Rotary cooling furnace for semi-coke dry quenching

A technology of dry quenching and cooling furnace, which is used in the cooling of coke, coke oven, petroleum industry, etc. It can solve the problems of consuming the latent heat of blue carbon, increasing the transportation cost, and high water content of the product, so as to improve the cooling efficiency and quality. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

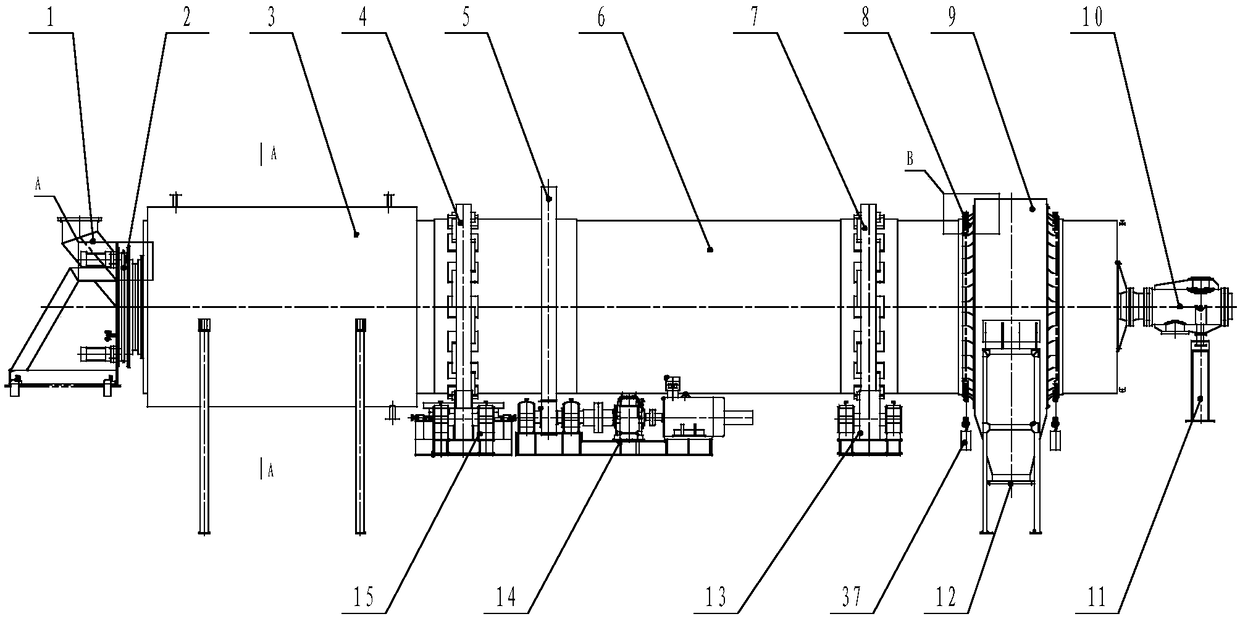

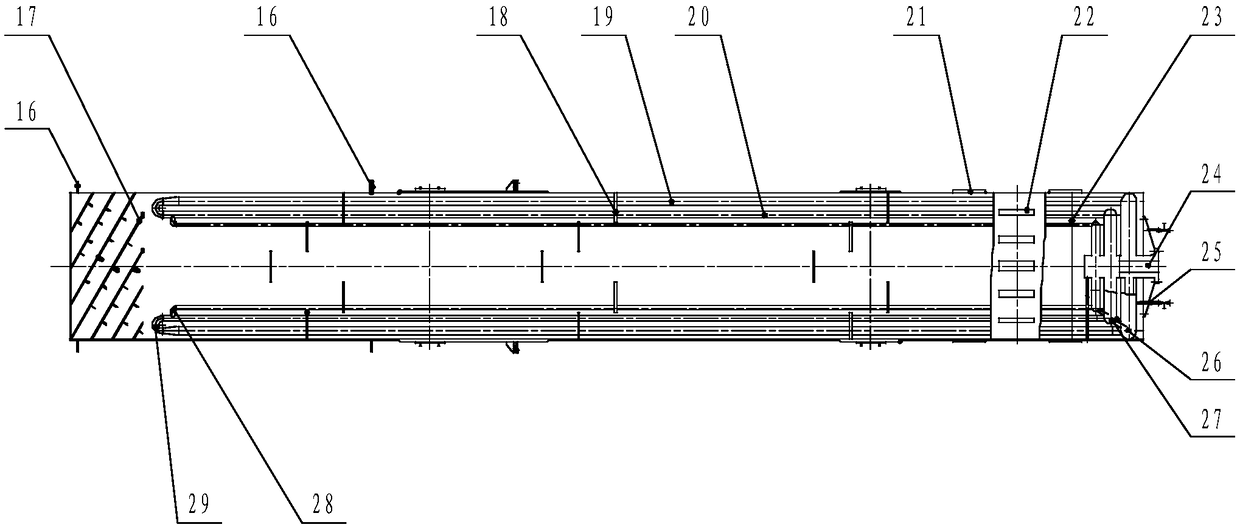

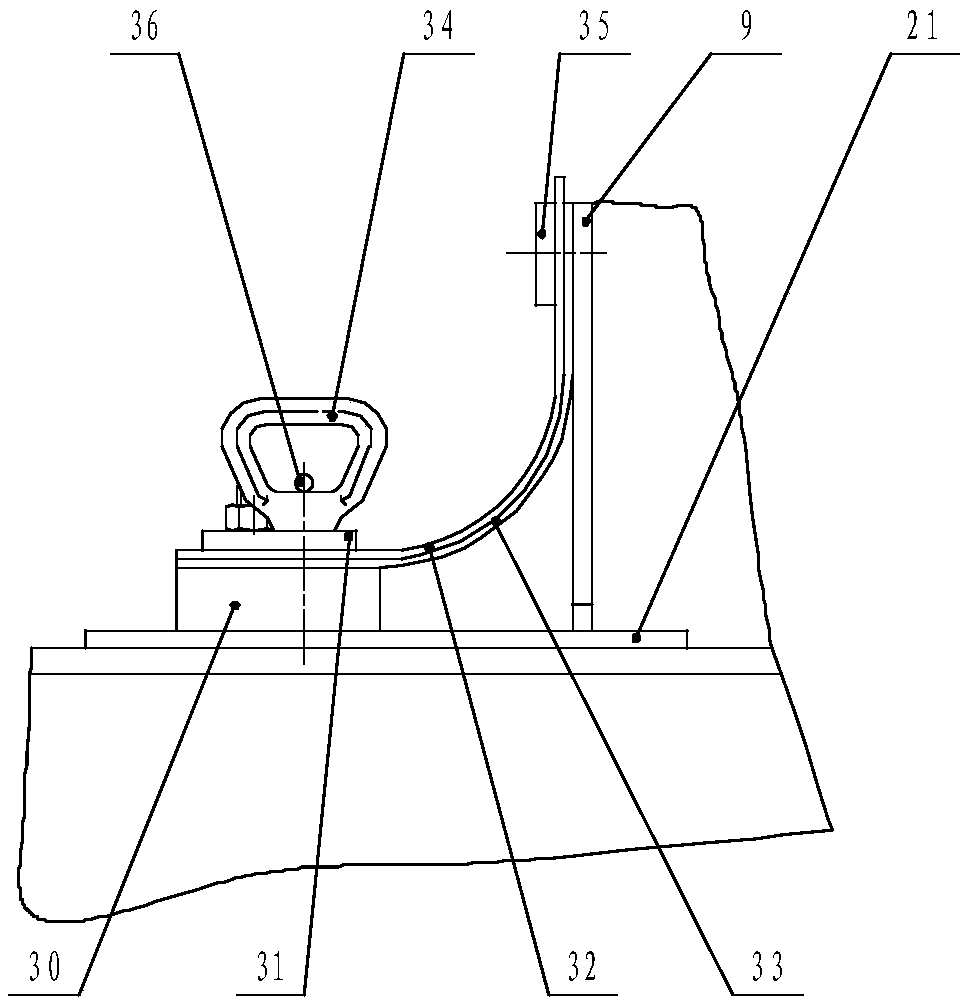

[0033] as attached figure 1 As shown, the main body of the equipment is the furnace body 6, on which the rolling ring I4 and the rolling ring II7 are arranged according to the principle of equal bending moment, they are held up by the supporting roller device 13 and the retaining roller device 15 respectively, and are jointly supported. Furnace body 6 and operating weight; large ring gear 5 drives the furnace body 6 to rotate through meshing transmission with the pinion on the transmission device 14; The feed box 9 is located at the rear section of the body of furnace 6, and is provided with a discharge port 12; the sealing structure of fish scale seal 8 is adopted between the two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com