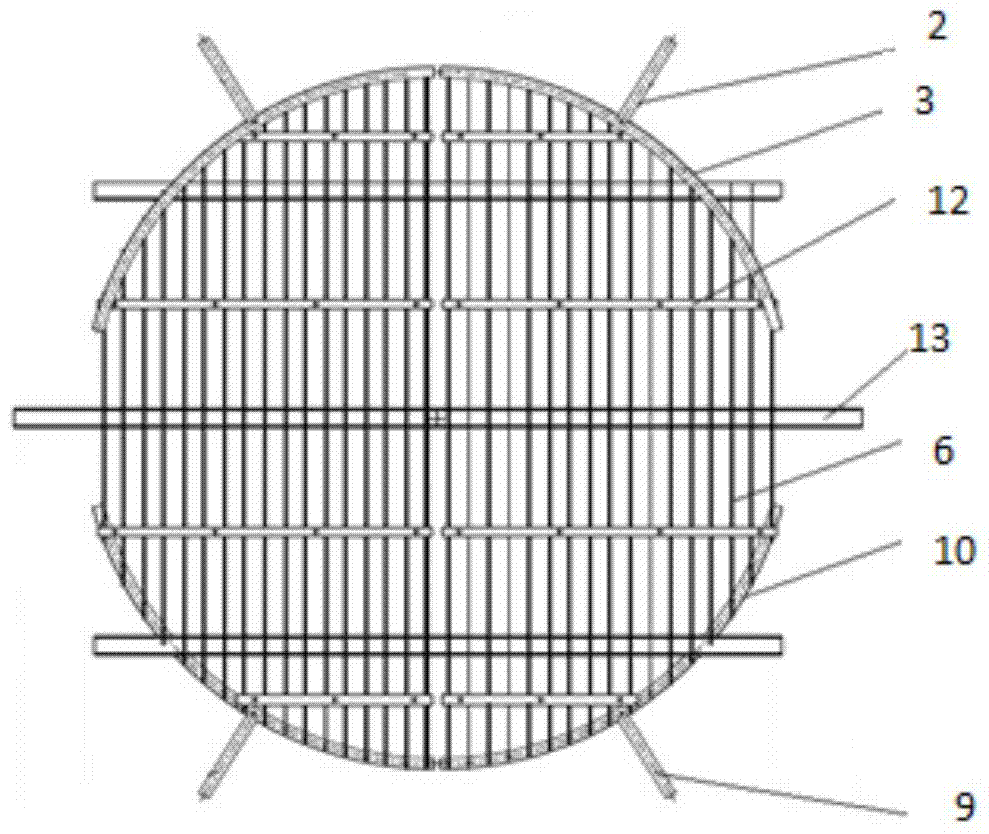

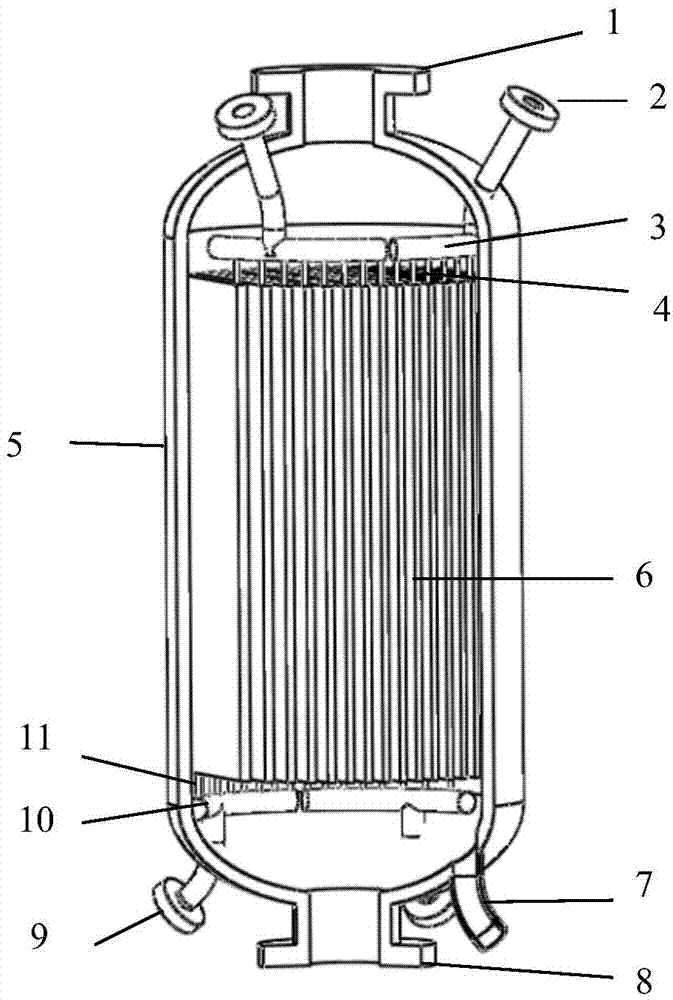

Tube bundle heat exchanger

ActiveCN110553519ACompact structureReduce weightStationary tubular conduit assembliesHeat exchange apparatusEngineeringHigh pressure

The invention discloses a tube bundle heat exchanger comprising a shell forming an annular cavity, wherein a plurality of heat exchange tube rows are arranged in the annular cavity, each of the heat exchange tube rows helically extends along the axial direction of the annular cavity, and the plurality of heat exchange tube rows are staggered in the circumferential direction of the annular cavity.The tube bundle heat exchanger provided by the solution has the advantages of compact structure, light weight and strong heat exchange capacity. It is particularly important that, under the premise ofobtaining the required heat exchange efficiency in the tube bundle heat exchanger, the external heat exchange medium does not need to change the flow direction, that is, enters in the axial direction, and continues to flow in the axial direction inside the annular cavity and finally flows out, thereby avoiding the back and forth turning of the airflow to reduce the flow energy loss of the external heat exchange medium. The tube bundle heat exchanger can also withstand high temperatures and pressures, and can work reliably under conditions that require super heat exchange capacity and in harshworking conditions.

Owner:BEIHANG UNIV

Boiler

A low-height boiler is composed of chimney, main body, firebox consisting of upper heat exchanging chamber and lower combustion chamber, coal feeder, ash discharger and power unit for coal feeder andash discharger. Said upper heat exchanging chamber is composed of common channel for exhausting smoke and feeding coal, reverse U-shaped water jacket, heat exchanging tubes, and water outlet tube. Said combustion chamber consists of external and internal water tubes and horizontal water tube. Its advantages are less floor area, big heat exchange area and high thermal efficiency.

Owner:刘毅

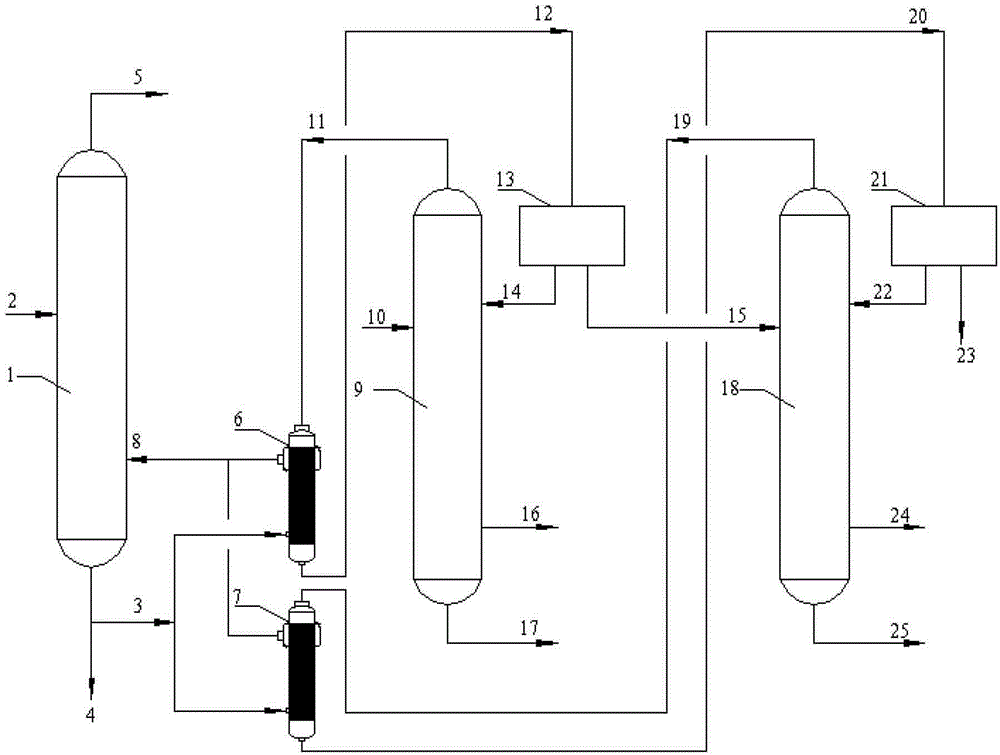

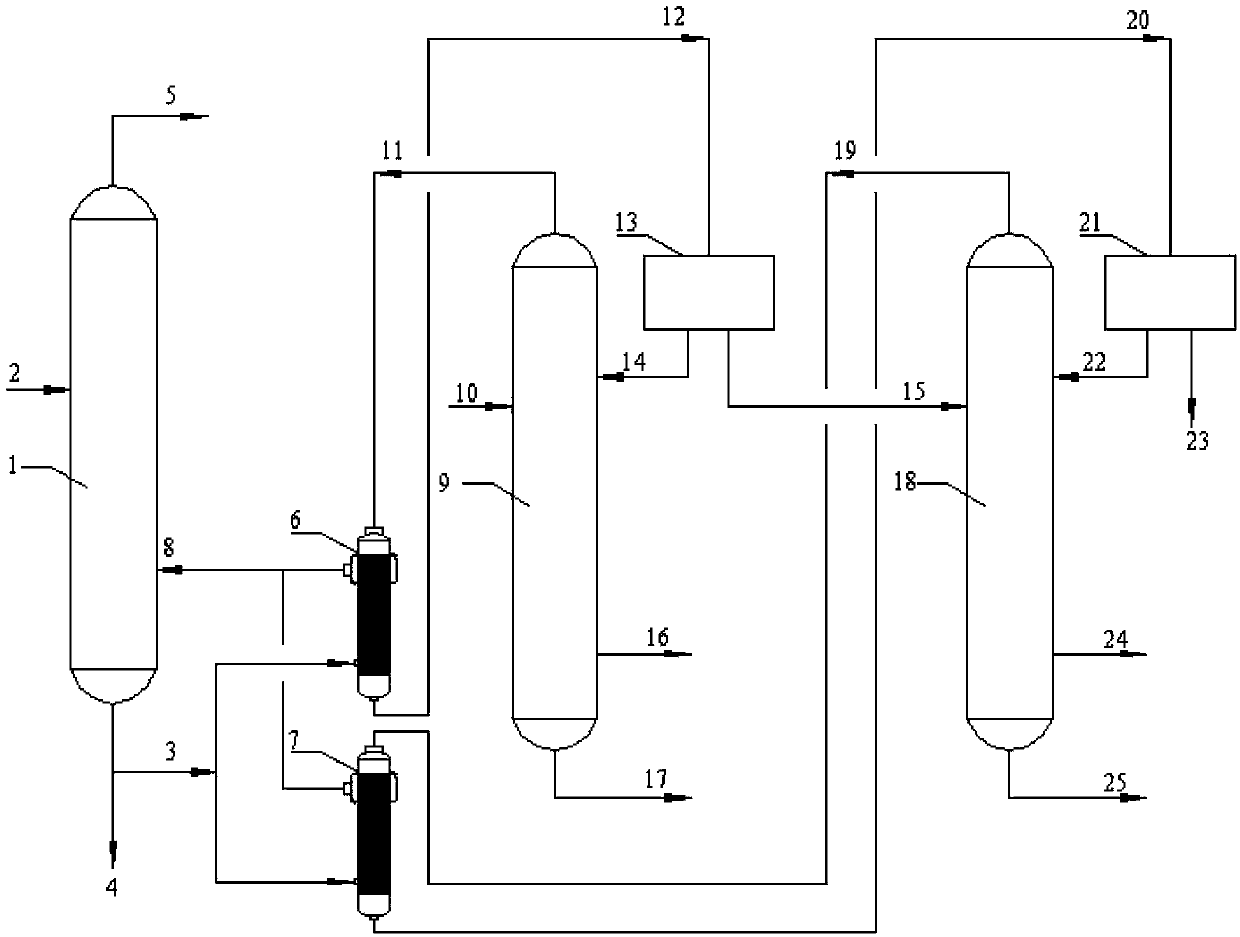

Method for recovering latent heat in sec-butyl acetate preparation device and combined device

ActiveCN102911045AReduce consumptionReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationRefluxCounter flow

The invention relates to a method for recovering latent heat in a sec-butyl acetate preparation device by using C4 raw material separation device. The method comprises the following steps of: introducing a tower top gas-phase material of an azeotropic rectification tower and / or a refining tower into shell-and-tube heat exchange equipment, wherein a tube pass of a vertical counter-flow condensation evaporator with a thinner cylinder lower section and a thicker cylinder upper section is preferably selected; introducing a liquid-phase material at a tower bottom or a tower bottom side line of a butene concentration tower of the C4 raw material separation device into a shell pass of the tube-and-shell heat exchange equipment; after heat exchange, condensing the tower top gas-phase material of the azeotropic rectification tower and / or the refining tower into a liquid-phase material to be fed into a tower top reflux accumulator; and gasifying the tower bottom liquid-phase material of the butene concentration tower into the gas-phase material to be circulated into the butene concentration tower. According to the method, the tower top gas-phase material of the azeotropic rectification tower of the sec-butyl acetate device and the tower bottom liquid-phase material of the butene concentration tower of the C4 raw material separation device are subjected to heat exchange, and the two streams of materials are subjected to phase shift in the shell-and-tube heat exchange equipment, so that the latent heat is fully utilized, the steam consumption of the C4 raw material separation device and the consumption of tower top circulating water of the refining tower are reduced, the energy consumption is greatly reduced, and the cost is saved.

