Drying and desliming system and process of plastic and fiber braided fabric waste

A technology of fiber weaving and plastic, which is applied in the field of plastic and fiber weaving waste drying and desliming system, which can solve the problems of increased operating costs, secondary pollution, and large floor space, and achieve the effect of eliminating pollution and preventing plastic melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

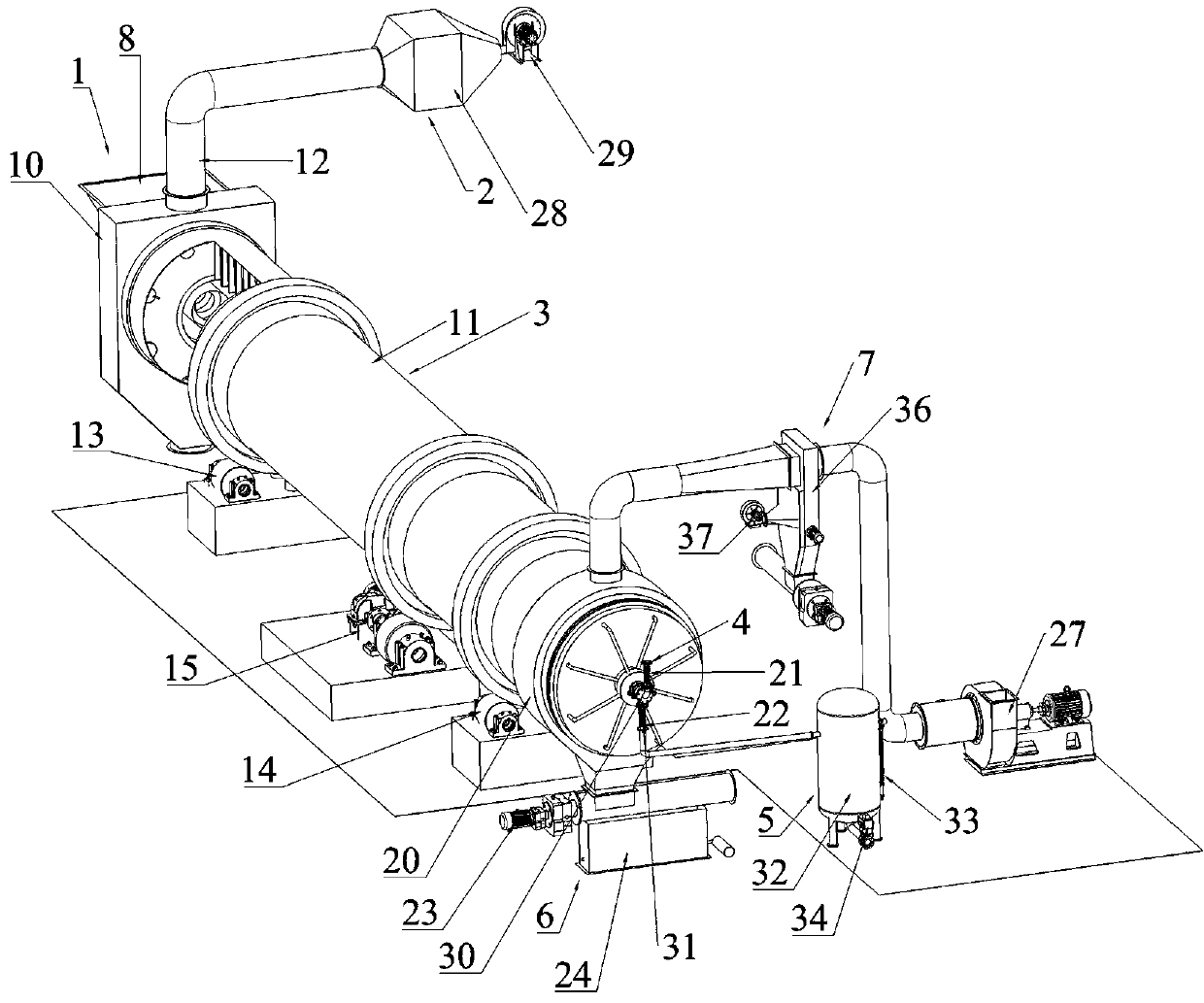

[0028] Now in conjunction with accompanying drawing, the present invention is described in detail:

