Hydrogen storage alloy PCT curve testing device and method

A technology of hydrogen storage alloy and testing device, which is applied to the analysis of materials, instruments, etc., can solve the problems of inaccurate measurement of the internal temperature of the sample chamber, affect the accuracy and objectivity of the test, and affect the accuracy of experimental data, etc., to achieve fully automatic PCT Curve test, small footprint, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

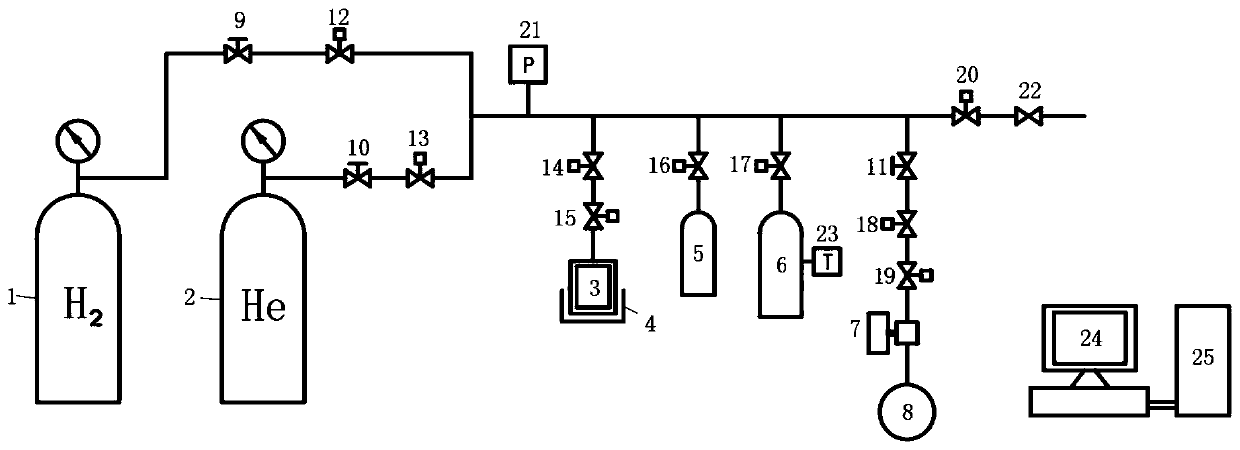

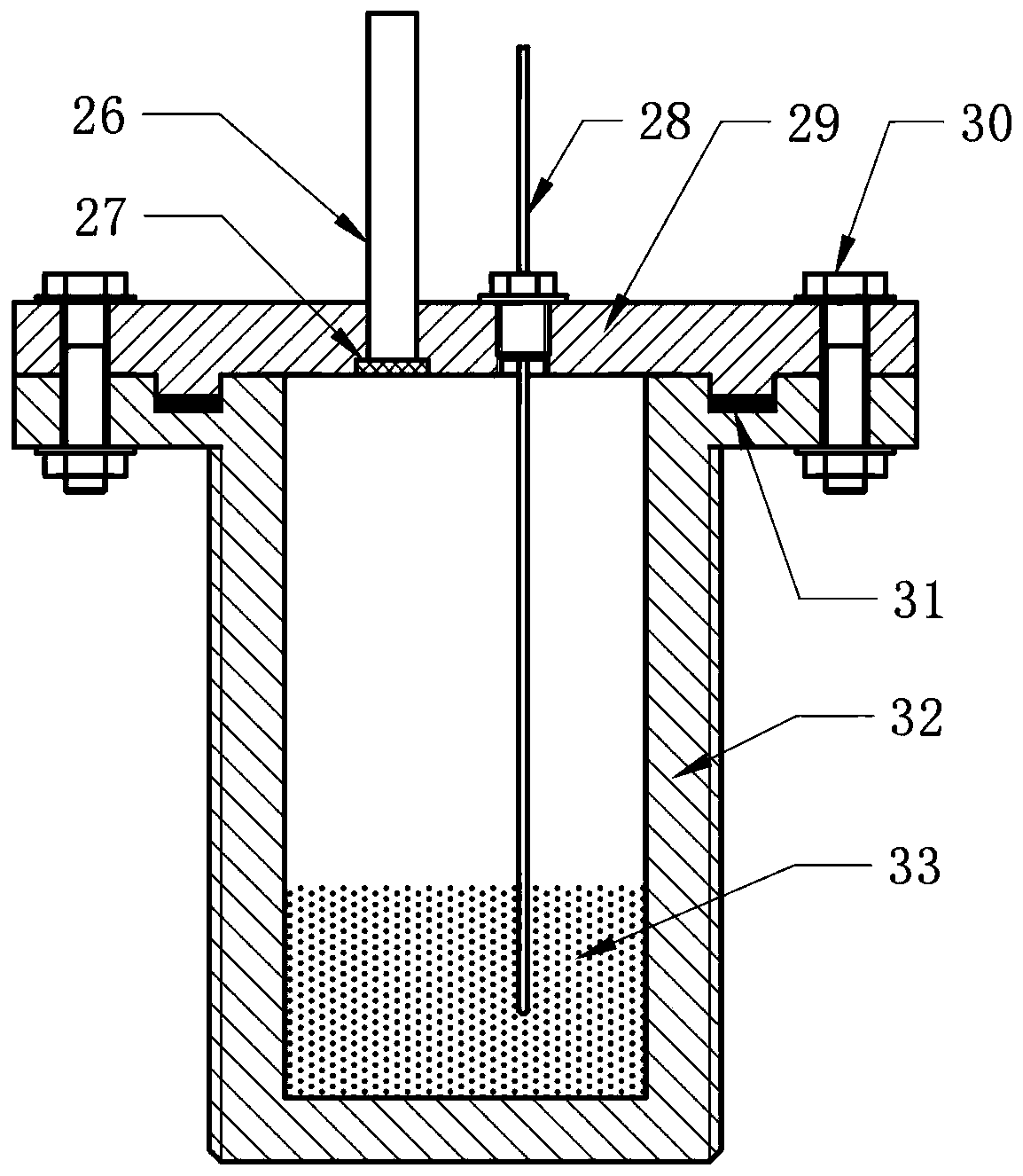

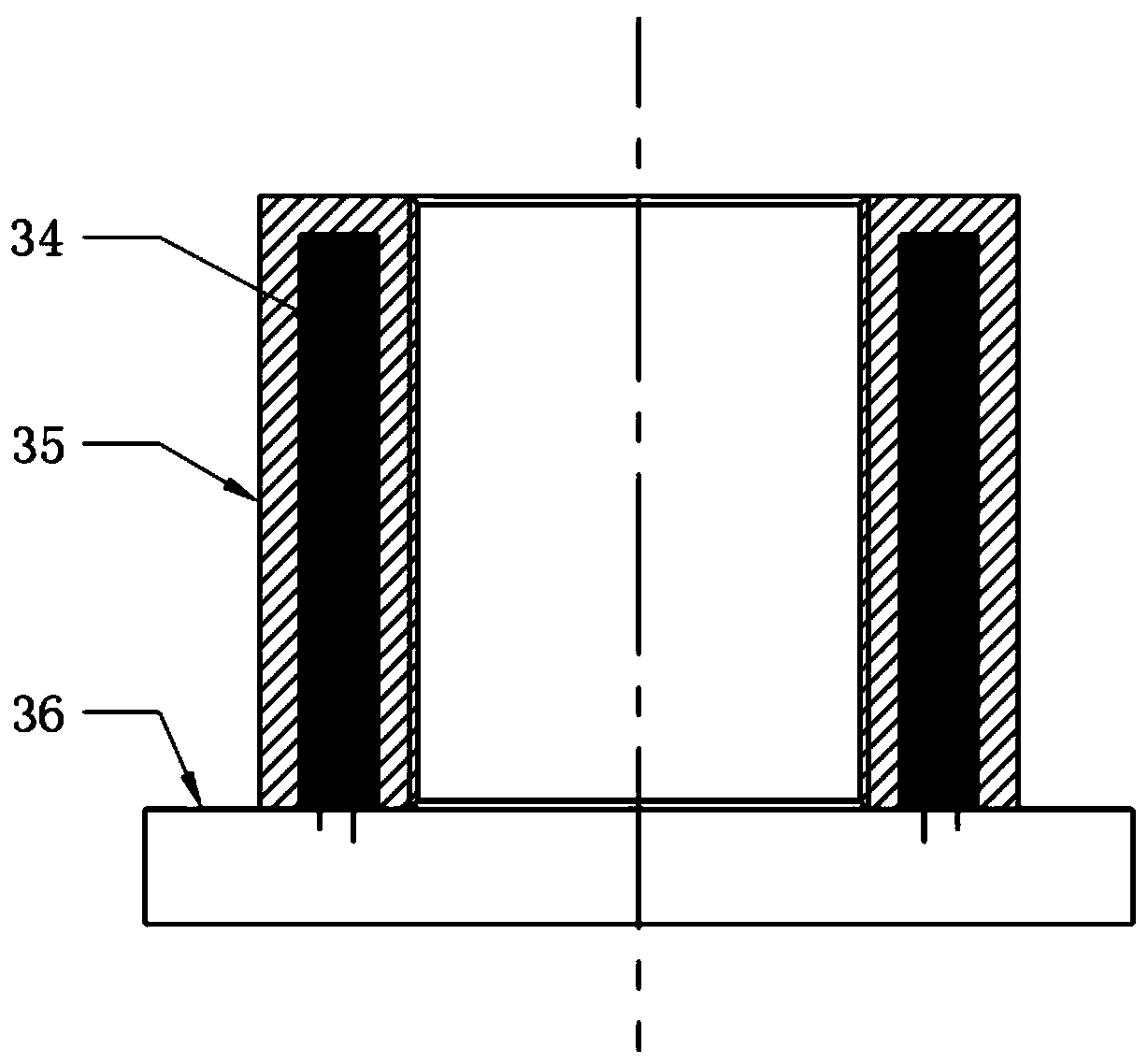

[0044] The hydrogen storage alloy PCT curve testing device of the present invention is as figure 1 As shown, it includes the sample chamber 3, the gas pipeline and the data collector; the gas pipeline includes the main pipeline and various branch pipelines; the sample chamber 3 is connected to the main pipeline through the solenoid valve III14 and the solenoid valve IV15, and one end of the main pipeline is respectively passed through Throttle valve Ⅰ9, solenoid valve Ⅰ12, throttle valve Ⅱ10, solenoid valve Ⅱ13 are connected with hydrogen cylinder 1 and helium cylinder 2, and the other end of the main pipeline passes through solenoid valve Ⅸ20, pressure reducing valve 22, throttle valve Ⅲ11, solenoid Valve VII18 and electromagnetic valve VIII19 are connected to the atmosphere and vacuum gauge 7, vacuum gaug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com