Novel reactor for preparing epoxy propane by oxidizing propylene with hydrogen peroxide

A technology of propylene oxide and hydrogen peroxide, applied in chemical instruments and methods, chemical industry, organic chemistry, etc., can solve problems such as limited mixing time and space, affecting product performance, and uneven materials, so as to improve reaction selectivity and yield, prolonging service life, and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

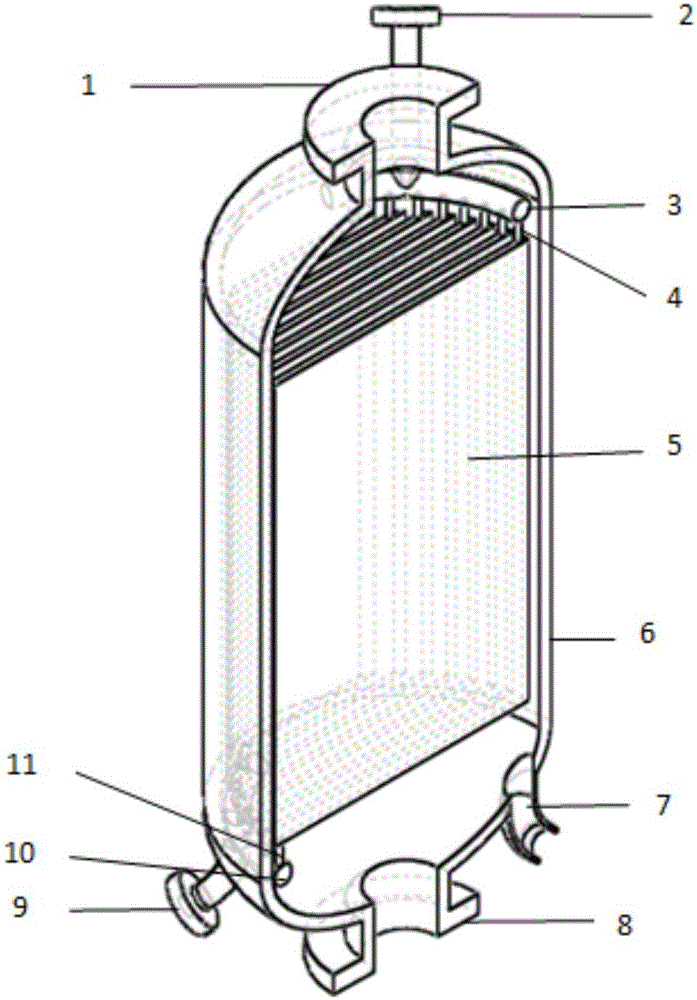

[0046] Such as figure 1 As shown, a new reactor for hydrogen peroxide oxidation of propylene to propylene oxide, including reactor shell, heat exchange plate bundle, heat exchange medium distribution main pipe, heat exchange medium distribution branch pipe, heat exchange medium collection main pipe and Heat exchange medium collection branch pipe, the reactor shell is provided with a reaction material inlet, a reaction material outlet, at least one heat exchange medium inlet and a heat exchange medium outlet, and the heat exchange plate pair bundle 6 is composed of multiple groups of sub-exchangers One end of each sub-heat exchange plate pair bundle is connected to the heat exchange medium inlet of the reactor shell 5 through the heat exchange medium distribution branch pipe 11 and the corresponding heat exchange medium distribution main pipe 10, and the other end is passed through the heat exchange medium collection branch pipe 4 and the corresponding heat exchange medium coll...

