Curb paving vehicle-mounted manipulator

A technology of curbs and manipulators, applied in the field of fully automatic intelligent pure electric engineering road construction vehicles, can solve the problems of low paving efficiency, high labor intensity, slow paving speed, etc., and achieve the goal of improving paving efficiency, reducing labor intensity and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

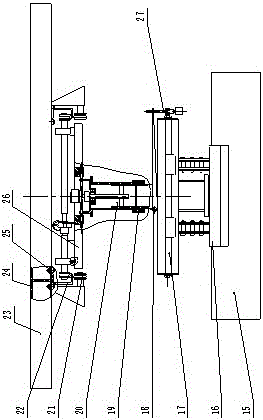

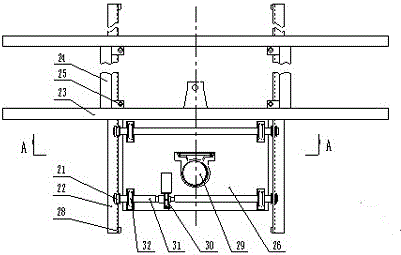

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

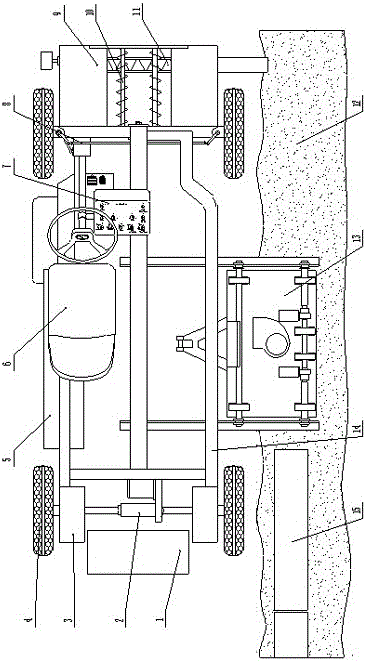

[0034] The vehicle-mounted manipulator for paving curbs disclosed by the present invention is mainly used for paving curbs in road construction operations. Including: car body structure, vehicle-mounted manipulator for curb stone paving, sand and ash spreading mechanism and sand and ash pushing mechanism.

[0035] A. Body structure see figure 1 .

[0036] Seat 6 is installed on the vehicle frame 14 of car body mechanism, manipulation control platform 7, steering mechanism 8, sand ash hopper 9, pushes away sand ash mechanism 10, spreads sand ash mechanism 11, parts such as curb stone paving hoisting platform 13.

[0037] The front axle of the car body is connected with the vehicle frame 14 through a rotating shaft to form a torque-resistant chassis structure with four wheels supported by three points. Such as Figure 9 shown. This chassis structure eliminates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com