A mining dump truck, fuel tank and anti-wave plate

A technology of a wave-proof board and a fuel tank, which is applied in the directions of vehicle components, the arrangement combined with the fuel supply of the internal combustion engine, the power plant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

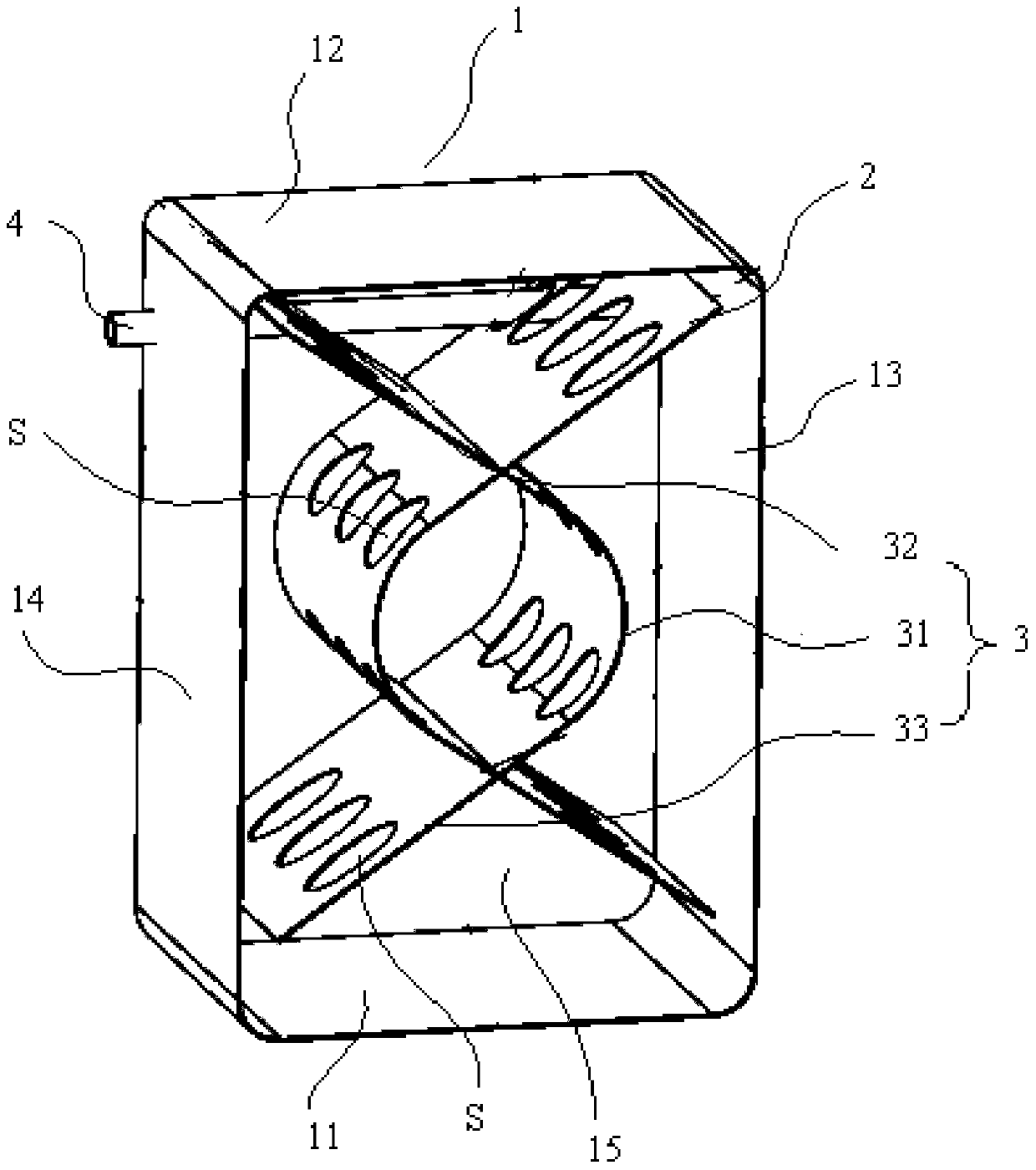

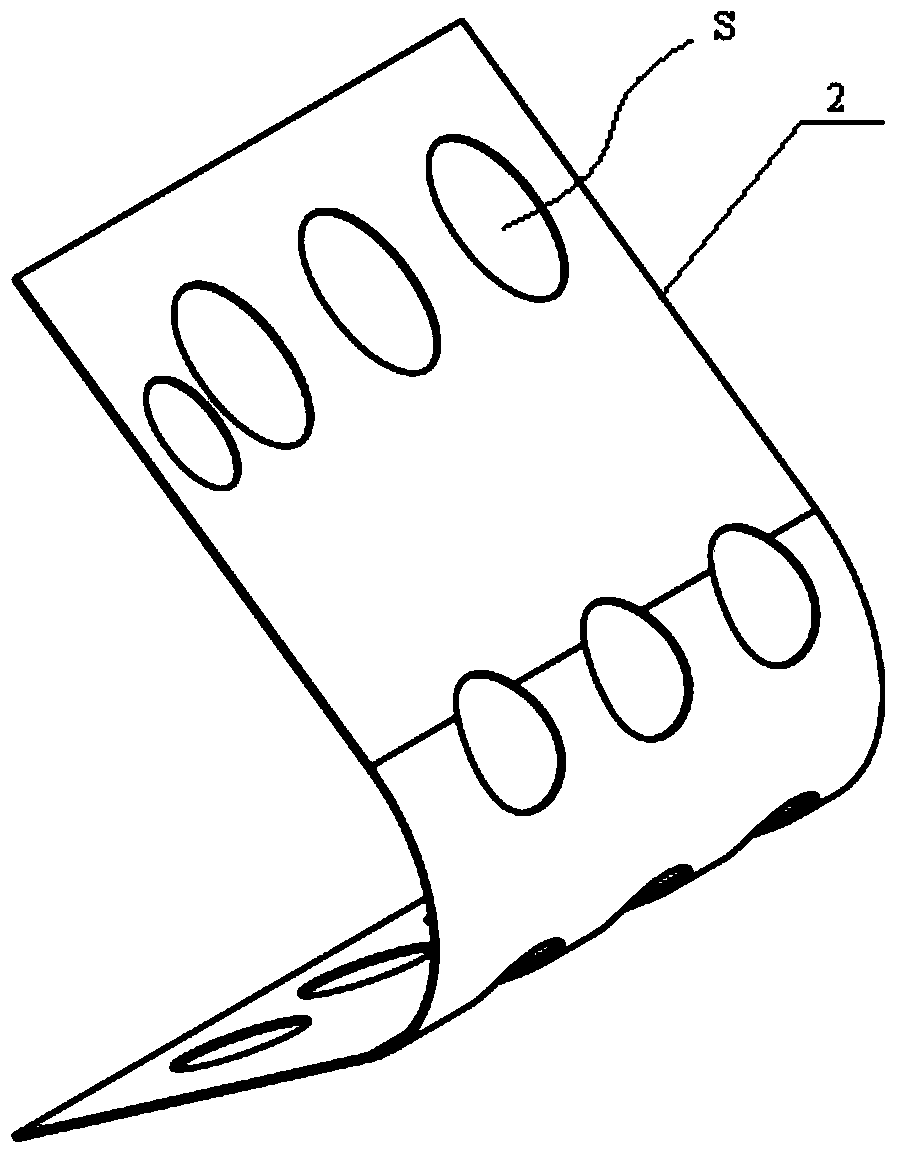

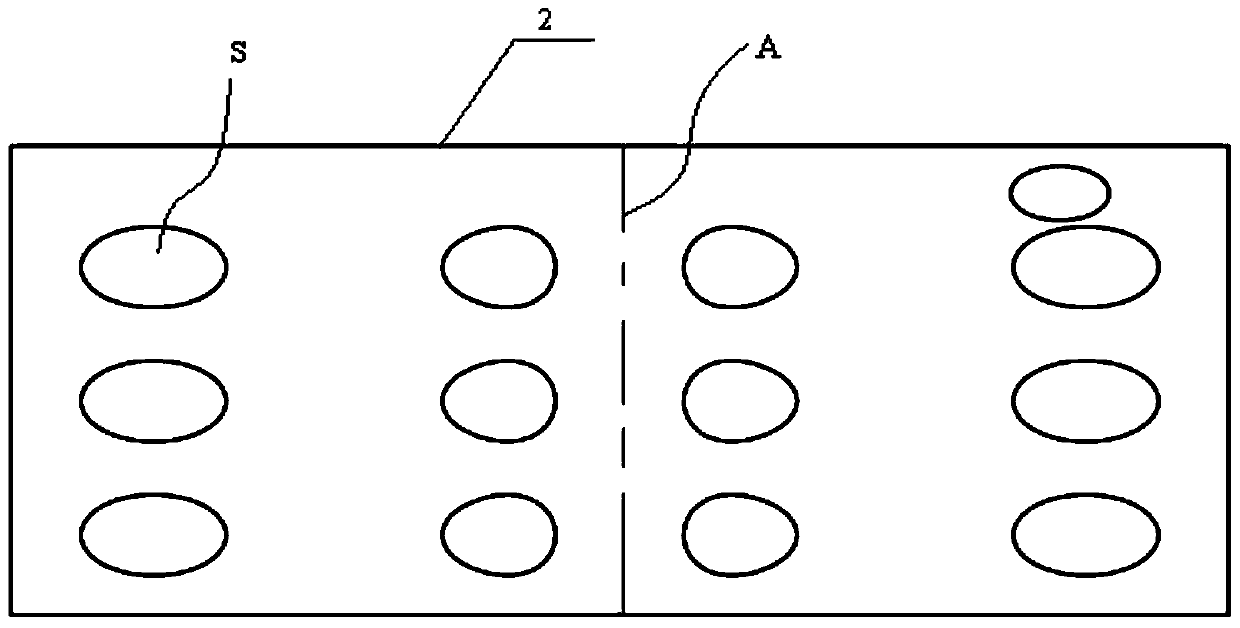

[0035] The core of the present invention is to provide a fuel tank anti-wave plate, which can improve the stress characteristics of the welding seam of the straight plate type anti-wave plate, and finally achieve the effect of prolonging the service life of the fuel tank. On this basis, the present invention also provides a fuel tank including the anti-wave plate, and a mining dump truck including the fuel tank.

[0036] The specific structure of the mining dump truck and its fuel tank provided by the present invention will now be described in detail in conjunction with the accompanying drawings. It should be noted that, except for the car body, the engine driving the car body and the fuel tank for supplying oil to the engine, the structure and working principle of the mine dump truck are exactly the same as those of the prior art. It can be realized completely, so this paper only details its improvement point - the fuel tank and its anti-wave plate.

[0037] See figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com