A fully premixed condensing heat exchanger

A heat exchanger, fully premixed technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc. Heat pipe working life and other issues, to achieve stable work, reduce material consumption, and maintain the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

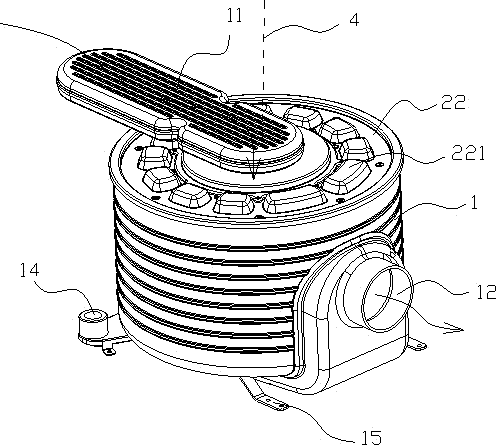

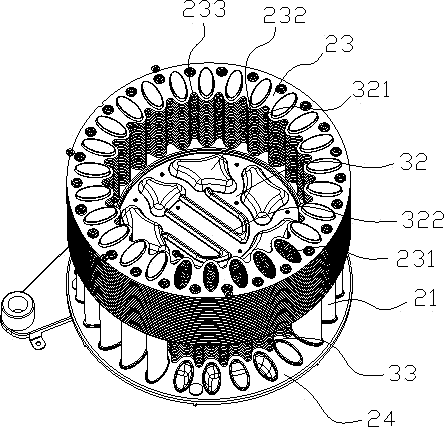

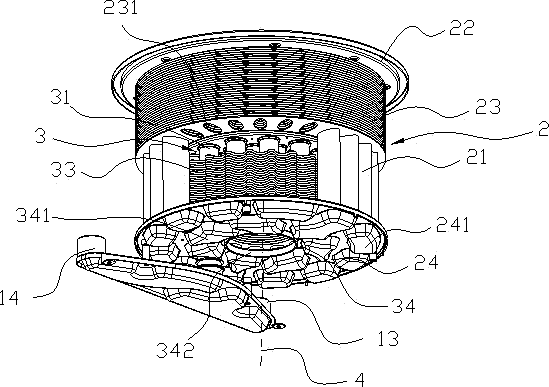

[0031] Such as Figures 1 to 5 As shown, the heat exchanger includes a first heat exchanger 2 and a second heat exchanger 3, and the first heat exchanger 2 is sequentially connected with the second heat exchanger 3 along the axis 4; The heat flow partition divides the cavity of the shell 1 into the main heat exchange chamber and the secondary heat exchange chamber, and the second heat exchanger 3 is arranged in the secondary heat exchange chamber; the first heat exchanger 2 includes the first heat exchange tube group , the first deflector plate and the first fin group; the first heat exchange tube group is composed of a plurality of first heat exchange tubes 21, and the first heat exchange tubes 21 are arranged along the axis 4 and distributed in a ring around the axis 4; The first deflector includes an upper first deflector 22 and a lower first deflector 24, the upper first deflector 22 is arranged in the main heat exchange chamber, and the upper first deflector 22 is arrange...

Embodiment 2

[0039] Such as Figure 6 As shown, the second deflector 32 at the upper end is a plate structure, and the heat flow partition is composed of the second deflector 32 at the upper end, and the second deflector 32 at the upper end is integrated with the first deflector 24 at the lower end Forming (or separately set up and then connected), the inner ring of the first fin group is closed by the integrally formed lower end first deflector 24 and upper end second deflector 32; the heat flow collides with the upper end second deflector When the plate 32 turns to the gap between the first fins 23; at the same time, the heat flow collides with the guide channel provided by the second guide plate 32 at the upper end, and exchanges heat with the water flowing in the guide channel; the second fin The outer ring area of 33 is smaller than the area of the first fin 23, and the second fin 33 groups are connected with the first fin 23 in a stepped shape, and the outer ring shape of the sec...

Embodiment 3

[0041] The shape of the outer ring of the second fin 33 is consistent with the shape of the outer ring of the first fin 23, and the second fin 33 is provided with a hole for the first heat exchange tube 21, and the first heat exchange tube 21 passes through the first heat exchange tube 21 The through hole is connected to the second fin 33 to ensure that the second fin 33 has a larger heat exchange area. In some cases, the number of the second fin 33 can be reduced, and the axial height of the entire heat exchanger can be reduced. , providing heat exchange for the first heat exchange tube group 21 at the same time, and reducing the difficulty of mold manufacturing when the first fins 23 and the second fins 33 are stamped and formed.

[0042] The present invention divides the shell into the main heat exchange chamber and the secondary heat exchange chamber, and sets the first fin group in the main heat exchange chamber to ensure sufficient heat exchange between the heat flow and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com