Owner:HUNAN ZHONGCHUANG CHEM

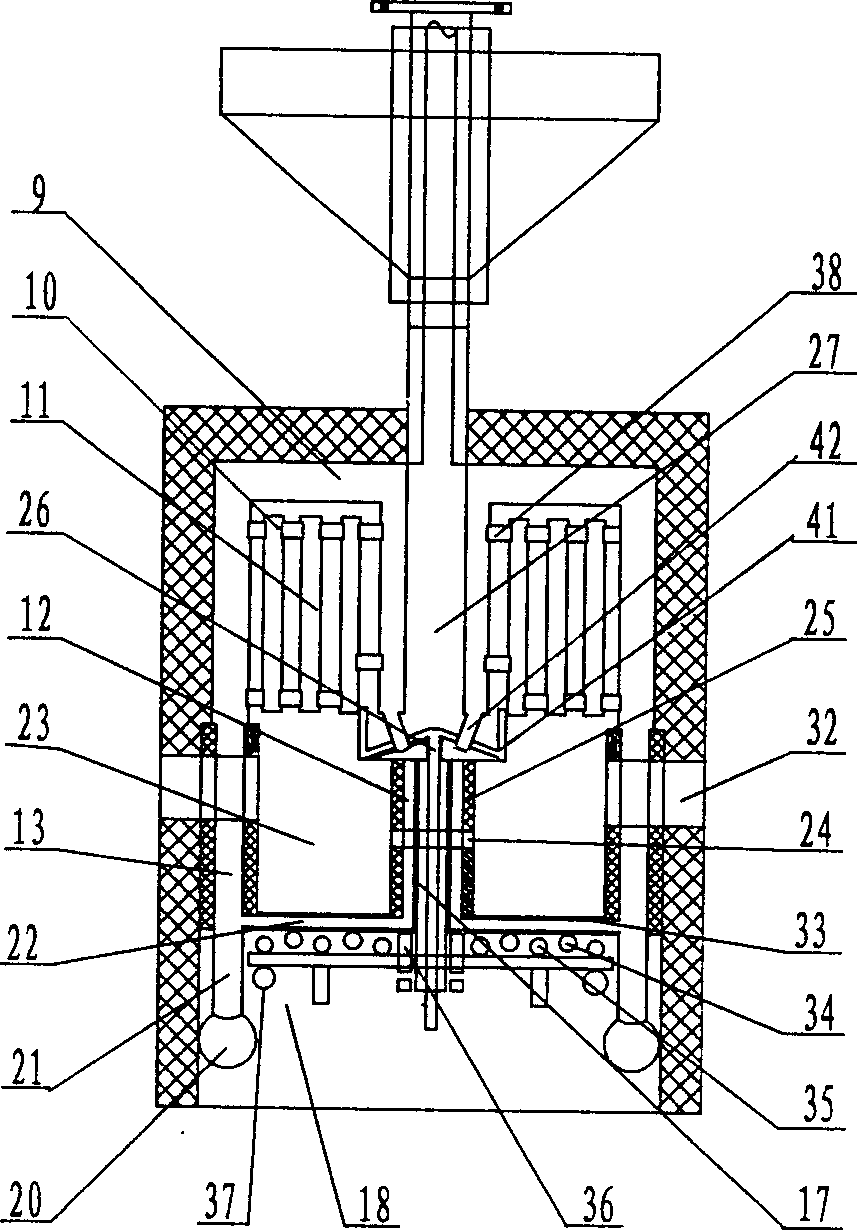

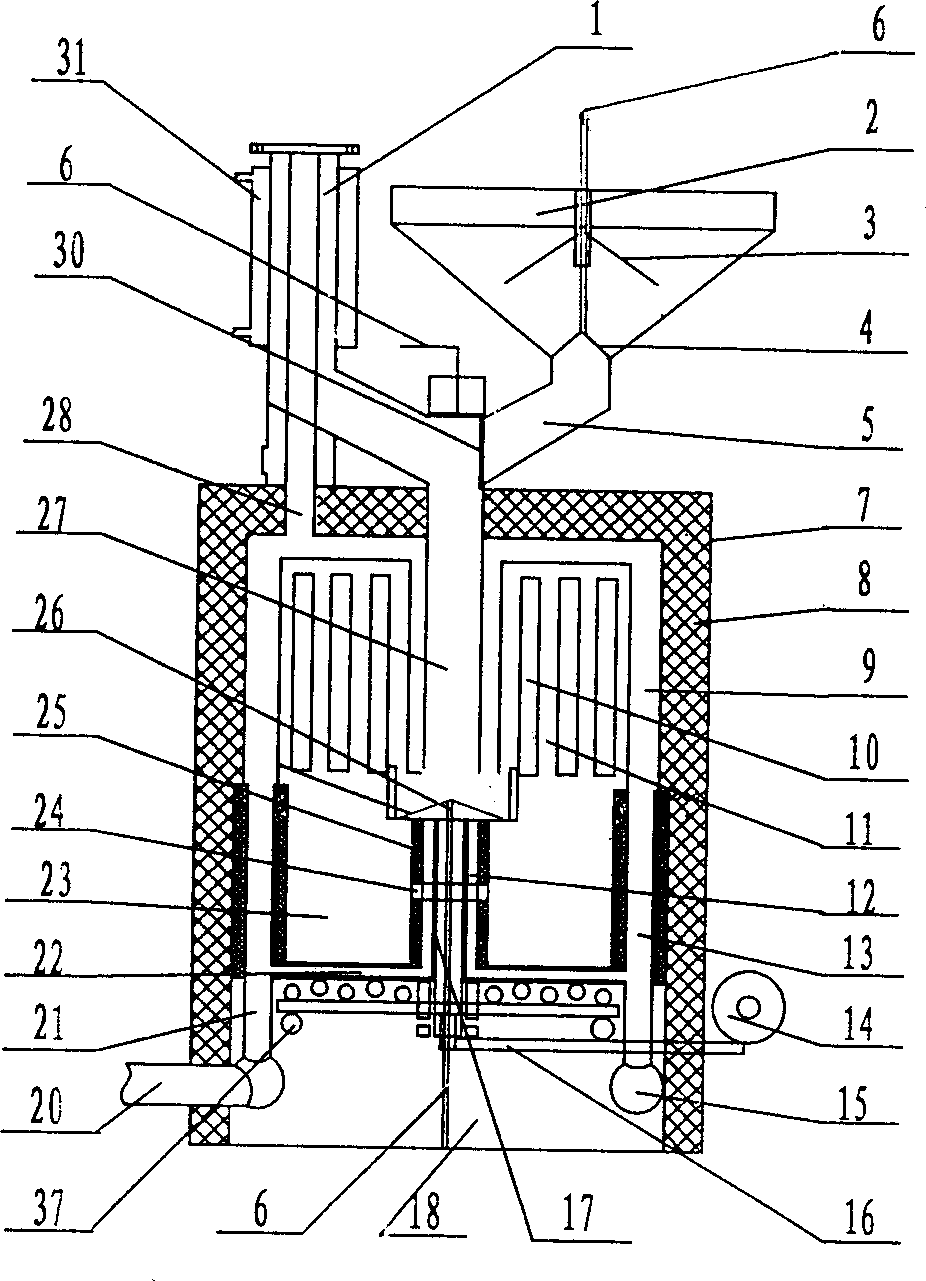

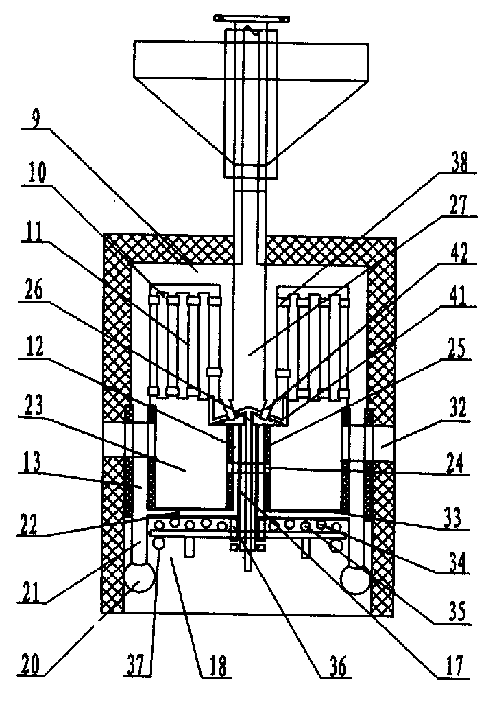

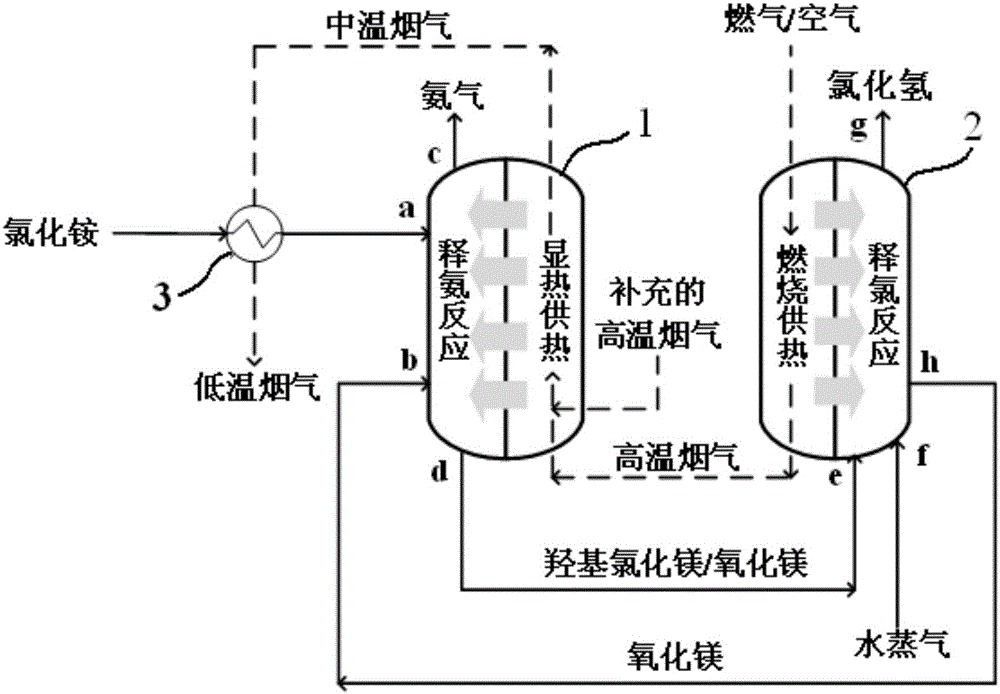

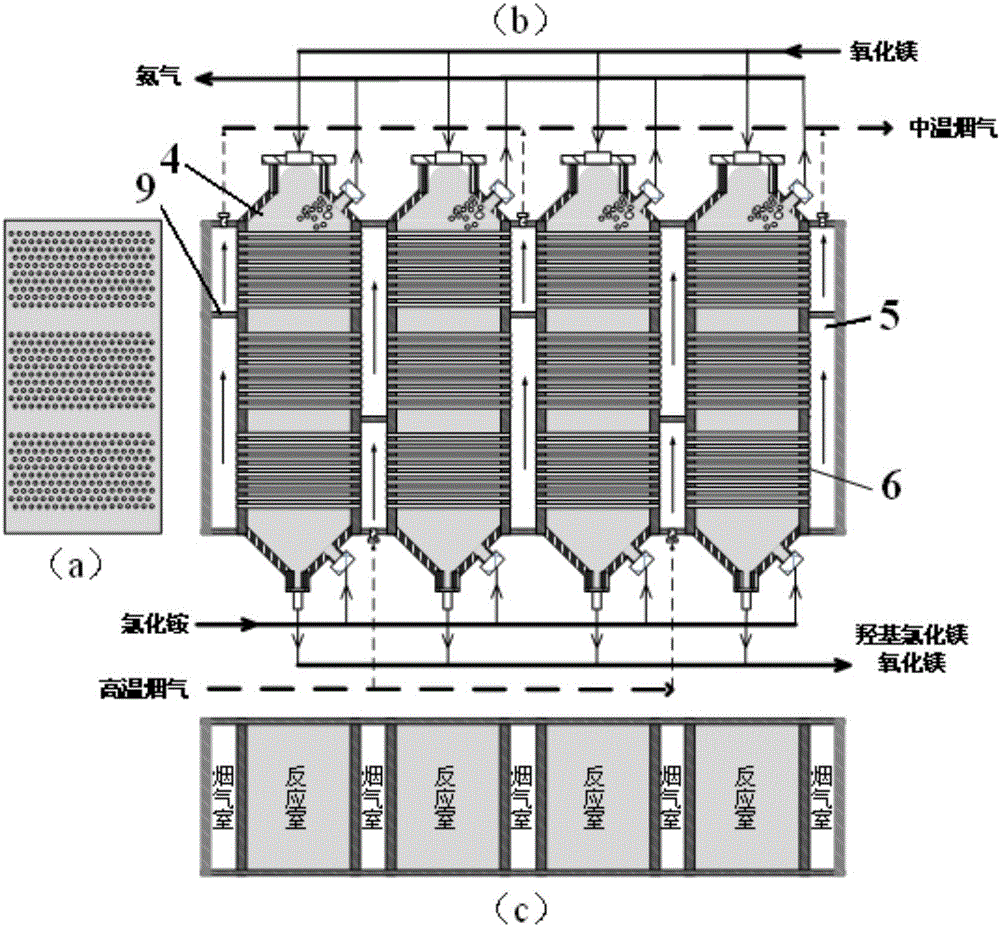

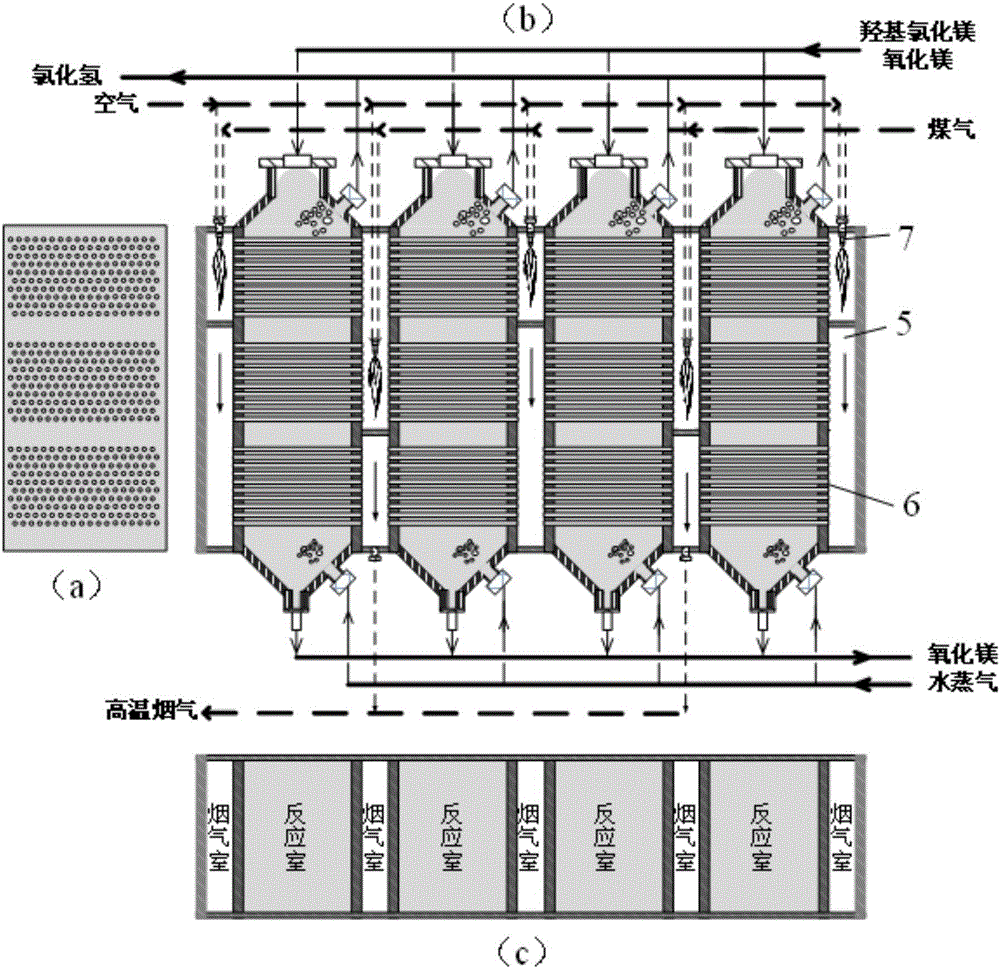

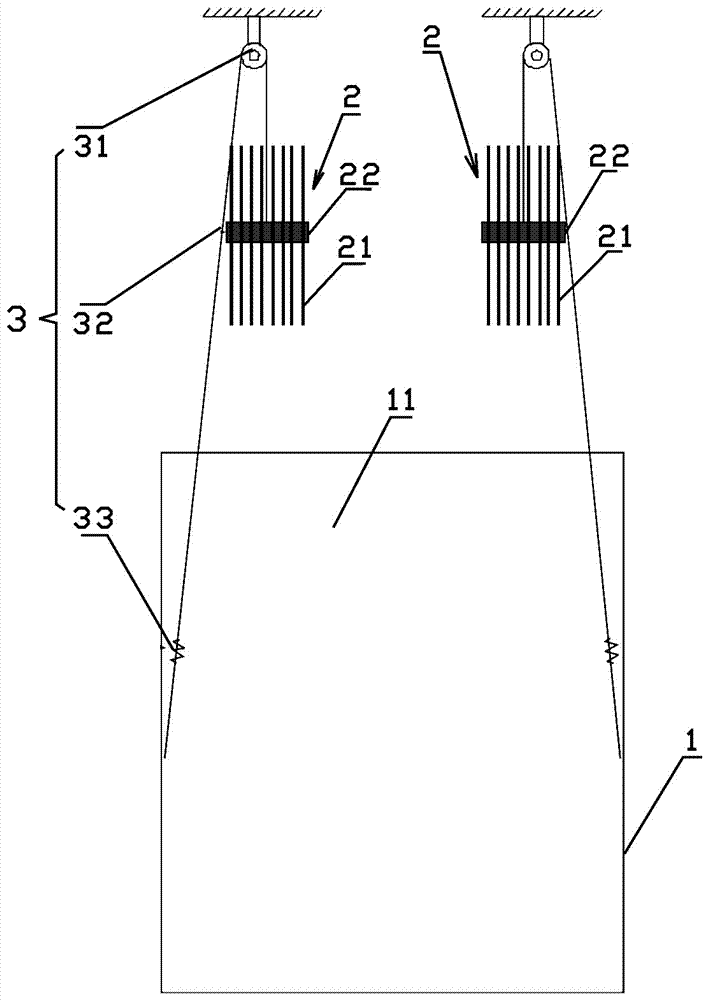

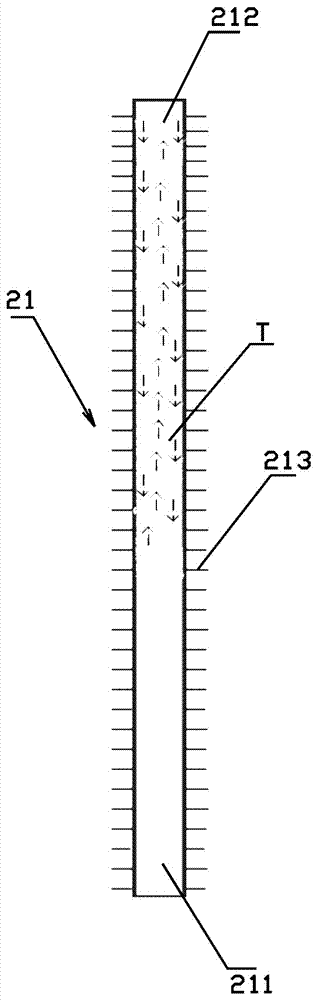

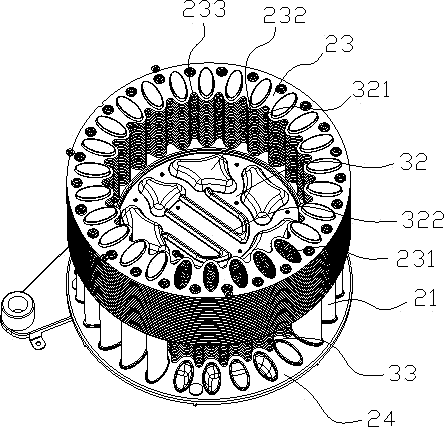

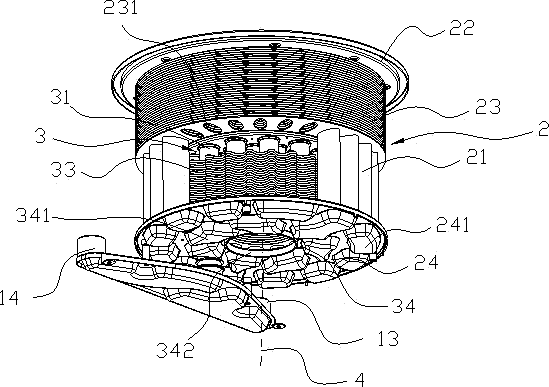

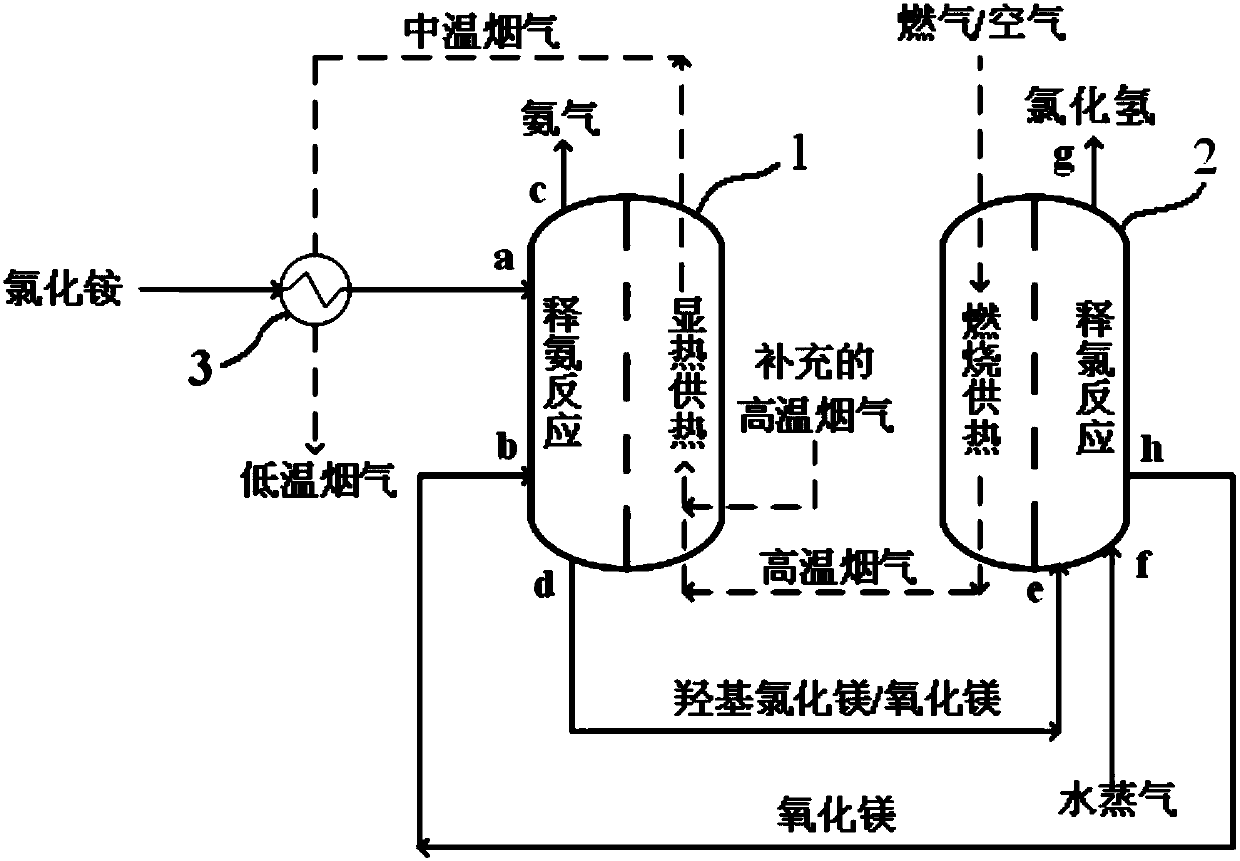

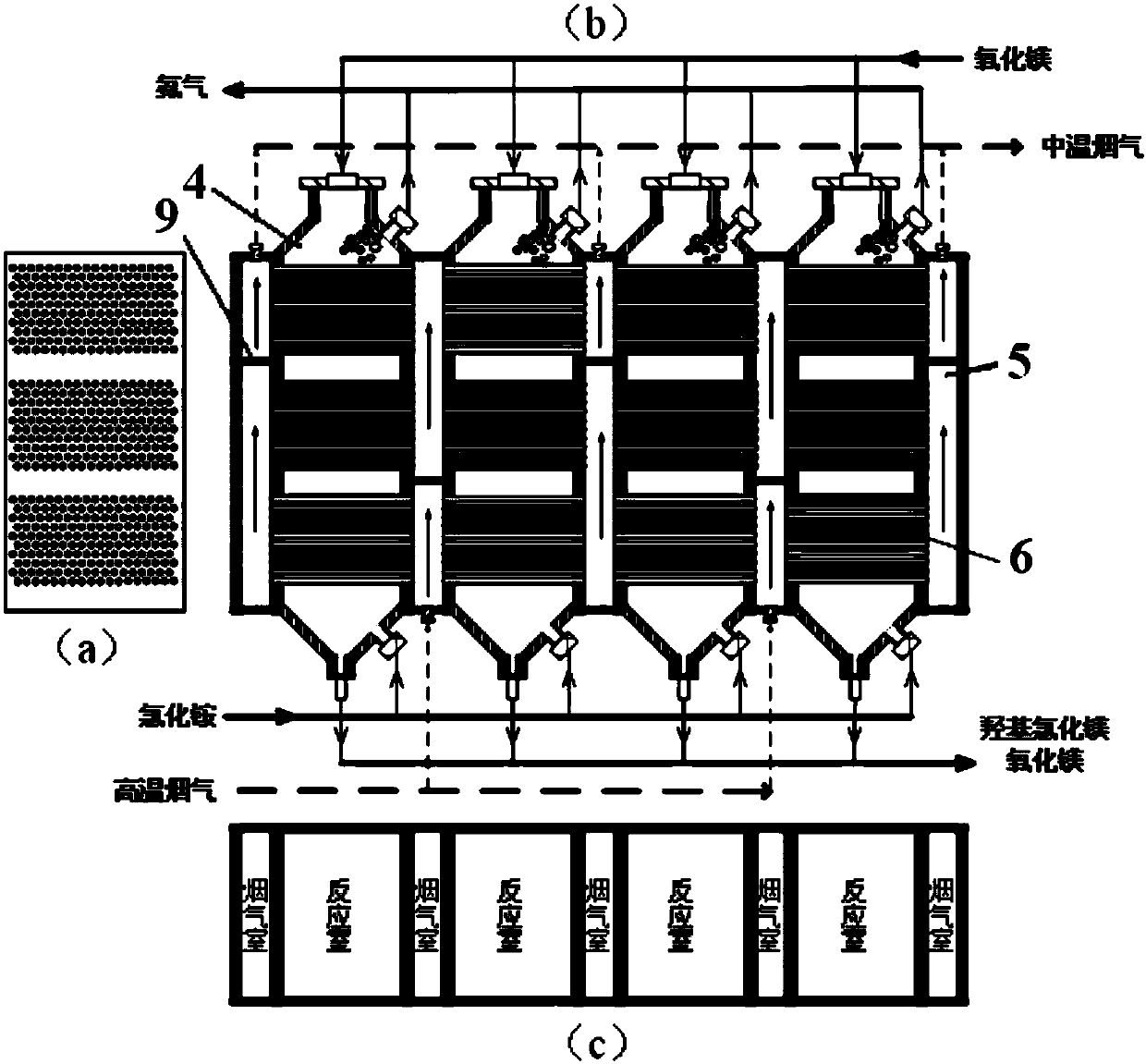

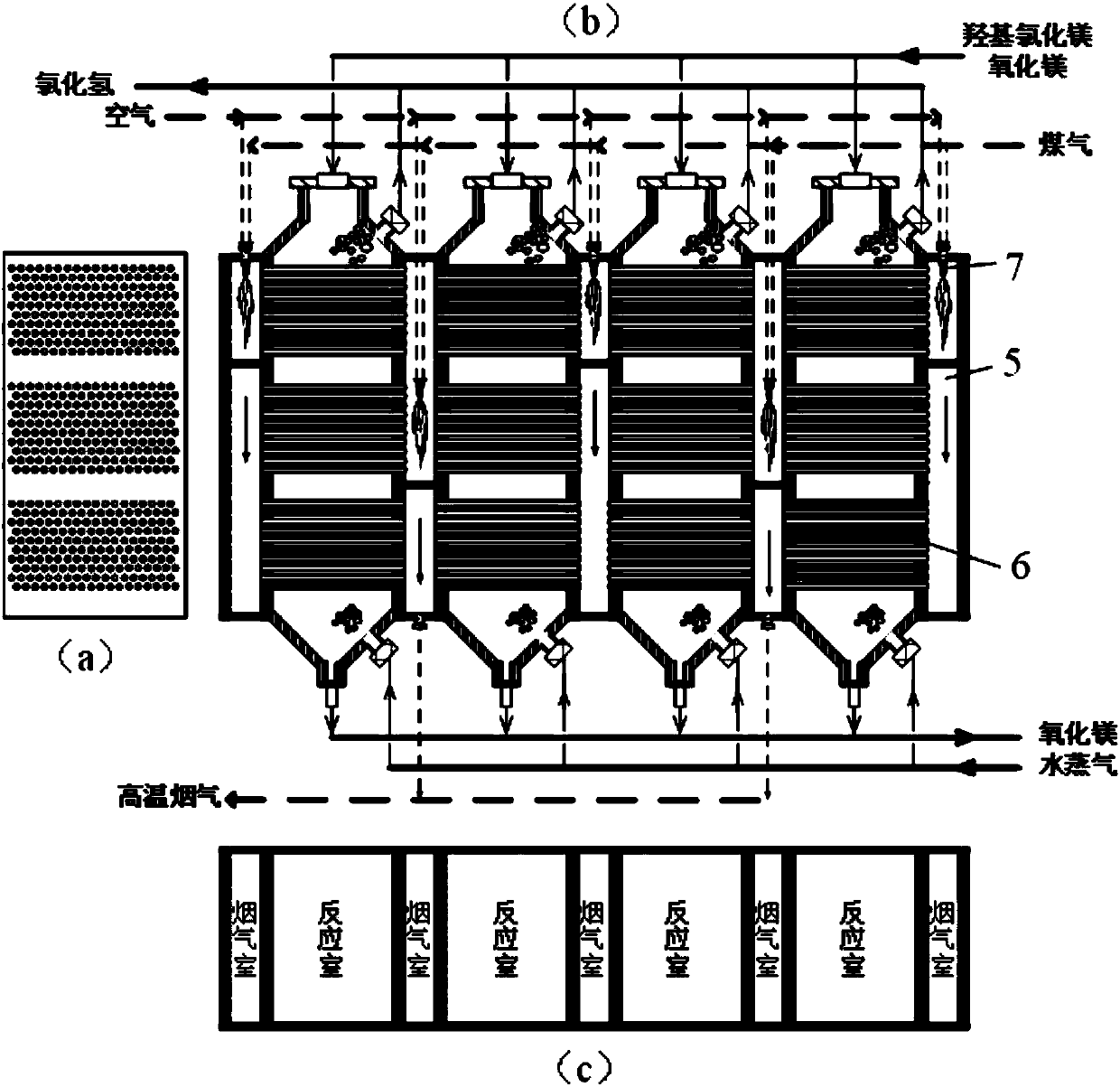

Multi-tube moving bed reaction device for preparing ammonia and hydrogen chloride by virtue of pyrolysis separation of ammonium chloride

ActiveCN105753016ARealize processingGood repeatabilityPreparation from chloridesAmmonia preparation/separationCombustionFlue gas

The invention discloses a multi-tube moving bed reaction device for preparing ammonia and hydrogen chloride by virtue of pyrolysis separation of ammonium chloride. The multi-tube moving bed reaction device comprises an ammonia releasing device and a chloride releasing device, wherein the ammonia releasing device and the chloride releasing device are respectively provided with one or more feeding holes and discharging holes and are multi-tube moving bed reactors, a solid discharging hole of the ammonia releasing device is connected with a solid feeding hole of the chloride releasing device, and a solid discharging hole of the chloride releasing device is connected with a carrier feeding hole of the ammonia releasing device; and meanwhile, a heat supply channel of the chloride releasing device is connected with a heat supply channel of the ammonia releasing device, the chloride releasing device is heated by virtue of combustion, and the ammonia releasing device is heated by virtue of high temperature flue gas produced after the combustion. According to the multi-tube moving bed reaction device, by mounting a large amount of heat exchanging row tubes in reactors, sufficient heat exchanging areas are provided, and the heat exchanging requirements of pyrolysis of ammonium chloride are met; meanwhile, by utilizing a proper structure and operation conditions, the requirements on the pyrolysis reaction and flow of ammonium chloride are met, and the large-scale continuous industrial production can be realized; and meanwhile, the multi-tube moving bed reaction device can be applied to a sodium carbonate-chloroethylene coproduction process.

Owner:ZHEJIANG UNIV

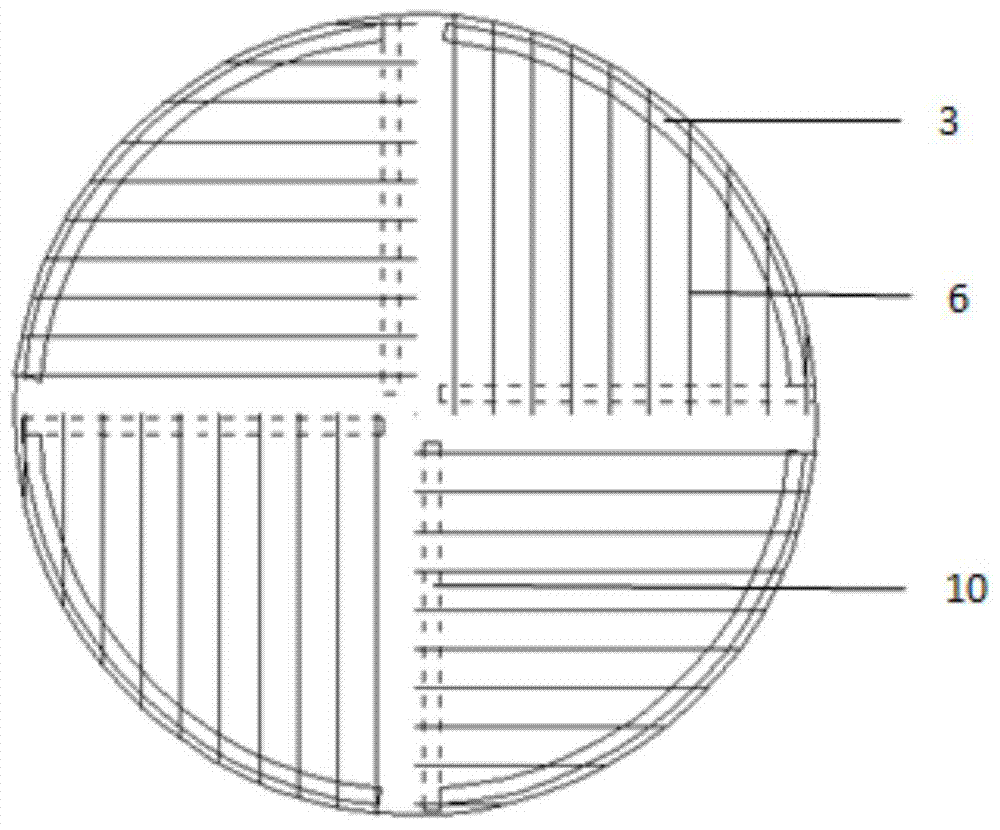

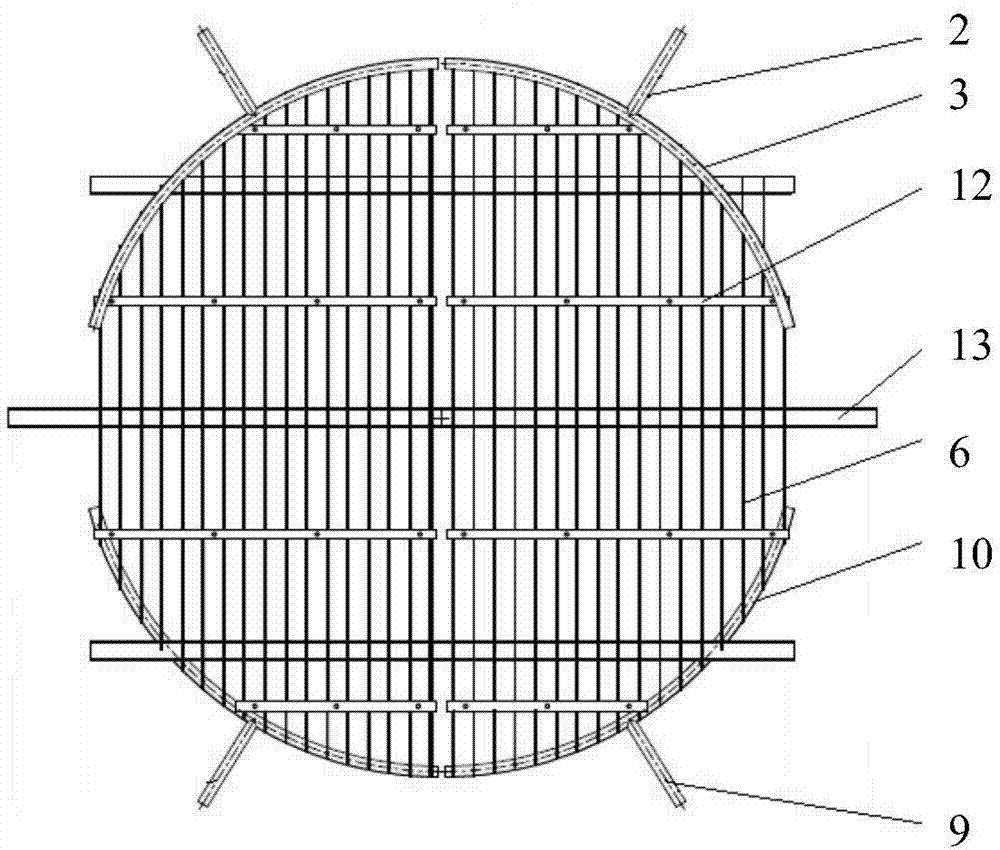

Novel reactor for preparing epoxy propane by oxidizing propylene with hydrogen peroxide

InactiveCN105107434AAvoid uneven distributionIncrease disturbanceOrganic chemistryChemical industryEngineeringPropane

