Method for recovering latent heat in sec-butyl acetate preparation device and combined device

A technology for the preparation of sec-butyl acetate and equipment, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, and can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

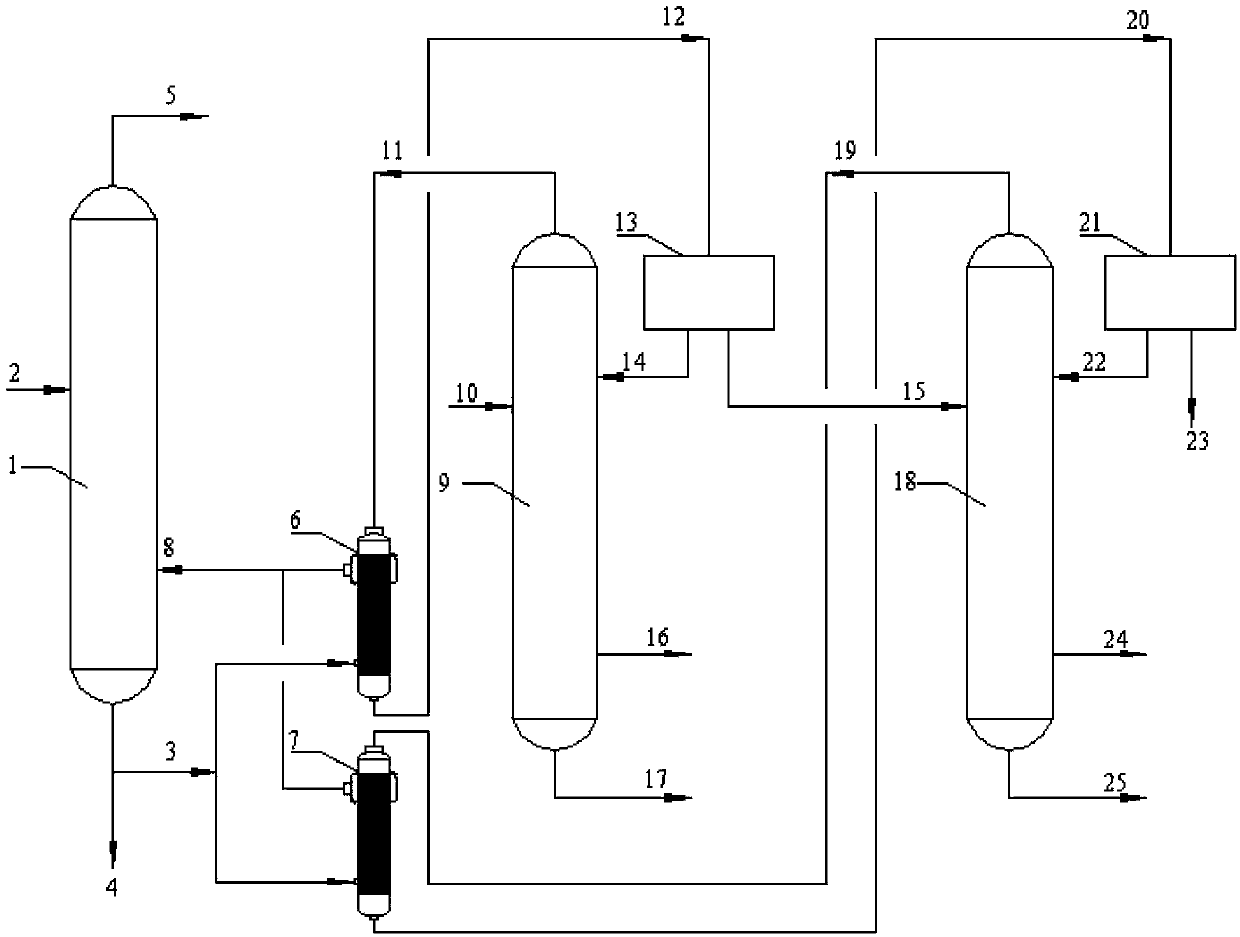

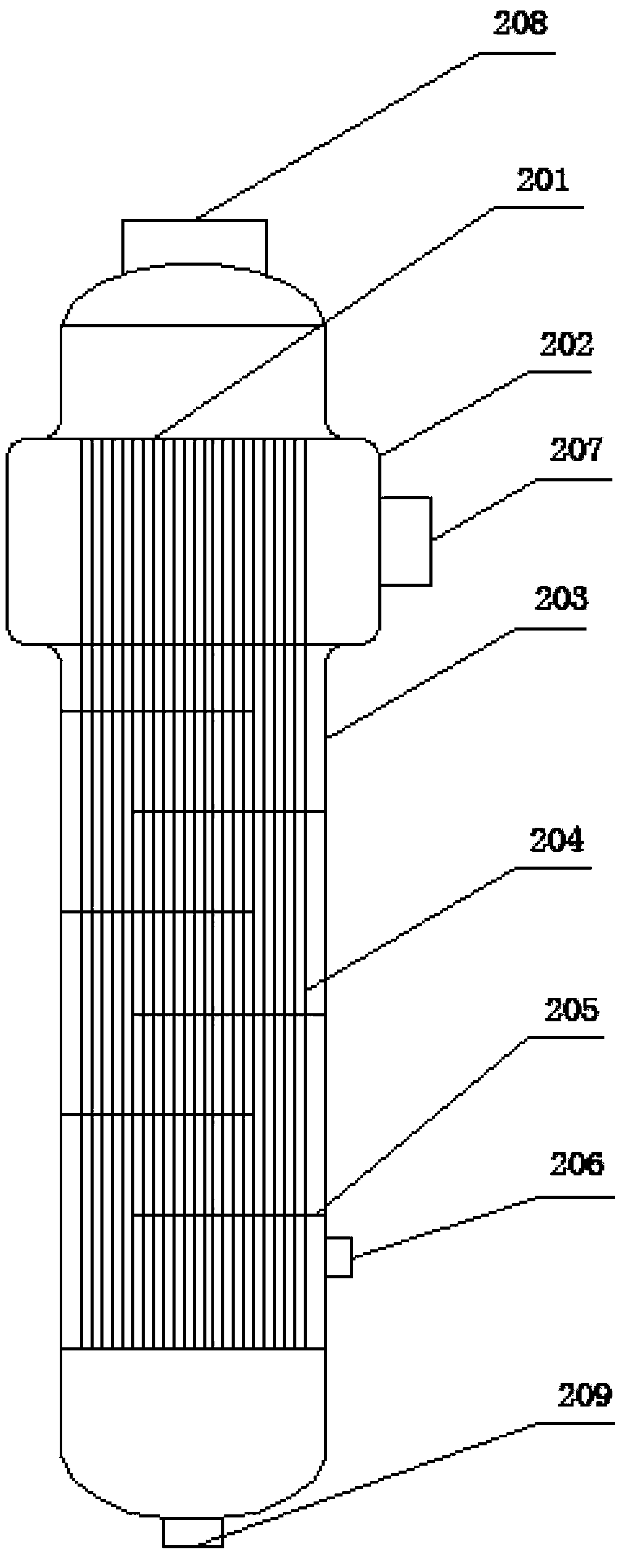

Embodiment 1

[0106] Adopt the mixed C4 after ether as raw material, wherein, in this raw material, the content of isobutane is 47.10%, the content of n-butane is 18.24%, the content of isobutene is 0.12%, the content of n-butene is 34.4%, the content of C5 The content is 0.14%, and the material flow rate is 28t / h ether and the mixed C4 (2) is passed into the butene concentration tower (1). The butene concentration tower (1) is a valve tower with 178 trays. Control the reflux ratio of the butene concentration tower (1) to be 12, the temperature at the top of the tower is 48.1°C, the gauge pressure at the bottom of the tower is 0.64MPa, the temperature at the bottom of the tower is 64.5°C, and the material flow rate is 12.6t / h of isobutane (5 ) from the top of the butene concentration tower (1), and a part of the liquid phase material (4) at the bottom of the butene concentration tower (1) is passed into the extractive distillation tower at a rate of 15.4t / h to continue the extraction Concen...

Embodiment 2

[0113] This embodiment adopts the same condensation evaporator as that of Embodiment 1.

