Method and device of hydrogen production by natural gas and steam reforming for micro fuel cells

A micro fuel cell and steam reforming technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of bulky and unsuitable reactors, and achieve safe and reliable operation and small footprint. , The effect of reducing channel flow and dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

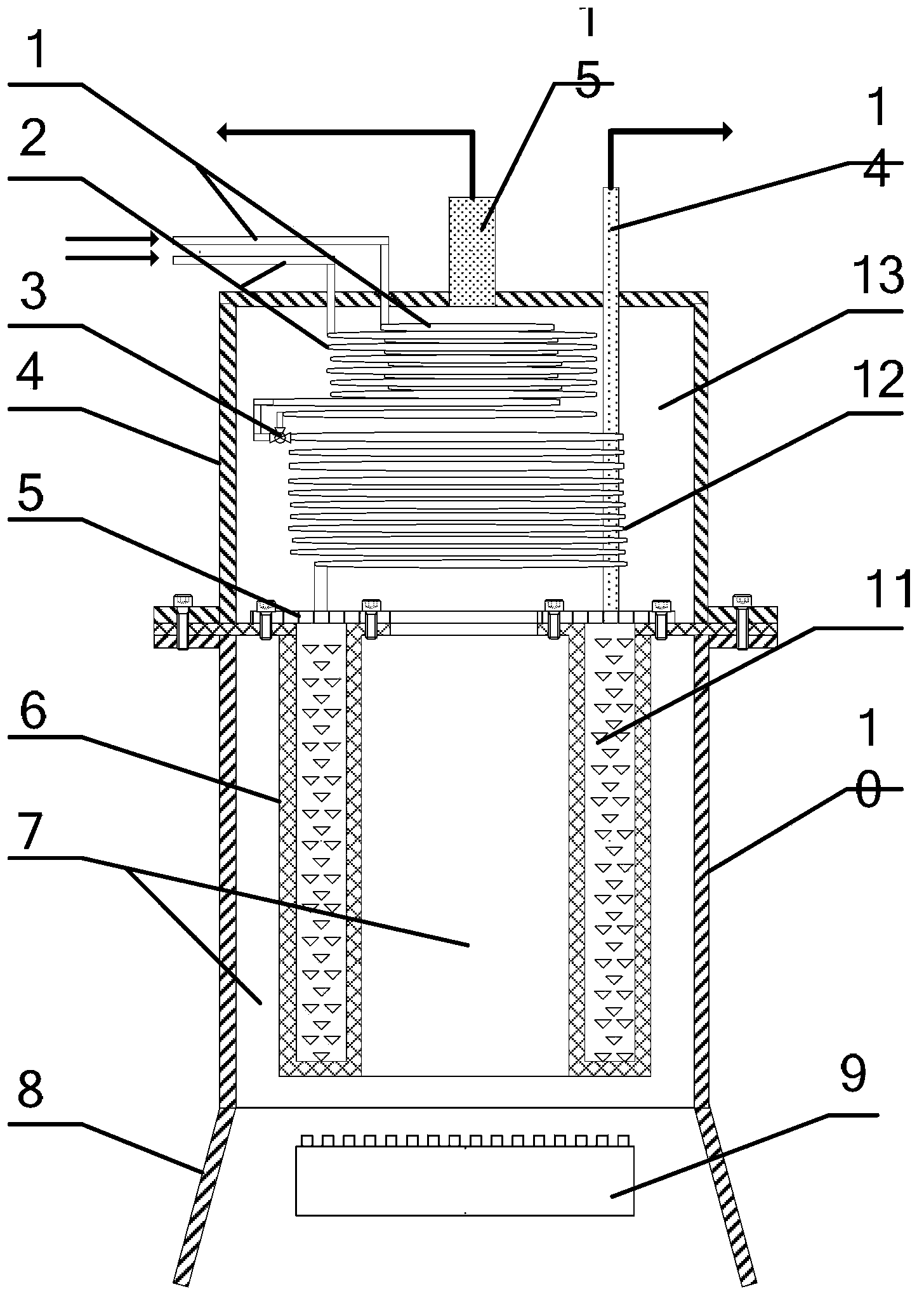

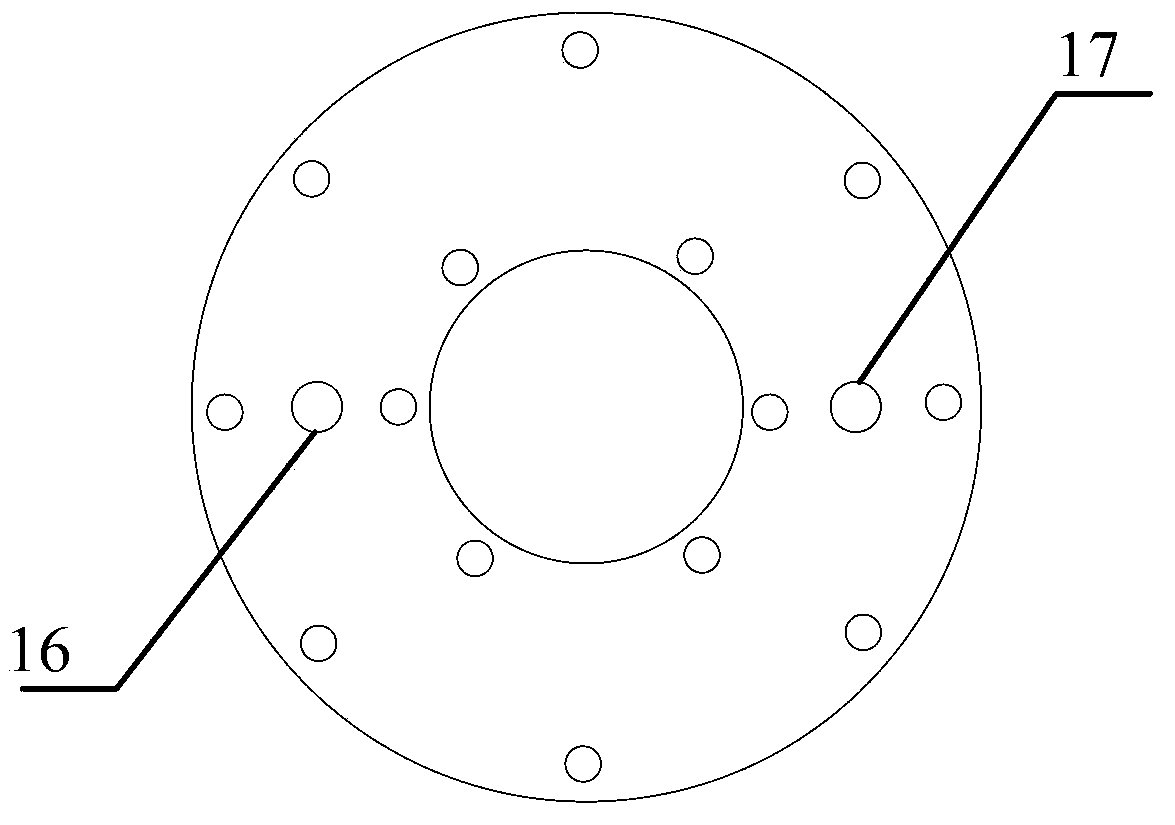

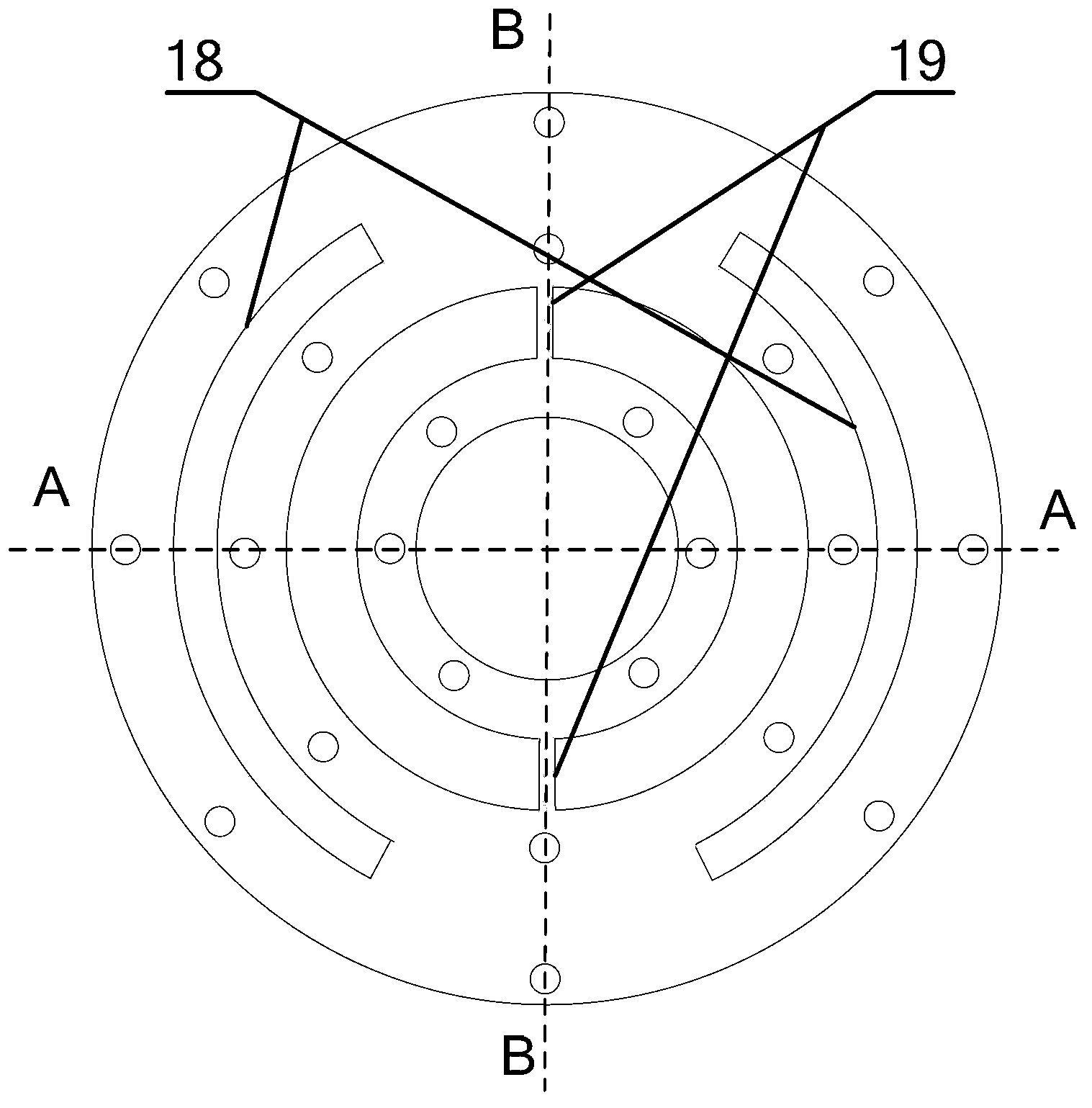

[0060] Catalyst particle 11 is selected from the reforming hydrogen production catalyst produced by Shandong Qilu Petrochemical Keli Chemical Research Institute. The catalyst is based on α-Al 2 o 3 As the carrier, metal nickel is the active component, the particle diameter is 5mm, and the loading capacity is 0.9L; the inner ring diameter