The invention relates to a novel reactor for preparing epoxy propane by oxidizing propylene with hydrogen peroxide. The novel reactor comprises a reactor shell (5), a heat transfer plate pair bundle (6), a heat transfer medium distribution main pipe (10), a heat transfer medium distribution branch pipe (11), a heat transfer medium collecting main pipe (3) and a heat transfer medium collecting branch pipe (4), wherein the reactor shell (5) is provided with a reaction material inlet (1), a reaction material outlet (8), a heat transfer medium inlet (9) and a heat transfer medium outlet (2), the heat transfer plate pair bundle (6) consists of multiple sets of sub-heat transfer plate pair bundles, one end of each set of sub-heat transfer plate pair bundle is connected with the heat transfer medium inlet (9) through the heat transfer medium distribution branch pipe (11) and the corresponding heat transfer medium distribution main pipe (10), and the other end of each set of sub-heat transfer plate pair bundle is connected with the heat transfer medium outlet (2) through the heat transfer medium collecting branch pipe (4) and the corresponding heat transfer medium collecting main pipe (3). Compared with the prior art, the novel reactor provided by the invention has the advantages of small volume, convenience in catalyst loading, high heat transfer efficiency and flexibility in structure.

Owner:李东儒

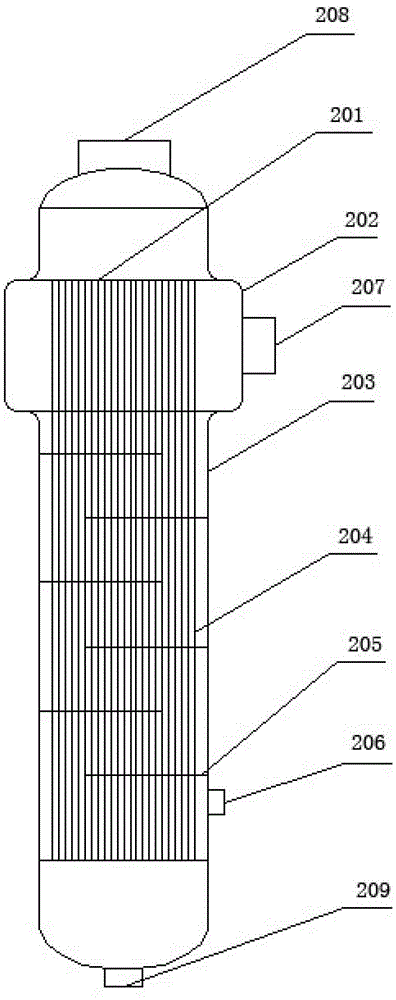

Condensing evaporator and application

InactiveCN102901380AReduce consumptionReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationCounter flowGas phase

The invention relates to a condensing evaporator used in a method for recovering latent heat in a sec-butyl acetate preparation device by using a C4 raw material separation device. According to the method, gas-phase materials on the top of an azeotropic distillation tower and / or a refining tower are introduced into a tube pass of the condensing evaporator (preferably a vertical counter-flow condensing evaporator of which a cylinder body has a relatively thin lower section and a relatively thick upper section); liquid-phase materials at the bottom or on side lines of the lower part of a butylene concentration tower of the C4 raw material separation device are introduced into a shell pass of the condensing evaporator; the gas-phase materials on the top of the azeotropic distillation tower and / or the refining tower are condensed into liquid-phase materials after being subjected to heat exchange, and the liquid-phase materials enter a return tank on the top of the tower; and the liquid-phase materials at the bottom of the butylene concentration tower are gasified into gas-phase materials, and the gas-phase materials return to the butylene concentration tower in a recycling mode. By the method, the gas-phase materials on the top of the azeotropic distillation tower of the sec-butyl acetate preparation device exchange heat with the liquid-phase materials at the bottom of the butylene concentration tower of the C4 raw material separation device, and the two kinds of materials are subjected to phase change in the condensing evaporator, so that the latent heat is fully utilized, consumption of steam in the C4 raw material separation device and consumption of recycling water on the top of the azeotropic distillation tower and the refining tower are reduced, energy consumption is greatly reduced, and the cost is saved.

