Vaporizer

A vaporizer and container technology, which is applied in the types of heat exchangers, indirect heat exchangers, dehydration of hydroxyl-containing compounds to prepare ether, etc., can solve the problems of low vaporization efficiency of vaporizers, improve vaporization efficiency, increase evaporation area, and maintain handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

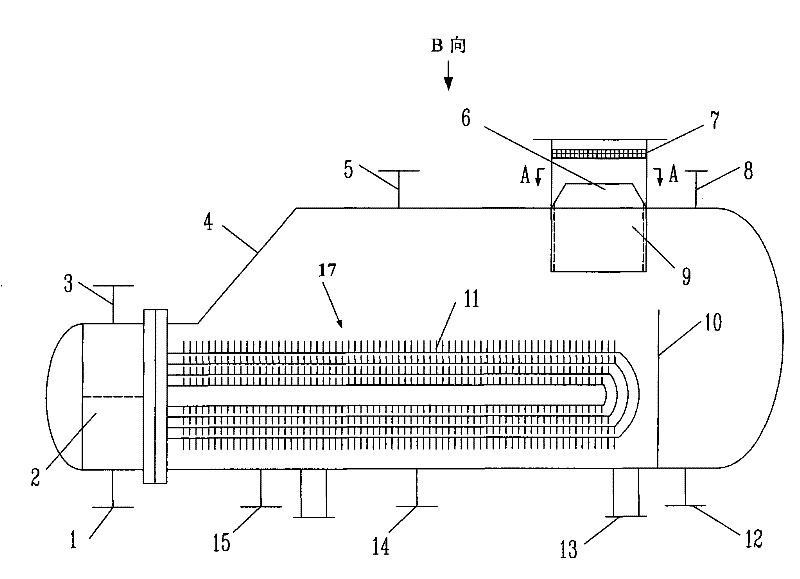

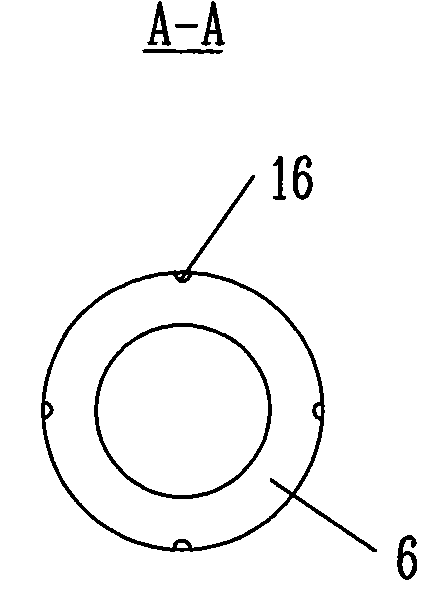

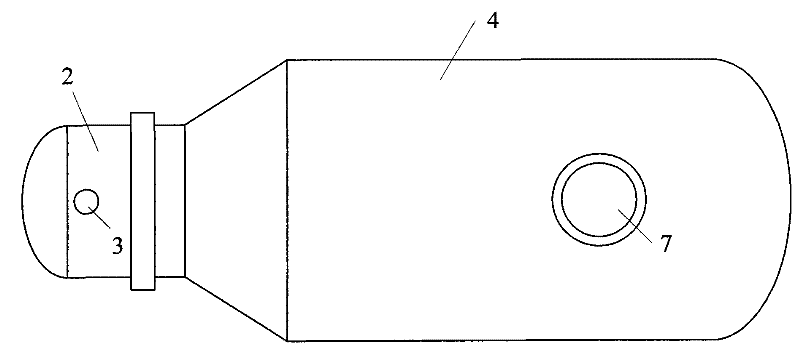

[0025] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0026] Take the process of preparing dimethyl ether by dehydration of methanol in liquid phase as an example, such as Figure 1 ~ Figure 3 As shown, the present invention specially designs a horizontal vaporizer, which includes a container 4 and a heating device 17 disposed in the container 4 , the heating device 17 has a pipe box 2 . Through the tube box 2 , an external heat source can be continuously input into the heating device 17 , so as to heat and vaporize the liquid-phase methanol in the container 4 . Wherein, the heating device 17 is used for heating the liquid in the container 4, and the pipe box 2 is connected with the heating device 17, and the steam of the external heat can be cyclically input into the heating device 17, and the condensed water output from the heating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com