R of the reactor main body 6 1 =160mm, outer ring diameter R 2 =196mm and height H=200mm, the height of the gap 22 on the baffle plate 19 is 20mm; the width of the arc-shaped channel on both sides of the joint between the upper part of the reactor main body 6 and the upper flange 5 of the reactor is 3cm; the diameter of the outer cylinder 10 of the reactor R 3 =300mm, length is 240mm, the length of the steel bar support of four stainless steels is 12cm, and the diameter of upper end cover 4 is 300mm, and height is 200mm; Thermal insulation material is ceramic fiber, and its thickness is 12cm; Natural gas preheating pipe 1, water The diamete...

Embodiment 2

[0063] Catalyst particle 11 is selected from the reforming hydrogen production catalyst produced by Shandong Qilu Petrochemical Keli Chemical Research Institute. The catalyst is based on α-Al 2 o 3 As the carrier, metal nickel is the active component, the particle diameter is 5mm, and the loading capacity is 1.8L; the diameter of the inner ring of the reactor body 6 is R 1 =160mm, outer ring diameter R 2 =196mm and height H=400mm, the height of the baffle plate 19 gap is 40mm; the width of the arc-shaped channel on both sides of the joint between the upper part of the reactor main body 6 and the upper flange 5 of the reactor is 3cm; the diameter R of the reactor outer cylinder 10 3=300mm, the length is 480mm, the length of the steel bar support made by four stainless steels is 20cm, the diameter of the upper end cover 4 is 300mm, and the height is 200mm; the insulation material is ceramic fiber, and its thickness is 12cm; natural gas preheating pipe 1, water The diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com