A multi-tubular moving bed reaction device for producing ammonia and hydrogen chloride by pyrolysis and separation of ammonium chloride

A technology of moving bed reactor and reaction device, which is applied in the direction of chlorine/hydrogen chloride, preparation with chloride, preparation/separation of ammonia, etc. It can solve the problems of lack of introduction of reactor type, structure and operating conditions, etc., and achieve repeatability and Make full use of and realize the effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

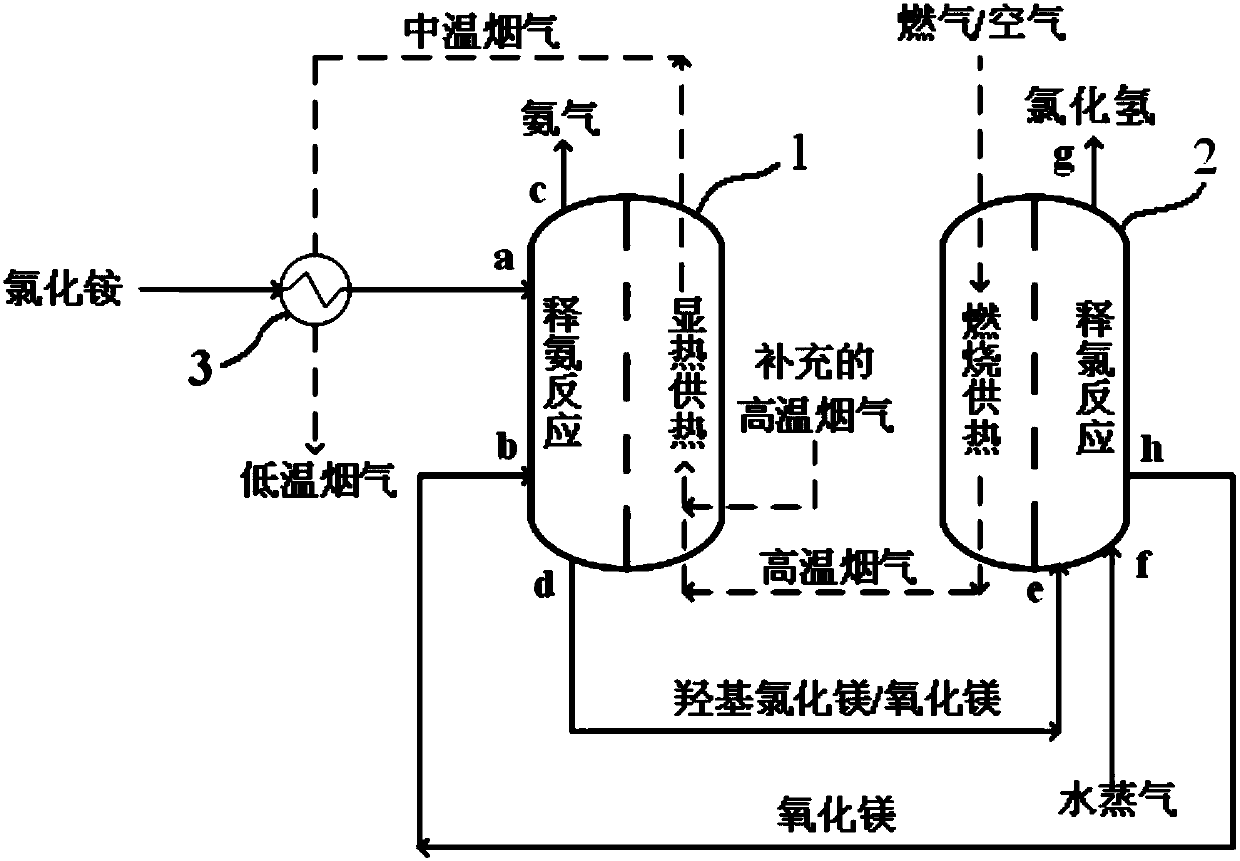

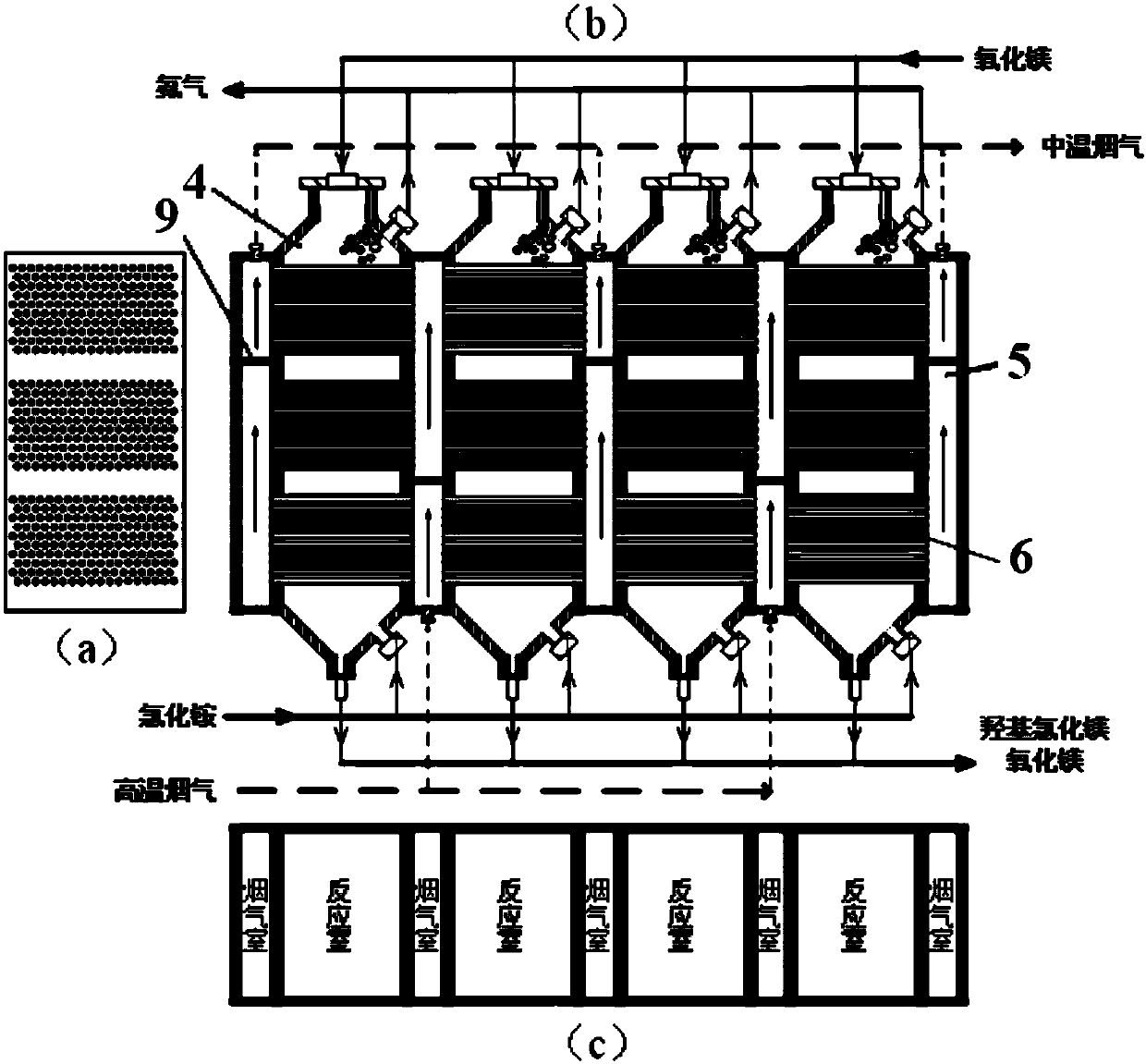

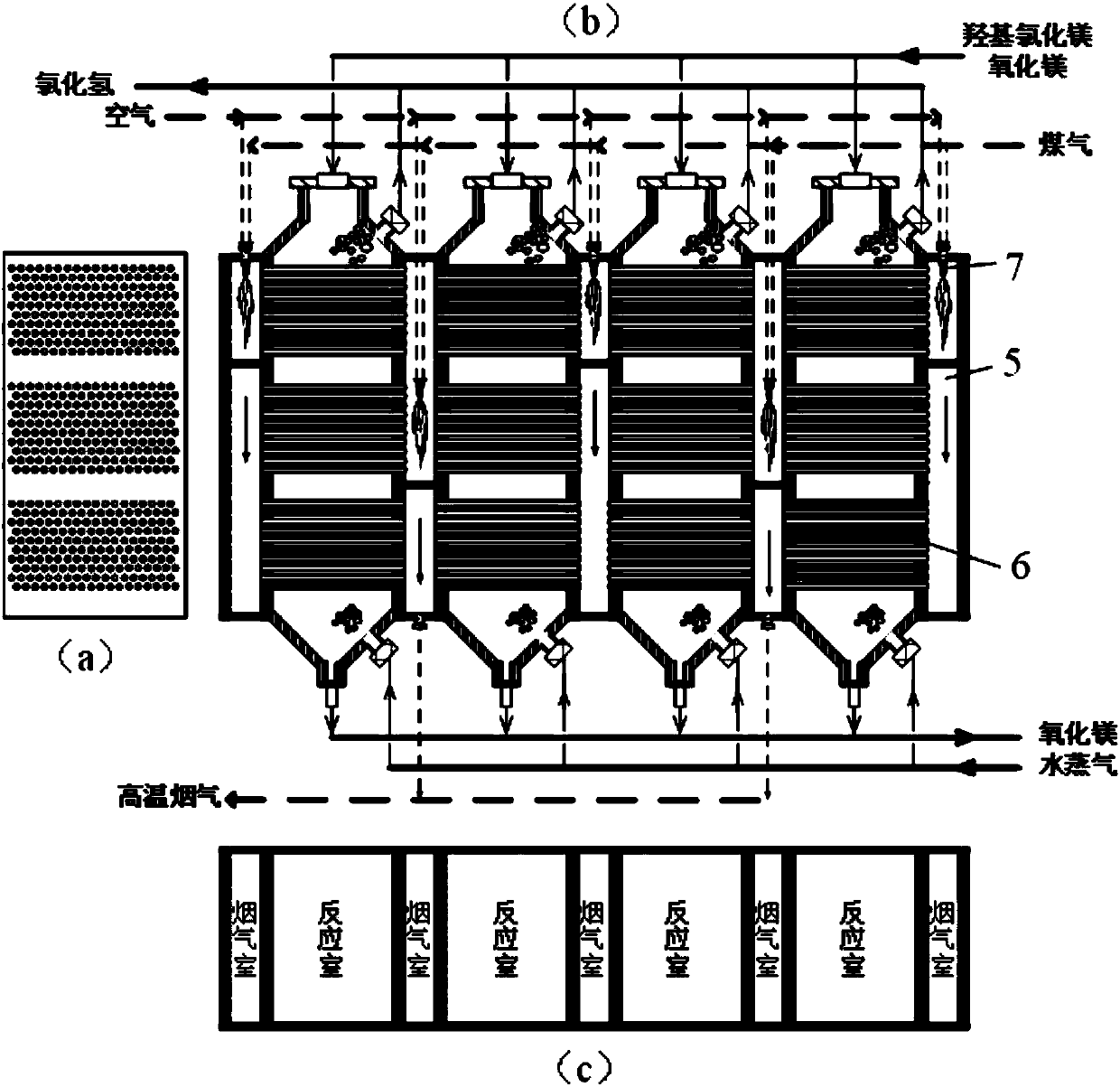

Embodiment 1

[0082] Taking the device that handles 10,000 tons of ammonium chloride per year as an example, the ammonium chloride chemical chain recycling ammonia and hydrogen chloride release process and chlorine release process are