Film tray paving mechanism for self-propelled combined machine for raising rice seedlings in greenhouse

A combined working machine, self-propelled technology, applied in agriculture, transplanting machinery, application, etc., can solve the problems of labor-intensive, labor-intensive, labor-intensive, etc., to solve the labor-intensive, improve the quality of the plate and improve the work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

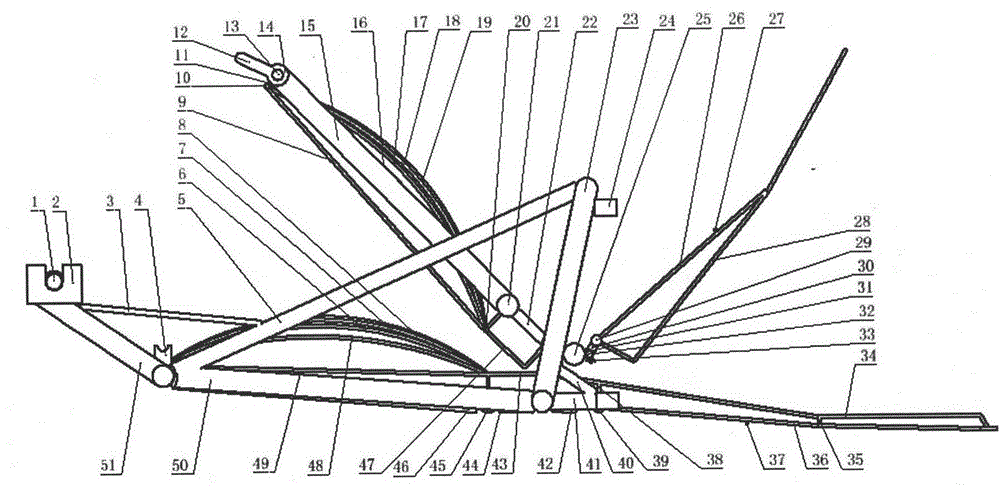

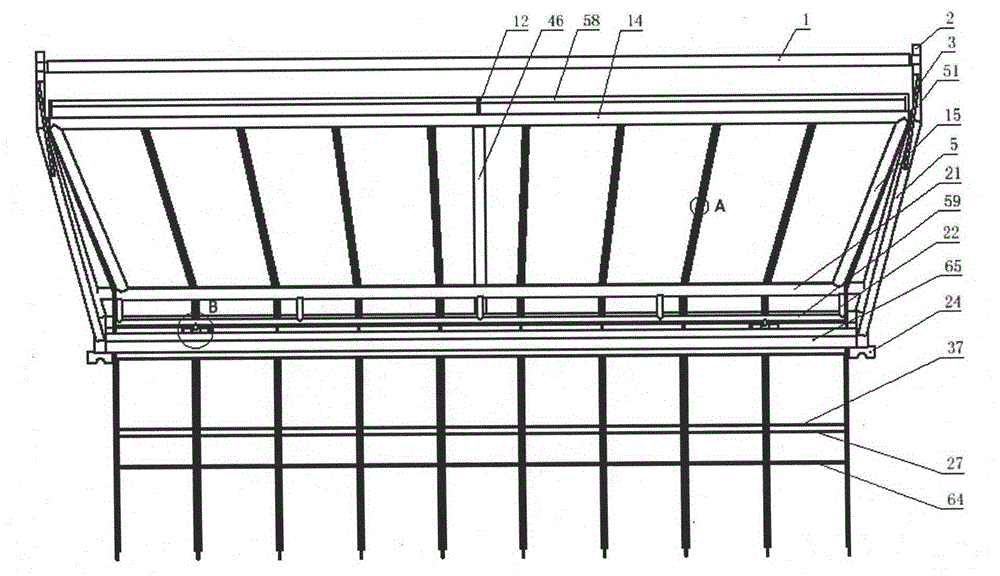

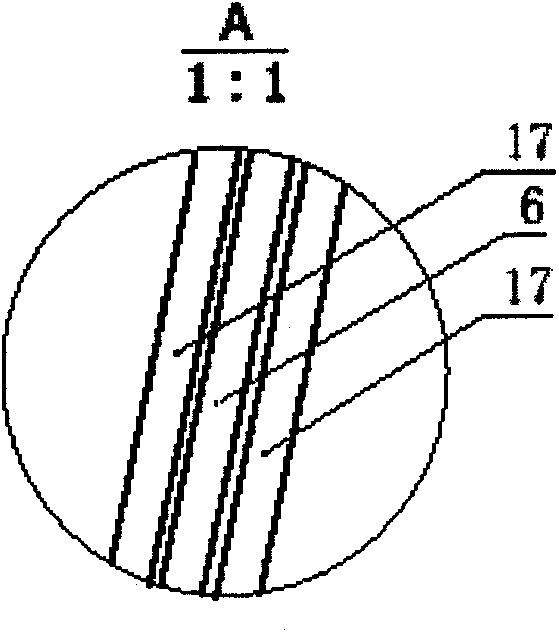

[0020] The utility model self-propelled rice greenhouse and seedling raising combined operation machine film plate laying mechanism is realized in this way: it consists of two parts: a folding forming part and a forming holding part; The upper cage is composed. Including chassis front main pole 52, chassis rear main pole 53, chassis side main pole 50, chassis auxiliary pole 45, chassis auxiliary support pole 44, chassis middle pole 46, first support film pole 49, second Supporting membrane rod 48, third supporting membrane rod 6, fourth supporting membrane rod 7, fifth supporting membrane rod 8, bottom frame forming rod 43, connecting frame main board 23, main board reinforcing rod 5, main board positioning shaft 65, connecting shaft 25 , Underframe connecting pipe 31, hinge pin shaft 32, hinge pin shaft cotter pin 33, connection seat 24, connection seat support shaft 41, support shaft reinforcement rod 40, support plate 51, support plate reinforcement rod 3, roll film mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com