Condensing evaporator and application

A condensing evaporator and shell-side technology, applied in the field of condensing evaporators, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

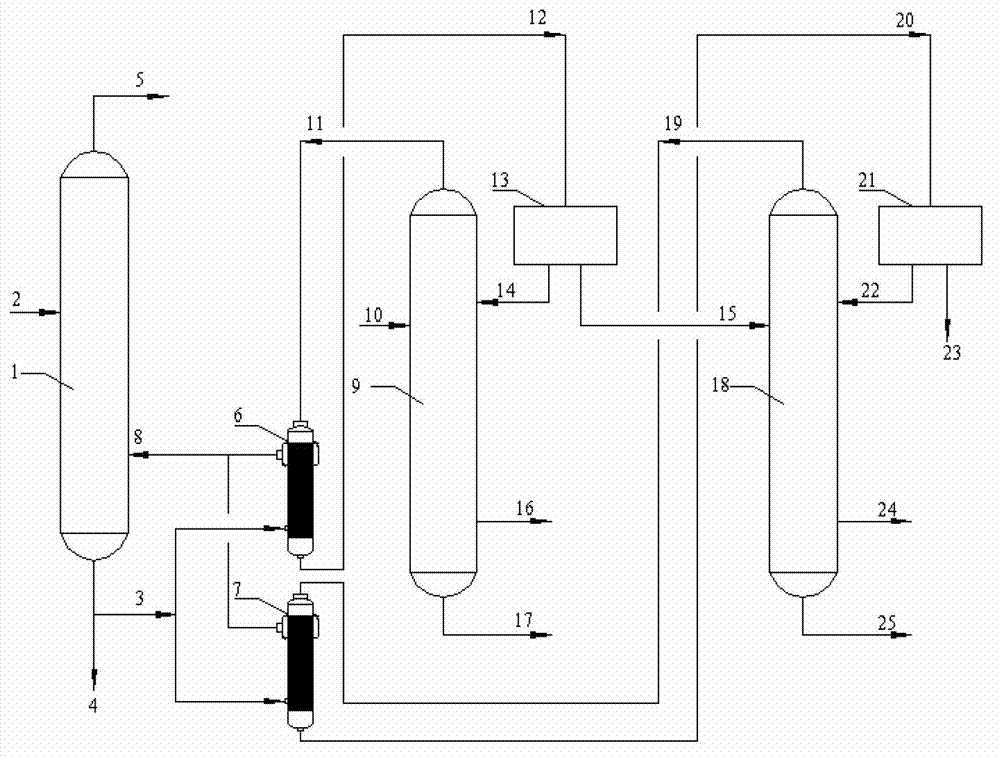

[0108] Adopt the mixed C4 after ether as raw material, wherein, in this raw material, the content of isobutane is 47.10%, the content of n-butane is 18.24%, the content of isobutene is 0.12%, the content of n-butene is 34.4%, the content of C5 The content is 0.14%, and the material flow rate is 28t / h ether and the mixed C4 (2) is passed into the butene concentration tower (1). The butene concentration tower (1) is a valve tower with 178 trays. Control the reflux ratio of the butene concentration tower (1) to be 12, the temperature at the top of the tower is 48.1°C, the gauge pressure at the bottom of the tower is 0.64MPa, the temperature at the bottom of the tower is 64.5°C, and the material flow rate is 12.6t / h of isobutane (5 ) from the top of the butene concentration tower (1), and a part of the liquid phase material (4) at the bottom of the butene concentration tower (1) is passed into the extractive distillation tower at a rate of 15.4t / h to continue the extraction Concen...

Embodiment 2

[0115] This embodiment adopts the same condensation evaporator as that of Embodiment 1.

[0116] Using ether mixed C4 as raw material, wherein the content of isobutane is 22.1%, the content of n-butane is 11.5%, the content of isobutene is 0.8%, the content of n-butene is 64.4%, and the content of C5 is 1.2%. , the material flow rate is 35t / h ether and the mixed C4 (2) is passed into the butene concentration tower (1). The butene concentration tower (1) is a valve tower with 205 plates and a 1 reboiler, the steam flow rate of the reboiler is controlled to be 5t / h, the reflux ratio of the butene concentration tower (1) is 15, the temperature at the top of the tower is 42.5°C, the gauge pressure at the bottom of the tower is 0.54MPa, and the temperature at the bottom of the tower is The isobutane (5) with a material flow rate of 7.6t / h at 57.5°C is distilled from the top of the butene concentration tower (1), and a part of the liquid phase material at the bottom of the butene co...

Embodiment 3

[0120] This embodiment adopts the same condensation evaporator as that of Embodiment 1.

[0121] Using ether after mixing C4 as raw material, the content of isobutane is 37.6%, the content of n-butane is 13.1%, the content of isobutene is 0.4%, the content of n-butene is 48.4%, and the content of C5 is 0.5%. , the material flow rate is 40t / h ether and the mixed C4 (2) is passed into the butene concentration tower (1). The butene concentration tower (1) is a valve tower with 230 trays and a 2 reboilers, the total steam flow rate of the reboilers is controlled to be 8t / h, the reflux ratio of the butene concentration tower is 18, the temperature at the top of the tower is 54.5°C, the gauge pressure at the bottom of the tower is 0.75MPa, and the temperature at the bottom of the tower is 69.5 °C, the isobutane (5) with a material flow rate of 14.6t / h is distilled from the top of the butene concentration tower (1), and a part of the bottom liquid phase material (4) of the butene con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com