Embodiment 2

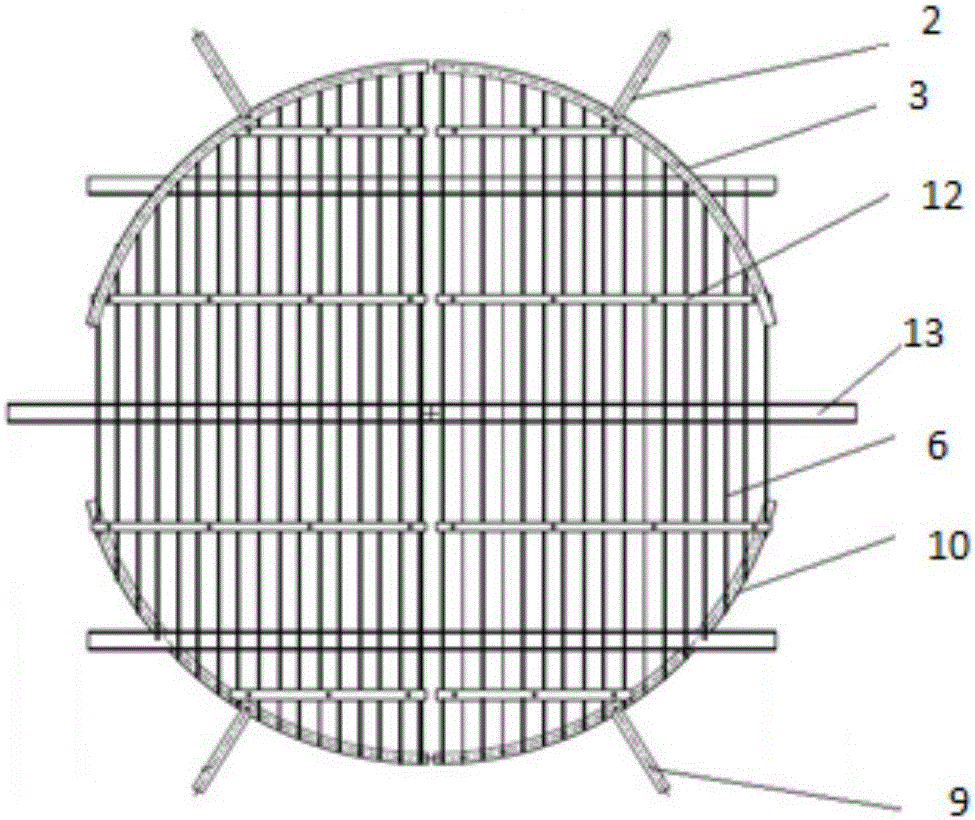

[0056] Such as image 3 As shown, in this embodiment, multiple groups of sub-heat exchange plate pairs divide the heat exchange plate pair bundle 6 into quarter structures in the horizontal direction, and the quarter structure is four groups of fan-shaped sub-heat exchange plate pairs The bundle is arranged around the central axis of the reactor, and the heat exchange plate pairs in each sub-heat exchange plate bundle are parallel to each other, and the heat exchange medium distribution main pipe 10 and the heat exchange medium collection main pipe 3 are also arc-shaped. The distance between heat exchange plates is 10-60mm. All the other are identical with embodiment 1.

Embodiment 3

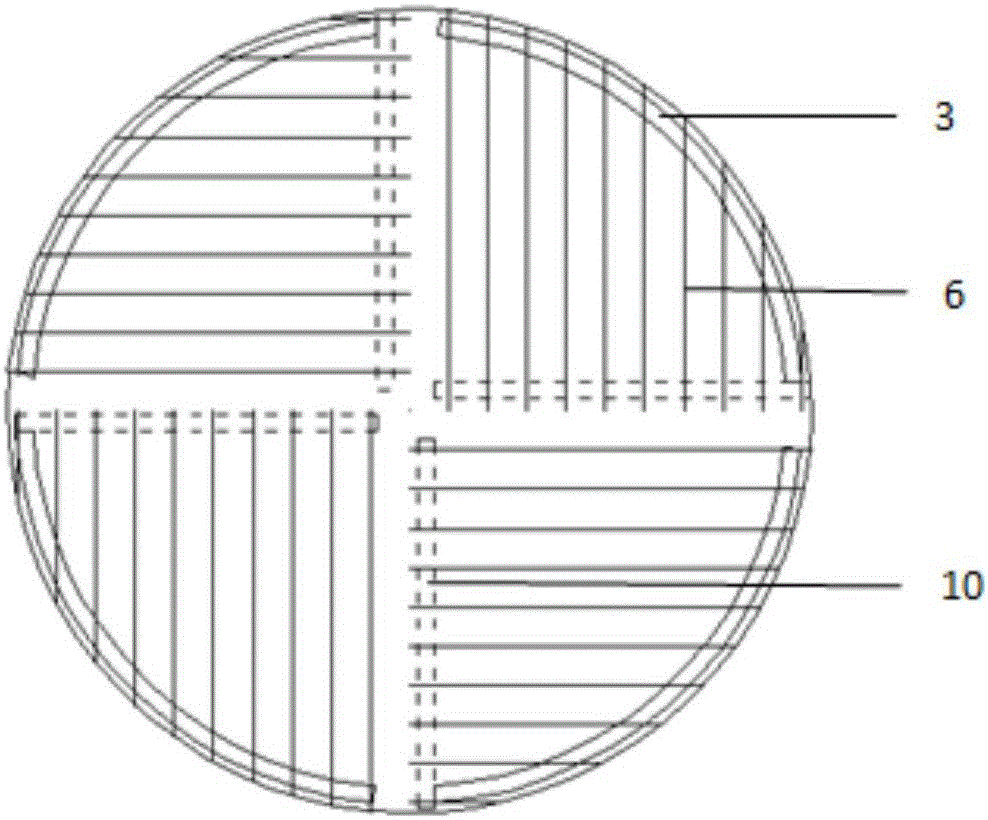

[0058] Such as Figure 4 As shown, in this embodiment, multiple groups of sub-heat exchange plate pairs divide the heat exchange plate pair bundle 6 into quarter structures in the horizontal direction, and the quarter structure is four groups of fan-shaped sub-heat exchange plate pairs The bundles are arranged around the central axis of the reactor. The difference from Example 2 is that in each sub-bundle of heat exchange plates, the heat exchange plate pairs in adjacent sub-pairs of heat exchange plates are perpendicular to each other. The distance between heat exchange plates is 10-60mm. All the other are identical with embodiment 2.

[0059] When the diameter of the reactor is less than or equal to 2m, the bisecting structure of Example 1 is preferably used; when the diameter of the reactor is between 2 and 4m, the quartering structure of Example 2 or Example 3 is preferably used to reduce the The manufacturing cost of the heat exchange plate pair is convenient for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com