[0114] Using ether mixed C4 as raw material, wherein the content of isobutane is 22.1%, the content of n-butane is 11.5%, the content of isobutene is 0.8%, the content of n-butene is 64.4%, and the content of C5 is 1.2%. , the material flow rate is 35t / h ether and the mixed C4 (2) is passed into the butene concentration tower (1). The butene concentration tower (1) is a valve tower with 205 plates and a 1 reboiler, the steam flow rate of the reboiler is controlled to be 5t / h, the reflux ratio of the butene concentration tower (1) is 15, the temperature at the top of the tower is 42.5°C, the gauge pressure at the bottom of the tower is 0.54MPa, and the temperature at the bottom of the tower is The isobutane (5) with a material flow rate of 7.6t / h at 57.5°C is distilled from the top of the butene concentration tower (1), and a part of the liquid phase material at the bottom of the butene co...

Embodiment 3

[0118] This embodiment adopts the same condensation evaporator as that of Embodiment 1.

[0119] Using ether after mixing C4 as raw material, the content of isobutane is 37.6%, the content of n-butane is 13.1%, the content of isobutene is 0.4%, the content of n-butene is 48.4%, and the content of C5 is 0.5%. , the material flow rate is 40t / h ether and the mixed C4 (2) is passed into the butene concentration tower (1). The butene concentration tower (1) is a valve tower with 230 trays and a 2 reboilers, the total steam flow rate of the reboilers is controlled to be 8t / h, the reflux ratio of the butene concentration tower is 18, the temperature at the top of the tower is 54.5°C, the gauge pressure at the bottom of the tower is 0.75MPa, and the temperature at the bottom of the tower is 69.5 °C, the isobutane (5) with a material flow rate of 14.6t / h is distilled from the top of the butene concentration tower (1), and a part of the bottom liquid phase material (4) of the butene con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com