A New Plate Axial Reactor

A reactor and plate-type technology, which is applied in the field of new plate-type axial reactors, can solve the problems of untimely heat transfer, limited mixing time and space, uneven materials, etc., and achieve large-scale equipment, easy catalyst loading, and increased production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

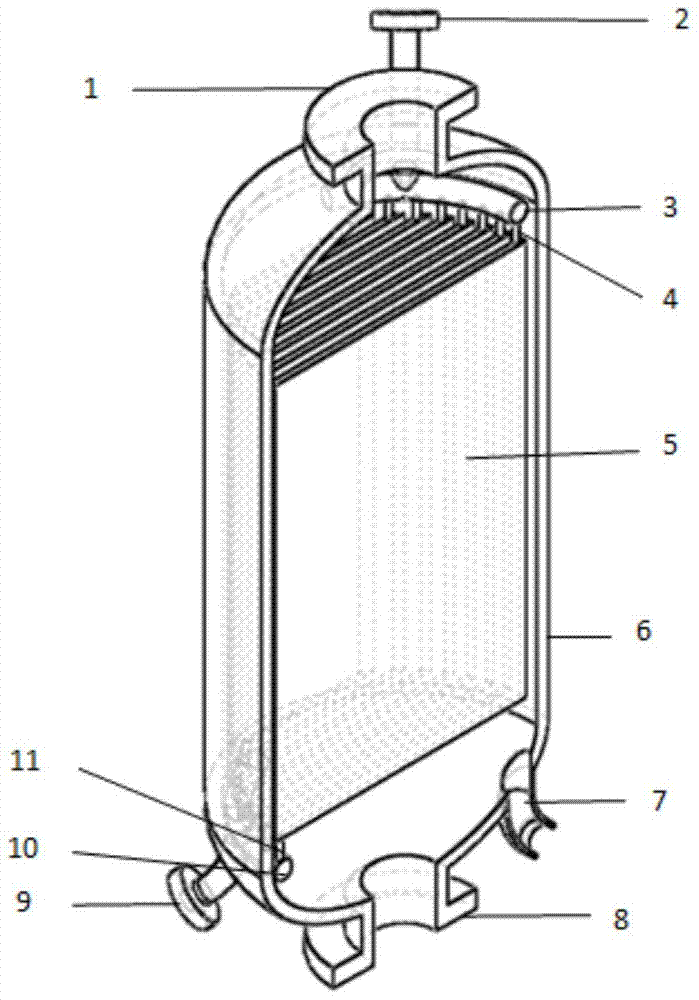

[0047] Such as figure 1 As shown, a new type of plate axial reactor includes a reactor shell 5, a pair of heat exchange plates 6, a heat exchange medium distribution main pipe 10, a heat exchange medium distribution branch pipe 11, a heat exchange medium collection main pipe 3 and a heat exchange medium collection The branch pipe 4, the reactor shell 5 is provided with a reaction material inlet 1, a reaction material outlet 8, a heat exchange medium inlet 9 and a heat exchange medium outlet 2. The heat exchange plate facing the bundle 6 consists of multiple sets of sub heat exchange plates For the bundle composition, one end of each group of sub-heat exchange plates is connected to the heat exchange medium inlet of the reactor shell 5 through the heat exchange medium distribution branch pipe 11 and the corresponding heat exchange medium distribution main pipe 10, and the other end passes through the heat exchange medium collection branch pipe 4 and The corresponding heat exchang...

