Bentonite waterproof board and method and special device for manufacturing same

A technology of bentonite and waterproof board, which can be used in protection devices, chemical instruments and methods, natural mineral layered products, etc., and can solve difficulties. Increase project cost and other issues to achieve the effect of improving paving efficiency, saving materials and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

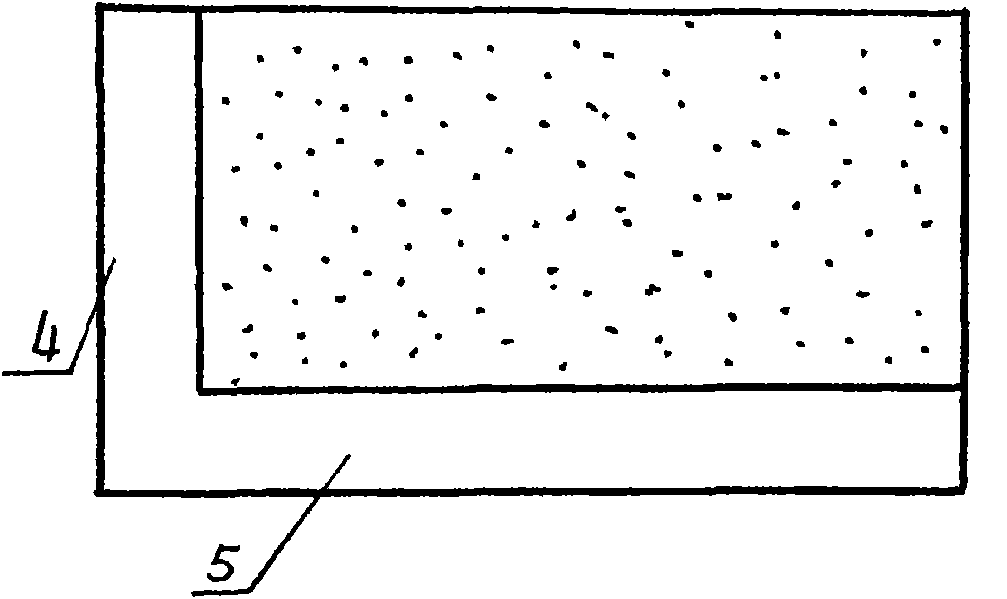

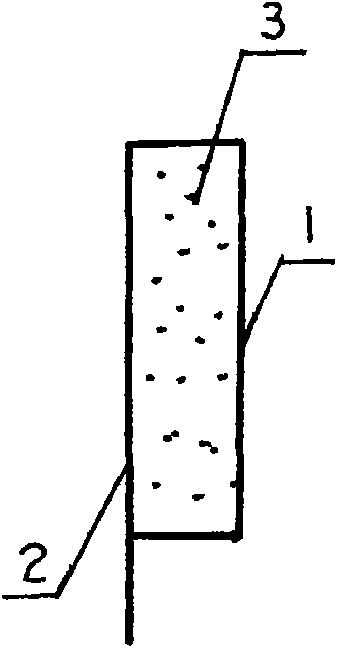

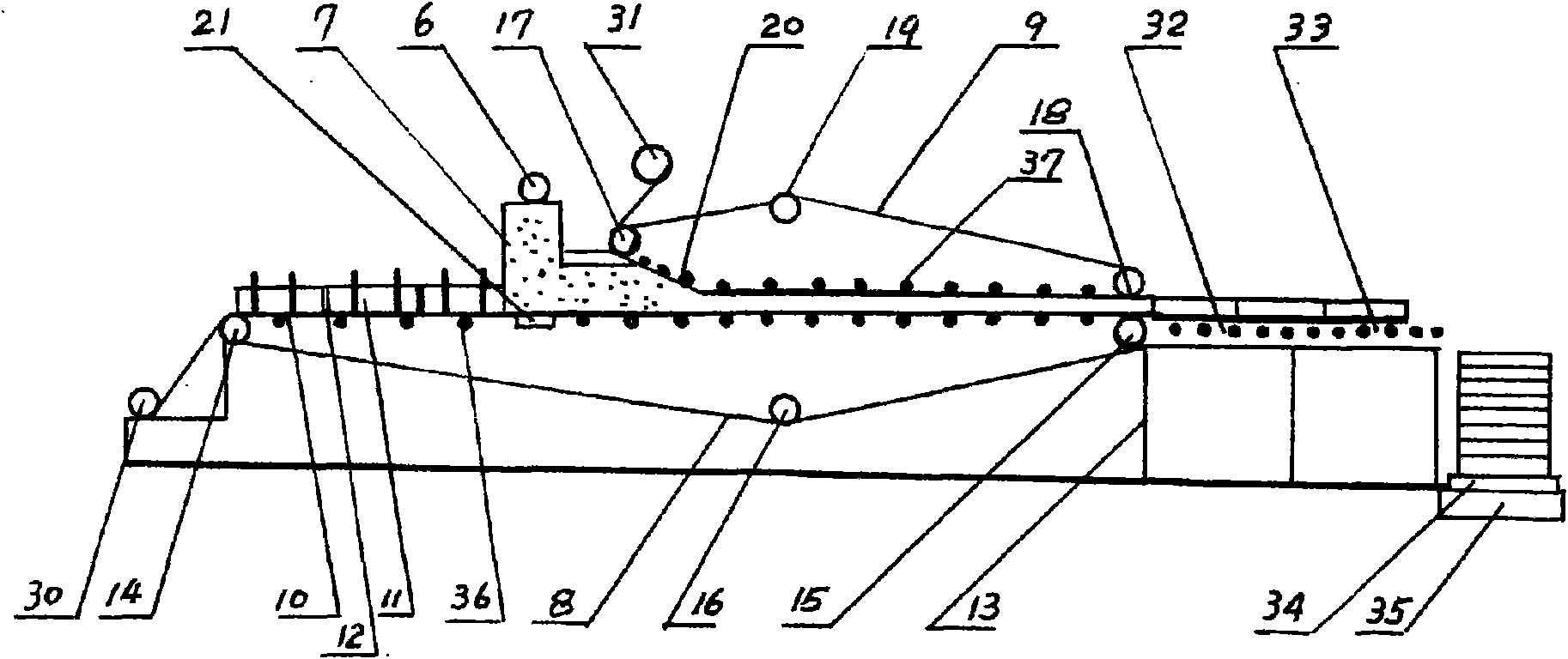

[0033] combine image 3 Schematic diagram of special equipment of the present invention and Figure 4The schematic diagram of the bentonite pretreatment equipment shown further explains: to produce bentonite waterproof board products with a thickness of 20mm, a board length of 2440mm, a width of 1220mm, and an overlapping edge of 50mm, a shaping device composed of a pressure belt machine, a retaining roller and a side plate is used, and the belt width is 1220mm+ The width of the overlapping side is 50mm×2, which is 1320mm, the length of the side plate is 2440mm+50mm, which is 2490mm, the two ends are chamfered at 25×45°, and the thickness is 20mm, while the thickness of the partition is 20mm, the length is 1270mm, and the width is 50mm.

[0034] The bentonite powder is evenly added with a length of 10mm glass fiber when running on the screw agitating conveyor 6, and then methyl cellulose is made into a 1% aqueous solution and sprayed on the surface of the bentonite and glass f...

Embodiment 2

