Enamel inner container water tank with condenser

A condenser and liner technology, which is applied in the field of hot water storage tanks, can solve the problems of low cost performance, low energy efficiency ratio, and poor heat exchange effect of enamel liner water tanks, and achieve small size, improved energy efficiency ratio, and improved cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

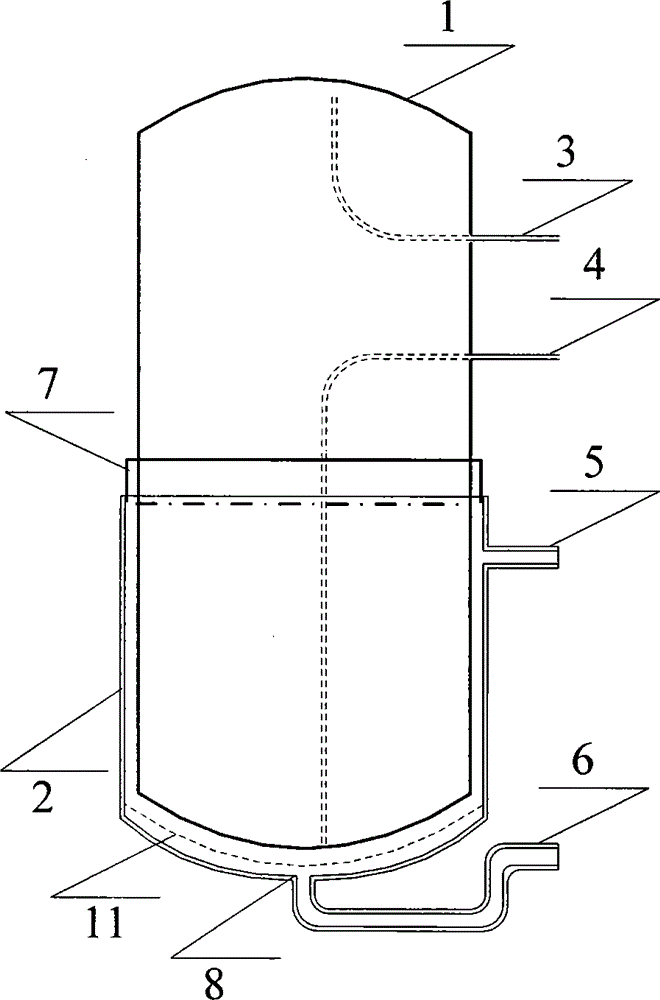

[0017] like figure 1 , 2 , the condenser of the present invention needs to withstand the pressure of about several Mpa, so in addition to the design and manufacture according to the requirements of the pressure vessel, the diameter of the enamel inner tank of the water tank is preferably smaller, which can reduce the thickness of the steel plate for making the inner tank and the cover, and also The capacity of the enamel liner should be determined according to the flow of hot water. Usually, the capacity of the enamel liner with a flow rate of 12L / 60S of hot water is in the range of 120-150L, and the capacity of the enamel liner with a flow rate of less than 10L / 60S of hot water is sufficient in the range of 70L-90L. For example, when the diameter of the enamel liner When the height of the former is about 300mm, the height of the former water tank is about 2M, which can be combined with the design and production of "post-type" water tanks in combination with the decoration ...