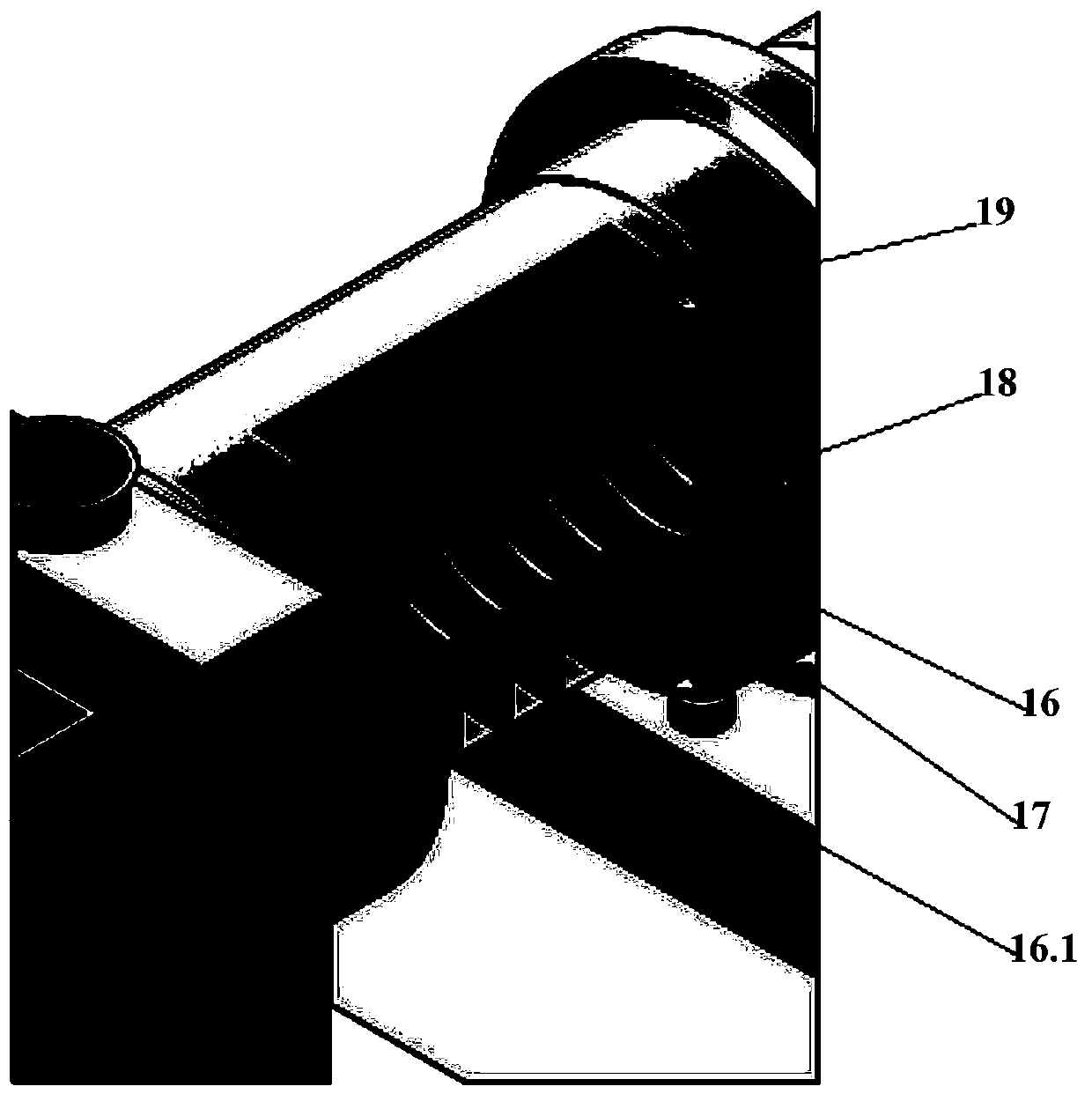

[0029] A plastic and fiber braided waste drying and desliming system: including quantitative feeding device 1, hot air compensation device 2, dryer main body 3, steam supply device 4, condensed water discharge device 5, discharge desliming device 6 and exhaust gas Capture device 7. The quantitative feeding device 1 is composed of a sealed feed box 10 and a frequency conversion shaftless screw feeder No. 19; the hot air compensation device 2 is composed of a finned tube heat exchanger 28 and a blower 29; the The main body 3 of the dryer is a steam rotary cylinder 11; the condensed water discharge device 5 is composed of a rotary joint 30, a metal hose 31, a condensed water storage tank 32, a liquid level gauge 33 and an electronically controlled drain valve 34; The discharge desliming device 6 is composed of the bottom reticulated shaftless screw discharge machine No. 1 23, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com