Owner:HUNAN ZHONGCHUANG CHEM

A passive cooling device and system for a floating spent fuel pool in a nuclear power plant

ActiveCN105006258BEnables passive cooling processReduce radiation doseNuclear energy generationCooling arrangementNuclear plantNuclear power

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Tube bundle heat exchanger

ActiveCN110553519BCompact structureReduce weightStationary tubular conduit assembliesHeat exchange apparatusEngineeringMechanical engineering

Owner:BEIHANG UNIV

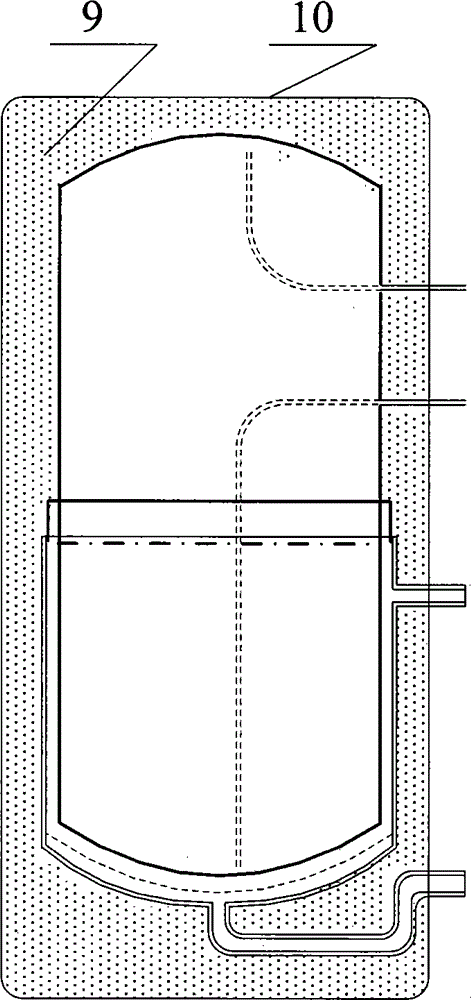

Enamel inner container water tank with condenser

InactiveCN105571133AImprove energy efficiency ratioCost-effectiveFluid heatersHeat pump water heaterBusiness efficiency

An enamel inner container water tank with a condenser is characterized in that: a case is arranged outside an end of the enamel inner container of a water tank, the case includes a seal head with a larger size, and a cylinder body, and likes a haft inner container which is radially cut open with a diameter greater than that of the enamel inner container; the case covers the enamel inner container from the end of the enamel inner container, an opening position of the case is connected to a circular rack which is arranged on a cylinder body of the enamel inner container and decides the size of a gap, and the case and a part of the enamel inner container covered by the case form a finite space; the finite space is the condenser of a heat-pump water heater. An enough heat exchanging area is arranged between the condenser and the enamel inner container, so that heat exchanging is fluent, and the energy efficiency ratio and the cost performance of a whole enamel inner container water tank can be improved. The enamel inner container water tank is small in size, can control the flow of hot water in cooperation with a heat pump machine, and can become an instant heating type heat-pump water heater; and the hot water capacity can transcend that of the other volumetric water heaters.

Owner:查荣生

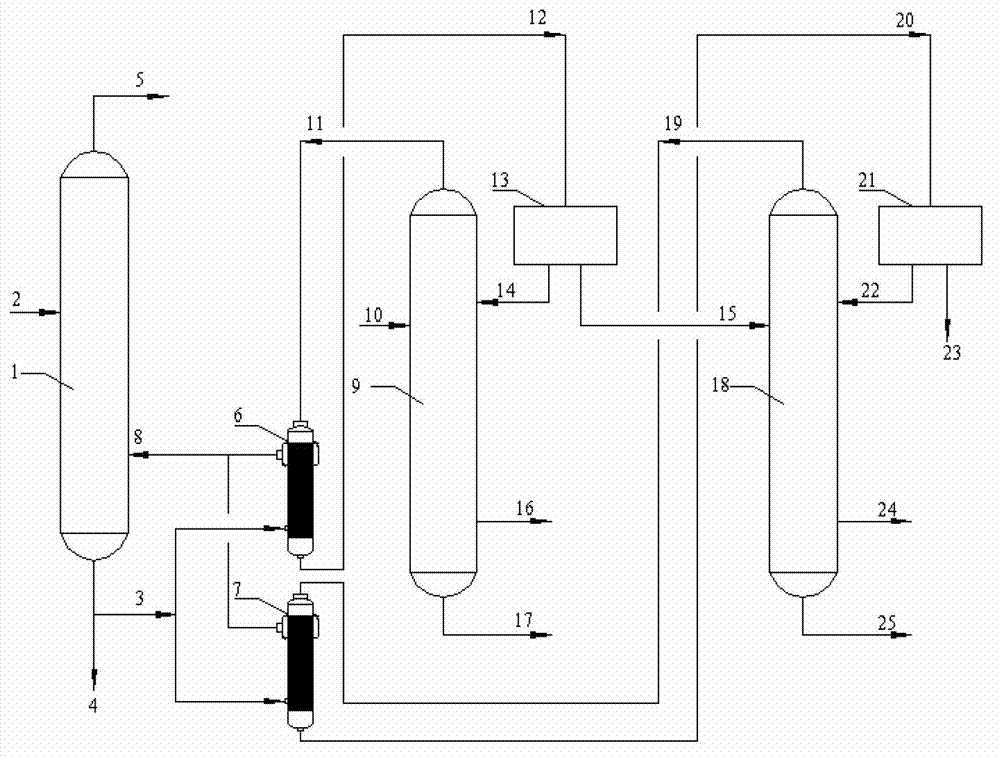

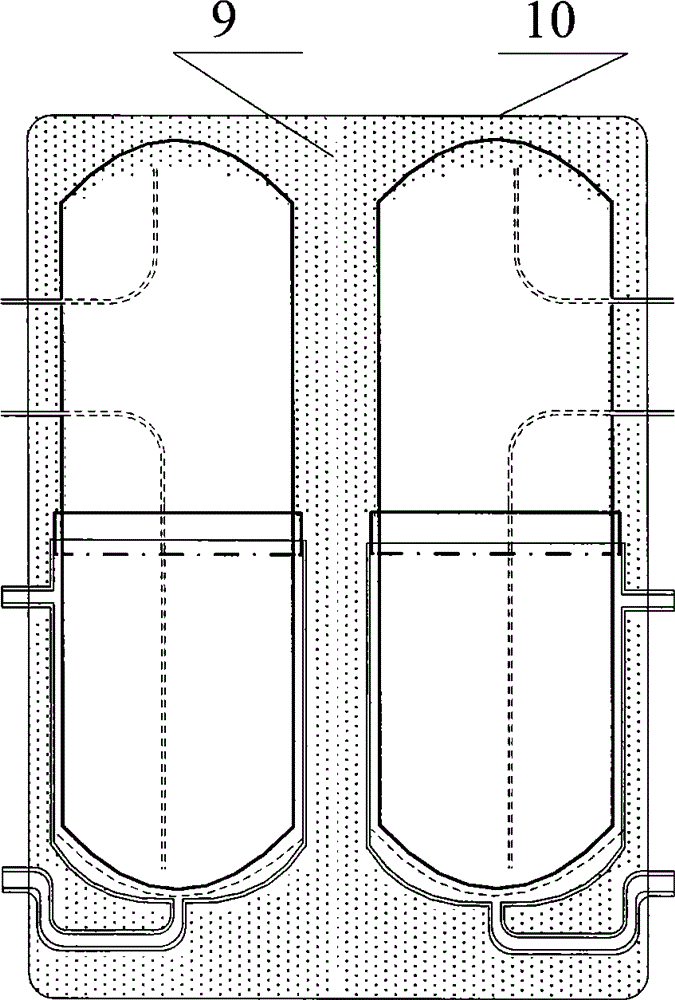

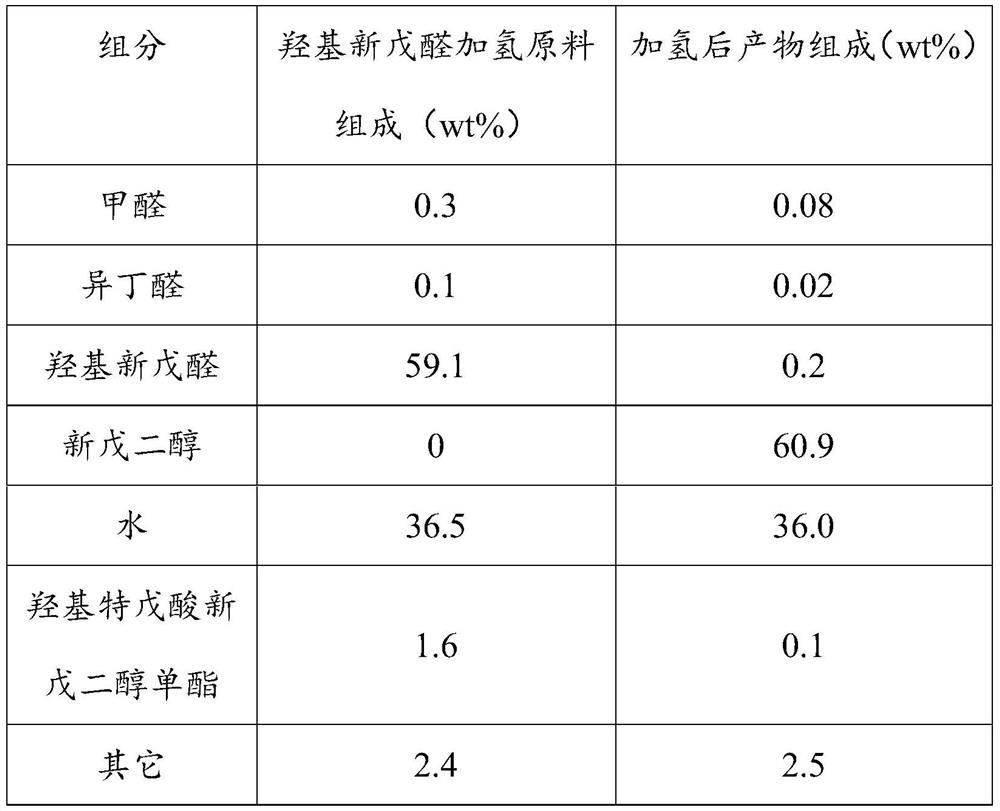

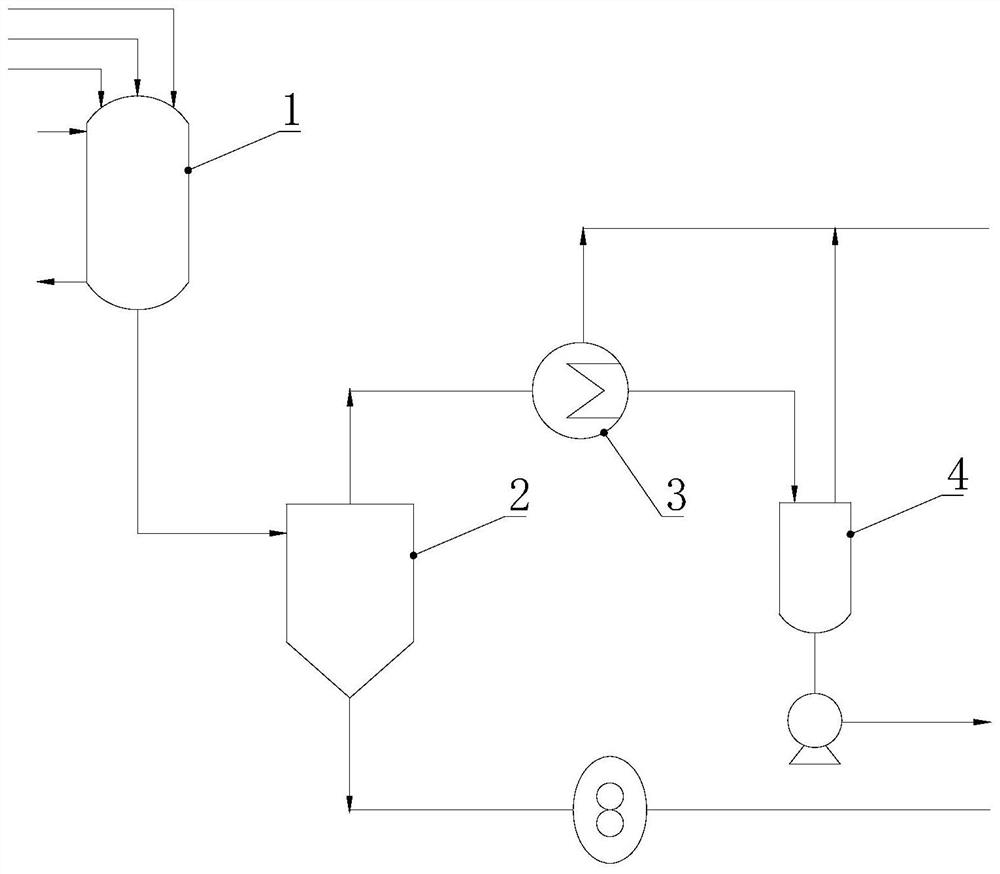

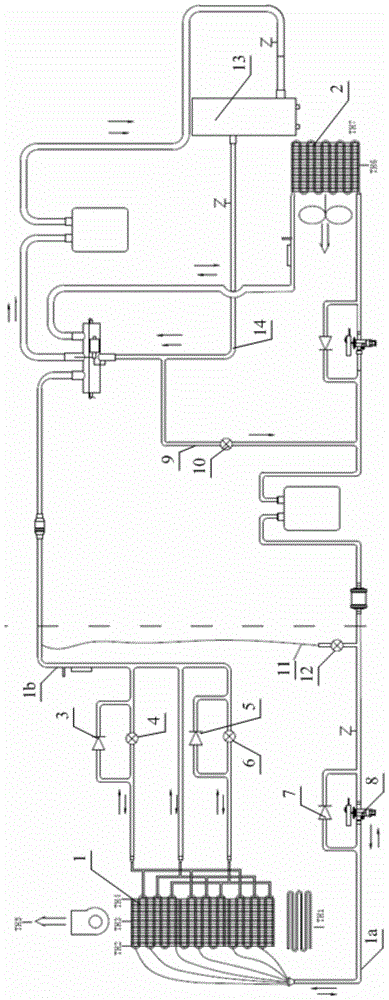

Process for producing neopentyl glycol by continuous catalytic hydrogenation

ActiveCN112537998AReduce lossesReduce energy consumptionOrganic compound preparationHydroxy compound preparationPtru catalystOrganic solvent

The invention discloses a process for producing neopentyl glycol by continuous catalytic hydrogenation, which solves the problems of complex operation, long flow and high investment and cost in the traditional neopentyl glycol production process, and adopts the technical scheme that a hydroxypivalaldehyde hydrogenation raw material and hydrogen are directly fed into a heat transfer hydrogenation reactor filled with a hydrogenation catalyst for reaction; a reaction product is led out from the bottom of the reactor and sent into a hydrogenation outlet separator for gas-liquid separation, one part of the separated gas returns to an inlet of the heat transfer hydrogenation reactor for cyclic utilization, and the other part of the separated gas is exhausted as purge gas; the separated liquid istreated through a light component removal tower and a heavy component removal tower to obtain a refined neopentyl glycol product; and the hydrogen-aldehyde molar ratio of the hydrogen to the hydroxypivalaldehyde hydrogenation raw material is (1.1-3): 1. The method has the advantages of simple process, short flow, mild reaction conditions, no need of additional addition of an organic solvent or separation and refining, energy saving, consumption reduction, low production cost and investment cost, and high yield.