Embodiment 2

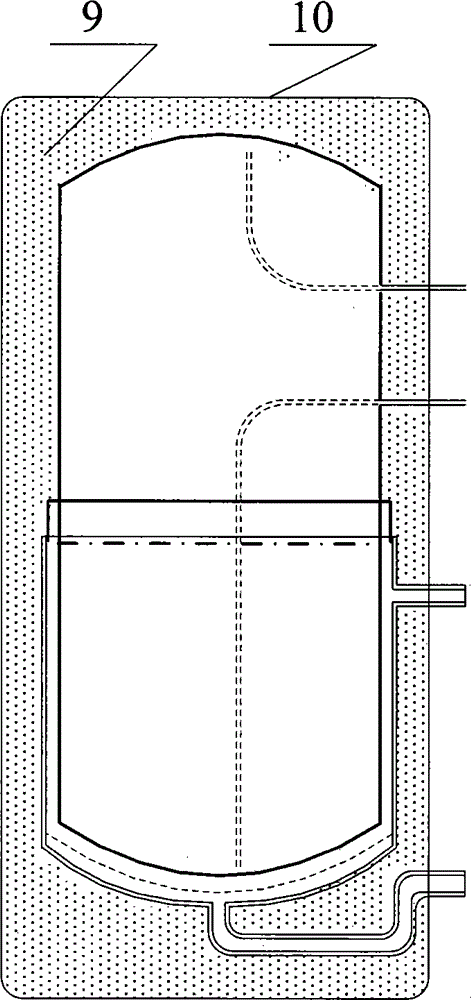

[0021] like image 3 , coexist two or more inner bladders of the present invention (two inner bladders in this example) in a water tank shell, and a heat pump unit is equipped with two or more water tanks, two or two The inner tank and the condenser of the above water tank are connected in parallel respectively, so that the capacity of the water tank is added.

Embodiment 3

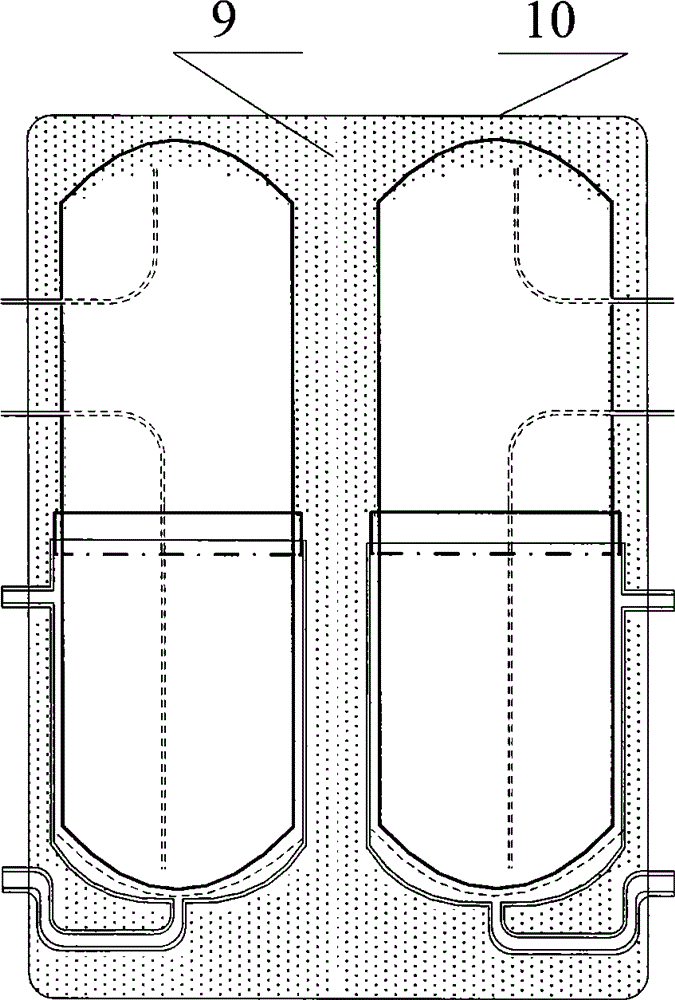

[0023] like figure 2 , connect two or more water tanks of the present invention (in this example, several water tanks are not marked for description) in parallel, the specific method is that the inner liner and the condenser of the two or more water tanks are connected in parallel respectively, so that The capacities of the smaller diameter tanks are added together until the volume and flow of hot water required by the user are met. In this way, the capacity of this example can exceed all "volumetric water heaters", and the overall volume is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com