Gooseneck hinge transmission rack

A conveying frame and hinge technology, which is applied in the field of temporary storage and conveying devices of automobile gooseneck hinges, can solve problems such as easy sliding out, uncompact products, and inability to position neatly, and achieve good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

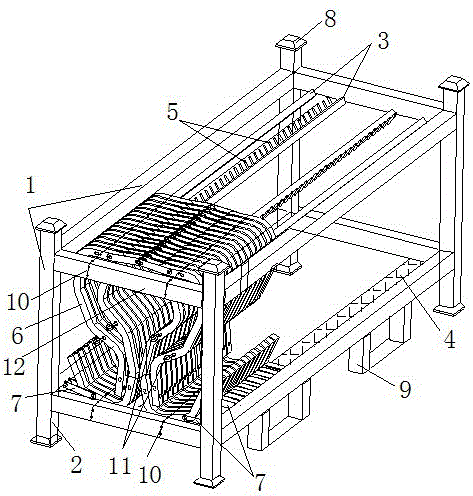

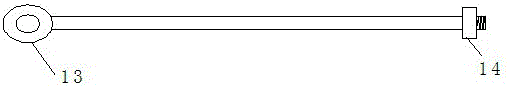

[0016] refer to figure 1 , propose an embodiment of the present invention, this embodiment comprises frame 1, support foot 2, is provided with 1 or more suspension units on the frame, each suspension unit comprises two suspension rods 3 at the top, the resistance at the bottom Plate 4, wherein a row of suspension nails 5 is fixed on the suspension rod on the inner side, when the gooseneck hinge 6 is hung upside down on the suspension nails 5, the short hinge rod 7 of the gooseneck hinge is supported by the said support plate, and the two Suspension bar 3, back plate 4 are all fixed on the frame; Several detachable soft strips 10, several discharge support rods 11 are arranged on the frame, after the gooseneck hinge is installed, the soft strips 10 Wrap the hooks of the rows of gooseneck hinges at least one turn, and the soft long strips 10 are bound and fixed on the beams 12 of the frame; the middle part of each gooseneck hinge has a hinged hole through which the unloading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com