Owner:上海翼湍科技有限责任公司 +1

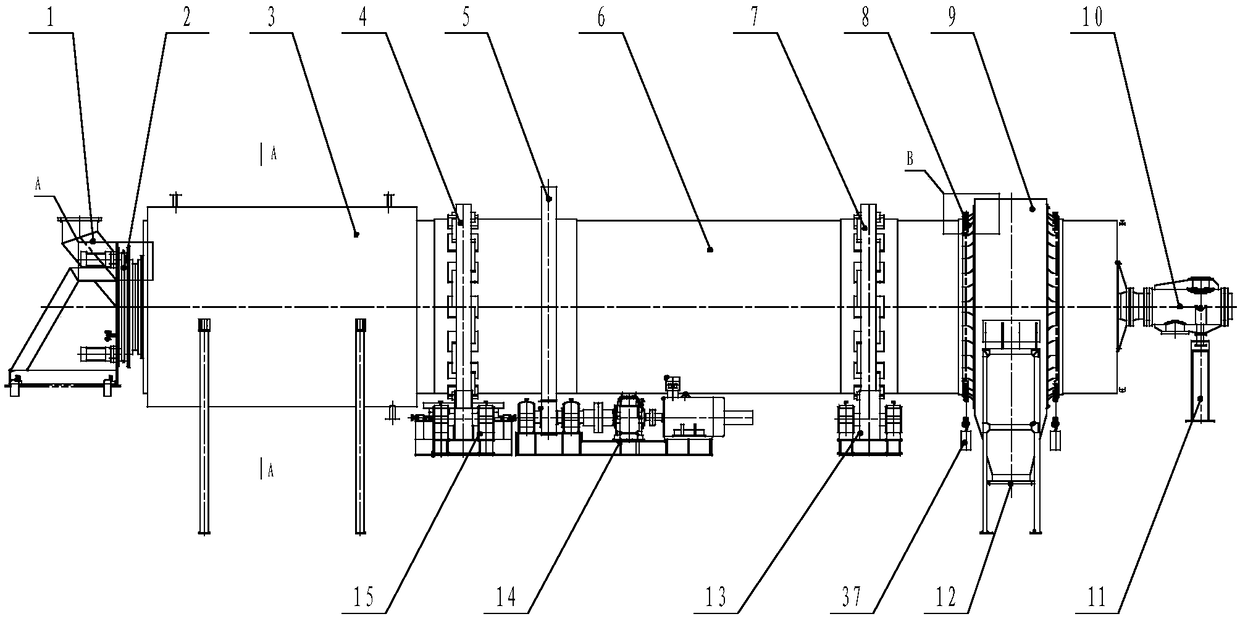

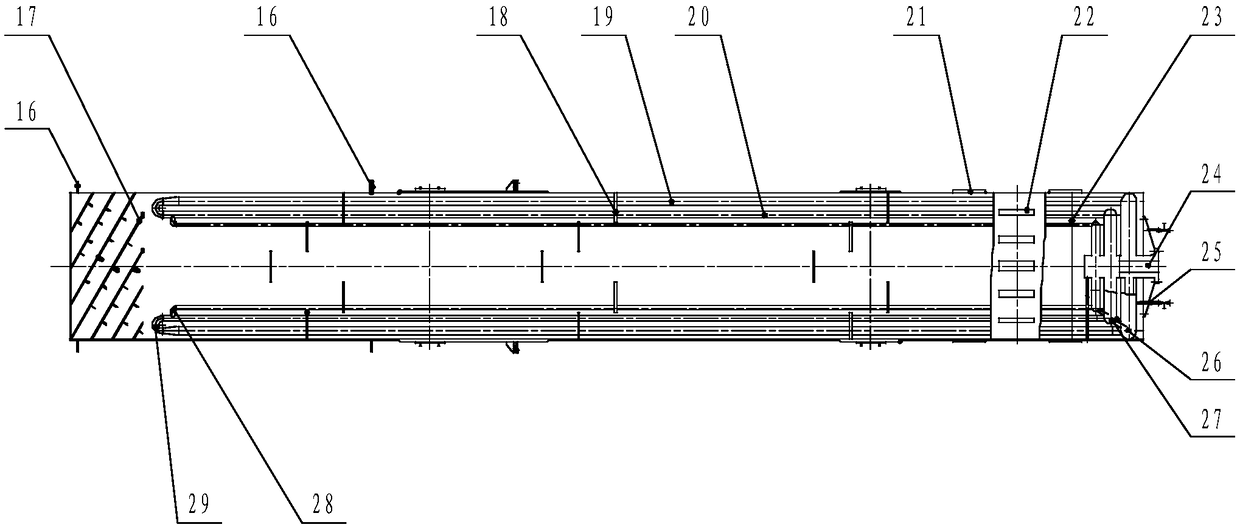

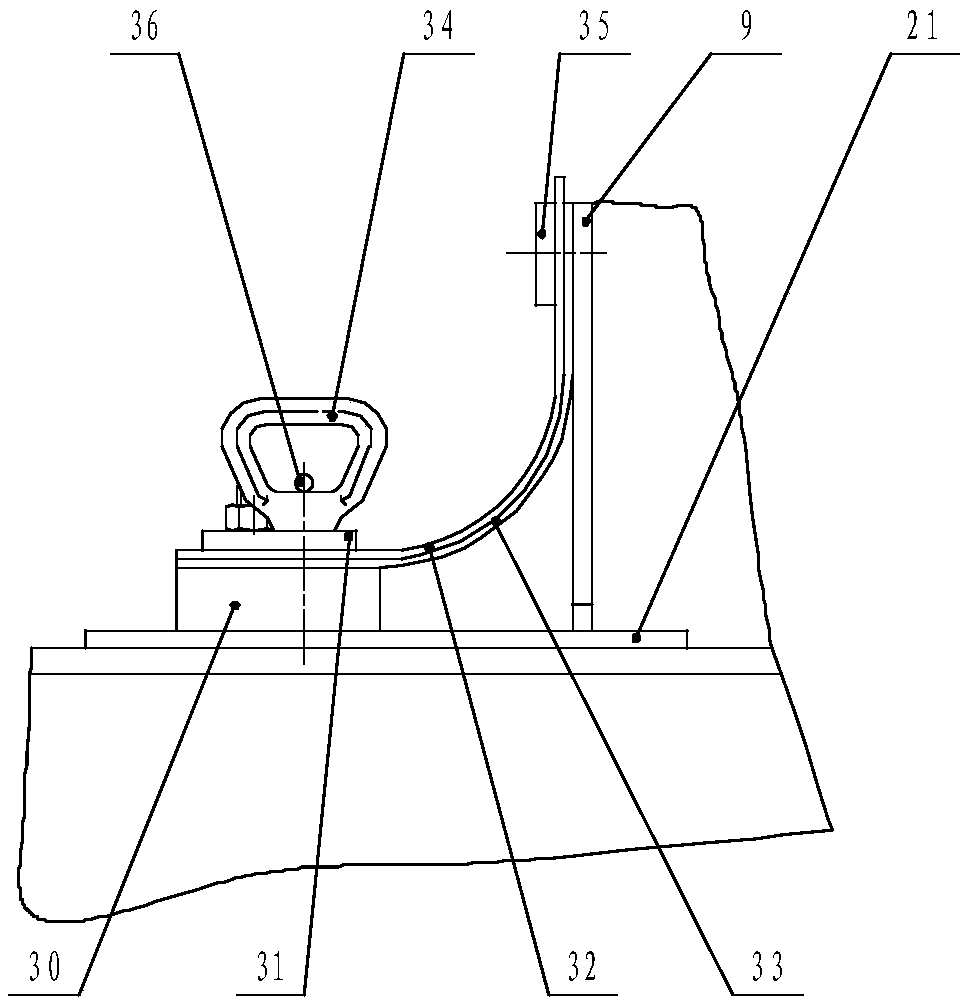

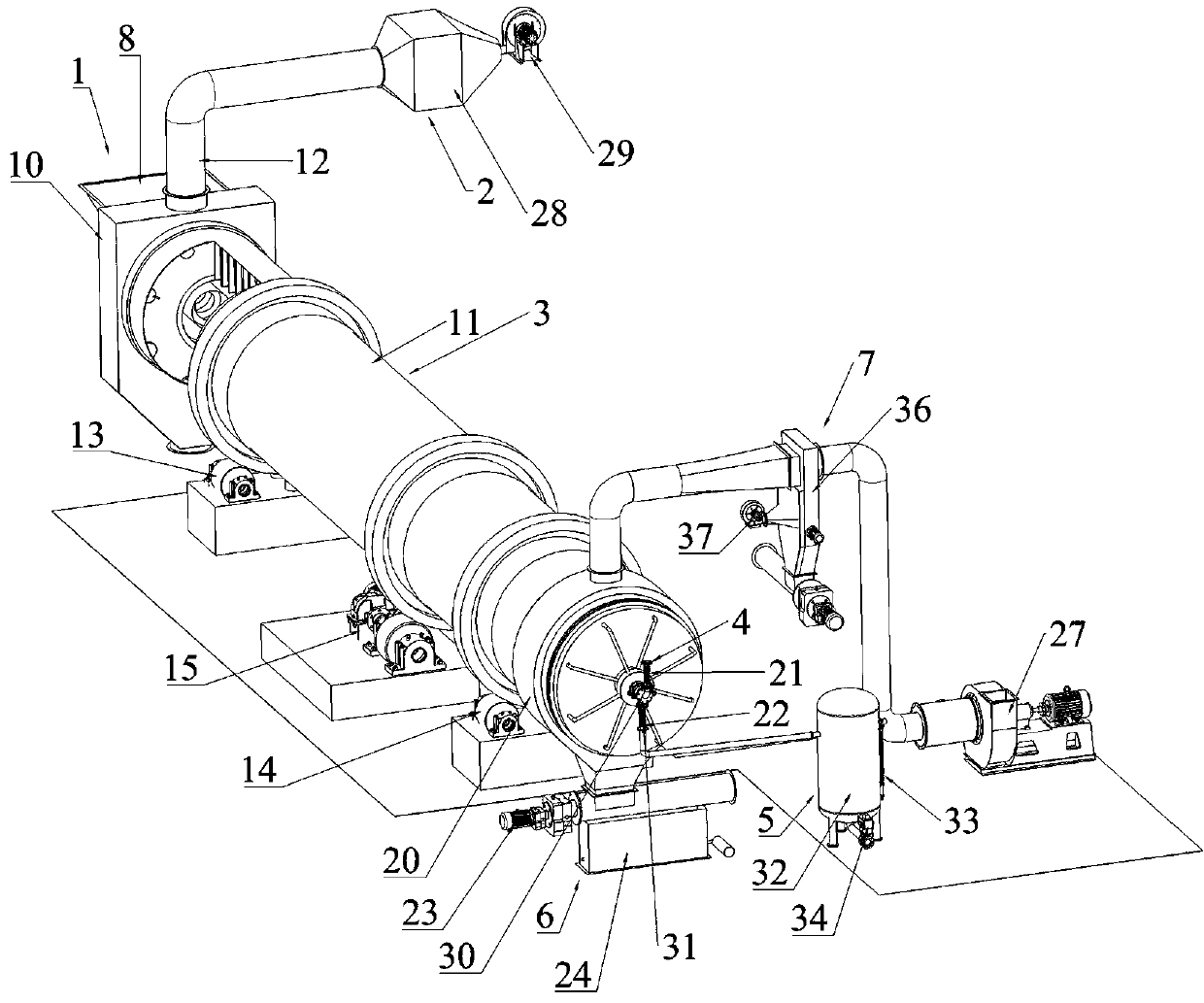

Rotary cooling furnace for semi-coke dry quenching

The invention discloses a rotary cooling furnace for semi-coke dry quenching. The rotary cooling furnace comprises a furnace body, wherein a plurality of rolling rings are arranged on the furnace body; the rolling rings are respectively supported by support wheel devices and baffle support wheel devices; a transmission device for driving the furnace to continuously rotate on the support wheel devices and the baffle support wheel devices is arranged outside the middle section of the furnace body; a feeding mechanism and a material feeding seal are arranged at the head of the furnace body; a water spraying cooling jacket is arranged at the front section of the furnace body; a discharge mechanism is arranged outside the rear section of the furnace body; a fish scale sealing structure is arranged between the furnace body and the discharge mechanism; the furnace body is internally provided with a cooling system; the cooling system is communicated with a rotating connector at the tail part of the furnace body; semi-coke is fed into a cooling zone in the furnace body through the feeding mechanism; through circulation water heat exchange in a cooling system tube bundle, indirect cooling quenching of the semi-coke in the furnace body is completed. By adopting the rotary cooling furnace, the semi-coke is continuously and indirectly cooled, so that the semi-coke barely has moisture, the quality of the semi-coke is improved, the environment can be protected, the energy can be saved, and the semi-coke does not need to be further dried by a user when being used.

Owner:西安三瑞实业有限公司

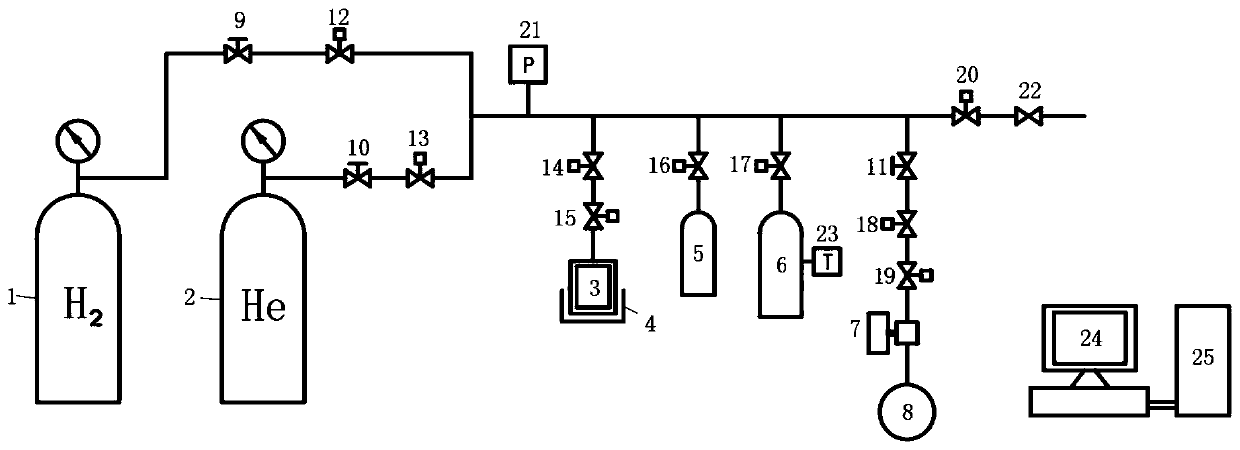

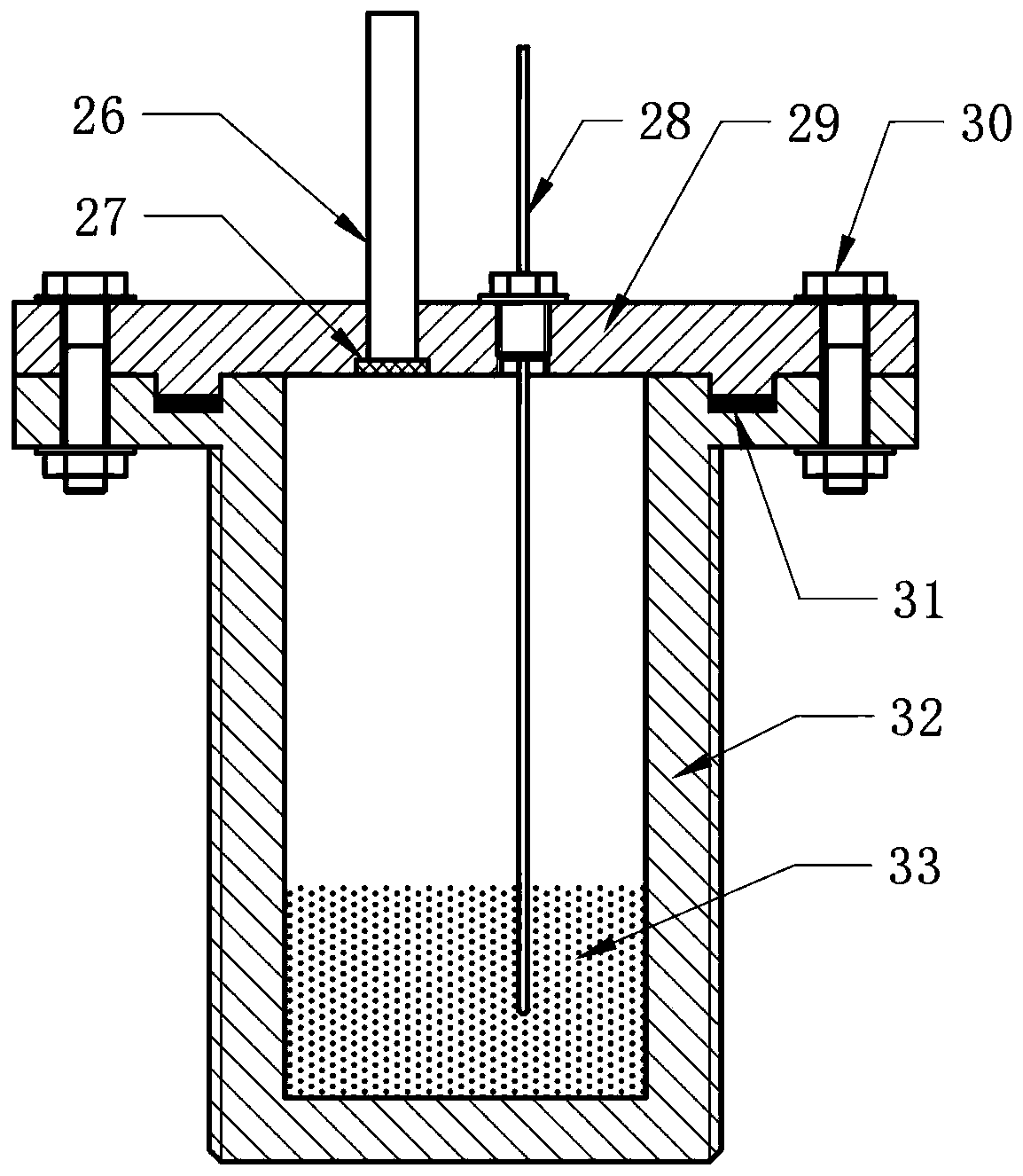

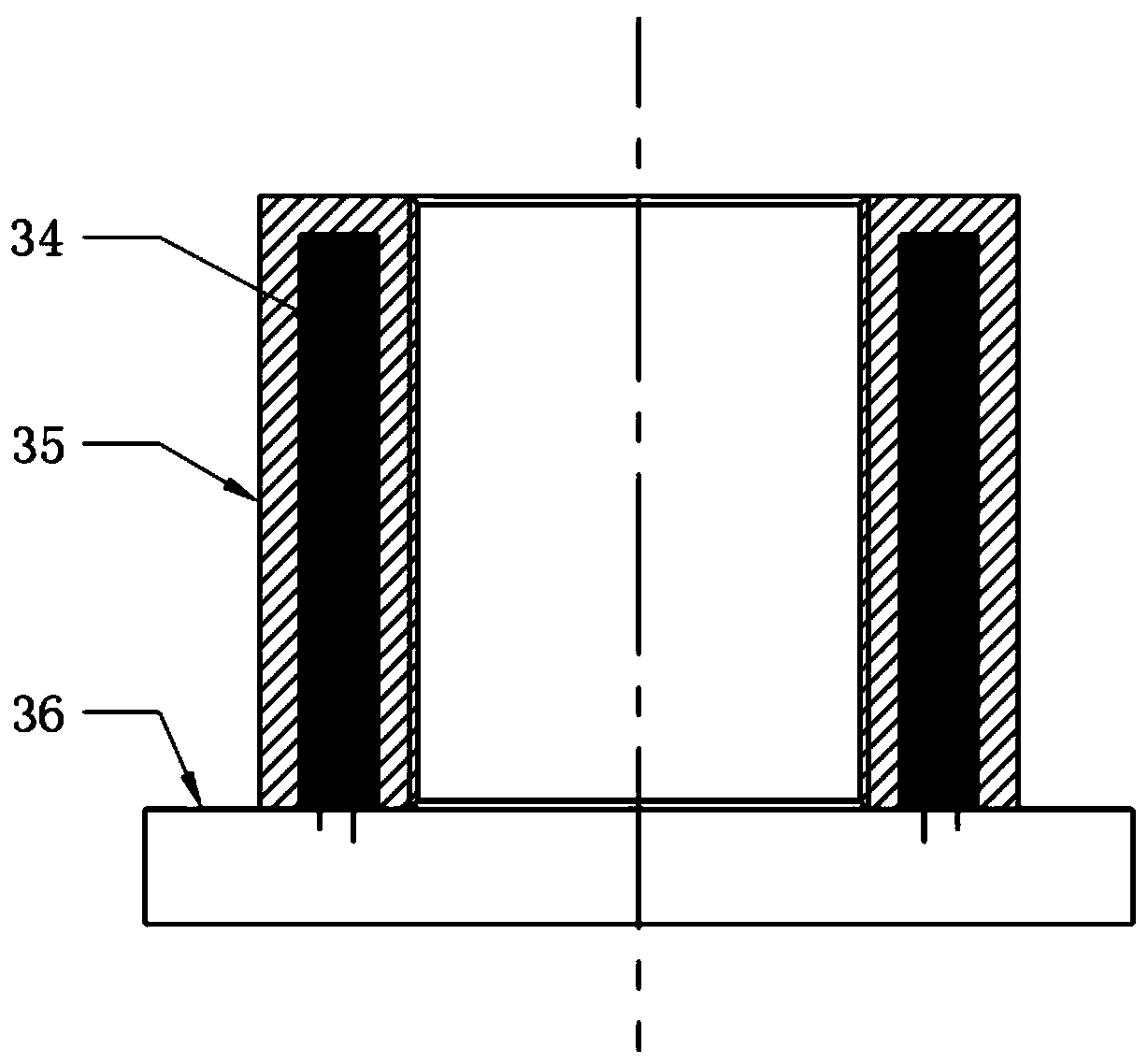

Hydrogen storage alloy PCT curve testing device and method

The invention belongs to the technical field of material performance detection, and relates to a hydrogen storage alloy PCT curve testing device and method. The hydrogen storage alloy PCT curve testing device comprises a sample room, a gas pipeline and a data collection system. The sample room and a pressure sensor are arranged on a main pipeline, threaded holes are formed in the flange of the sample room and connected with a k-type thermocouple which is arranged separately with a hydrogen inlet and a hydrogen outlet, and the outer part of the sample room is connected with a heating device anda cooling device through threads. One end of the main pipeline is correspondingly connected with a hydrogen cylinder and a helium cylinder through a throttle valve and a solenoid valve; the other endof the main pipeline is correspondingly connected with a vacuum gauge and atmosphere through the throttle valve and the solenoid valve, and the vacuum gauge is connected with a vacuum pump; and the pressure sensor is directly connected with the main pipeline. According to the hydrogen storage alloy PCT curve testing device and method, the internal temperature of the sample room can be rapidly heated and reduced and accurately measured, thus the time required for activation of the hydrogen storage alloy is saved, the whole set of the device is high in test efficiency, accurate in test, simplein structure, convenient in operation, and is safe and reliable.