[0039] With the equipment and bentonite pretreatment equipment and method of embodiment 1, produce thickness 15mm, board length 2000mm, the waterproof board product of 80mm of overlapping edge, select the shaping device that horizontal belt conveyor, pressure belt conveyor, retaining roller and side plate are formed, belt The width is 1320mm, the actual plate width is 1160mm, the side plate length is 2000mm+80mm, which is 2080mm, the height is 15mm, the partition height is 15mm, the length is 1240mm, and the width is 80mm.

[0040] When the bentonite powder is running on the screw agitating conveyor, evenly add plant fibers with a length of 15 mm, and then use carboxymethyl cellulose to make a 2% aqueous solution and spray it on the surface of the homogenized bentonite for humidification treatment, with a moisture content of 9%. , and then transported to the bentonite filler bin 7 for subsequent use, and then by the method of embodiment 1 and special equipment, the bottom layer...

Embodiment 3

[0042] The bentonite powder is stirred and conveyed on the screw conveyor, and the man-made fibers with a length of 12 mm are evenly added, and then ethyl cellulose is made into a 3% aqueous solution and sprayed on the surface of the homogenized bentonite for humidification treatment. The moisture content is 8%, and then transported to the bentonite filling bin for later use,

[0043] Select a sizing device composed of a horizontal belt conveyor, a pressure belt conveyor and a non-transmission belt, cancel the side plates or partitions of the sizing device in Example 1, and then install non-woven fabrics on the retaining rollers on both sides of the pressure section of the upper and lower belts. Driving belt (not shown in the figure) forms pressure chamber simultaneously, and the plate produced at this moment is continuous, needs to set up cutting machine after upper and lower belt, cuts plate according to required length, all the other are with the method and special equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com