A method for adjusting a finish rolling stand and a rolling line control system

A technology of a control system and an adjustment method, applied in the field of steel rolling, can solve the problem that the crown of the roll gap of the rolling mill does not conform to the actual conditions of the production site, and achieve the requirements that the crown and flatness of the exit of the stand are satisfied, suitable for the steel type, and the wave shape is stable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

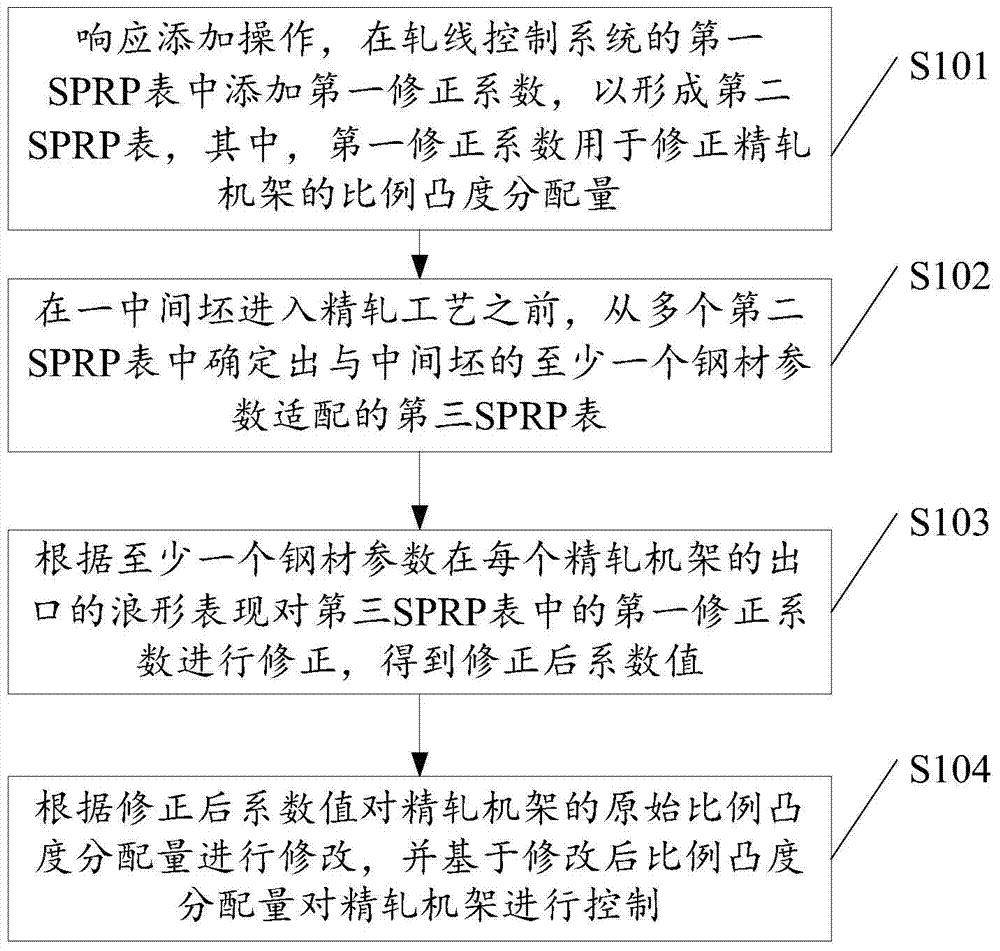

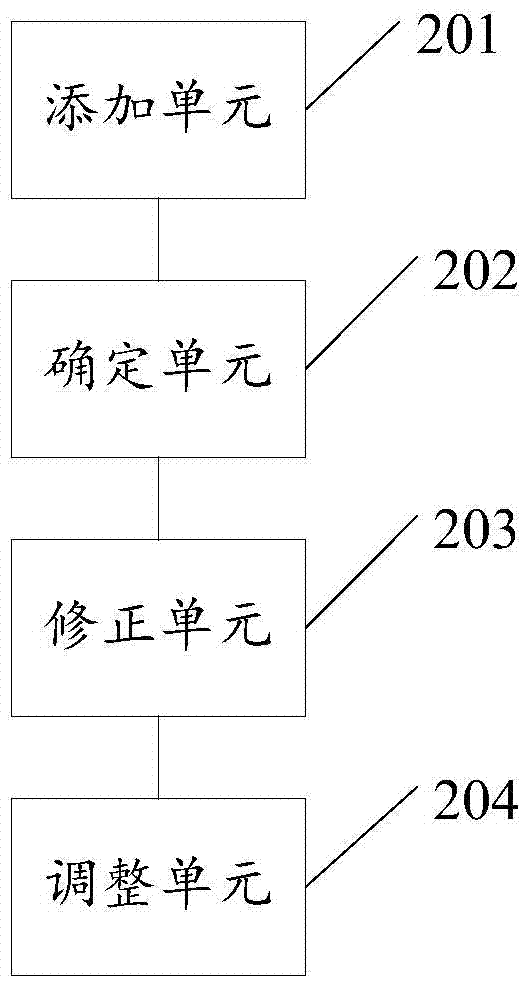

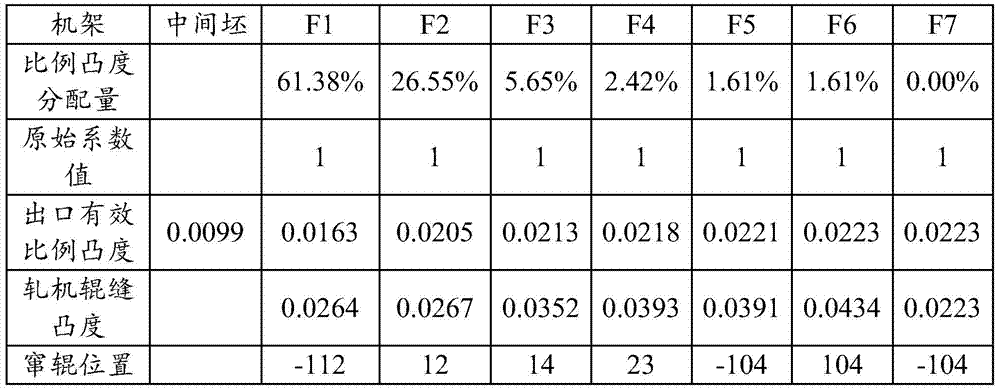

[0018] In order to solve the technical problem that the calculated effective proportional crown of each stand entrance and the calculated rolling mill roll gap crown in the prior art do not conform to the actual conditions of the production site, the present invention provides a finishing rolling stand adjustment method and a rolling line control system , the general idea is as follows:

[0019] Add the first correction coefficient for correcting the proportion crown distribution amount of the finishing stand in the SPRP table, and modify the first correction coefficient according to the wave shape performance of the steel parameters at the exit of each finishing stand, according to the correction The coefficient value modifies the proportional crown distribution of the finishing stand, thereby realizing the technical means of modifying the proportional crown distribution of the finishing stand on-line. As a result, the modification of the proportional crown distribution amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com