Folding screw conveying mechanism for paver

A screw conveying and paver technology, applied in roads, road repair, roads, etc., can solve the problems of construction quality impact, impact on road smoothness and compactness, lack of materials at both ends, etc., to achieve high work reliability, Long service life, easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

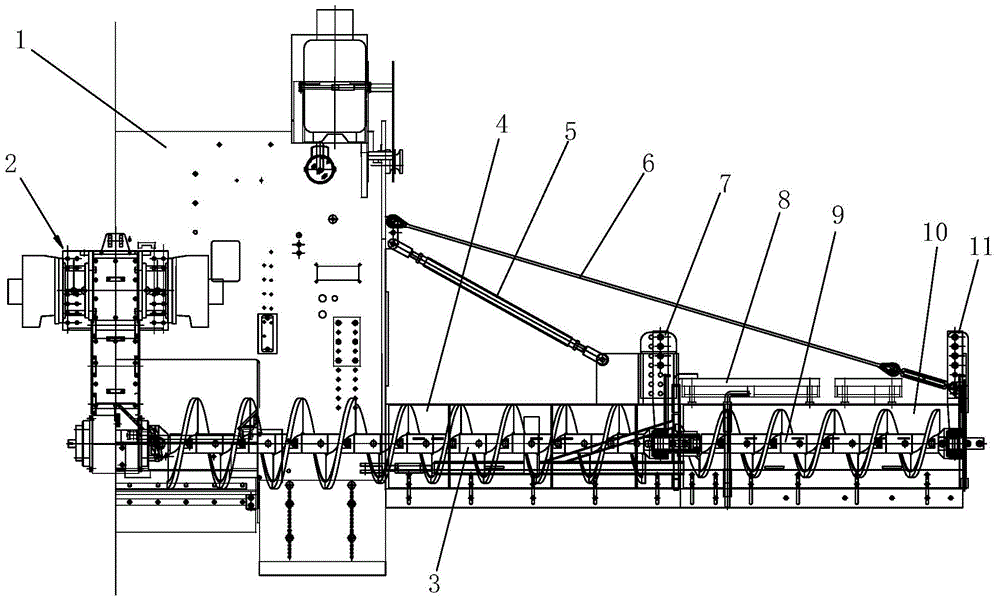

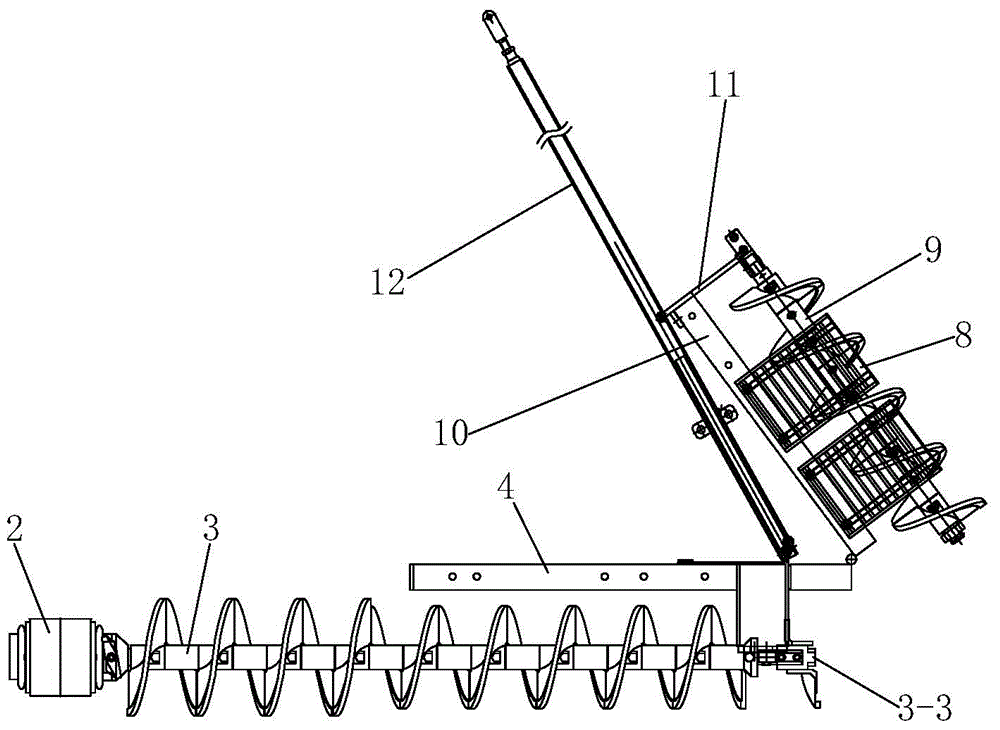

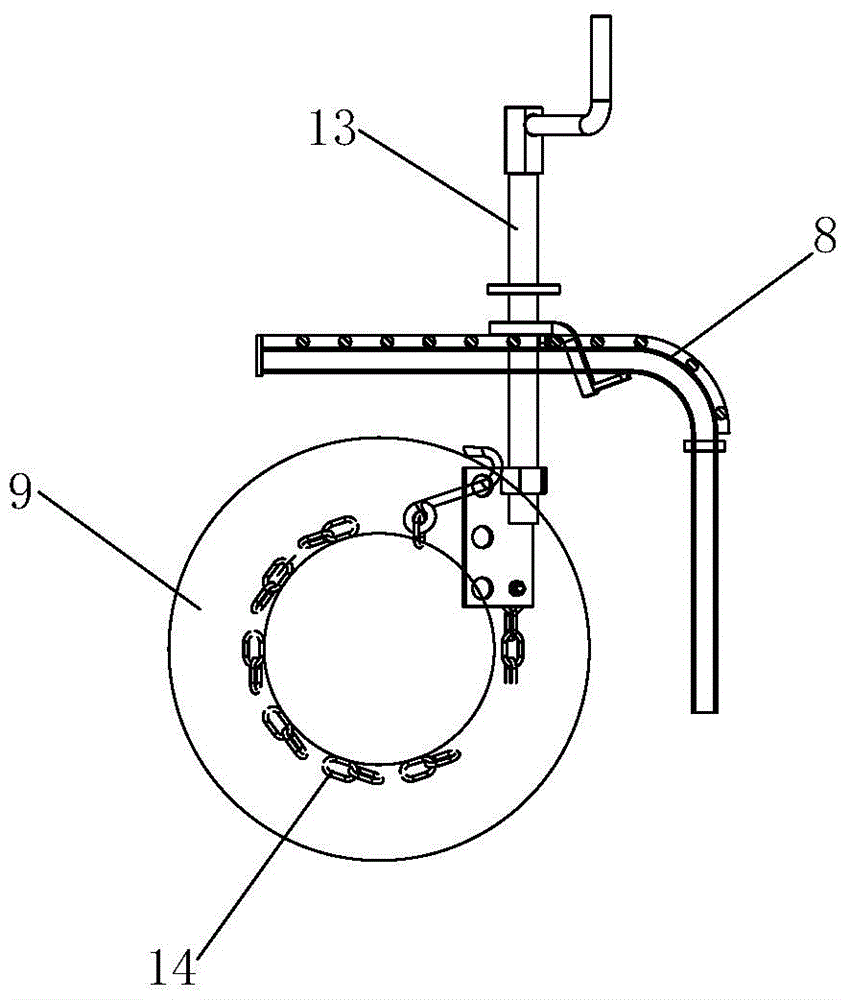

[0037] Such as figure 1 and figure 2 The shown folding screw feeding mechanism for a paver includes a first screw shaft 3 arranged on one side of the paver 1 and a first material baffle plate 4 located on the front side of the first screw shaft 3, and a set The second screw shaft 9 at the end of the first screw shaft 3 away from the paver 1 and the second material baffle plate 10 located at the front side of the second screw shaft 9; the first material baffle plate 4 is provided with a first support frame 7. The end of the first screw shaft 3 away from the paver 1 passes through the first support frame 7 and rotates with the first support frame 7. One end of the first screw shaft 3 and the second screw shaft 9 One end is a detachable connection, and the end of the first material retaining plate 4 away from the paver 1 is hinged with a second material retainer for driving the second screw shaft 9 to rotate after the second screw shaft 9 is detached from the first screw shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com