Automatic coiling and uncoiling device for large-caliber flat composite hose

A composite hose, automatic retractable technology, applied in the field of hose retractable devices, can solve the problems of hose wear, increased safety hazards, high work labor intensity, etc., and achieves reduced work intensity, simple and easy operation, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

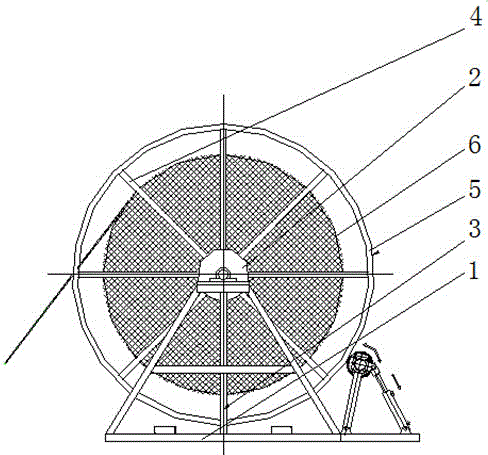

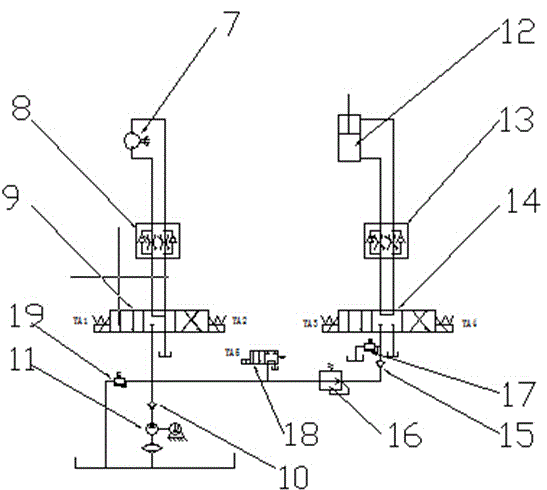

[0026] Such as figure 1 and figure 2 As shown, the large-diameter flat composite hose automatic retracting device of the present invention includes a bracket 1, a bracket bearing 2 is connected to the bracket 1, the bracket bearing 2 is fixed on the bracket 1 through the bracket 3, and the bracket bearing 2 passes through the rotating shaft 4. Connect the swivel frame 5, the swivel frame 5 is wound with a flexible pipe 6, one side of the swivel frame 5 is connected with a rotating device, and the rotating device is connected with a lifting cylinder device that controls the lifting of the rotating device.

[0027] The rotating device includes a hydraulic motor 7 that controls the forward and reverse rotation of the swivel frame. The hydraulic motor 7 is connected to the throttle valve I8, the throttle valve I8 is connected to the reversing valve I9, and the reversing valve I9 is connected to the oil pump 11 through the check valve I10.

[0028] The one-way valve I10 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com