Owner:SHANDONG CHAMBROAD EQUIP MFG INSTALLATION CO LTD +1

Method for recovering latent heat in sec-butyl acetate preparation device and combined device

ActiveCN102911045BReduce consumptionReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationRefluxCounter flow

The invention relates to a method for recovering latent heat in a sec-butyl acetate preparation device by using C4 raw material separation device. The method comprises the following steps of: introducing a tower top gas-phase material of an azeotropic rectification tower and / or a refining tower into shell-and-tube heat exchange equipment, wherein a tube pass of a vertical counter-flow condensation evaporator with a thinner cylinder lower section and a thicker cylinder upper section is preferably selected; introducing a liquid-phase material at a tower bottom or a tower bottom side line of a butene concentration tower of the C4 raw material separation device into a shell pass of the tube-and-shell heat exchange equipment; after heat exchange, condensing the tower top gas-phase material of the azeotropic rectification tower and / or the refining tower into a liquid-phase material to be fed into a tower top reflux accumulator; and gasifying the tower bottom liquid-phase material of the butene concentration tower into the gas-phase material to be circulated into the butene concentration tower. According to the method, the tower top gas-phase material of the azeotropic rectification tower of the sec-butyl acetate device and the tower bottom liquid-phase material of the butene concentration tower of the C4 raw material separation device are subjected to heat exchange, and the two streams of materials are subjected to phase shift in the shell-and-tube heat exchange equipment, so that the latent heat is fully utilized, the steam consumption of the C4 raw material separation device and the consumption of tower top circulating water of the refining tower are reduced, the energy consumption is greatly reduced, and the cost is saved.

Owner:HUNAN ZHONGCHUANG CHEM

Exposure lighting set and exposure machine

ActiveCN102096298BTake away quicklyEnough heat exchange areaOptical filtersPhotomechanical exposure apparatusEffect lightEngineering

Owner:AU OPTRONICS CORP

Esterification device and method for AA and BDO in PBAT production process

PendingCN113499596ANo backmixingReduce circulationVacuum distillation separationChemical/physical/physico-chemical stationary reactorsEngineeringProcess engineering

An esterification device for AA and BDO in the PBAT production process comprises a micro-interface wound tube type reactor, a stock bin and a vacuum flash tank. A feeding port of the stock bin is used for being connected with an AA source and a BDO source, a discharging port of the stock bin is connected with a material channel inlet of the reactor through a feeding pump and a heater, and a material channel outlet of the reactor is connected with the vacuum flash tank. A micro-interface generator is arranged at an inlet of the material channel, a liquid outlet in the bottom of the vacuum flash tank is used for discharging BSA, a steam outlet in the top of the vacuum flash tank is connected with a vacuum separator through a condenser, and non-condensable gas outlets of the condenser and the vacuum separator are both connected with a negative pressure source. The device is simple in structure and convenient to operate, the operation efficiency is greatly improved, the production requirement of large-scale production of PBAT can be met at low cost, the esterification reaction can be carried out in the forward direction without adopting an excessive BDO mode, the esterification rate of AA and BDO can be effectively improved and reaches 98.5% or above, material backmixing can be effectively avoided, the circulation amount of BDO is reduced by 95%, and energy consumption is greatly reduced.

Owner:华峰集团上海工程有限公司

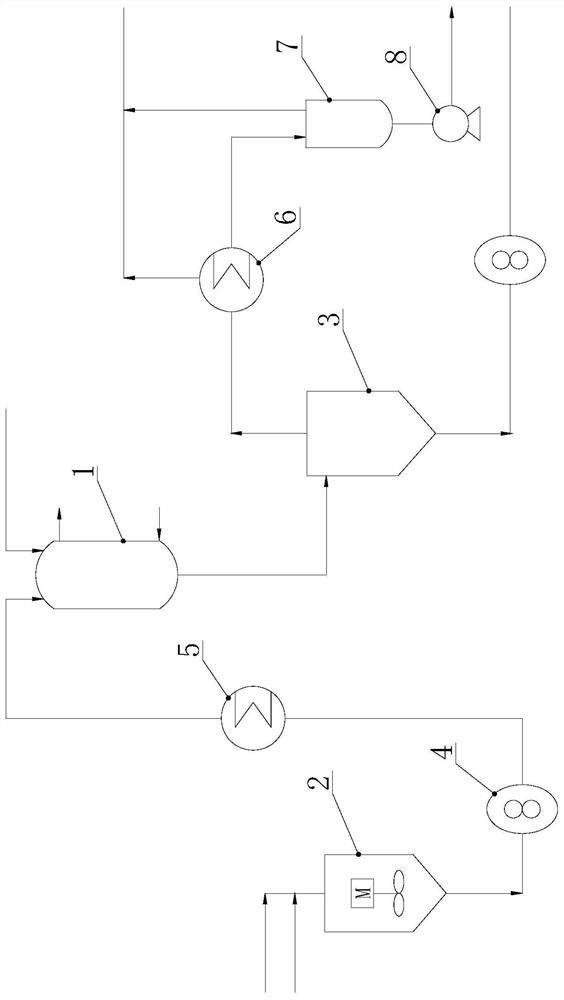

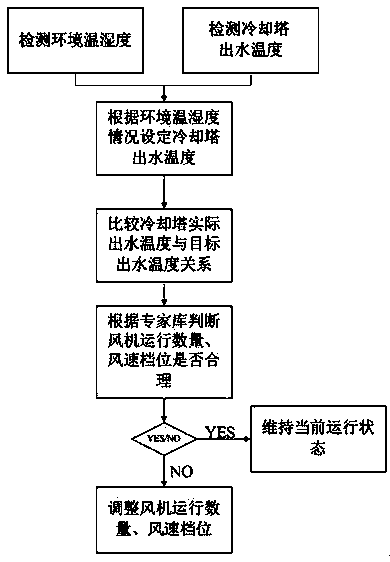

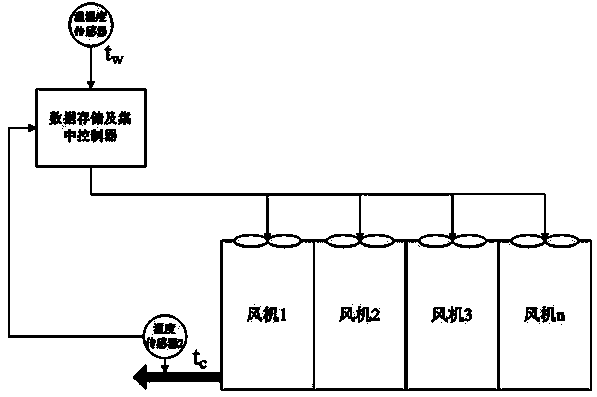

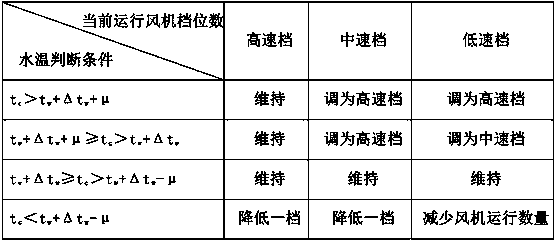

Multi-fan cooling tower control method, cooling tower and air conditioner

ActiveCN110553369BEnough heat exchange areaQuickly and accurately adjust the outlet water temperatureMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsCooling tower

The invention discloses a multi-fan cooling tower control method, a cooling tower and an air conditioner. The multi-fan cooling tower control method comprises the following steps that the actual wateroutlet temperature tc of the cooling tower is detected, the current environment wet bulb temperature tw is acquired, the middle temperature interval is calculated according to the current environmentwet bulb temperature tw, and the actual water outlet temperature is compared with the middle temperature interval; when the actual water outlet temperature is higher than the middle temperature interval, whether all fans are in an open state or not is judged, if yes, the air speed of the fans are increased, or otherwise the running number of the fans is increased; and / or when the actual water outlet temperature is lower than the middle temperature interval, whether all the fans are at the lowest air speed or not is judged, if yes, the running number of the fans is reduced, or otherwise, the air speed of the fans is reduced. According to the multi-fan cooling tower control method, the cooling tower and the air conditioner, the advantages of being accurate in adjusting effect, simple to control, prominent in energy-saving performance, low in production cost and the like are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