all carried out in a horizontal tube moving bed reactor ( figure 2 with image 3 ). exist image 3 In the chlorine release device shown, the reaction material is the solid phase material obtained after the ammonia release process, that is, a mixture of magnesium oxide (chemical chain cycle carrier) and magnesium hydroxychloride, and the mass flow rate of the mixture feed is 2.3t / h, of which the oxidation The molar ratio of magnesium to hydroxymagnesium chloride is about 1:2. At the same time, during the reaction process, a certain amount of atmospheric pressure water vapor is reversed into the cylinder, and the water vapor is provided by a vaporizer at 200°C. Combustion nozzles are evenly arranged on the upper part of the flue gas chamber, and the volume fl...

Embodiment 2

[0086] Still taking the annual processing capacity of 10,000 tons of ammonium chloride as an example, the ammonium chloride chemical chain recycling ammonia and hydrogen chloride release process and chlorine release process are all carried out in the vertical pipe moving bed reactor ( Figure 4 with Figure 5 ). exist Figure 5 In the shown chlorine release device, the reaction material is the solid-phase material obtained after the ammonia release process, that is, a mixture of magnesium oxide (chemical chain cycle carrier) and magnesium hydroxychloride, and the mass flow rate of the mixture feed is 2.3t / h, of which magnesium oxide The molar ratio to hydroxymagnesium chloride is about 1:2. At the same time, during the reaction process, a certain amount of atmospheric pressure water vapor is reversed into the tube, and the water vapor is provided by a vaporizer at 200°C. The volume flow rate at normal temperature is about 0.28m 3 The air and volume flow rate of / s is about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com