Paving width automatic control system of paver

An automatic control and paver technology, which is applied to roads, road repairs, roads, etc., can solve problems such as heavy installation and debugging workload, high failure rate, and difficult maintenance, so as to achieve convenient installation and debugging, improve reliability, and improve The effect of paving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

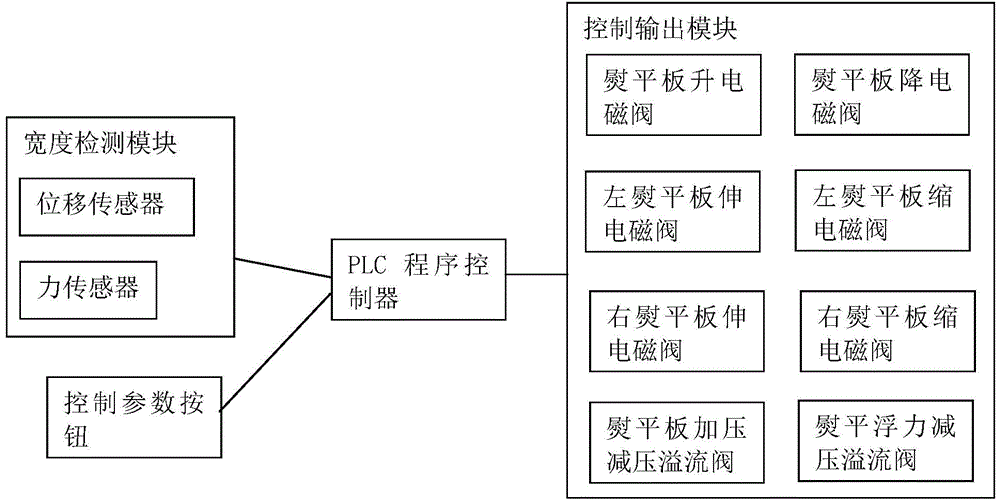

[0012] An automatic control system for paving width of a paver, including a PLC program controller, a control output module, a width detection module, and a control parameter button for controlling the width adjustment of the screed. The PLC program controller communicates with the control through signal lines. The output module, the width detection module and the control parameter button are connected. The control output module includes a screed up solenoid valve, a screed down solenoid valve, a left screed extension solenoid valve, a left screed reduction solenoid valve, and a right screed extension solenoid valve. Solenoid valve, right screed reduction solenoid valve, screed pressure-reducing relief valve, screed buoyancy pressure-reducing relief valve, the width detection template includes a force sensor set on the traction arm, and set on the left and right irons The displacement sensor on the screed, the left screed retracting solenoid valve, the left screed extension sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com