Anti-scattering conveyor belt

A conveyor belt and anti-scattering technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easy-to-spill items and single structure, and achieve the effect of eliminating deviation, avoiding slipping, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

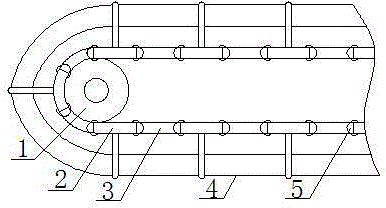

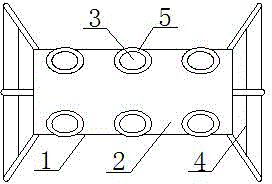

[0014] Such as figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the left view of the present invention, a spill-proof conveyor belt, including a roller 1 and a belt body 2, the belt body 2 is sleeved on the roller 1, and the belt body 2 is provided with a storage hole 3 and a blocking net 4. There are two blocking nets 4, which are respectively vertically connected to the edges of the belt body 2 both sides to form a "V" shaped structure. The storage holes 3 are circular transparent holes, which are evenly distributed on the belt surface of the belt body 2 . A preload ring 5 is provided inside the storage hole 3 . The pre-tightening ring 5 is an elastic rubber ring embedded in the hole wall circumference of the storage hole 3 .

[0015] Blocking nets 4 are arranged vertically on the edges of both sides of the belt body 2 to form a "V"-shaped structure, which can not only hold more items, but also prevent side leakage of items. The tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com