Full-mixing esterification device and method in PBAT production process

A production process and chemical device technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of high investment cost of PBAT, small production capacity, low esterification efficiency, etc., and improve the esterification efficiency. , to avoid the back mixing of materials and improve the efficiency of esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

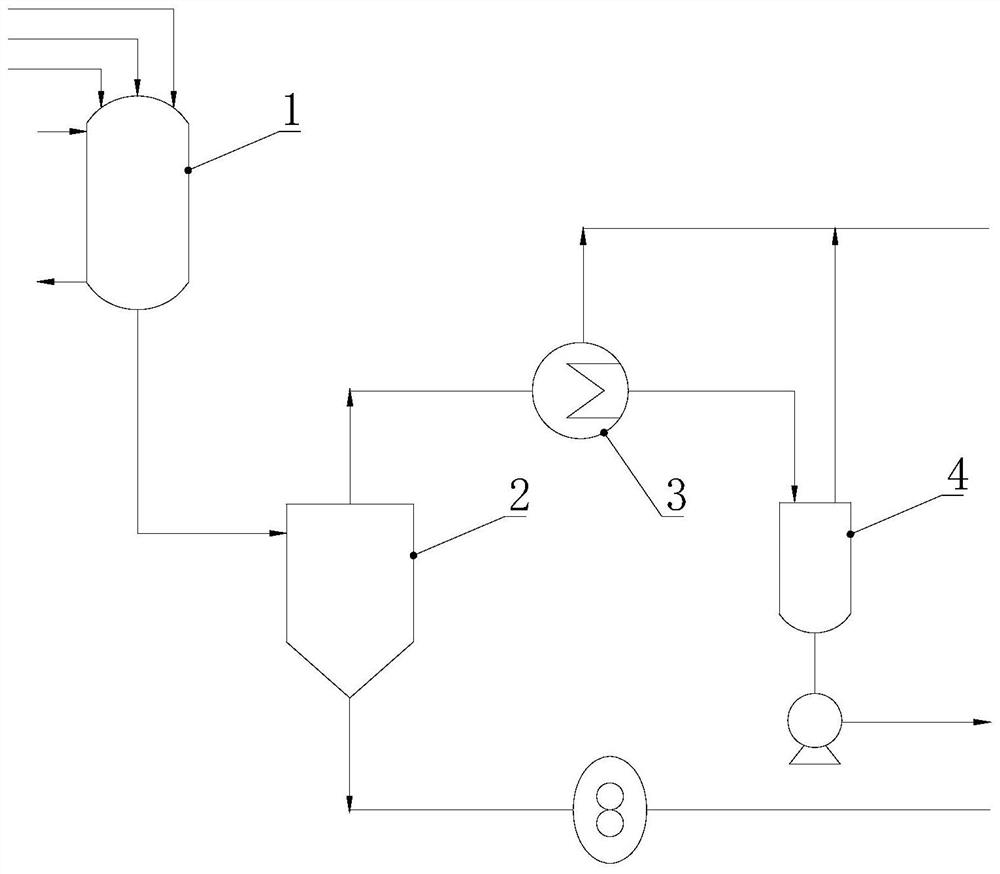

[0040] see figure 1 , is a specific embodiment of a fully mixed esterification device in the production process of PBAT. The fully mixed esterification device in the PBAT production process includes a reactor 1 and a flash tank 2. In this embodiment, the reactor includes a micro-interface generator, a coiled pipe, and a closed shell, and the closed shell extends vertically. The coiled tube of the housing is a material channel, and the space between the material channel and the housing is a heat medium channel. The medium inlet of the medium channel is located at the upper part of the side wall of the housing, and the medium outlet of the medium channel is located at the side of the housing. In the lower part of the wall, the heat medium channel uses a mixture of biphenyl and diphenyl ether as the heat medium. The mass ratio of biphenyl and diphenyl ether is 1:3. The material channel extends in a reciprocating bend in the inner space of the shell. Specifically , the pipeline i...

Embodiment 2

[0042] The method for synthesizing BAT using the fully mixed esterification device of embodiment 1 may further comprise the steps:

[0043] 1) BSA (butylene adipate, obtained from the AA / BDO esterification process), BHBT (bishydroxybutyl terephthalate, obtained from the PTA / BDO esterification process) in a molar ratio of 1:1, Enter the material channel of the reactor through the micro interface generator with the catalyst (tetrabutyl titanate, the addition amount is 0.1-0.5kg / tPBAT) to carry out the esterification reaction, and the inlet of the medium channel is passed into the gaseous heat medium (biphenyl Mixed with diphenyl ether at a mass ratio of 1:3), exothermic and liquefied, discharged from the outlet of the medium channel, and formed a cycle after vaporization, so that the temperature of the internal esterification reaction in the material channel is 200-270 ° C, in the material channel 1.5h of the time, obtain the mixture of BAT, oligomer;

[0044] 2) The mixture of B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com