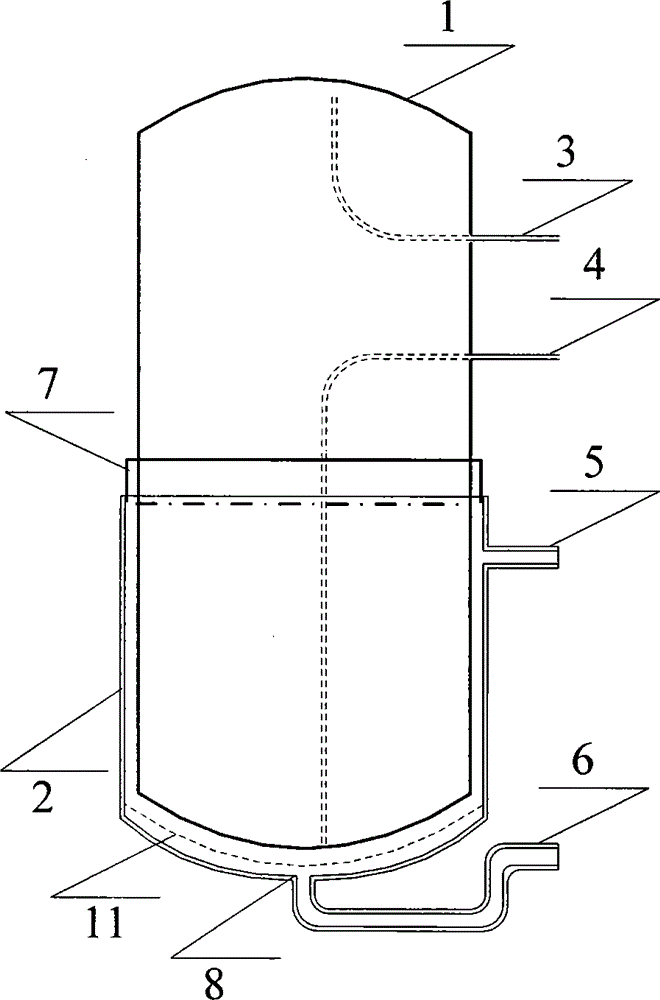

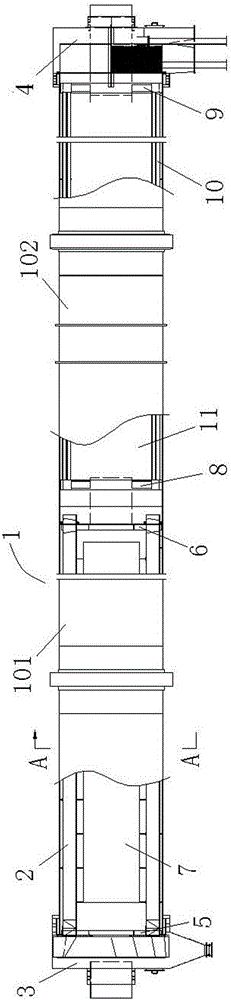

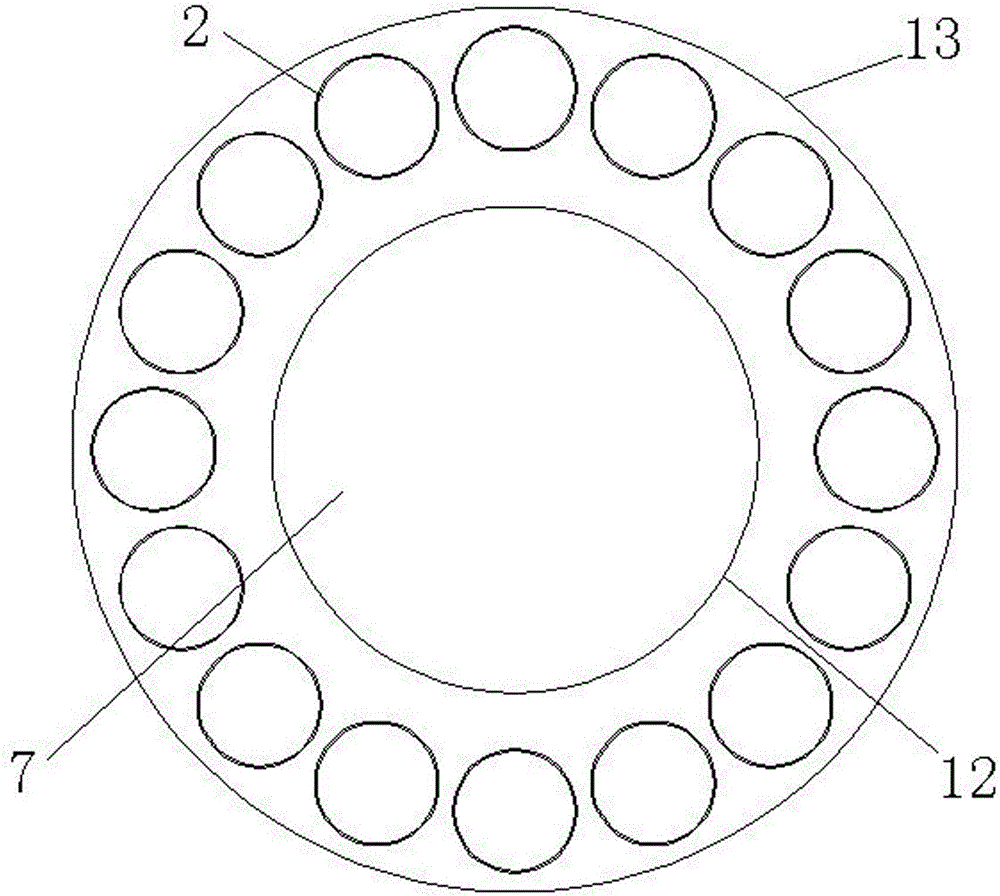

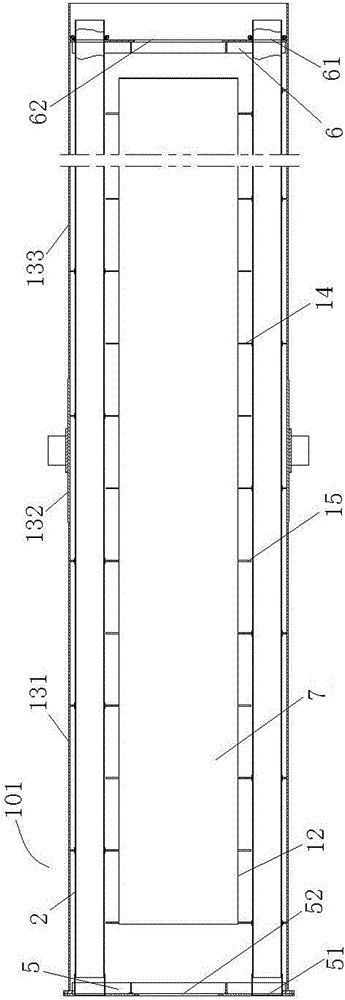

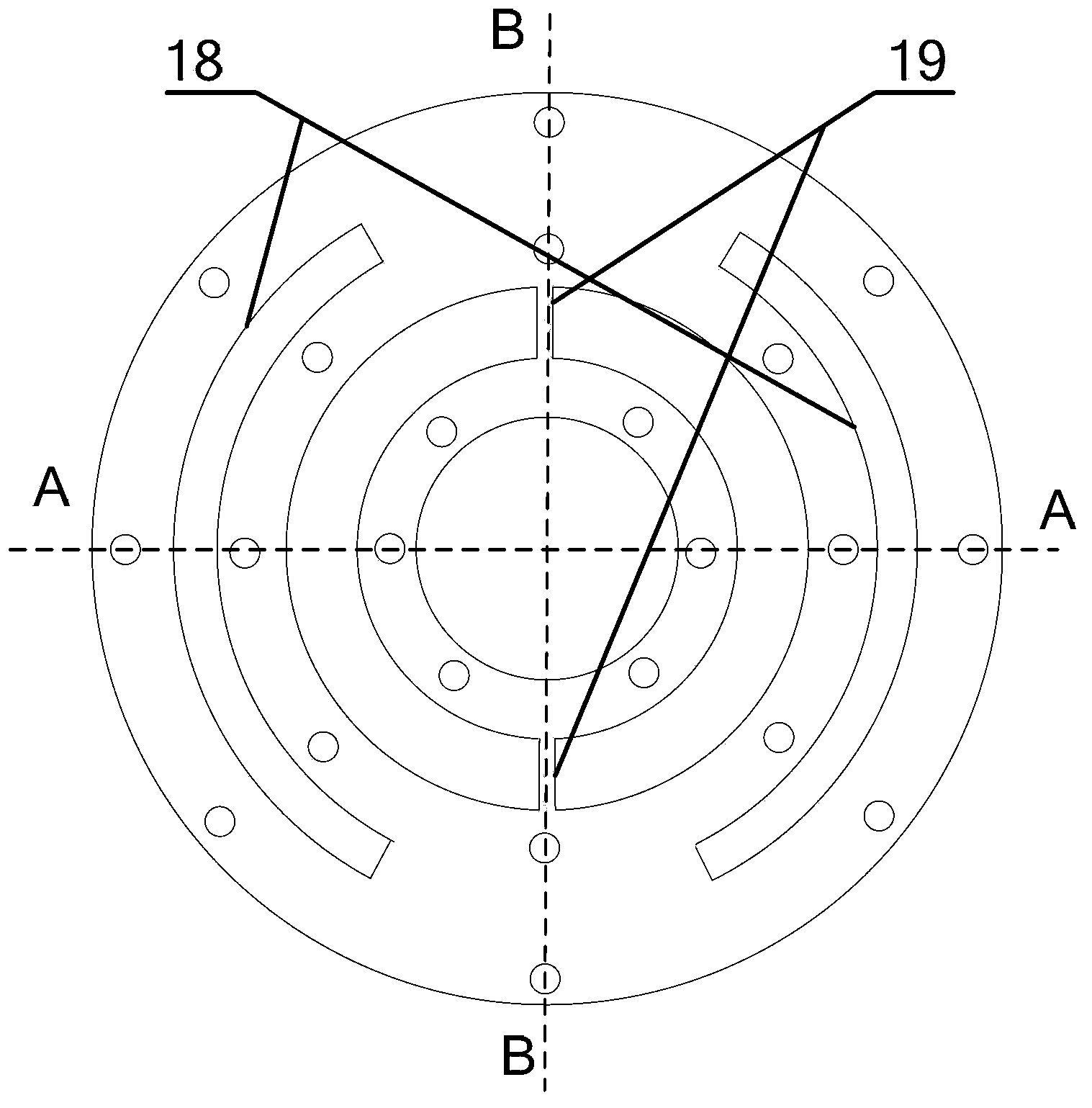

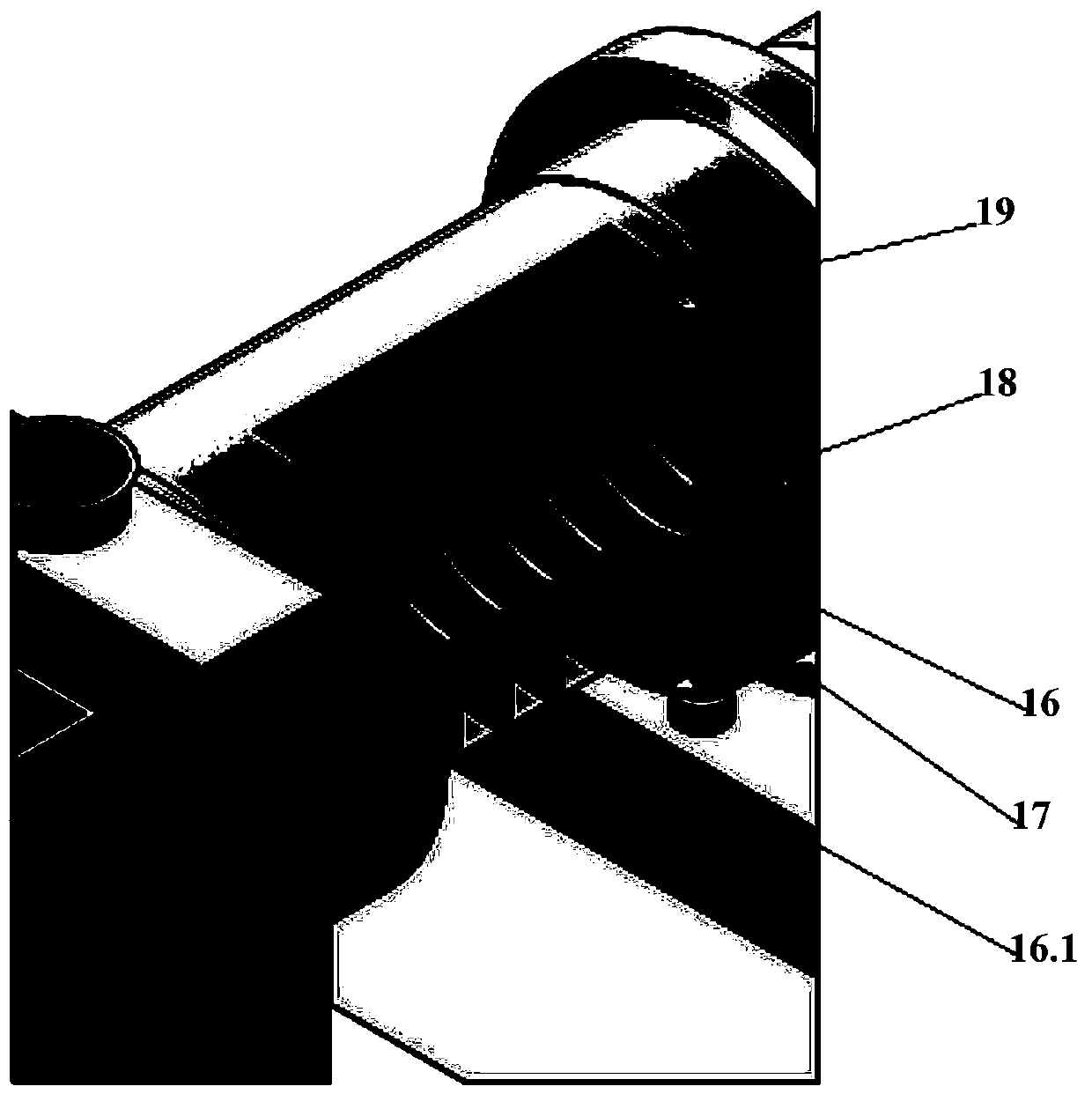

A cooling device for high-temperature calcination production

ActiveCN104913644BEasy to cleanEnough heat exchange areaHandling discharged materialWaste heat treatmentMetallic materialsEngineering

The invention belongs to the technical field of non-metallic material production equipment, and particularly relates to a cooling device for high-temperature calcination production. The cooling device comprises a cooling barrel (1) which comprises a primary cooling section (11) and a secondary cooling section (12), the primary cooling section (11) comprises a material pipe (2) and an air cavity (14), and the secondary cooling section (12) comprises an air pipe (10) and a material cavity (19). The cooling device has the advantages that the heat energy can be sufficiently recovered, and materials can be prevented from being brought into a rotary kiln for secondary overburning through cooling air.

Owner:SHANDONG LUBEI ENTERPRISE GROUP +1

Vaporizer

InactiveCN101769593BImprove vaporization efficiencyRemarkable effect of reducing consumption and saving energyStationary conduit assembliesStationary tubular conduit assembliesVaporizationProcess engineering

The invention discloses a vaporizer, which comprises a container and a heating device. The container is at least provided with one feed pipe and one discharge pipe; and the heating device is arranged in the container and provided with a group of heat exchange members. The invention also discloses application of the vaporizer in a process of preparing dimethyl ether by dehydrating liquid phase methanol. The vaporizer of the invention has the advantages of high vaporization efficiency, stable operation and control, safe use and convenient maintenance in the process of preparing the dimethyl ether by dehydrating the liquid phase methanol.

Owner:SHANGHAI WUJING CHEM

A fully premixed condensing heat exchanger

ActiveCN105823354BIncrease the heat exchange areaReduce in quantityCorrosion preventionHeat exchanger casingsHeat flowCombustion

The invention discloses a full-premix condensing heat exchanger which comprises a shell and a heat exchanger, wherein the heat exchanger comprises a first heat exchanger and a second heat exchanger; the first heat exchanger is connected with the second heat exchanger along the axial line; a heat flow partition for partitioning the shell into a primary heat exchange chamber and a secondary heat exchange chamber is further arranged in the shell; the second heat exchanger is arranged in the secondary heat exchange chamber; the first heat exchanger comprises first heat exchange pipes distributed along and around the axial line; the first heat exchange pipes are further connected with first fins; due to gaps between the first fins, a first fin group is formed; heat flow generated by combustion of mixed gas in the inner rings of the first fins is stopped by the heat flow partition and then penetrates through the gaps between the first fins to flow into the secondary heat exchange chamber, to exchange heat with the second heat exchanger. By the arrangement of the first fin group in the primary heat exchange chamber, enough heat exchange areas can be reserved between the heat flow and the first fins as well as between the heat flow and the first heat exchange pipes, and a proper gap is reserved between every two adjacent first fins; the heat exchanger is difficult to block and can difficultly corrode the first heat exchange pipes.

Owner:NINGBO HRALE PLATE HEAT EXCHANGER

Full-mixing esterification device and method in PBAT production process

PendingCN113877225AAvoid backmixingHigh esterification rateChemical/physical/physico-chemical microreactorsDistillation separationPtru catalystProcess engineering

A full-mixing esterification device in a PBAT production process comprises a reactor and a flash tank, a material channel inlet of the reactor is used for being connected with a BSA source, a BHBT source and a catalyst source, a micro-interface generator is arranged at the material channel inlet, a material channel outlet of the reactor is connected with the flash tank, a bottom liquid outlet of the flash tank is used for discharging BAT outwards, a top steam exhaust port of the flash tank is connected with a vacuum separator through a condenser, and non-condensable gas outlets of the condenser and the vacuum separator are both connected with a negative pressure source. The device is simple in structure and convenient to operate, the operation efficiency is greatly improved, the production requirement for large-scale production of PBAT can be met at low cost, the esterification rate of BSA and BHBT can be effectively increased to 98.5% or above in the BAT synthesis process, material backmixing can be effectively avoided, the load of the esterification steam separation procedure is relieved, and energy consumption is greatly reduced.

Owner:华峰集团上海工程有限公司

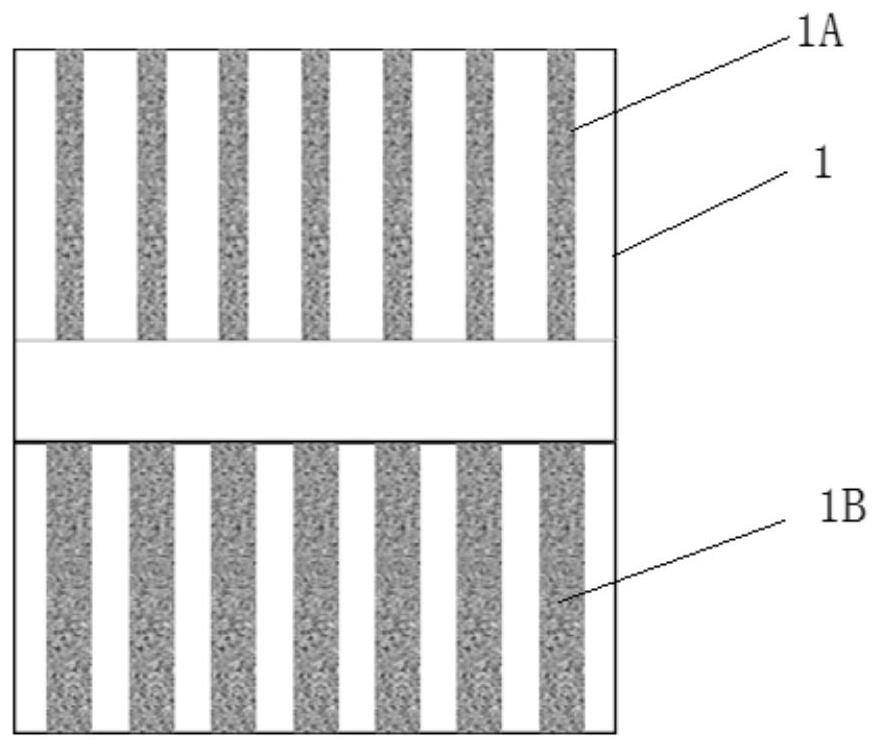

A multi-tubular moving bed reaction device for producing ammonia and hydrogen chloride by pyrolysis and separation of ammonium chloride

ActiveCN105753016BMeet the needs of pyrolysis heat exchangeEnough heat exchange areaPreparation from chloridesAmmonia preparation/separationCombustionFlue gas

The invention discloses a multi-tube moving bed reaction device for preparing ammonia and hydrogen chloride by virtue of pyrolysis separation of ammonium chloride. The multi-tube moving bed reaction device comprises an ammonia releasing device and a chloride releasing device, wherein the ammonia releasing device and the chloride releasing device are respectively provided with one or more feeding holes and discharging holes and are multi-tube moving bed reactors, a solid discharging hole of the ammonia releasing device is connected with a solid feeding hole of the chloride releasing device, and a solid discharging hole of the chloride releasing device is connected with a carrier feeding hole of the ammonia releasing device; and meanwhile, a heat supply channel of the chloride releasing device is connected with a heat supply channel of the ammonia releasing device, the chloride releasing device is heated by virtue of combustion, and the ammonia releasing device is heated by virtue of high temperature flue gas produced after the combustion. According to the multi-tube moving bed reaction device, by mounting a large amount of heat exchanging row tubes in reactors, sufficient heat exchanging areas are provided, and the heat exchanging requirements of pyrolysis of ammonium chloride are met; meanwhile, by utilizing a proper structure and operation conditions, the requirements on the pyrolysis reaction and flow of ammonium chloride are met, and the large-scale continuous industrial production can be realized; and meanwhile, the multi-tube moving bed reaction device can be applied to a sodium carbonate-chloroethylene coproduction process.

