A cooling device for high-temperature calcination production

A cooling device and high-temperature calcination technology, applied in the direction of processing discharged materials, waste heat treatment, furnaces, etc., can solve the problems of low heat exchange efficiency and low heat energy recovery rate, and achieve the effect of increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Cooling 18~20t / h high temperature calcined a-alumina

[0050] The material temperature before cooling is 890 C°, the material volume is 18-20t / h, and the material temperature after cooling is <100 C°.

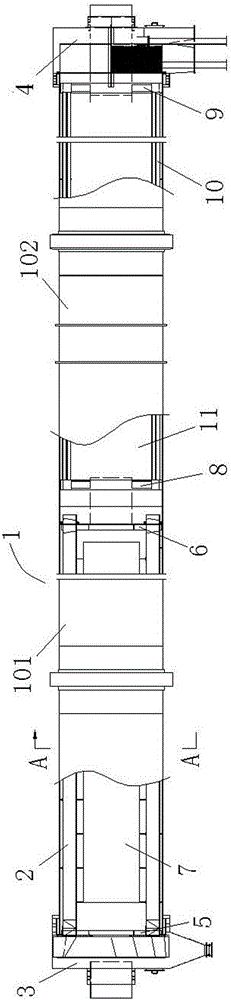

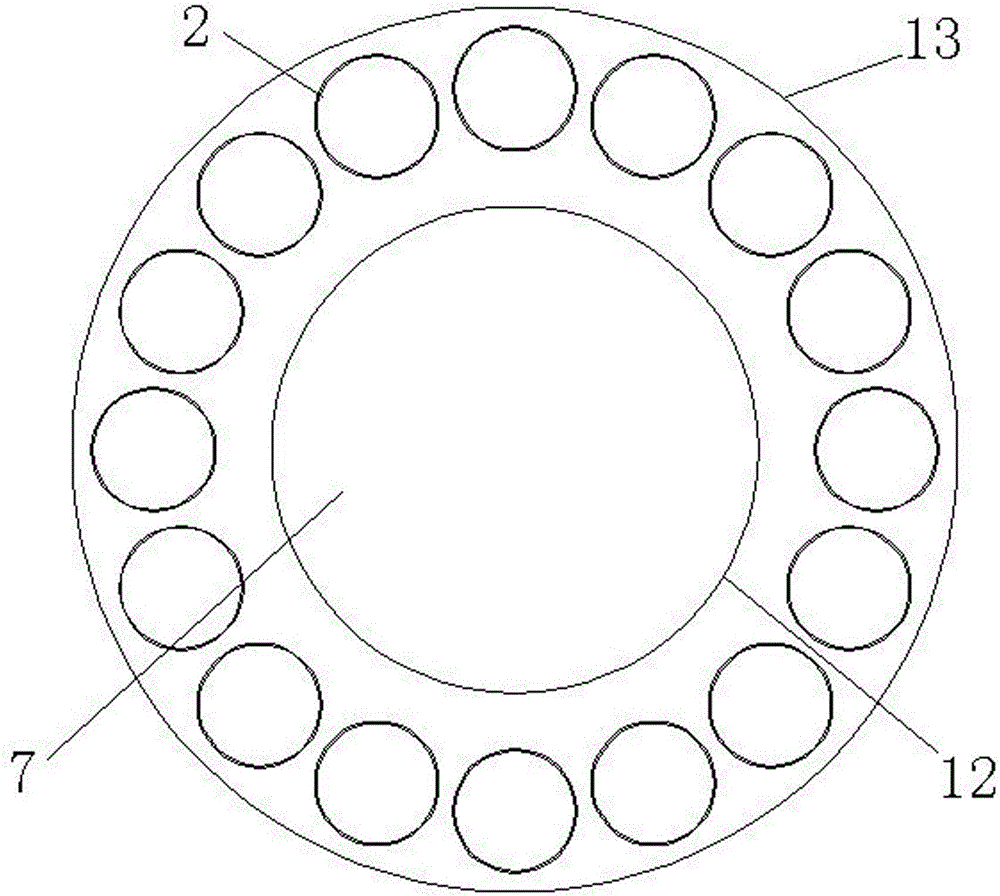

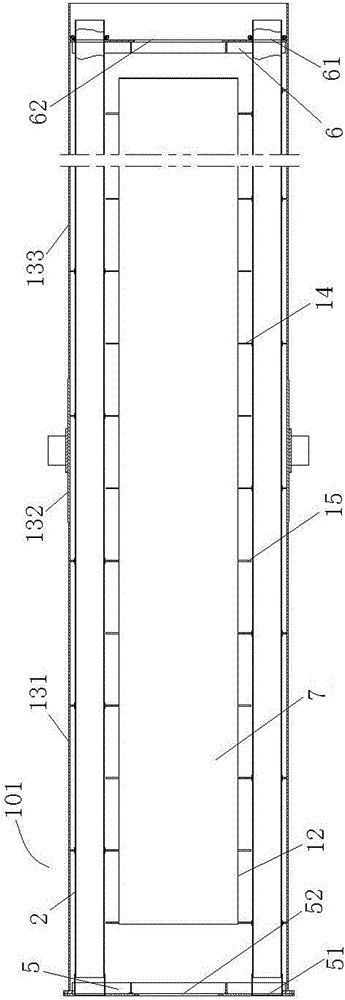

[0051] The specifications of the cooling cylinder: cylinder 13 diameter 3.6m*38m, material pipe 2 diameter 470mm, thickness 6mm, length 18000mm, quantity 18, single-layer distribution, material stainless steel, air duct 10 diameter 108mm, thickness 6mm, length 18000mm, quantity 100, double-layer distribution, material carbon steel, blower air volume 22500m3 / h.

[0052] Cylinder installation slope: 4%, cylinder speed: 4.23r / min.

[0053] Energy-saving effect of cooling device:

[0054] 1.23kj / kg. ℃×1000kg×(890℃-100℃)=971700 kj / t

[0055] 971700 kj / t×60%=583020 kj / t

[0056] Save 583020 kj of heat energy per hour.

Embodiment 2

[0057] Example 2: cooling 10t / h high temperature calcined a-alumina

[0058] The material temperature before cooling is 910 C°, the material volume is 10t / h, and the material temperature after cooling is <100 C°.

[0059] Cooling cylinder specifications: diameter 3.m*38m, material pipe 2 diameter 400mm, thickness 6mm, length 18000mm, quantity 16, single-layer distribution, material stainless steel, air duct 10 diameter 108mm, thickness 6mm, length 18000mm, quantity 80, Double-layer distribution, material carbon steel, blower air volume 15000m3 / h.

[0060] Cylinder installation slope: 4%, cylinder speed: 4.23r / min.

[0061] Energy-saving effect of cooling device:

[0062] 1.23kj / kg. ℃×1000kg×(910℃-100℃)=996300kj / t

[0063] 996300kj / t×60%=597780kj / t

[0064] Save 5977800kj of heat energy per hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com