Embodiment 2

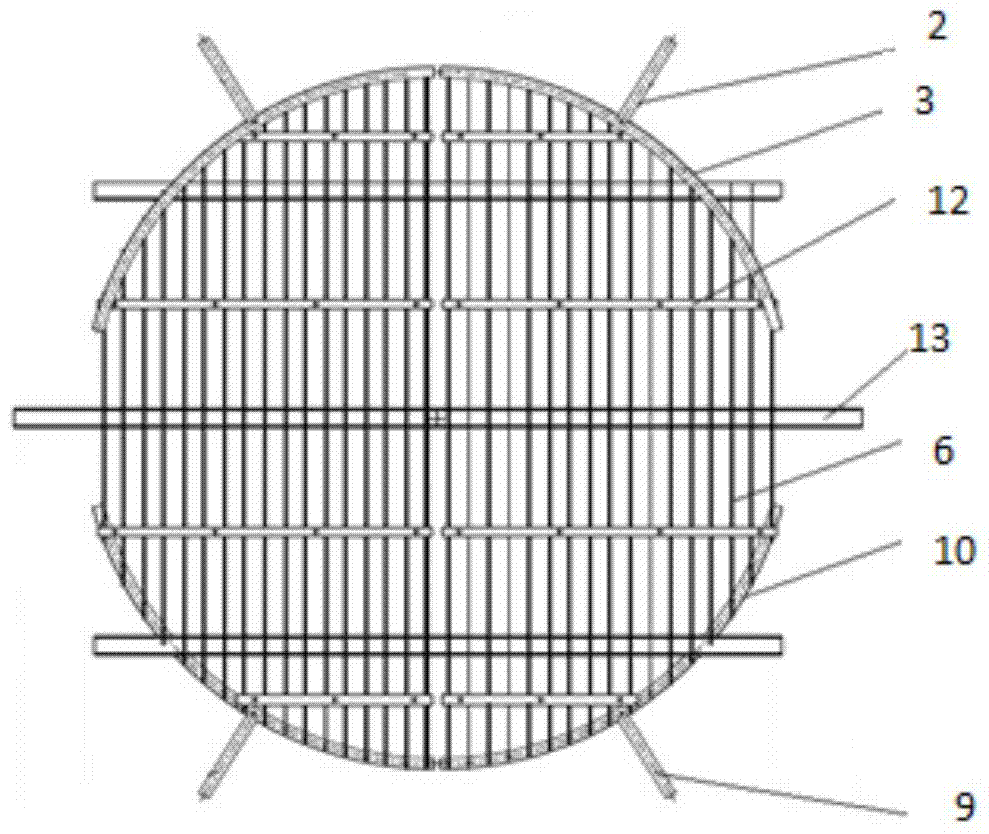

[0057] Such as image 3 As shown, in this embodiment, the multiple sets of sub-heat exchange plate pairs divide the heat exchange plate pair bundle 6 into a quarter structure in the horizontal direction, and the quarter structure is four groups of sub-heat exchange plate pairs in a sector shape. The bundle is arranged around the central axis of the reactor, the heat exchange plate pairs in each sub-heat exchange plate pair bundle are parallel to each other, and the heat exchange medium distribution main pipe 10 and the heat exchange medium collection main pipe 3 are also arc-shaped. In this embodiment, the number of the heat exchange medium inlet 9 and the corresponding heat exchange medium outlet 2 can be between 1 and 4, which are set according to the flow rate of the heat exchange medium.

[0058] The rest is the same as in Example 1.

[0059] The reactor of this embodiment is used for the hydration reaction, and the catalyst is not easily broken, the catalyst has the advantages...

Embodiment 3

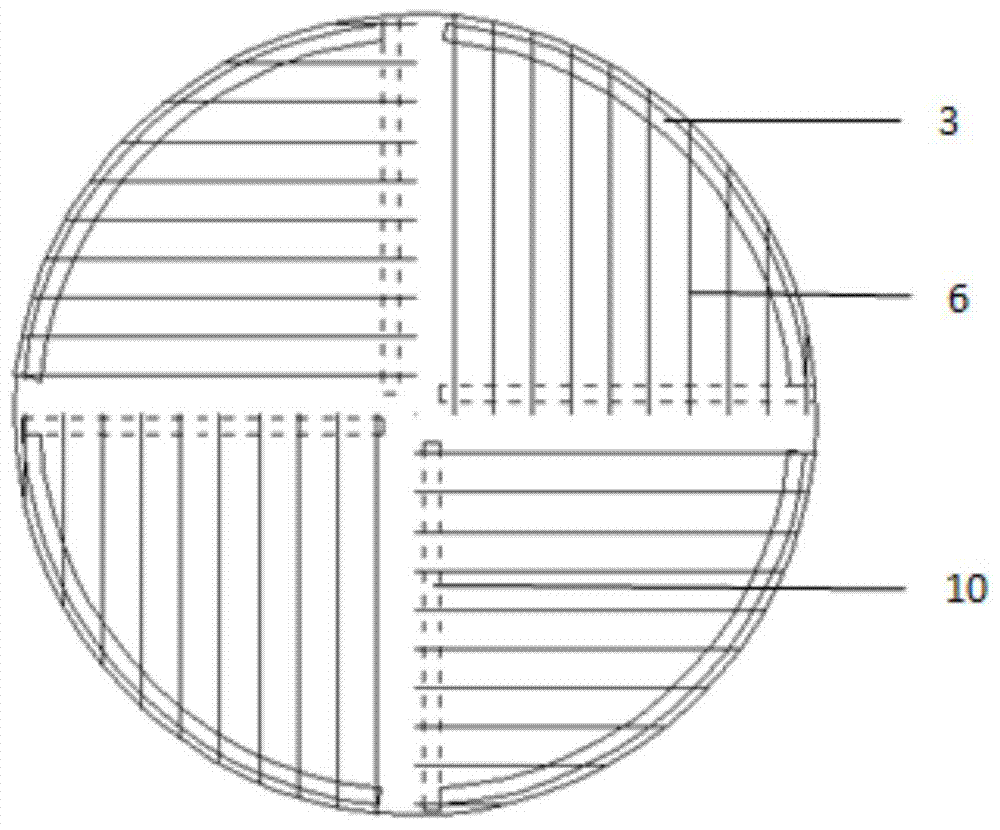

[0061] Such as Figure 4 As shown, in this embodiment, the multiple sets of sub-heat exchange plate pairs divide the heat exchange plate pair bundle 6 into a quarter structure in the horizontal direction, and the quarter structure is four groups of sub-heat exchange plate pairs in a sector shape. The beam is arranged around the central axis of the reactor. The difference from Embodiment 2 is that in each sub-heat exchange plate pair, the heat exchange plate pairs in adjacent sub-heat exchange plate pairs are perpendicular to each other.

[0062] The rest is the same as in Example 2.

[0063] When the diameter of the reactor is between 2 and 4 m, it is preferable to use the quarter structure of Example 2 or Example 3 to reduce the manufacturing cost of the heat exchange plate pair and facilitate installation; when the reaction diameter continues to increase, the same From the perspective of manufacturing and installation, correspondingly, a multi-division structure can be used. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com