Owner:ZHEJIANG UNIV

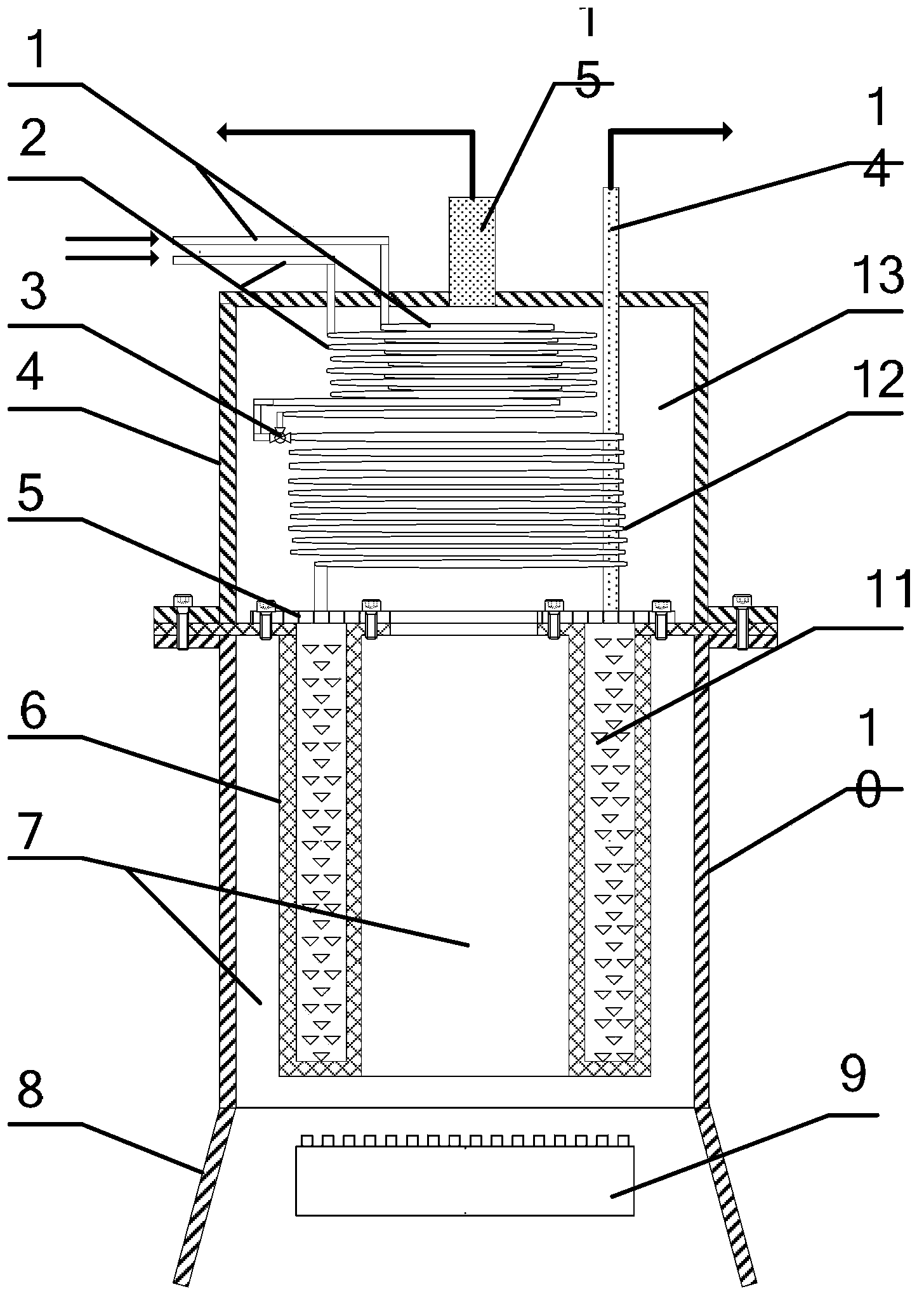

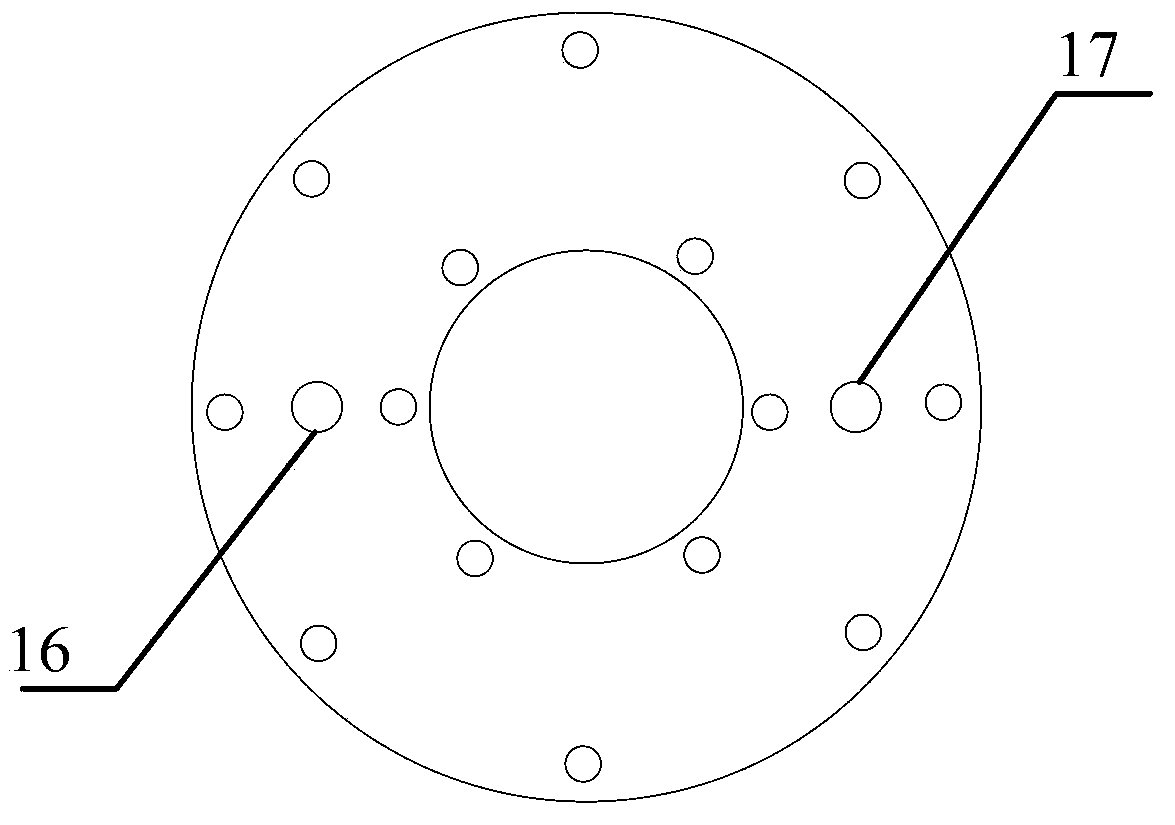

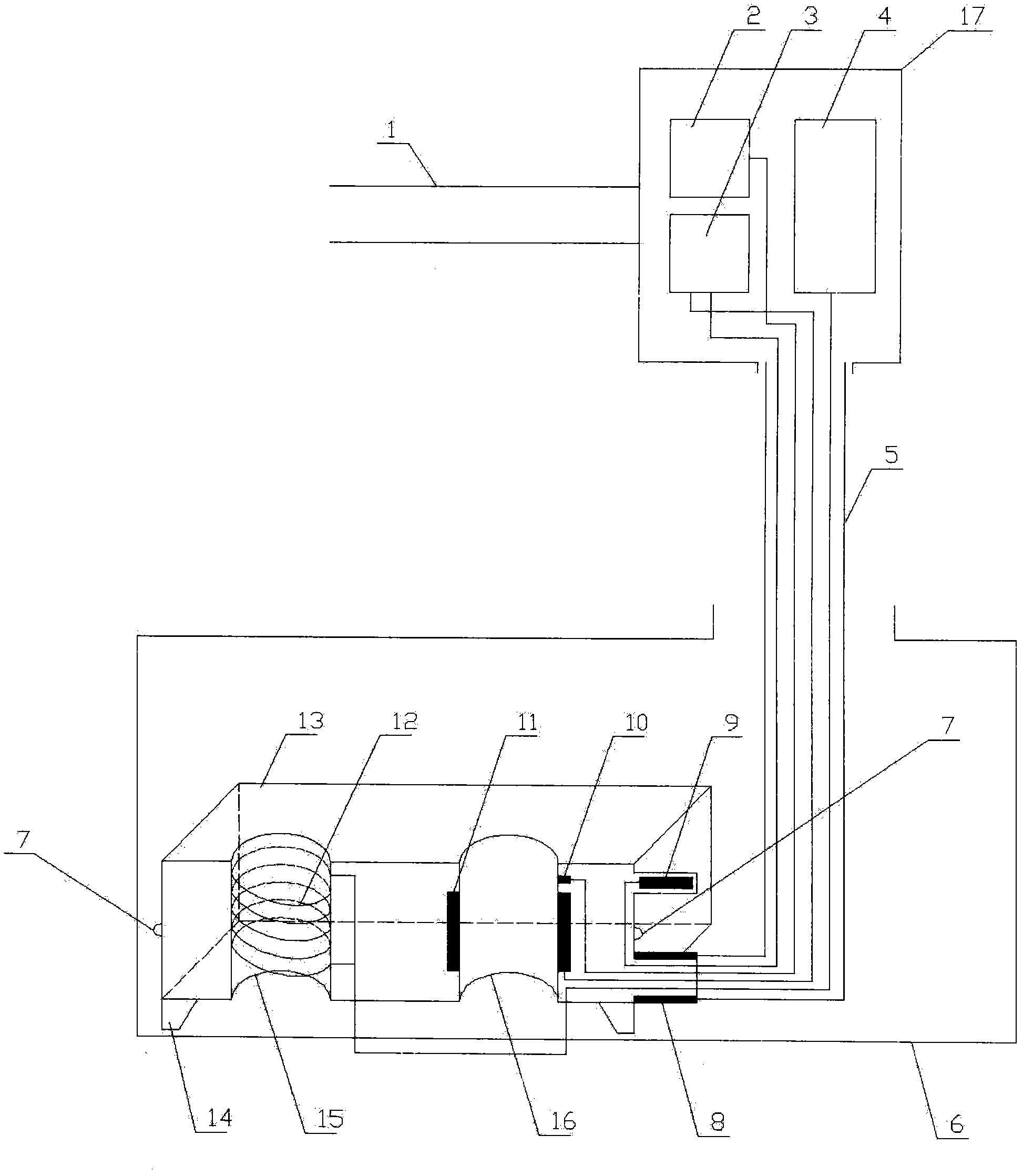

Method and device of hydrogen production by natural gas and steam reforming for micro fuel cells

InactiveCN102826507BImprove the heating effectImprove insulation effectHydrogenFuel cell heat exchangeMicrobial fuel cellSteam reforming

The invention discloses a method and a device of hydrogen production by natural gas and steam reforming for micro fuel cells. The device comprises an upper end cover, a reactor body, a reactor upper flange, a reactor outer cylinder, a combustor and a preheating coiled tube, the preheating coiled tube comprises a natural gas preheating tube, a water preheating tube and a gas mixture preheating tube, the upper end cover and the reactor outer cylinder are of hollow cylindrical structures, the preheating coiled tube is arranged in the upper end cover, the reactor body is arranged in the reactor outer cylinder, the combustor is arranged on the lower portion of the reactor body, the reactor body is in flange connection with the reactor outer cylinder and the upper end cover and is of a hollow annular structure with a hollow center, an annular cavity is arranged on the periphery of the hollow center, two baffles are arranged in the annular cavity and divide the annular cavity into a left cavity and a right cavity, gaps are reserved on the lower portions of the baffles, and catalyst particles are distributed in the left cavity and the right cavity. The device is used for preparing synthesis gas by natural gas and steam reforming, and is fast in starting, convenient and feasible to mount and demount and small in size and occupied area.

Owner:SOUTH CHINA UNIV OF TECH

A New Plate Axial Reactor

ActiveCN105080433BReduce volumeBig spaceHydrocarbon from oxygen organic compoundsChemical/physical processesEngineeringHeat exchanger

The invention relates to a novel plate-type axial reactor, comprising a reactor shell (5), a pair of heat exchange plates (6), a heat exchange medium distribution main pipe (10), a heat exchange medium distribution branch pipe (11), a heat exchange medium Collection main pipe (3) and heat exchange medium collection branch pipe (4), the reactor shell (5) is provided with reaction material inlet (1), reaction material outlet (8), heat exchange medium inlet (9) and heat exchange The medium outlet (2), the heat exchange plate pair bundle (6) is composed of multiple sub-heat exchange plate pair bundles, and one end of each sub-heat exchange plate pair bundle passes through the heat exchange medium distribution branch pipe (11) and the corresponding heat exchanger The heat medium distribution main pipe (10) is connected to the heat exchange medium inlet (9), and the other end is connected to the heat exchange medium outlet (2) through the heat exchange medium collection branch pipe (4) and the corresponding heat exchange medium collection main pipe (3). Compared with the prior art, the invention has the advantages of small volume, convenient catalyst loading and unloading, flexible structure, and multi-stage reaction.

Owner:ATHCO ENG SHANGHAI CO LTD

Fresh air unit and its control system

ActiveCN103528136BPrevent liquid backPrevent heat from frostingSpace heating and ventilation safety systemsLighting and heating apparatusFrostSolenoid valve

Owner:SHENZHEN MCQUAY AIR CONDITIONING

Drying and desliming system and process of plastic and fiber braided fabric waste

ActiveCN110274239AAvoid meltingMeet the needs of a large number of dryingIncinerator apparatusFiberEngineering

The invention relates to a drying and desliming system of plastic and fiber braided fabric waste. The system is composed of a quantitative feeding device, a hot air compensation device, a drying machine main body, a steam supplying device, a condensate water discharging device, a discharging and desliming device and a tail gas collecting device; and the drying machine main body is a steam rotary cylinder. The invention further relates to a drying and desliming process of the plastic and fiber braided fabric waste. According to the drying and desliming system and process, the problems of long drying time, low heat utilization efficiency and secondary pollution exist in an existing plastic and fiber braided fabric waste drying process can be solved, and the plastic and fiber braided fabric after drying and desliming can be efficiently treated or recycled.

Owner:张贤根

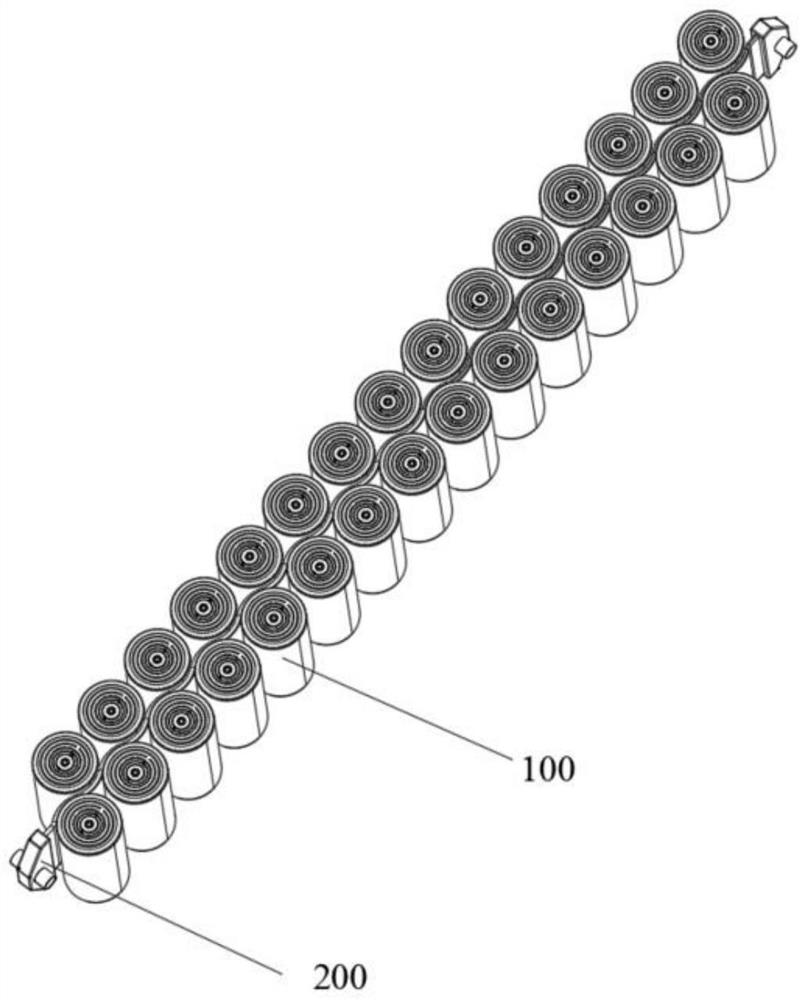

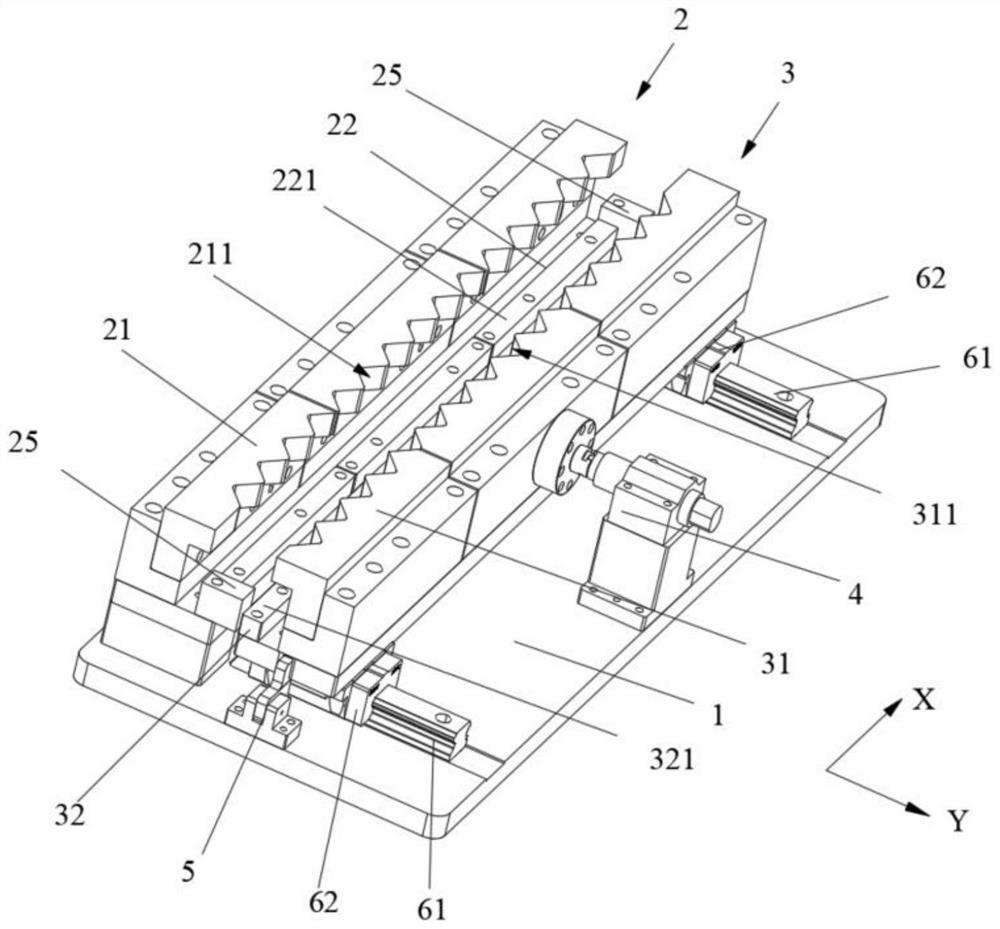

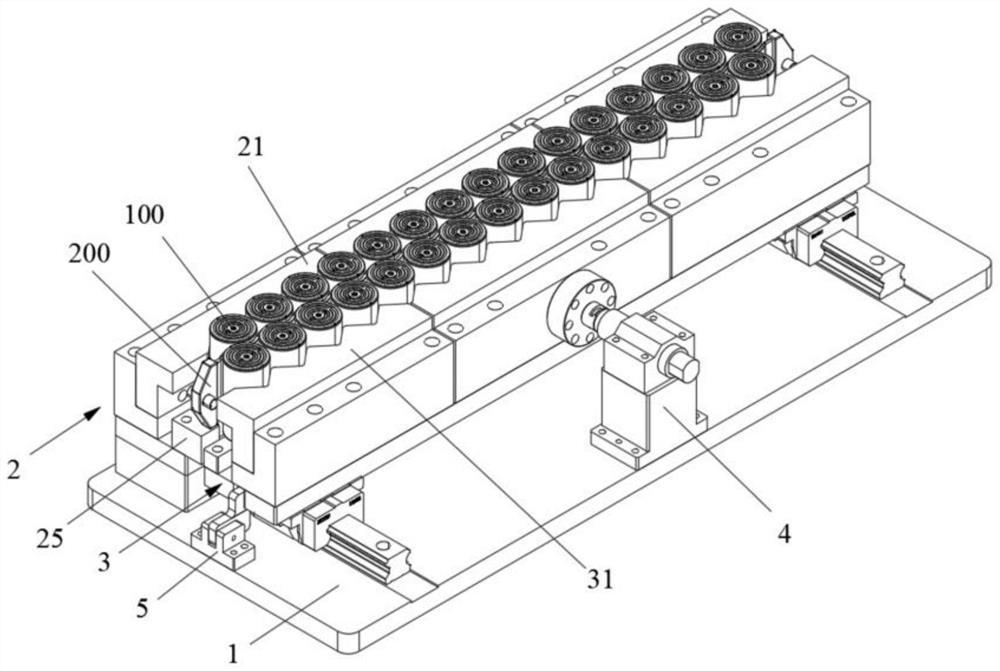

Cylindrical battery module assembling tool

PendingCN114759248AAvoid thermal runaway problemsImprove securityLi-accumulatorsElectrolyte accumulators manufactureEngineeringMechanical engineering

The invention relates to the technical field of battery assembly, and discloses a cylindrical battery module assembly tool. The cylindrical battery module assembling tool comprises a base, a first chuck assembly, a second chuck assembly and a driving assembly, the first chuck assembly is arranged on the base and can position a first row of cylindrical batteries arranged in the first direction, and the second chuck assembly is movably arranged on the base and can position a second row of cylindrical batteries arranged in the second direction. The side, facing the first chuck assembly, of the second chuck assembly can position a second row of cylindrical batteries arranged in the first direction, and the driving assembly is arranged on the base and used for driving the second chuck assembly to be close to the first chuck assembly in the second direction. And the two rows of cylindrical batteries clamp the liquid cooling plate between the two rows of cylindrical batteries under the preset pressure. According to the cylindrical battery module assembling tool, it can be guaranteed that the liquid cooling plate and the side wall of the cylindrical battery have the enough attaching area, and then the safety of the cylindrical battery module is guaranteed.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Tower of internal thermal coupling distillation tower and control process thereof

InactiveCN101596372BAvoid the difficult problem of internal thermal couplingGreat operating flexibilityFractional distillationEngineeringTower

The invention relates to a tower of an internal thermal coupling distillation tower and a control process thereof; the tower realizes the thermal coupling between a rectifying section and a stripping section only by using three external heat exchangers, one external heat exchanger is used for carrying out heat exchange between the top of the rectifying section and the top of the stripping sectionto realize the operation without external reflux of the internal thermal coupling distillation tower. One external heat exchanger is used for carrying out the heat exchange between the bottom of the rectifying section and the bottom of the stripping section, thus realizing the operation without external backheating of the internal thermal coupling distillation tower. One external heat exchanger is used for carrying out exchange between the middle of the rectifying section and the middle of the stripping section, thus realizing the thermal coupling action between the rectifying section and thestripping section. In the invention, the heat exchangers are arranged outside the rectifying section and the stripping section for facilitating the areas of the heat exchangers not to be limited by the distillation process any more, thus ensuring enough heat exchange areas. Due to the heat exchangers arranged at the top of the rectifying section and the bottom of the stripping section, the operation elasticity, dynamic characteristic and controllability of the distillation tower are improved.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method](https://images-eureka.patsnap.com/patent_img/ea3dff81-53be-4567-bec7-f83e0d2d6bfa/150520163456.png)

![High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method](https://images-eureka.patsnap.com/patent_img/ea3dff81-53be-4567-bec7-f83e0d2d6bfa/150520163505.png)

![High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method](https://images-eureka.patsnap.com/patent_img/ea3dff81-53be-4567-bec7-f83e0d2d6bfa/150520163510.png)